Device for monitoring the level of a container

A technology of liquid level and liquid storage, which is applied in the field of liquid level devices of liquid storage, and can solve problems such as device failure, magnet rupture, and prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

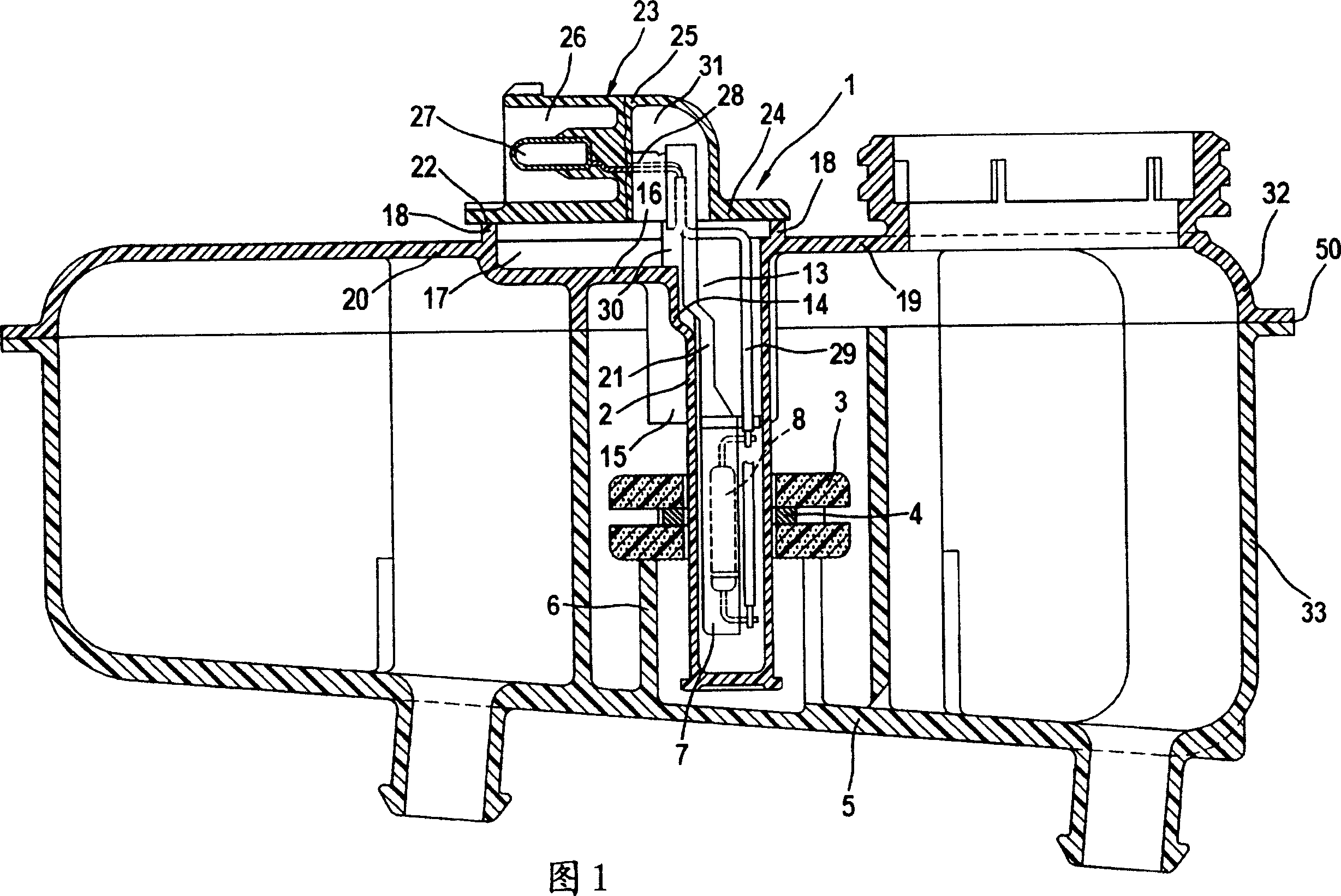

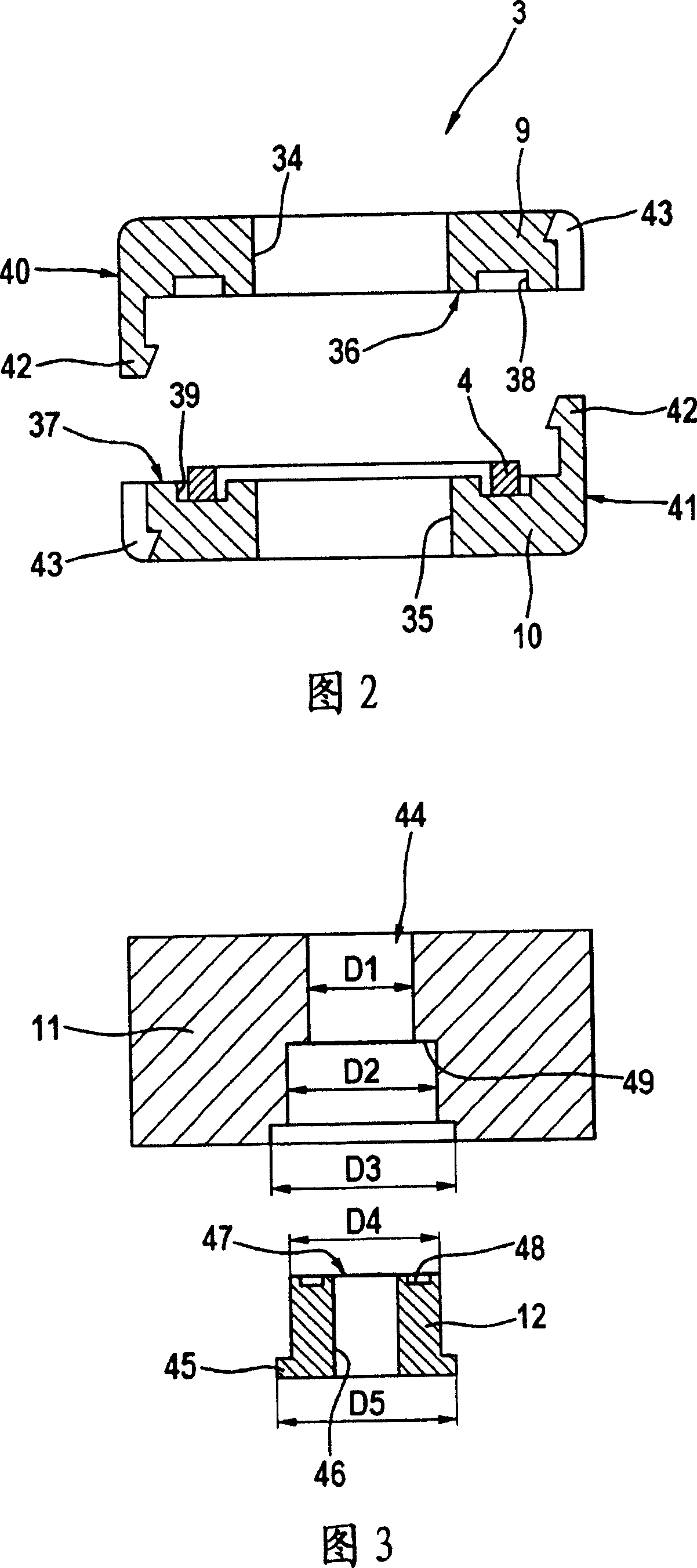

[0018] Figure 1 shows a reservoir 1 for hydraulic fluid, especially brake fluid, comprising a device for monitoring the liquid level of a container known from DE3716135A1. The accumulator 1 is fixed, for example, to the master cylinder (not shown) of the brake device of a motor vehicle, and is connected to a conduit 2 which extends into the accumulator and is closed at its end facing the inside of the accumulator, making The buoy 3, for example in a ring shape, is movably mounted along a duct 2 which preferably has a circular cross-section. The buoy 3 has a ring magnet 4. A tubular sleeve 6 protruding from the bottom 5 of the reservoir 1 and partially enclosing the duct 2 concentrically serves as a stop for the buoy 3. The stop limits the lowest position of the buoy 3 in the reservoir 1 and prevents the buoy 3 from leaving the duct 2.

[0019] A bracket 7 is provided in the catheter 2, and a reed switch 8 is fixed on the bracket. A terminal piece (Fahne) 21 is connected to the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com