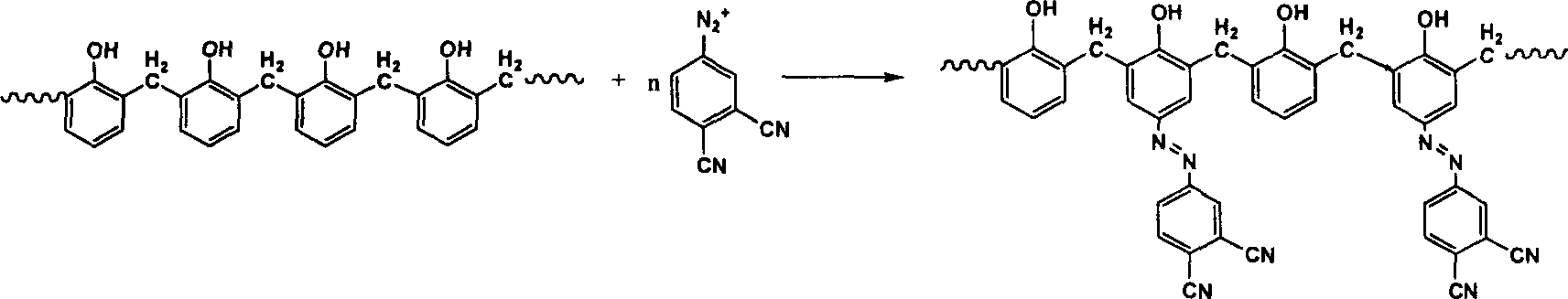

O-phthalo nitrile modified high ortho phenolic resin and its preparing method

A technology of phthalonitrile and phenolic resin, applied in the field of phenolic resin, to achieve the effect of improving heat resistance and toughness, improving heat resistance and ablation resistance, and easily obtaining raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 1.12 moles of phenol, 0.78 moles of phenolic solution (phenolic formaldehyde weight concentration 37%) and 0.02 moles of zinc acetate in a 250ml three-necked flask designed with a stirring device, a reflux condensing device and a thermometer, and reflux at about 102°C for about 4 hour, after the reaction finished, the product obtained was cooled down, then filtered, washed and dried to obtain 98.3g yellow powder high ortho phenolic resin with a yield of about 85%.

Embodiment 2

[0034] Add 1.12 moles of phenol, 0.78 moles of phenolic solution (phenolic formaldehyde weight concentration 37%) and 0.03 moles of zinc acetate into a 250ml three-necked flask designed with a stirring device, a reflux condensing device and a thermometer, and reflux at about 100°C for about 2 hour, after the reaction finished, the product obtained was cooled down, then filtered, washed and dried to obtain 96.3g yellow powder high ortho phenolic resin with a yield of about 84%.

[0035] Preparation of phthalonitrile diazonium salt solution.

[0036] Example 1

[0037] Dissolve 0.02 mole of 4-aminophthalonitrile in 20ml of sulfuric acid solution with a concentration of 70%, stir well and cool to about 5°C, and dissolve 10ml of the solution containing 0.04 mole of sodium nitrite at about 5°C within 1 hour Add dropwise to the above solution to prepare phthalonitrile diazonium salt solution.

[0038] Example 2

[0039] Dissolve 0.01 mole of 4-aminophthalonitrile in 20ml of 70% a...

Embodiment 5

[0046]Add 0.03 mole of high ortho phenolic formaldehyde into 150ml of NaOH solution with a concentration of 1mol / L and add it to a reaction kettle equipped with a stirring device and a thermometer, so that the high ortho phenolic formaldehyde is dissolved in NaOH solution, and then 0.007 mole of 4-aminophthalamide The diazonium salt solution of phthalonitrile prepared by nitrile synthesis was added dropwise to the phenolic NaOH solution while stirring within 1 hour, and the temperature was kept at about 13°C. During the dropping process, use alkaline solution to adjust the pH of the system to 8. After the dropping, use sulfuric acid solution to adjust the pH to 5 to obtain a red precipitate. After suction filtration, hot water washing and drying, the phthalonitrile-modified The high ortho-position phenolic resin, the yield is 83.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com