Small power cage type induction motor

A low-power, cage-type technology, applied in asynchronous induction motors, electric components, electromechanical devices, etc., can solve the problems of multi-material cost and suboptimal cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

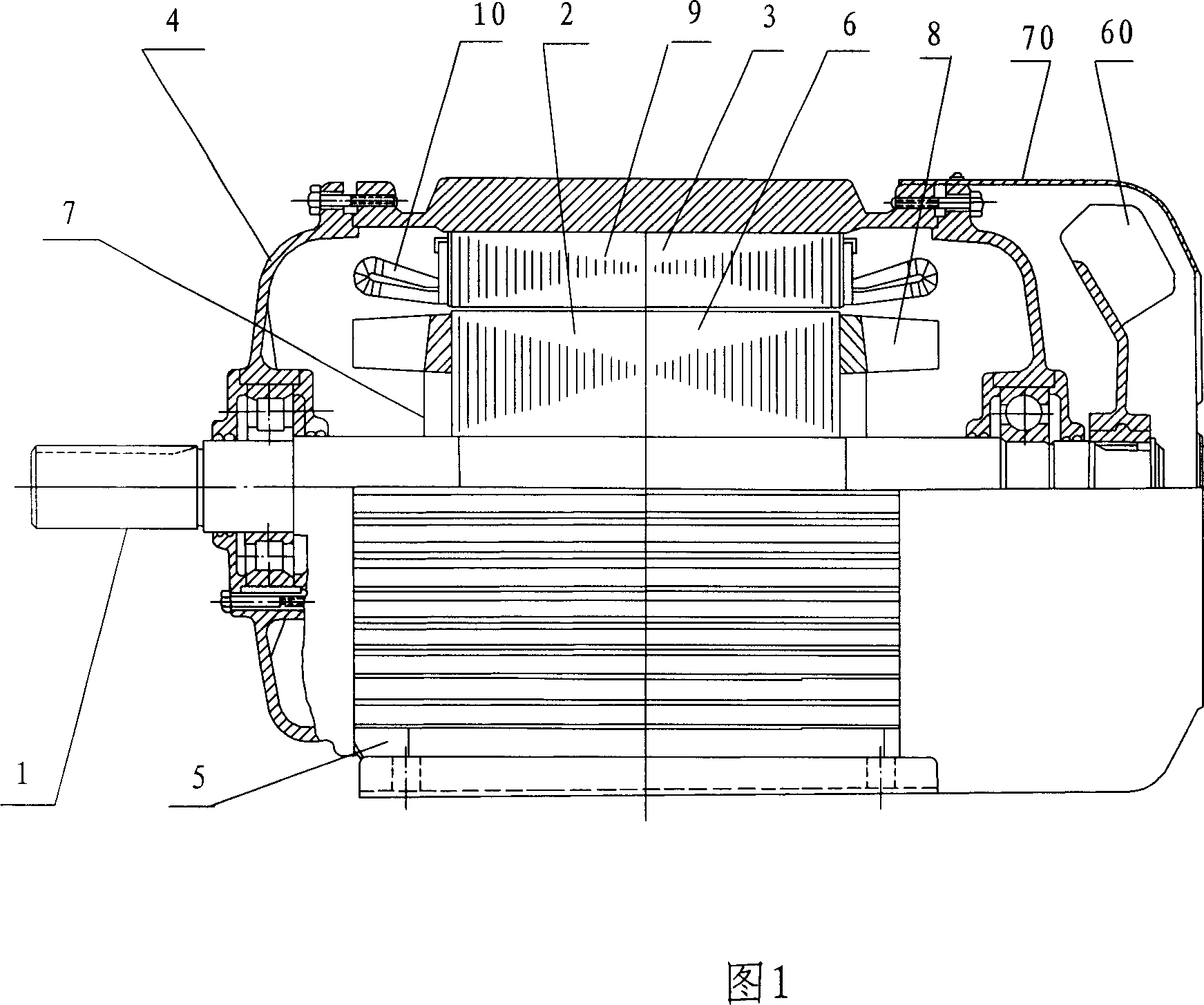

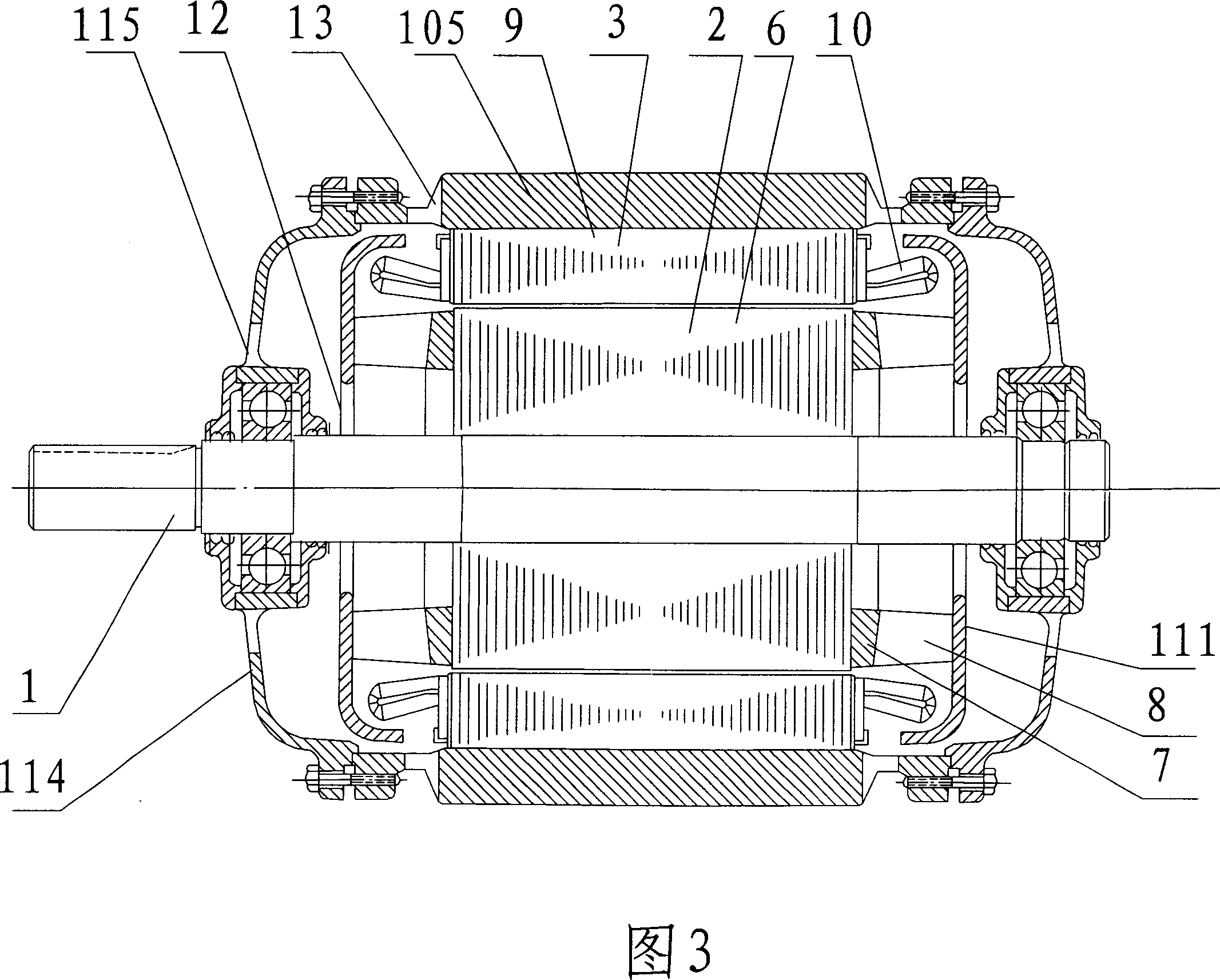

[0027] The motor of the embodiment of the present invention can be improved on the basis of the traditional design of the national industry standard Y series or AO2, BO2, CO2 and DO2 series motors, as shown in Figure 8-3 in the "Motor Design" mentioned in the background technology. The structure of a small cage induction motor is shown in Figure 1, including:

[0028] ——rotating shaft 1, rotor 2, stator 3, end cover 4, frame 5, outer fan 60 and windshield 70;

[0029] - The rotor 2 includes a rotor core 6 and a cast aluminum cage winding, the cage winding includes a conductive ring 7 and its inner fan blades 8 protruding axially;

[0030] - the stator 3 includes the stator core 9 and the stator windings;

[0031] - The end 10 of the stator winding radially surrounds the rotor inner fan blade 8 .

