A high torque density motor with stator winding and heat pipe integrated heat dissipation structure

A technology of stator winding and heat dissipation structure, which is used in motors, electric components, electric vehicles, etc., to achieve the effects of high reliability, improved heat conduction and heat dissipation, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

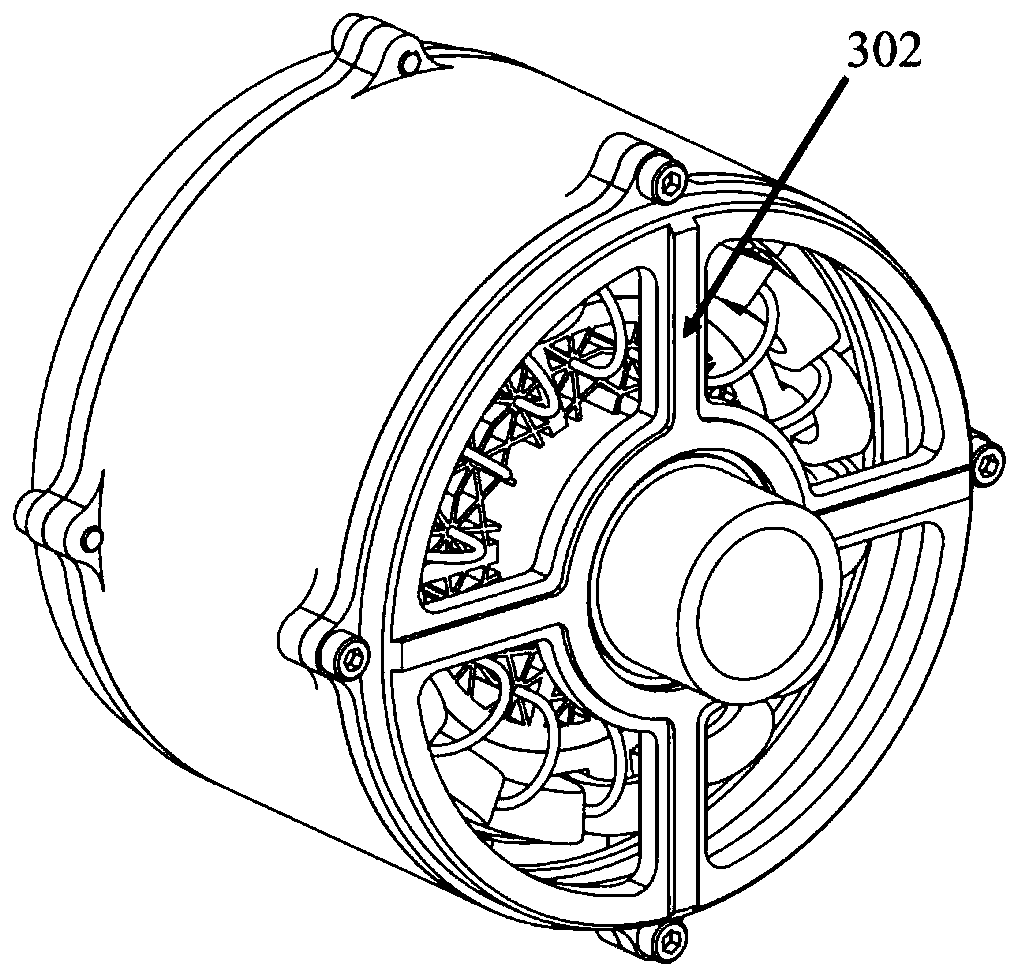

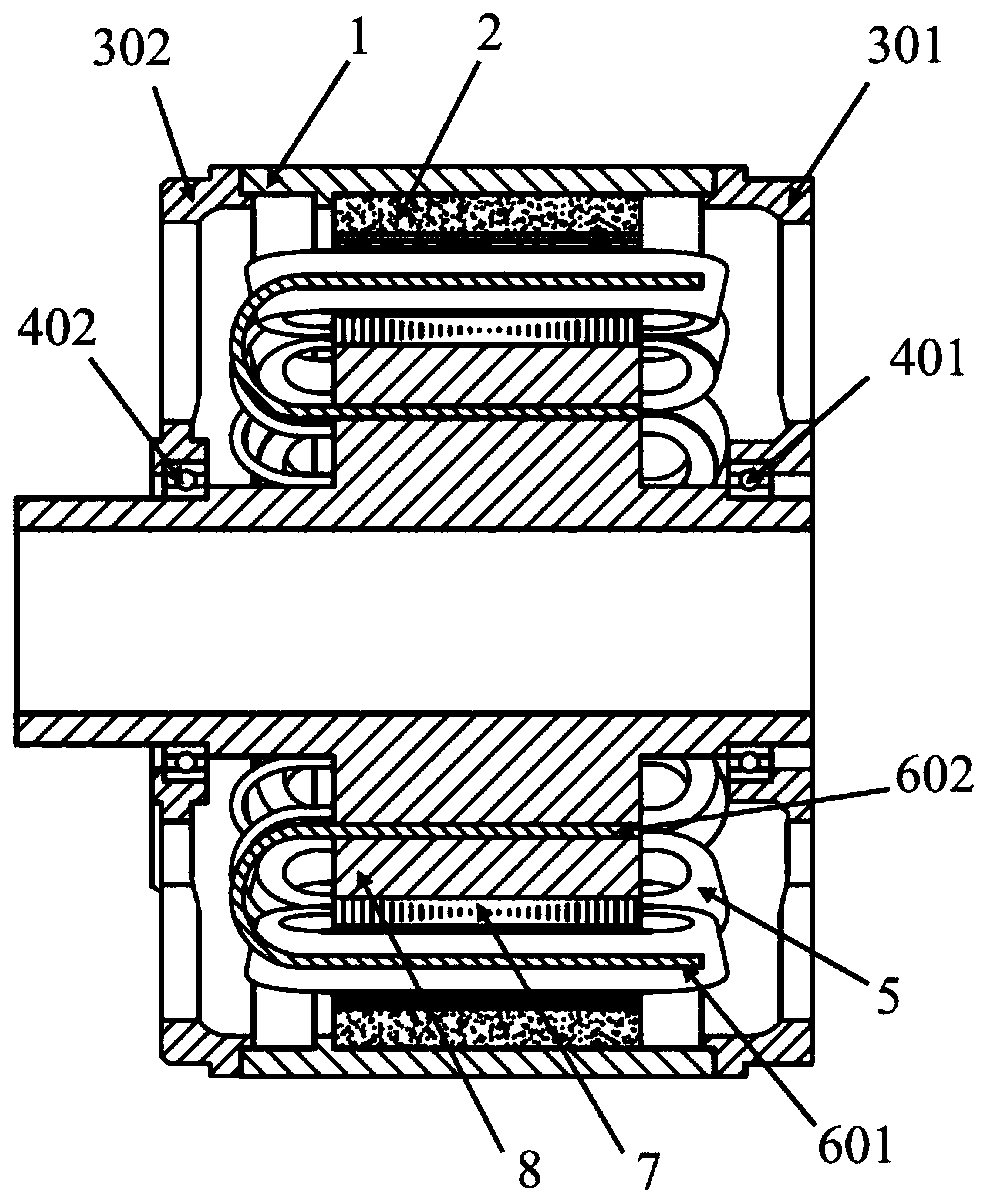

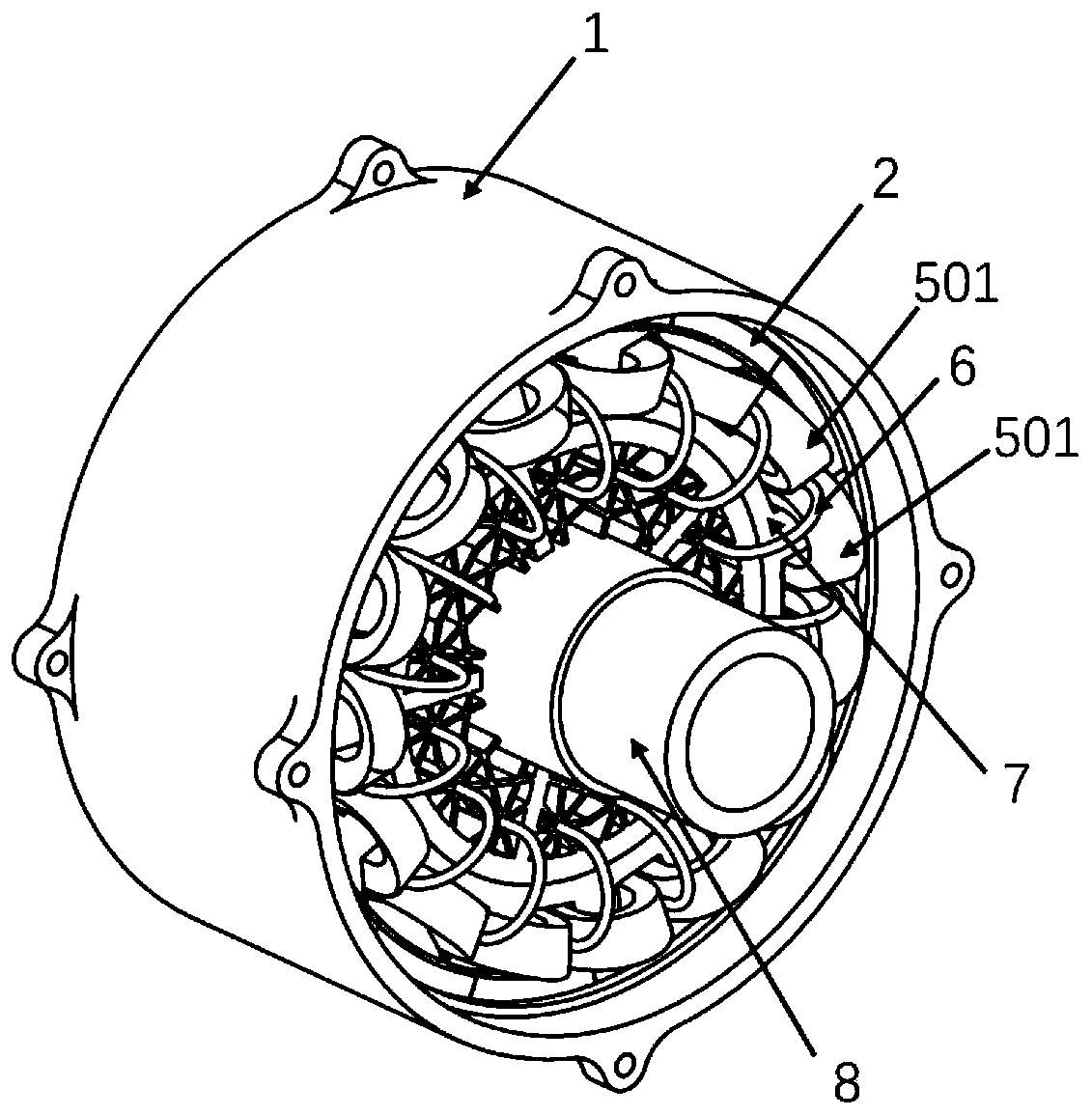

[0028] refer to Figure 1-Figure 6 As shown, the present invention proposes an embodiment of a high torque density motor with a stator winding and heat pipe integrated heat dissipation structure, including a stator assembly, a rotor assembly and a casing 1, and the casing 1, the rotor assembly and the stator assembly Arranged coaxially from the outside to the inside, the stator assembly includes a stator core 7, a motor stator winding 5 and a stator shaft 8, and a plurality of stator teeth 701 are uniformly arranged on the outer peripheral surface of the stator core 7, and two adjacent Stator slots are formed between the stator teeth 701, the motor stator winding 5 includes a plurality of winding coils 501, the rotor assembly includes a permanent magnet 2, and a heat pipe radiator 6, each stator tooth 701 is wound with a winding coil 501 , then the stator slots contain winding coils 501 on the left and right sides, each winding coil 501 is wrapped with insulating material, and...

Embodiment 2

[0043] refer to Figure 6-Figure 8 As shown, a high torque density motor with integrated heat dissipation structure of stator windings and heat pipes. The rotor is inside and the stator is outside. It is a permanent magnet synchronous motor structure with an outer stator and an inner rotor. Its components are the same as those in Embodiment 1. The rear end cover 301 of the motor is made of aluminum alloy, which is used for fixing and installing the motor. The casing 1 is made of aluminum alloy, and the cooling fins 802 are designed as an integral structure with the casing. Heat pipe radiator 6 is a U-shaped heat pipe (copper water heat pipe or aluminum ammonia heat pipe). The motor front cover 302 is made of aluminum alloy and adopts a spoke-type non-sealed structure. The rotor shaft 9 is made of titanium alloy or aluminum alloy. The stator core 7 is made of silicon steel sheet or iron-cobalt alloy or other soft magnetic materials. The winding coil 501 in the stator windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com