Book spine dehurring grooving machine

A slotting machine and book back technology, applied in machining/deformation, machine tools and grinding machines suitable for grinding the edge of workpieces, etc., can solve problems such as missing pages, uneven gluing on the back of books, etc., and achieve uniform gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

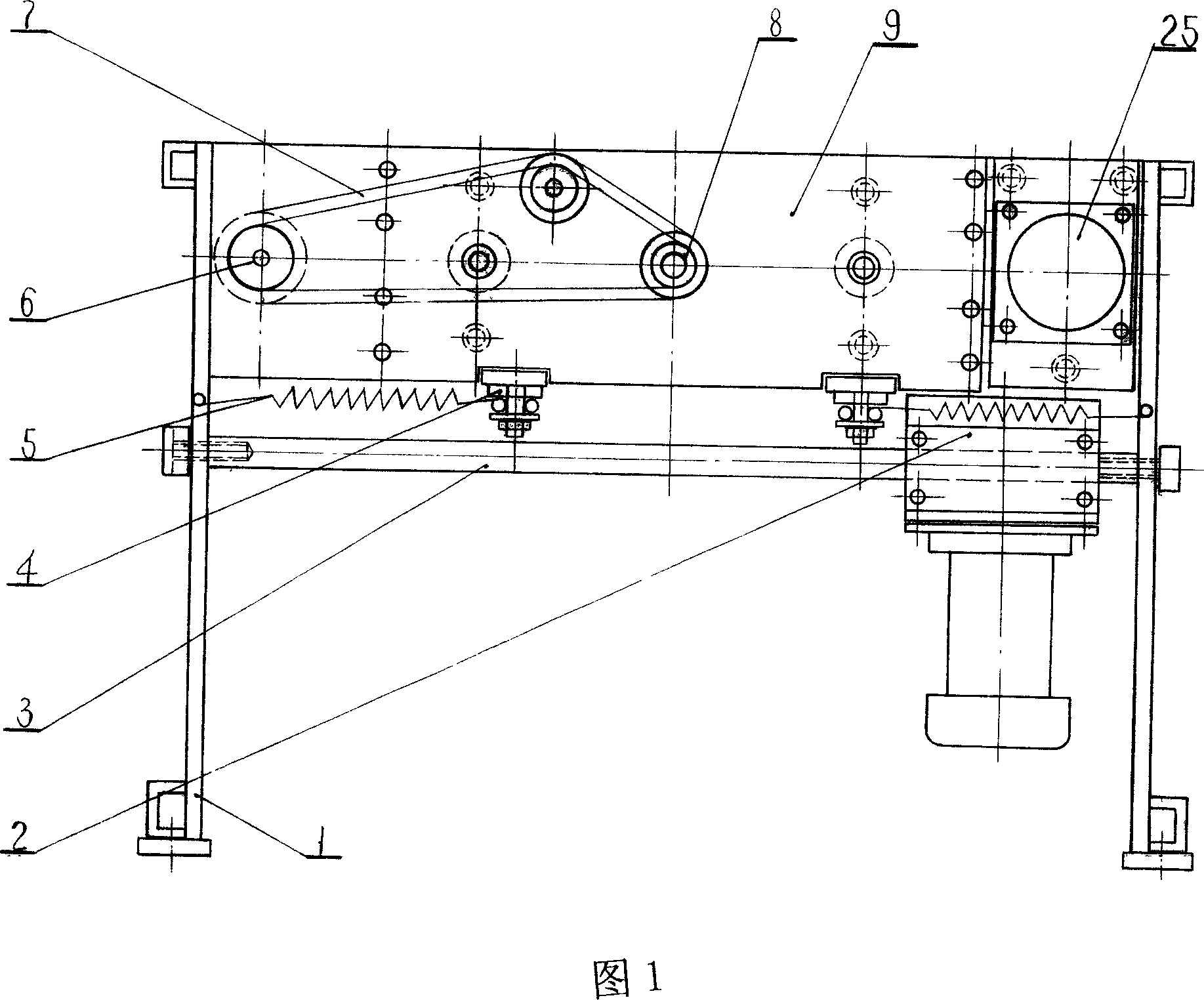

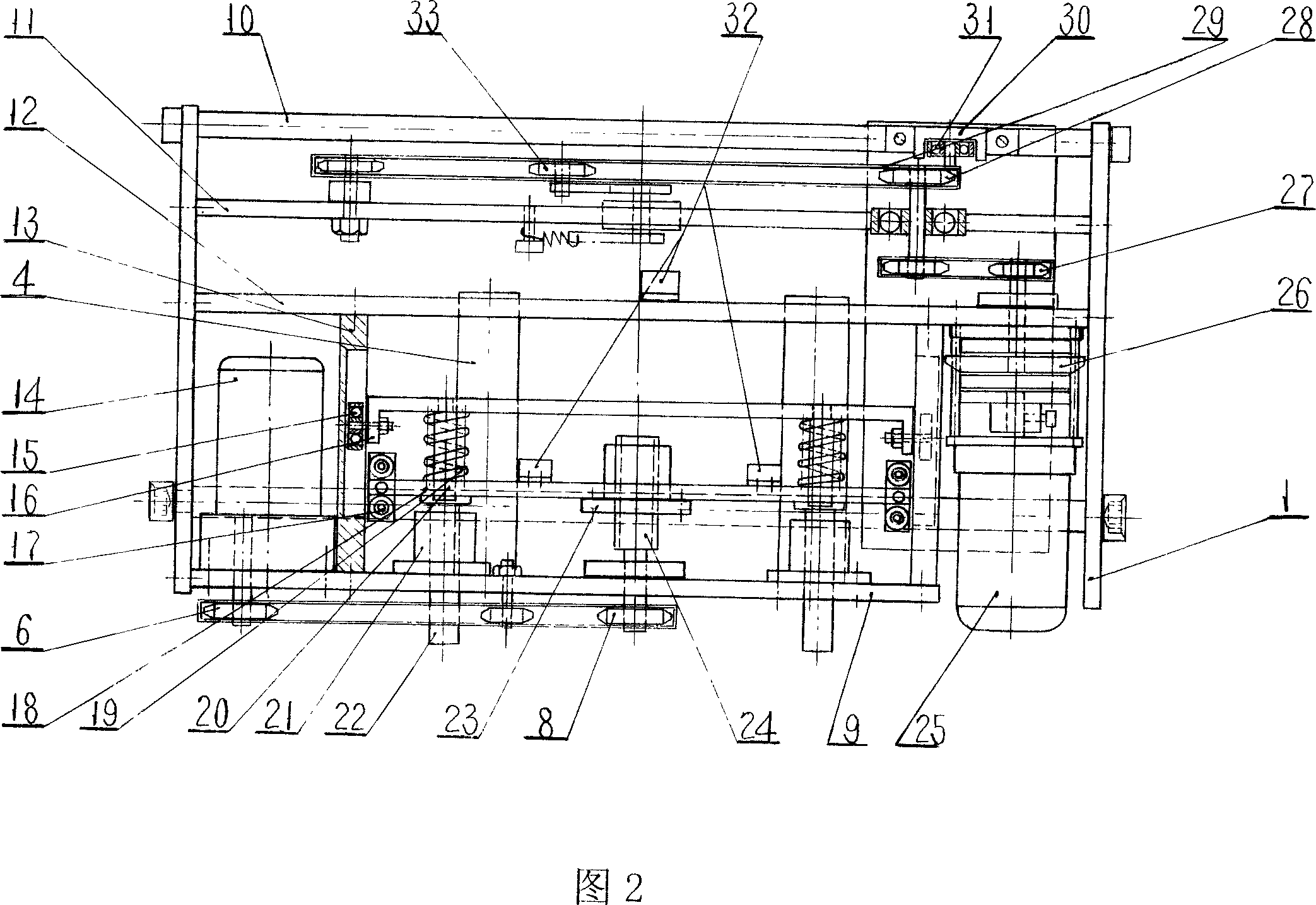

