Patents

Literature

44results about How to "Reduce higher harmonic content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

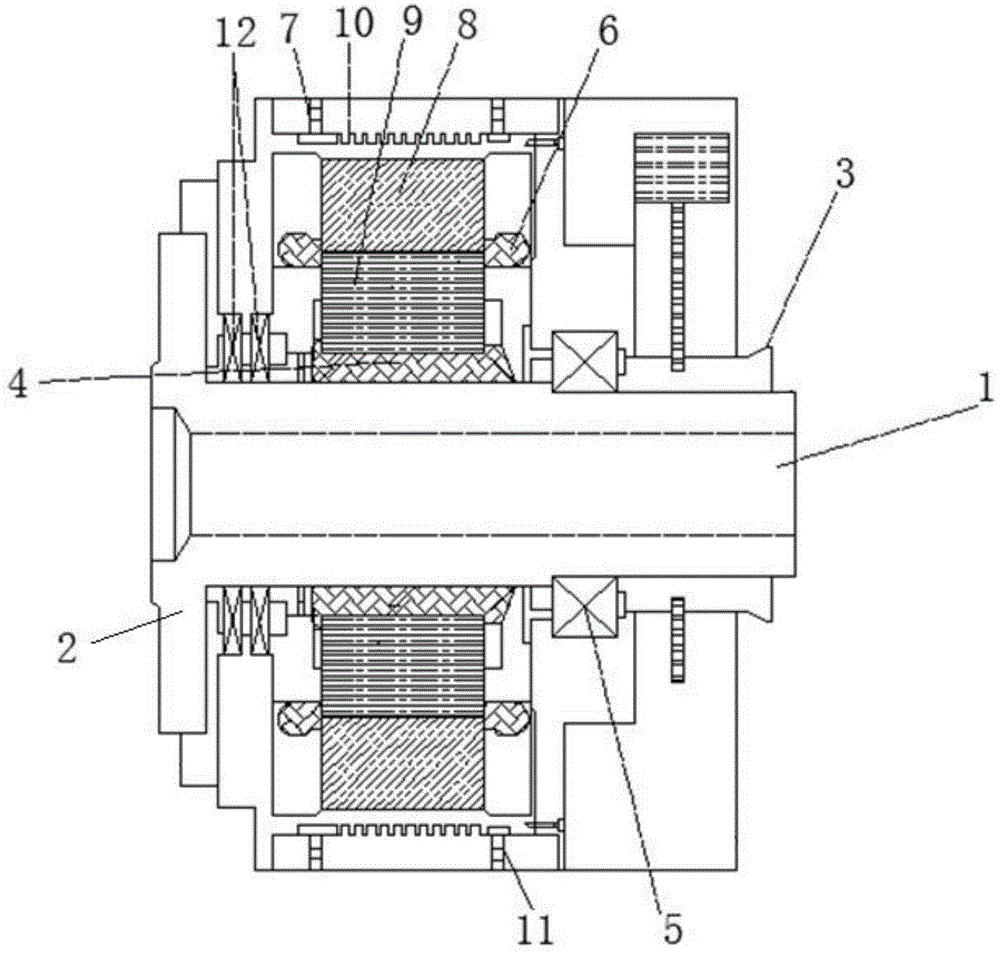

Rotary machine

InactiveCN1665101AEasy to manufactureSimple processWindings insulation shape/form/constructionWindings conductor shape/form/constructionElectrical conductorConductor Coil

