Gain compensating method for flaw detector

A technology of gain compensation and flaw detector, which is applied in the direction of processing detection response signals, etc., can solve problems such as complex circuits, adjustment of potentiometers and other components, complex circuits, etc., and achieve precise dB value control, gain compensation, and precise gain control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

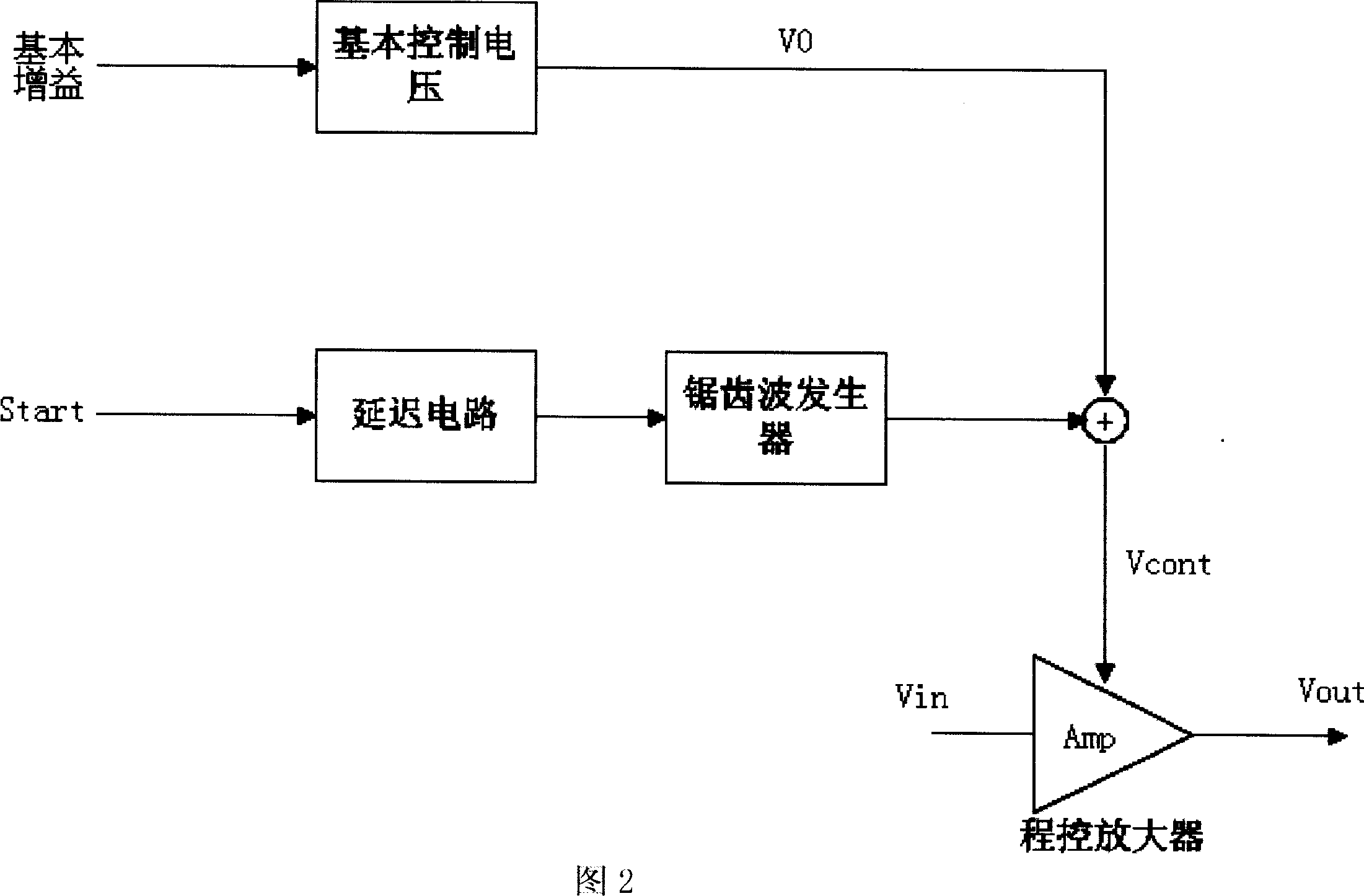

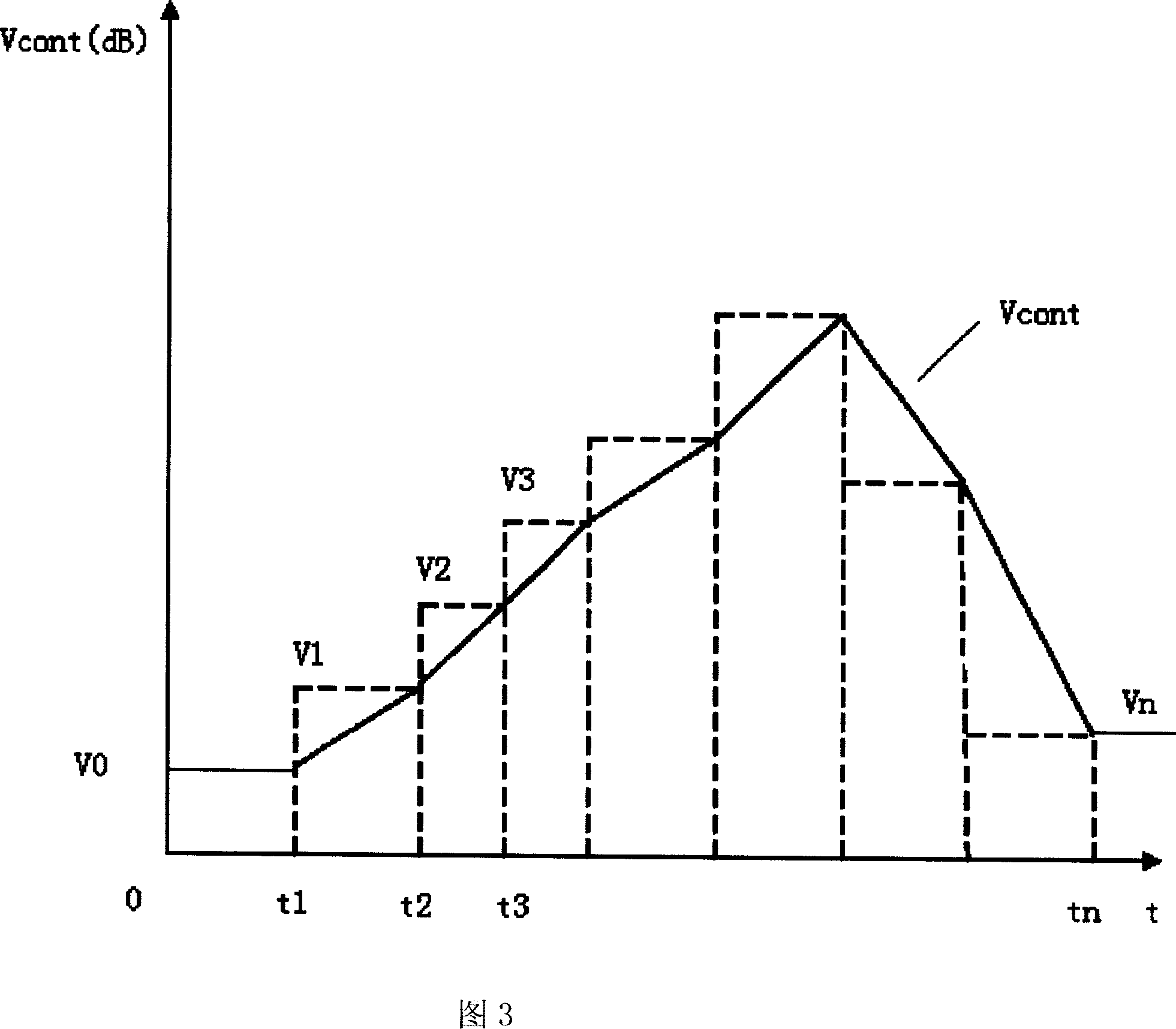

[0034] As shown in Figures 3-5, the gain compensation method of the flaw detector in this preferred embodiment, the method uses a device including a CPU module, a programmable logic device and a digital-to-analog converter to control the voltage of the voltage control terminal of the program-controlled amplifier of the flaw detector. Control to realize gain compensation, the method includes the following steps:

[0035] (1) Set the time parameter of each channel (the time parameter is the count value of a certain time) and the corresponding gain data parameter;

[0036] (2) The control panel transmits the channel number signal to the CPU module;

[0037] (3) The CPU module transmits the parameters of the corresponding channel to the programmable logic device according to the channel number, and starts the programmable logic device at the same time;

[0038] (4) the programmable logic device timing, and comparing the time value of the timing (the count value of a certain time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com