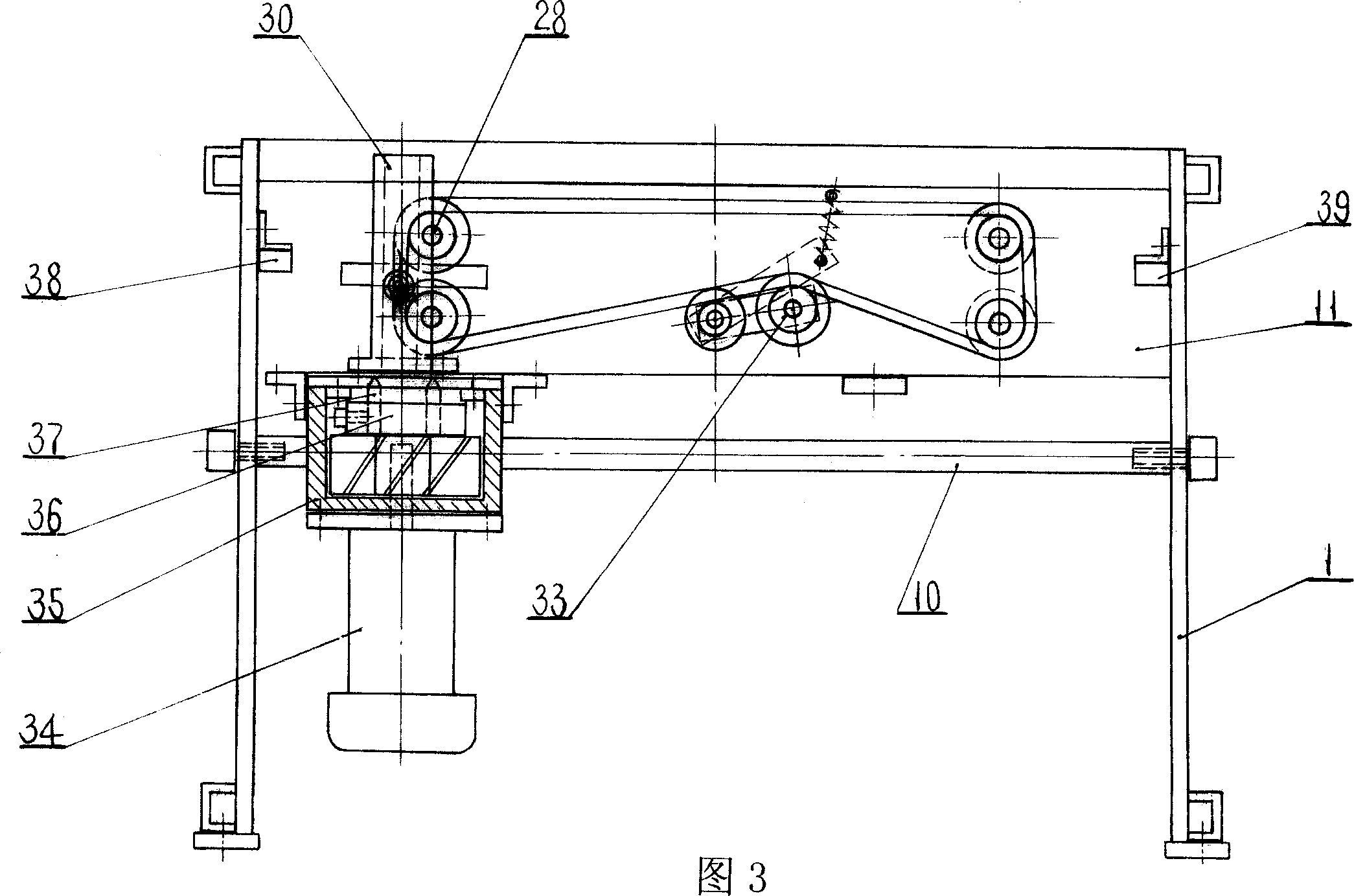

[0015] As shown in the figure, the upper part between the two vertical body vertical plates 1 is equipped with a vertical horizontal front fixed plate 9, a middle fixed plate 12, and a rear fixed plate 11, and the middle part of the body vertical plate 1 is equipped with a horizontal Front guide shaft 3 and rear guide shaft 10, milling cutter case 35 and milling cutter motor 34 are housed between front guide shaft 3 and rear guide shaft 10, the left end of middle fixed plate 12 is equipped with cutter motor 25, the middle part of front fixed plate 9 Three-wire screw shaft 24 is housed, and the inner end of three-wire screw shaft 24 is equipped with three-wire nut 23, and three-wire nut 23 is equipped with horizontal propulsion plate 18, and the outside of the left and right ends of propulsion plate 18 is equipped with longitudinal propulsion track plate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap