Boron/cardanol/nano-material modified phenolic resin material and preparation method therefor

A nano-material and phenolic resin technology, which is applied in the field of boron/cardanol/nano-material modified phenolic resin material and its preparation, can solve the problems of low molecular weight of phenolic resin, limited modification effect, harsh reaction conditions, etc., and achieve improved durability. Heat resistance and toughness, excellent thermal stability, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

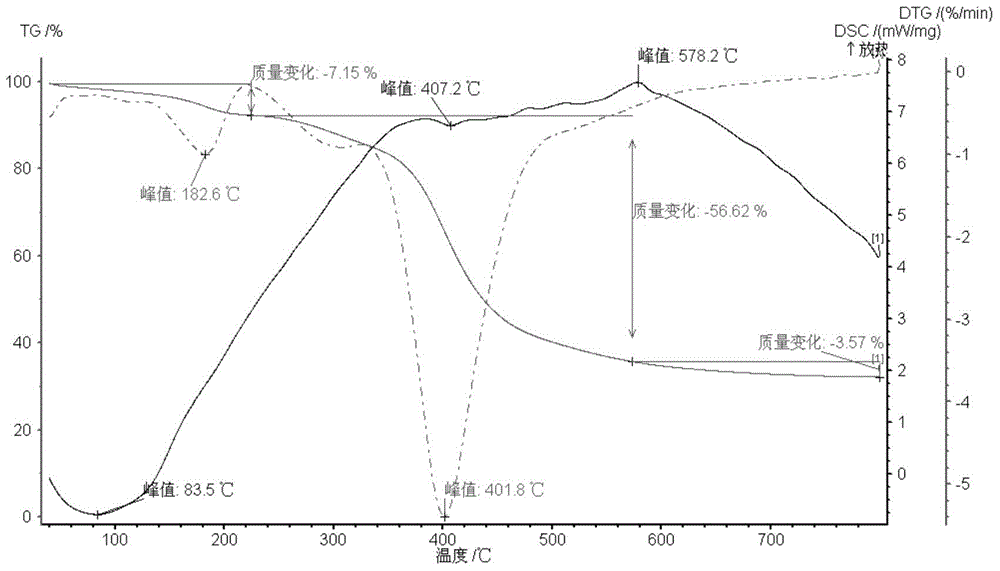

Embodiment 1

[0033] A boron / cardanol / nano material modified phenolic resin material, prepared by the following method:

[0034] (1) Esterification reaction of cardanol / phenol-boric acid: 0.01 part of cardanol, 7 parts of boric acid, 1 part of acetic acid and 50 parts of water-carrying agent were refluxed at 100 ° C for 3 hours, and then divided into 5 batches Add 20 parts of phenol in each batch, continue to react for 3 hours, then raise the temperature to 130°C, distill 5 parts of water-carrying agent, and then lower the temperature to below 60°C;

[0035] (2) Polymerization: Add 16 parts of paraformaldehyde, 5 parts of nano-SiO modified by silane coupling agent to the reactant obtained in step (1) 2 , 0.01 part of calcium chloride, reflux at 90°C for 5 hours of water separation reaction, after the reaction is completed, heat up to 140°C and distill the remaining water-carrying agent, then cool down to room temperature and discharge, that is, boron / cardanol / nanomaterial Modified phenolic...

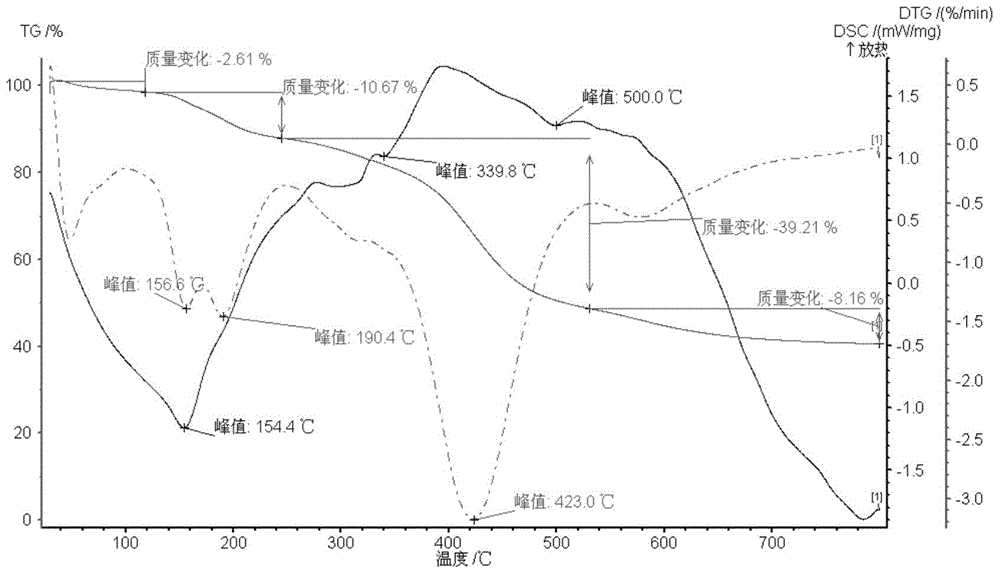

Embodiment 2

[0037] A boron / cardanol / nano material modified phenolic resin material, prepared by the following method:

[0038] (1) Esterification reaction of cardanol / phenol-boric acid: return 6 parts of cardanol, 15 parts of boric acid, 2 parts of oxalic acid, 1 part of hydrochloric acid, 1 part of sulfuric acid, and 100 parts of water-carrying agent at a temperature of 115 ° C to separate water React for 0.5 hours, then add 20 parts of phenol in 5 batches, continue the reaction for 5 hours, raise the temperature to 140°C, distill 90 parts of water-carrying agent, and then cool down to below 60°C;

[0039] (2) Polymerization: Add 25 parts of paraformaldehyde, 8 parts of nano-SiO modified by silane coupling agent to the reactant obtained in step (1) 2 , 1.5 parts of barium chloride, 1.3 parts of manganese sulfate, reflux at 105°C for water separation for 1 hour, after the reaction, heat up to 140°C to distill off the remaining water-carrying agent, then cool down to room temperature and dis...

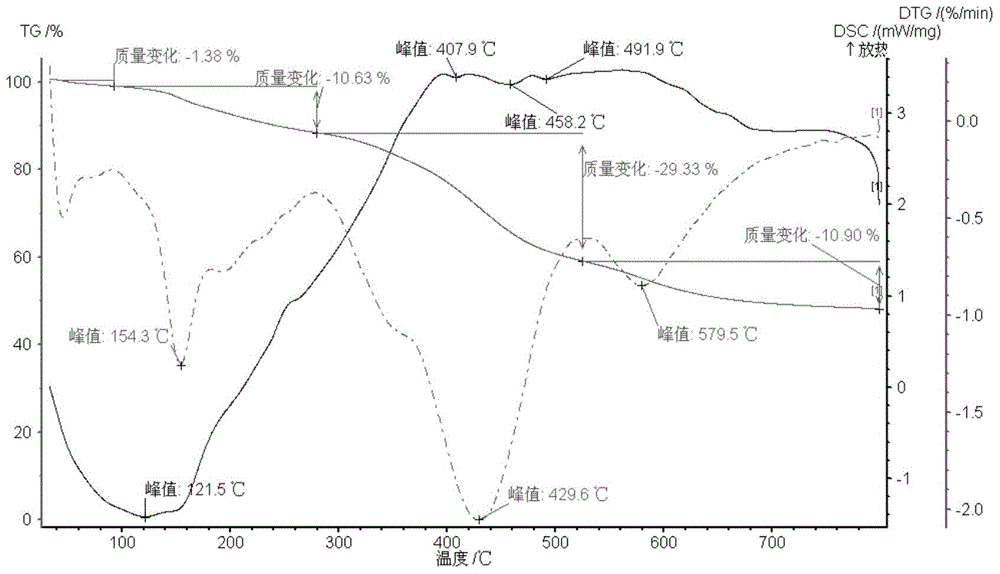

Embodiment 3

[0041] A boron / cardanol / nano material modified phenolic resin material, prepared by the following method:

[0042] (1) Esterification reaction of cardanol / phenol-boric acid: 40 parts of cardanol, 22 parts of boric acid, 2 parts of oxalic acid, 3.2 parts of trifluoroacetic acid, 2.6 parts of methyl silicic acid, 500 parts of water-carrying agent at 130 ° C Reflux and water separation reaction at high temperature for 5 hours, then add 20 parts of phenol in 5 batches in each batch, continue the reaction for 1 hour, then raise the temperature to 140°C, distill 25 parts of water-carrying agent, and then cool down to below 60°C;

[0043] (2) Polymerization: Add 54 parts of paraformaldehyde, 16 parts of nano-SiO modified by silane coupling agent in the reactant obtained in step (1) 2 , 1 part of copper chloride, 6.2 parts of magnesium chloride, reflux and water separation reaction at 130 °C for 2.5 hours, after the reaction, heat up to 140 °C to distill the remaining water-carrying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com