Hydraulic expansion forming process

A forming process and liquid expansion technology, applied in the field of hydraulic forming process, can solve the problems of easy to produce defects, increase investment cost and high investment cost, and achieve the effect of eliminating stretching and annealing, improving production efficiency and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

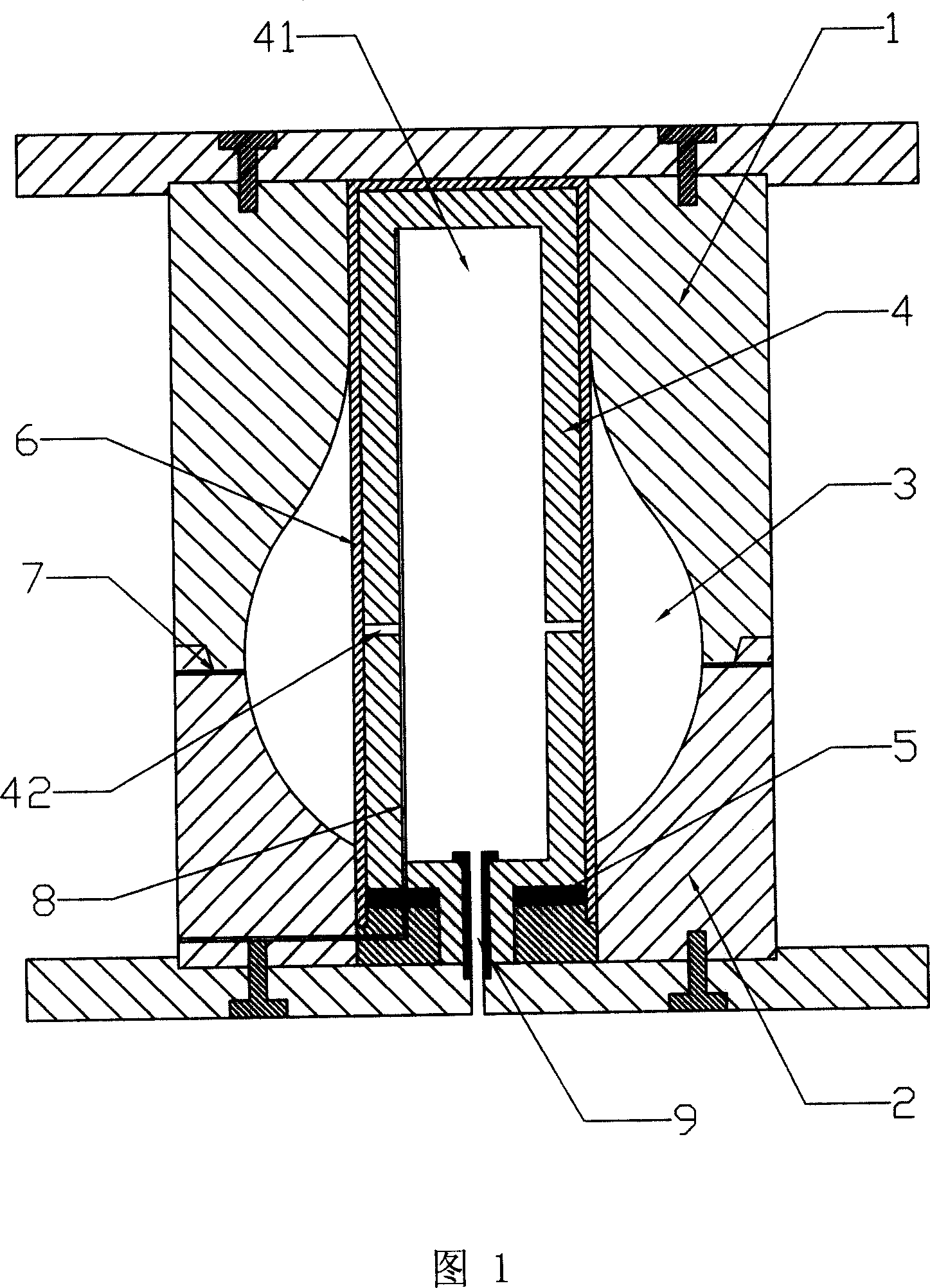

[0010] A liquid expansion molding process, one end of the metal pipe is welded with a metal plate to close the opening of the end to form a metal cylinder 6, and then the metal cylinder 6 is put into the mold and the opening of the metal cylinder 6 is sealed, and then the high-pressure liquid is filled into the cylinder. The wall of the metal cylinder 6 is expanded under pressure and formed in the mould. Taking the preparation process of a metal teapot as an example, the traditional process first cuts the plate into a circle, and then uses a hydraulic stretching machine to perform multiple stretches to form a cylindrical prefabricated part. Since the material needs to undergo a large deformation, the stretching process There may be cracking issues. Then the prefabricated part is assembled into the expansion machine for expansion, and then the wrinkles generated at the mouth of the cylinder due to stretching are also removed. Because this process uses metal tubes to weld the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com