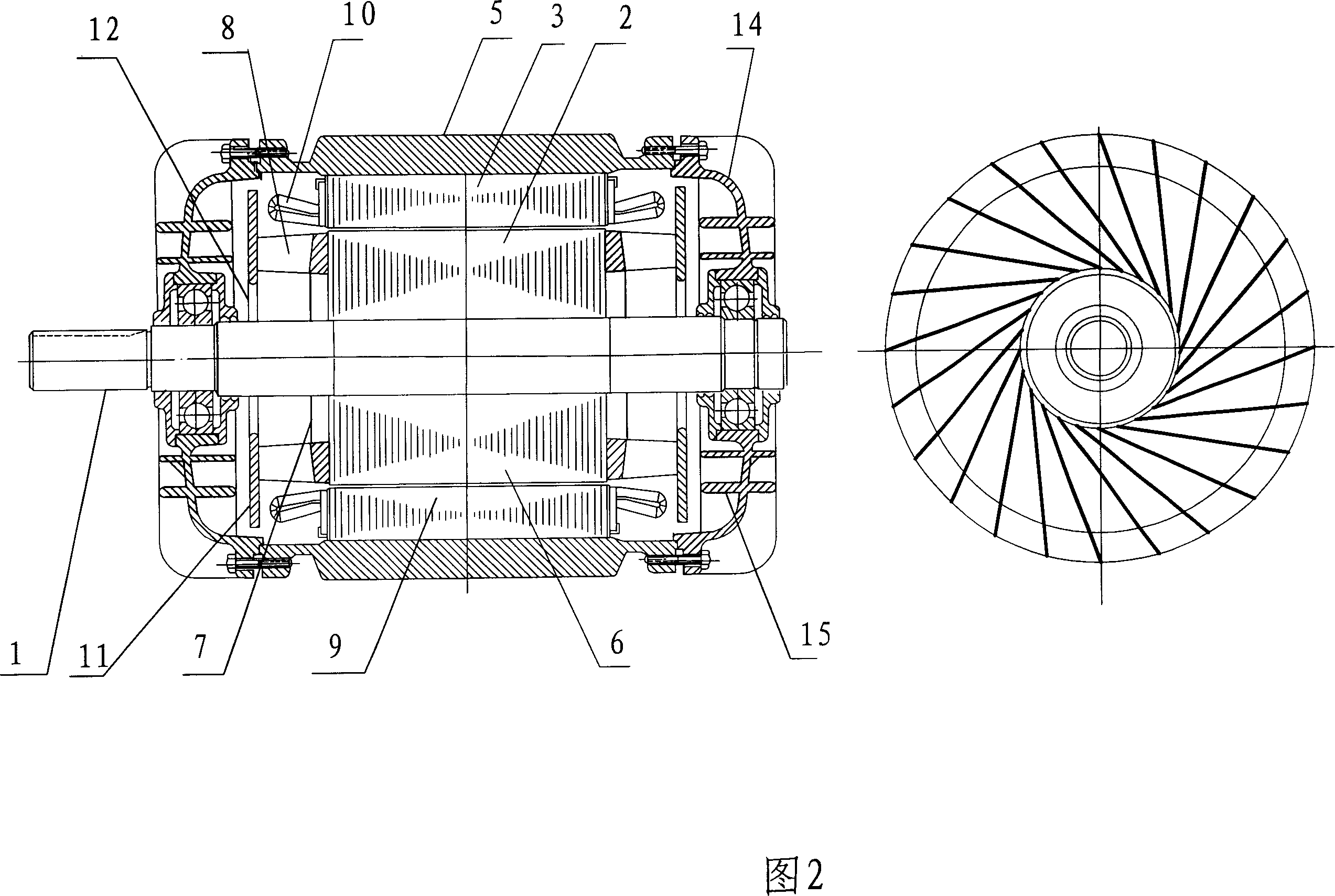

[0032] The structural diagram of the motor of the first embodiment of the present invention is shown in FIG. 2 . The motor is a modified design of the enclosed small and medium-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com