Rotary compressor

A rotary compressor and rotor technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problem of low production efficiency, achieve the effect of improving production efficiency, simplifying operation process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

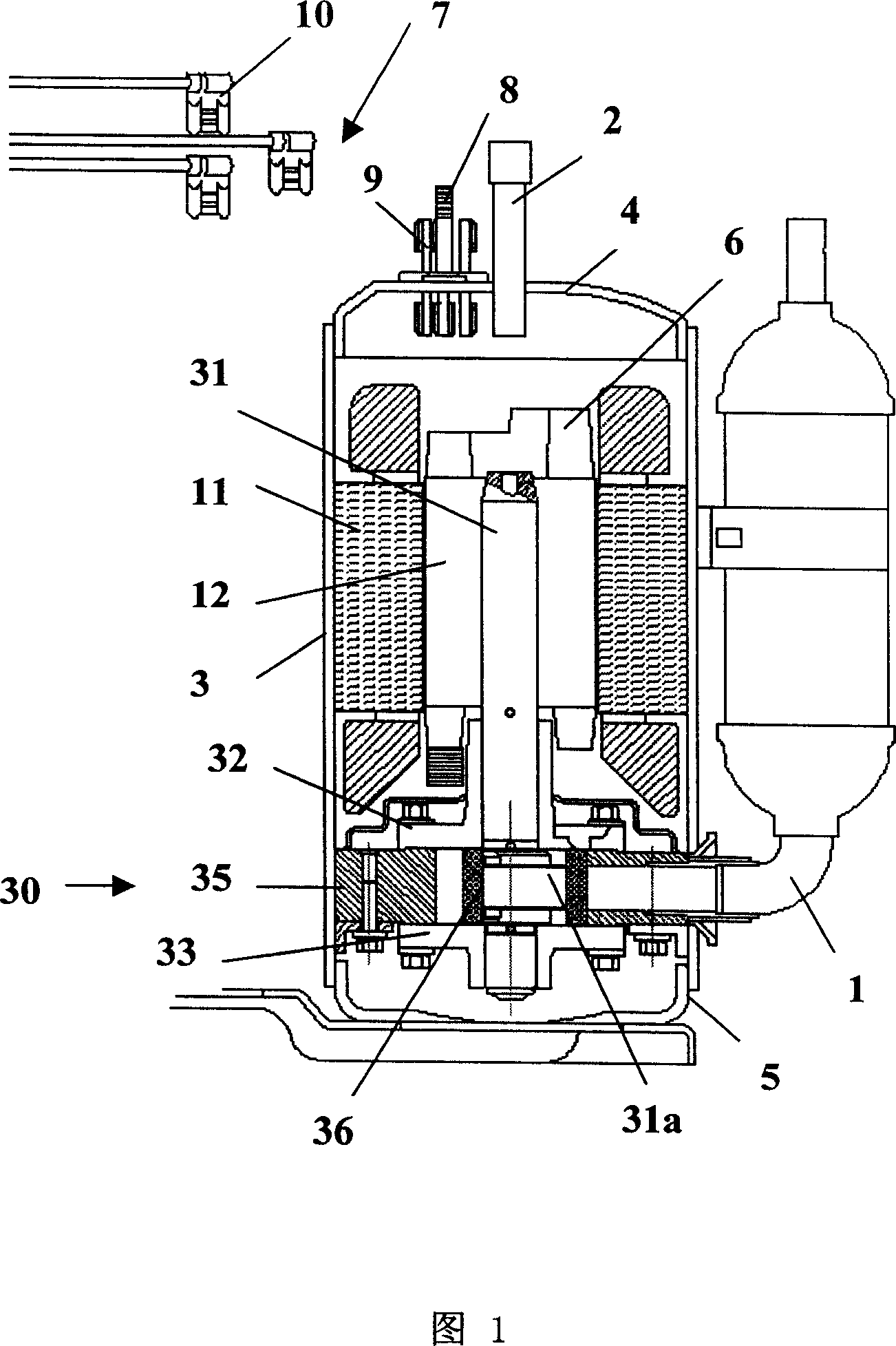

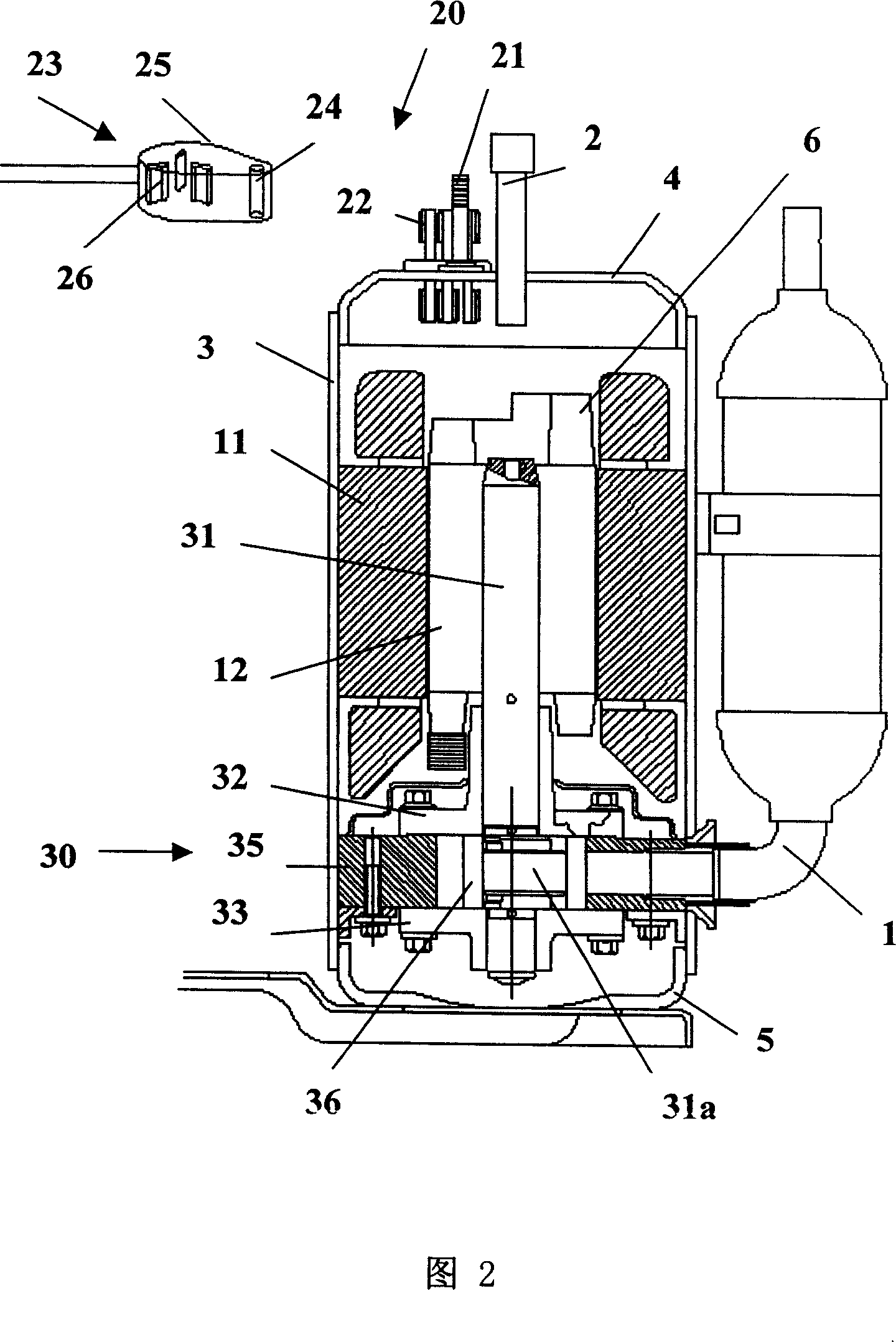

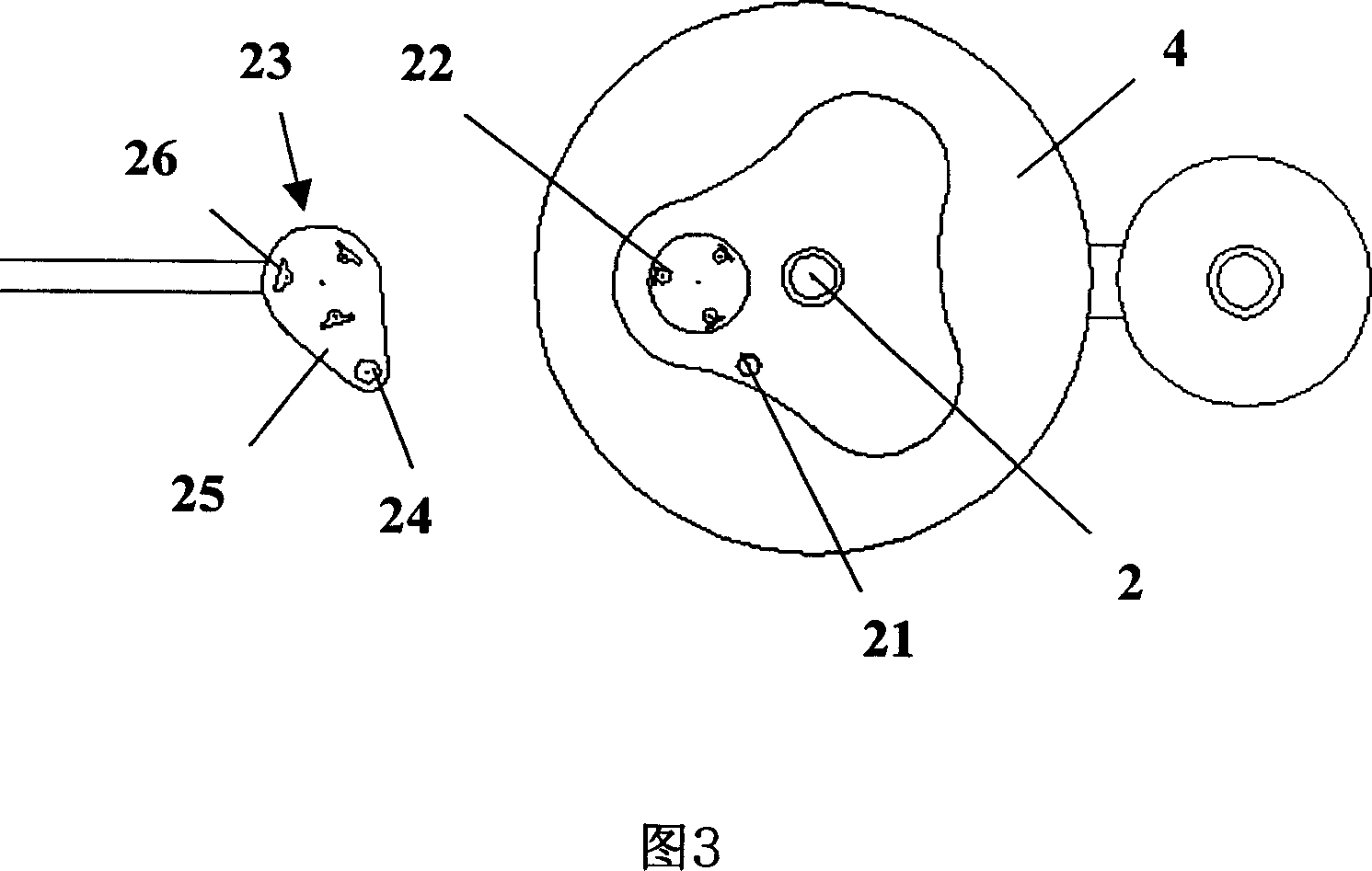

[0012] As shown in Fig. 2 and Fig. 3, the rotary compressor provided by the present invention includes an airtight container, an electromechanical part and a compression mechanical part; wherein the airtight container is composed of a cylindrical shell 3, an upper cover 4 and a lower cover 5, and the outer shell 3 A refrigerant inlet 1 is provided on one side of the upper cover 4, a refrigerant outlet 2 is provided at the center of the upper cover 4, and a power wiring device 20 is installed on one side of the upper cover 4; The stator 11 on the inner wall of the cylindrical casing 3 and the rotor 12 that is positioned at the center of the stator 11 and can rotate through the electromagnetic interaction between the stator 11; The upper bearing 32 and the lower bearing 33 installed on the upper and lower end surfaces of the cylinder 35 penetrate the center of the rotor 12 and the cylinder 35, and the lower part is formed with an eccentric part 31a, which can rotate together with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap