Dyeing caldron in supercritical CO2 dyeing device

A carbon dioxide and dyeing device technology, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc., can solve problems such as equipment and technical difficulties, reduce fluid flow resistance, ensure continuity, The effect of simplifying the delivery pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

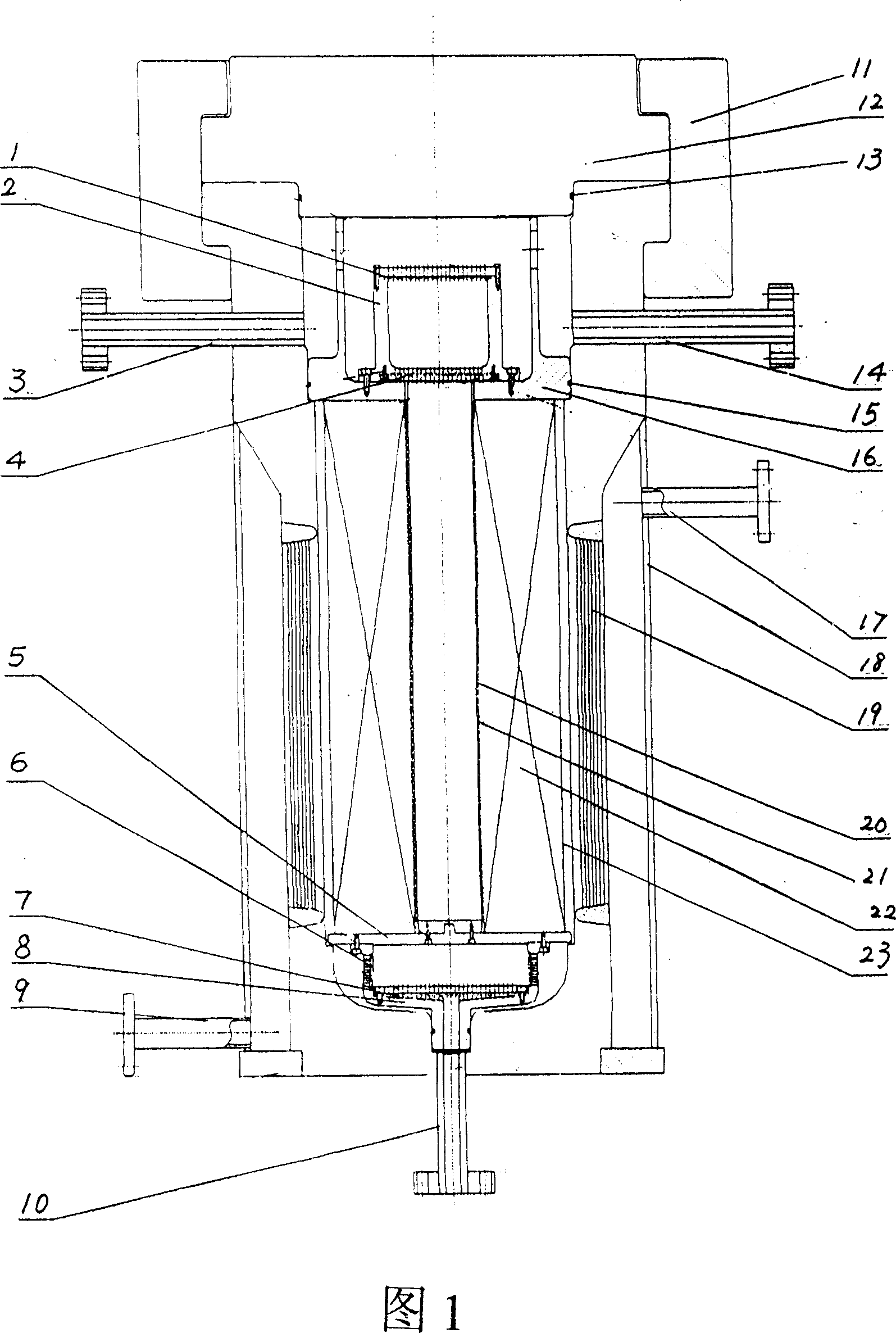

[0025] According to shown in Fig. 1, the present invention is in the kettle body 23 of prior art, still lid 12, jacket 18, hot oil inlet 9, hot oil outlet 17, carbon dioxide import and export 10 at the bottom of the kettle, carbon dioxide inlet and outlet 14 on the top of the kettle body, The perforated pipe 20, the present invention is especially provided with a chamber formed by a fabric upper baffle plate 16 isolated above the kettle body 23, the fabric upper baffle plate 16 center area has a through hole, the upper chamber is provided with an upper dye box 2, The bottom of the kettle body 23 is provided with a lower chamber formed by fabric lower baffle plate 5 segregation, there is a carbon dioxide flow passage between the fabric lower baffle plate 5 and the inner wall of the kettle body 23, and the lower dye box 8 is arranged in the lower chamber. There is a porous tube 20 coaxial with it, the upper end of the porous tube 20 matches and fixes the through hole in the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com