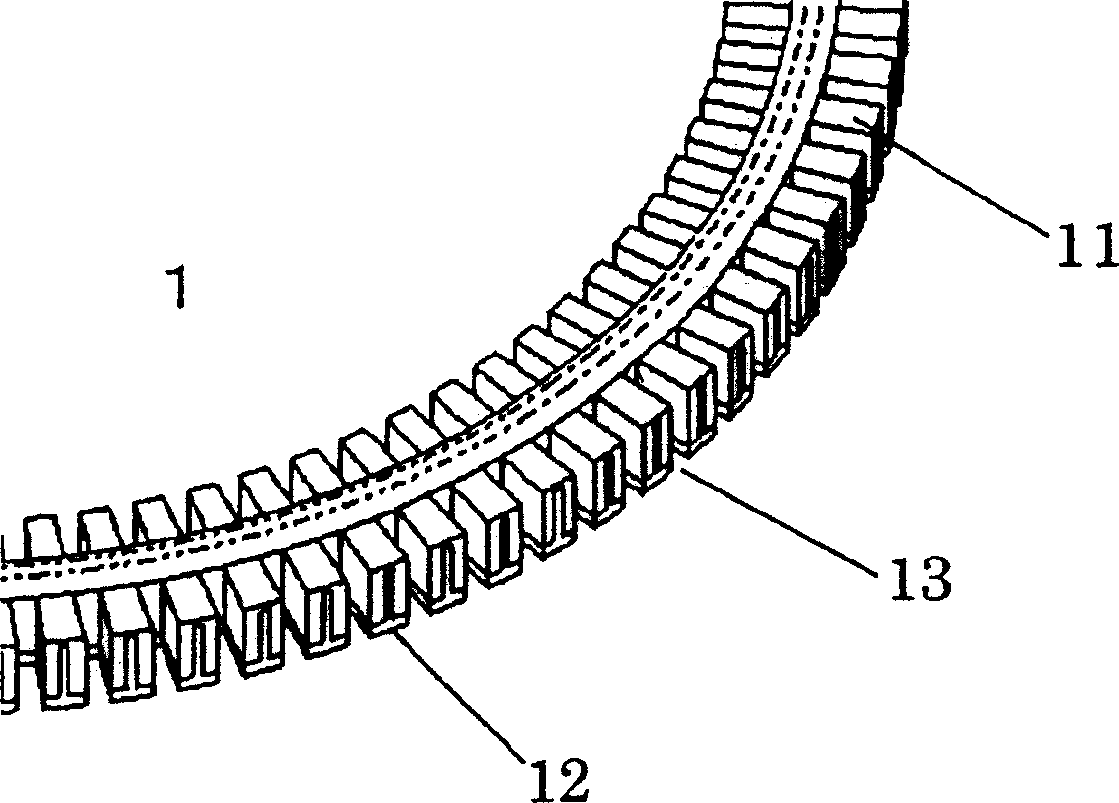

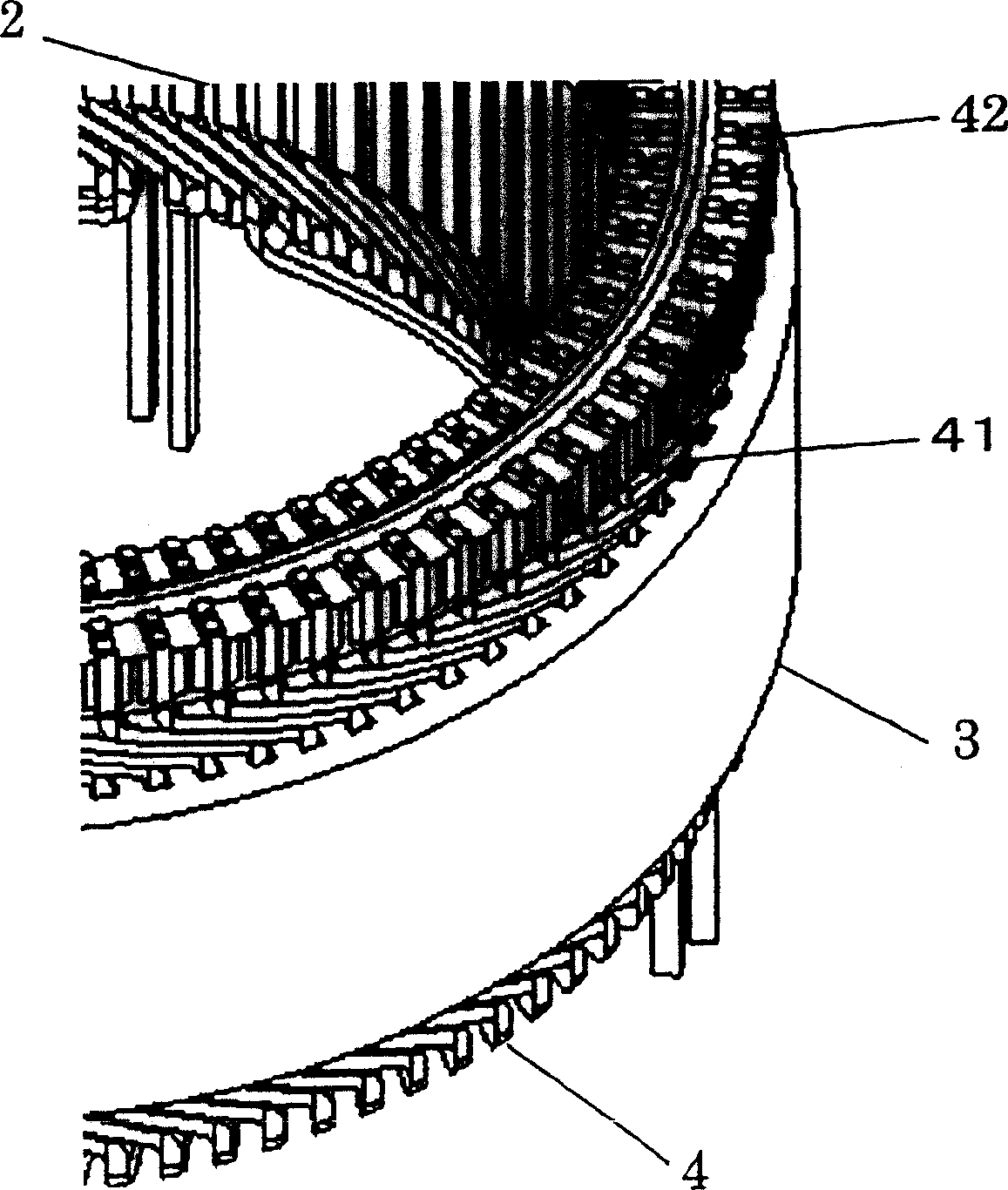

