Binding method for transformer iron core

A transformer and iron core technology, which is applied in the field of transformer iron core binding, can solve the problems of poor heat dissipation ability of the iron core, increased thickness of PP wrapping paper, large transformer noise and loss value, etc., to achieve strong heat dissipation ability, simple process, noise and no-load Effect of Loss Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

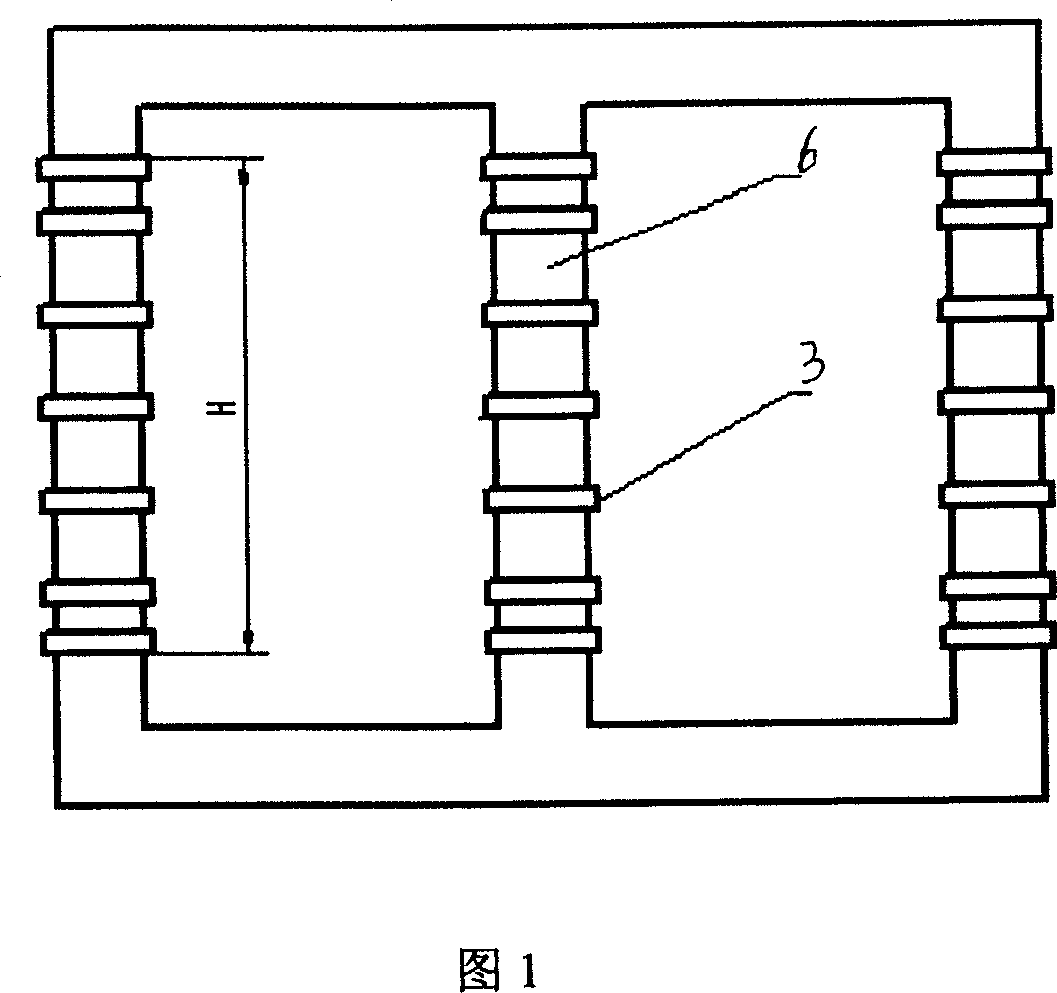

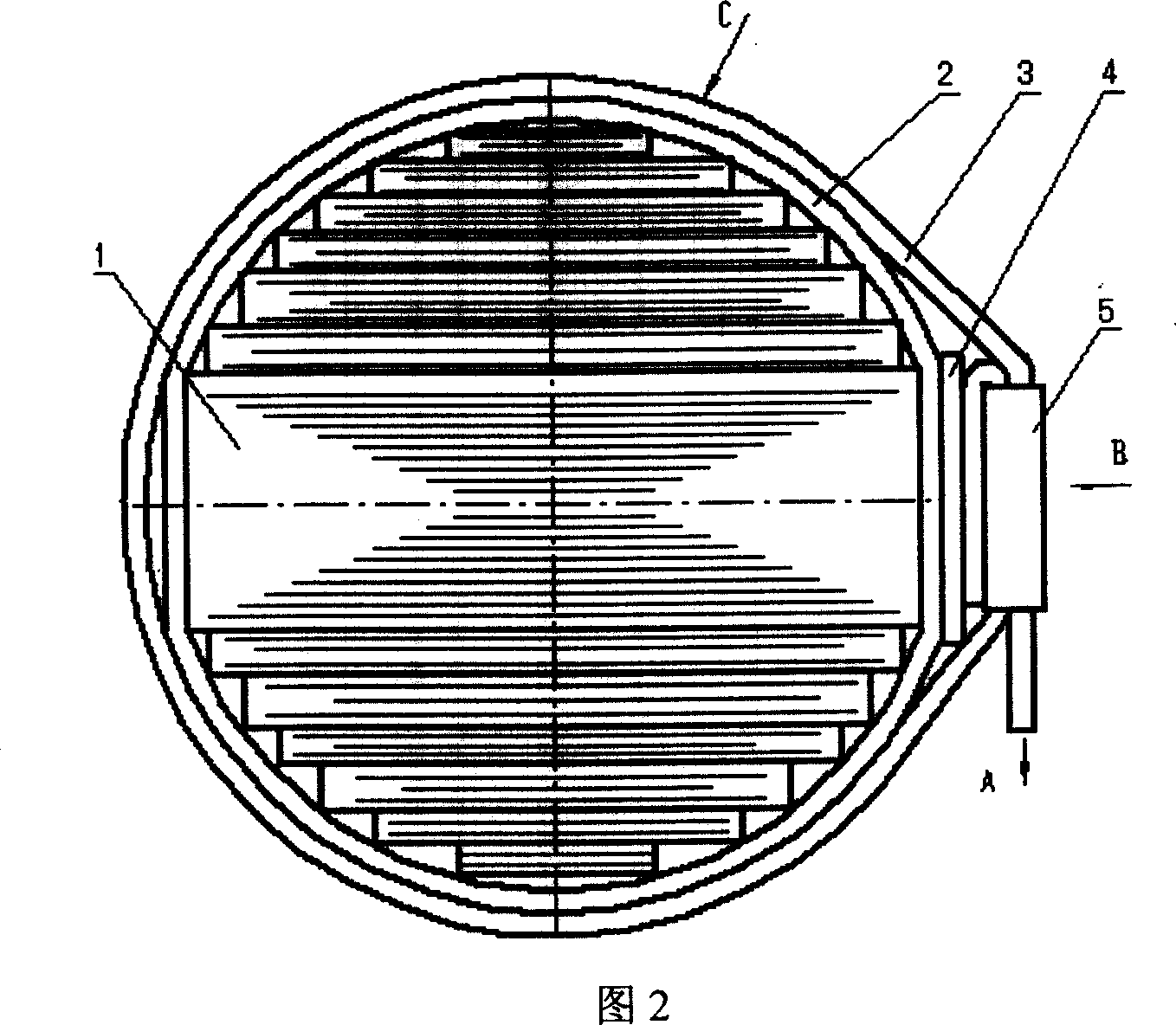

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. The method steps of this embodiment: (1) as shown in Figure 2, use PP paper 2 with a thickness of 0.18mm and a width of 50mm to wrap 2 layers around the iron core at the position where the polyester plastic tape is to be bound, and use 502 at the end of the PP paper strip Glue firmly; (2) use (thickness 0.5mm, width 12mm) polyester plastic tape 3 to surround the iron core wrapped with PP paper for one circle, penetrate the stainless steel seal 5 as shown in Figure 2, and seal the stainless steel seal 5 Bend the polyester plastic tape on the inner side, and the bending length is not less than 25mm; (3) prefabricated (thickness 0.5mm, size 50×50mm 2 ) of the insulating epoxy glass cloth plate 4 penetrates into the inner side of the seal 5, and straightens it to ensure that the iron core laminations 1 are fixed reliably after binding; (4) one person supports the seal to prevent it from being sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com