Three-phase permanent magnet synchronous motor for injection molding

A permanent magnet synchronous and motor technology, applied in synchronous machines, electric components, magnetic circuit rotating parts, etc., can solve the problems of low efficiency of injection molding machines, and achieve the effect of eliminating electromagnetic noise and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

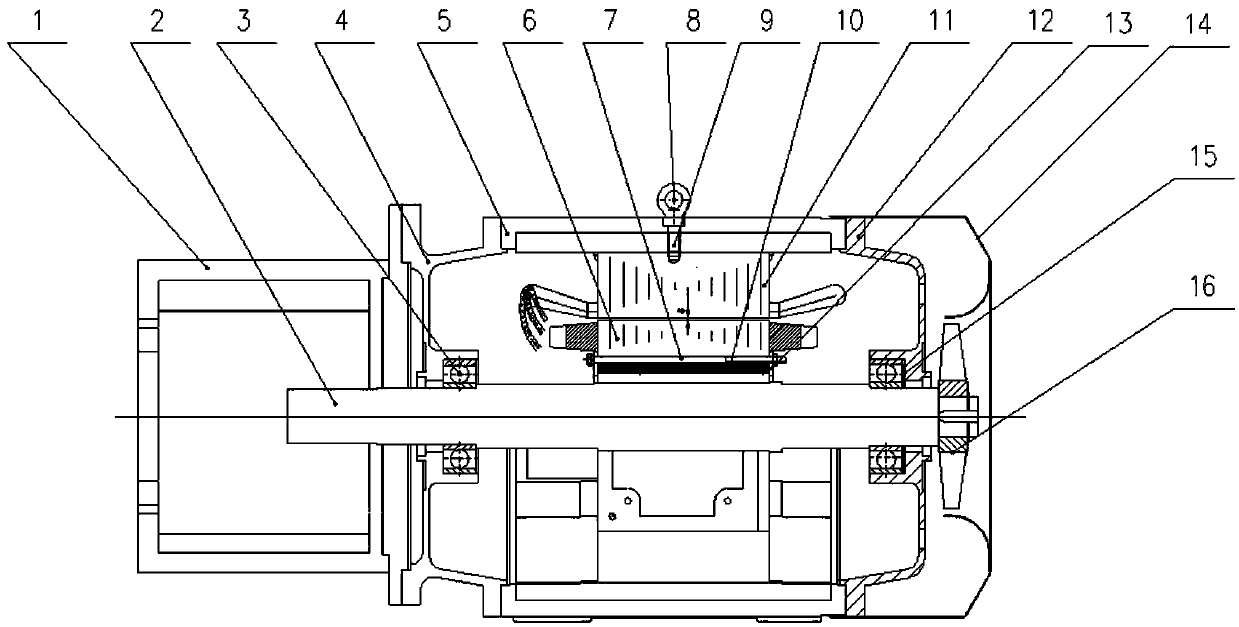

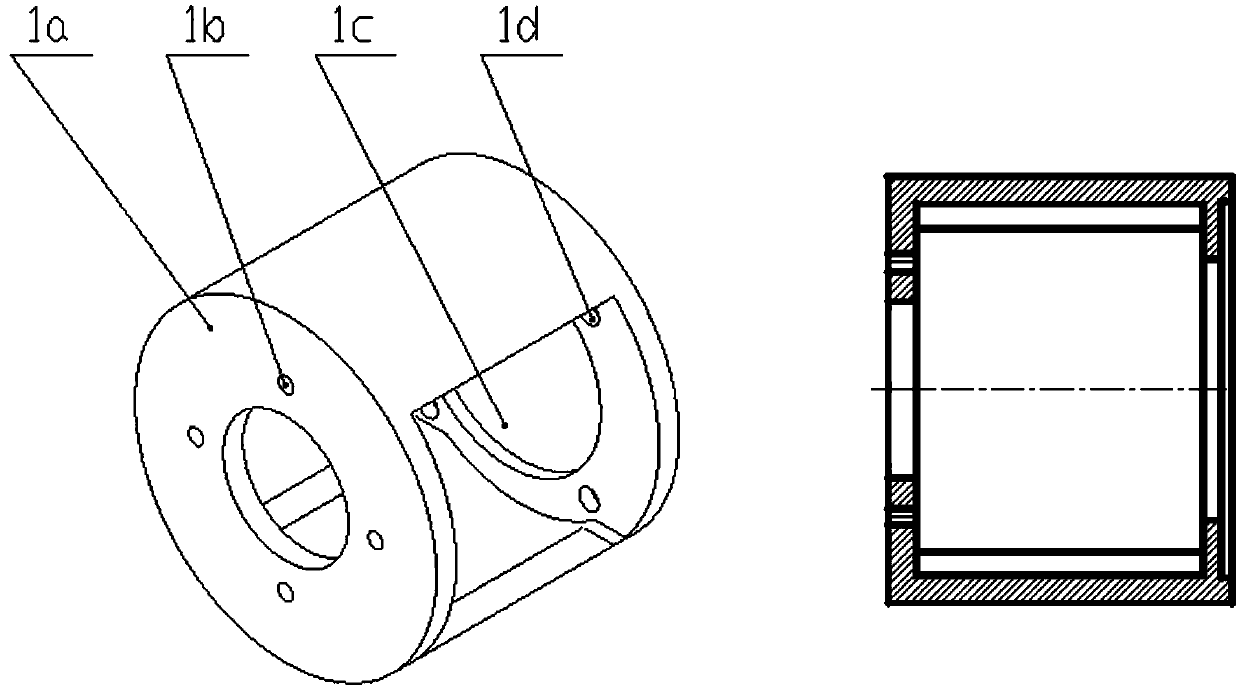

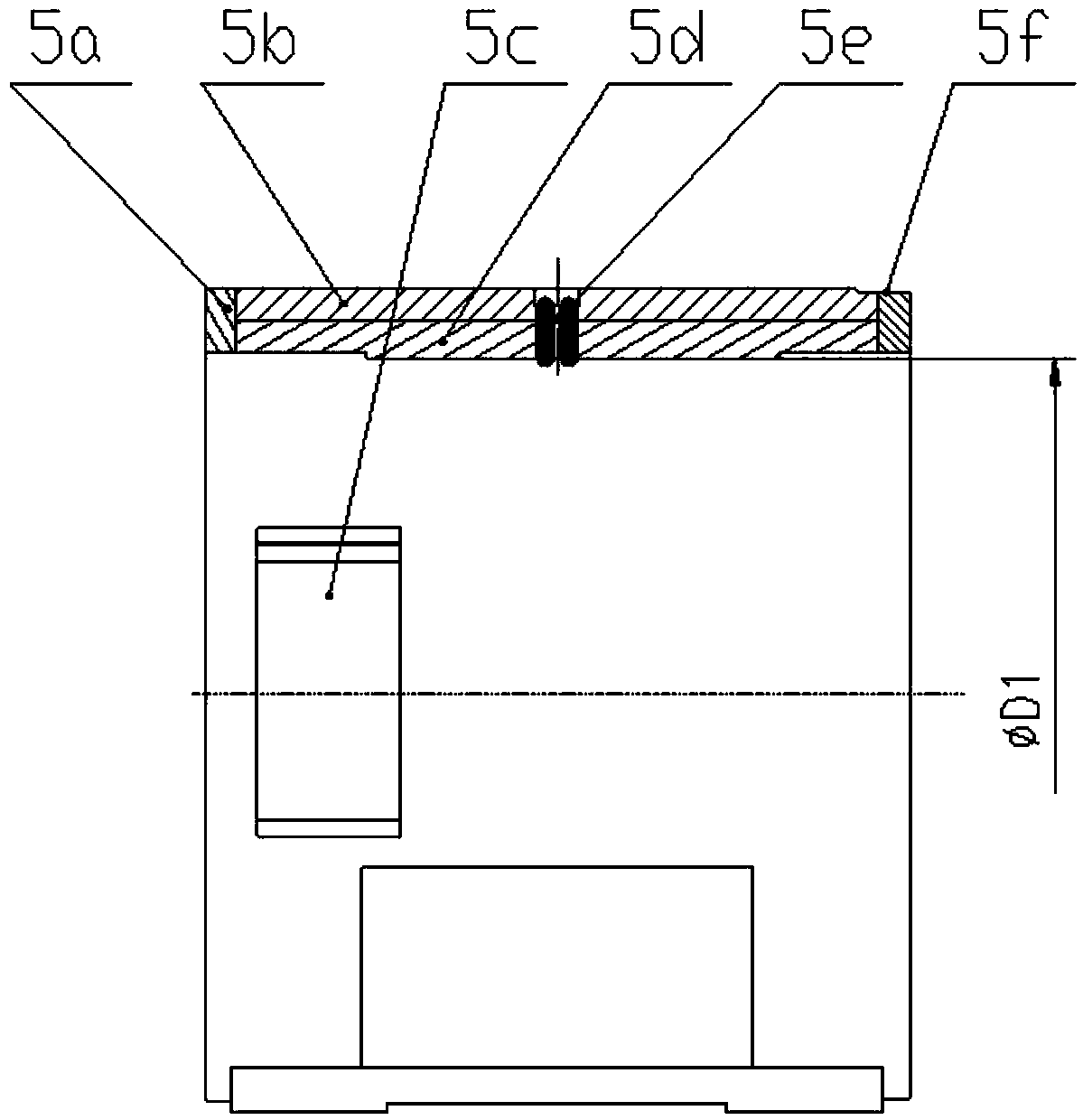

[0044] Such as figure 1 As shown, the three-phase permanent magnet synchronous motor of the present invention consists of a stator, a rotor, a front end cover 4, a rear end cover 12, a fan 16, a windshield 14, a bearing 3, a support ring 1, a wave spring 15 for a shaft, a suspension ring 8 and a tightening Screws 9 etc., wherein the stator consists of a machine base 5 and a winding stator core 11, and the winding stator core 11 includes the stator core and the coil winding embedded in its slot. The rotor consists of a rotating shaft 2 and a cast aluminum rotor 6 equipped with magnetic steel 10 . A magnetic steel pressure plate 13 is arranged on both ends of the magnetic steel 10, and is locked and pressed firmly by the screw rod 7; a front end cover 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com