Combined continuous extruder cavity

An extrusion cavity and combined technology, which is applied in metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of rising production costs, deformation of block materials, expensive materials, etc., and achieve economical manufacturing Material, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

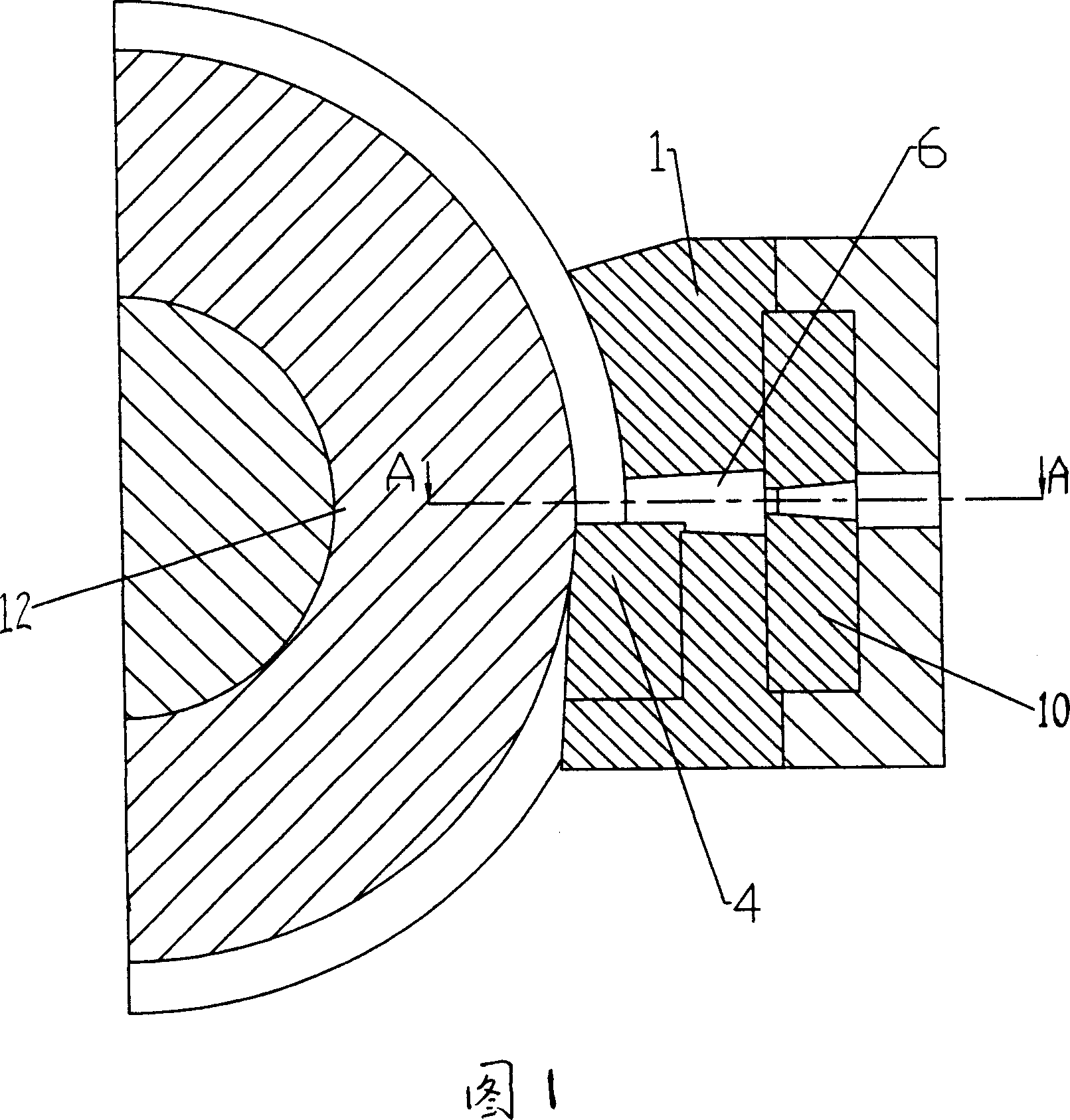

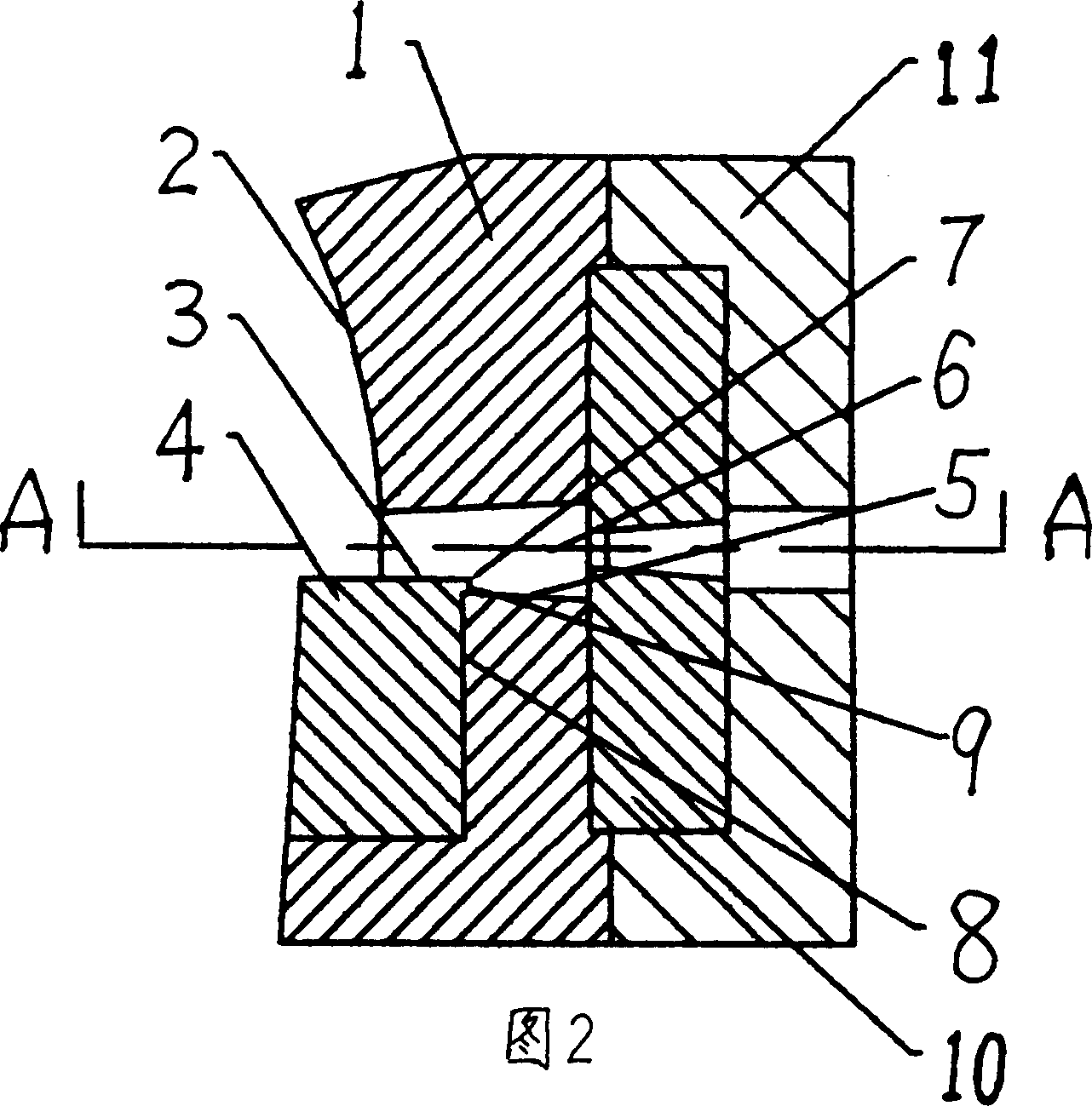

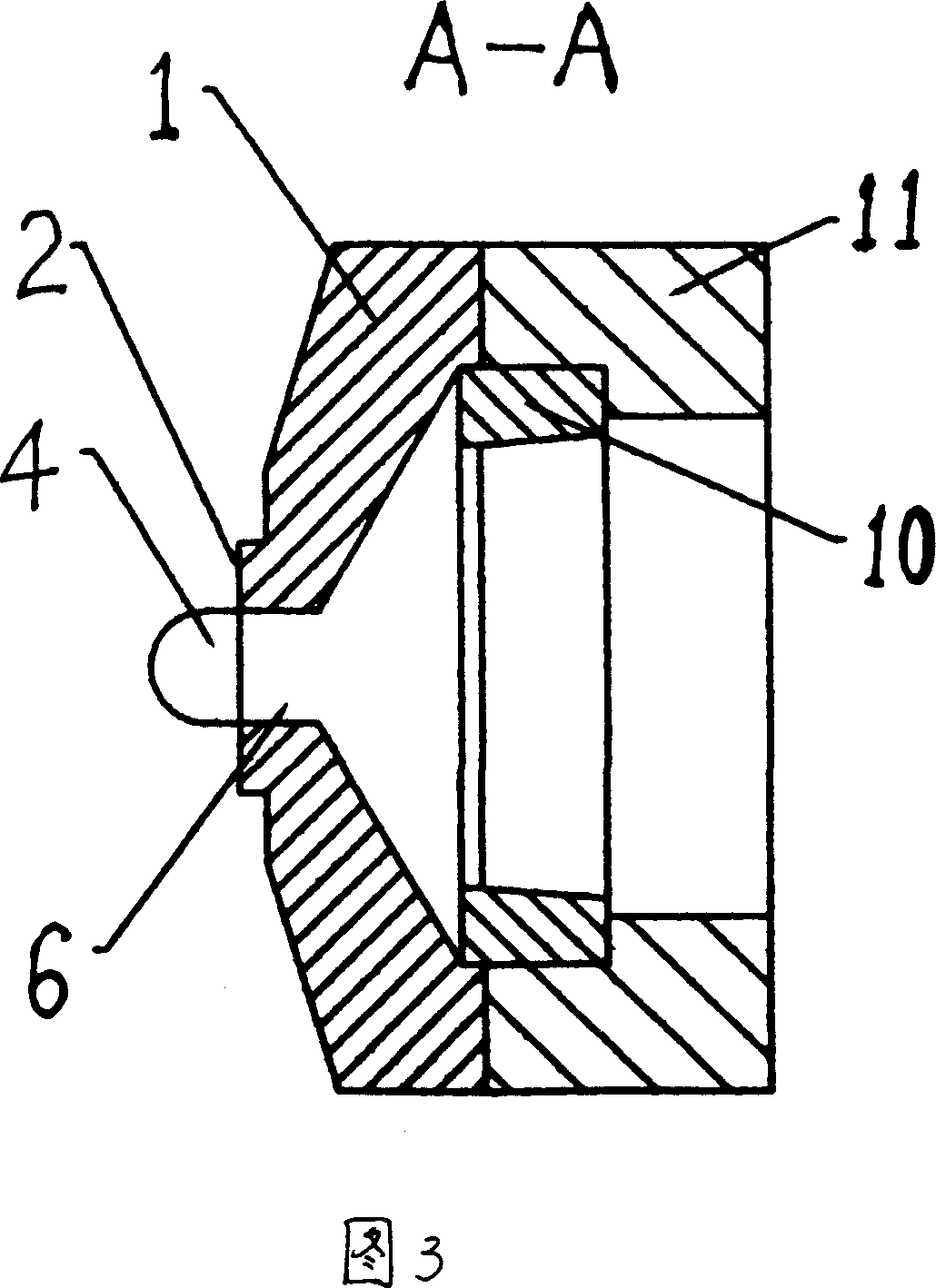

[0014] Extrusion equipment as shown in Figure 1, comprises extrusion wheel 12 and cavity, and cavity is shown in Figure 2, is made up of cavity panel, cavity bottom plate, stopper block and mould, includes seal on cavity panel 1 The surface 2, and the feed port 6, the stop block 4 and the cavity panel are split structures, the stop block is mounted on the cavity panel, and can be disassembled, and the end face 3 of the feed port of the stop block 4 is higher than the entrance The feed port surface 5 can also be aligned with the feed port face 5, and there is a sealing boss 7 that goes deep into the cavity feed port 6 at the junction of the feed block 4 feed port surface and the cavity. The end surface 9 under the table covers the joint surface 8 formed between the blocking block 4 and the cavity panel 1, the blank metal flow channel of the cavity panel 1 is a trapezoidal flat channel, and the mold 10 is only partially installed in the cavity panel 1, The rest of the mold 10 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com