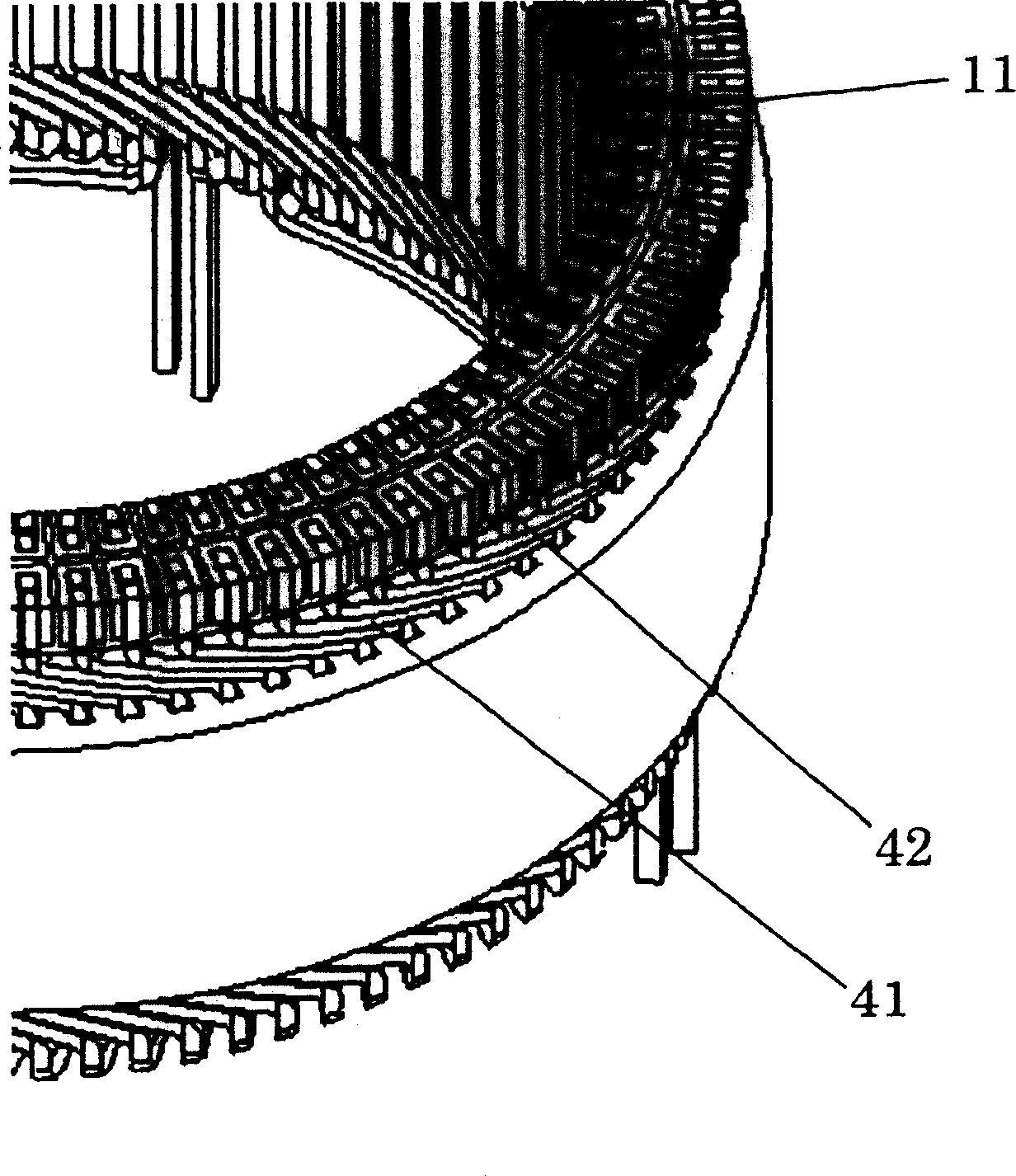

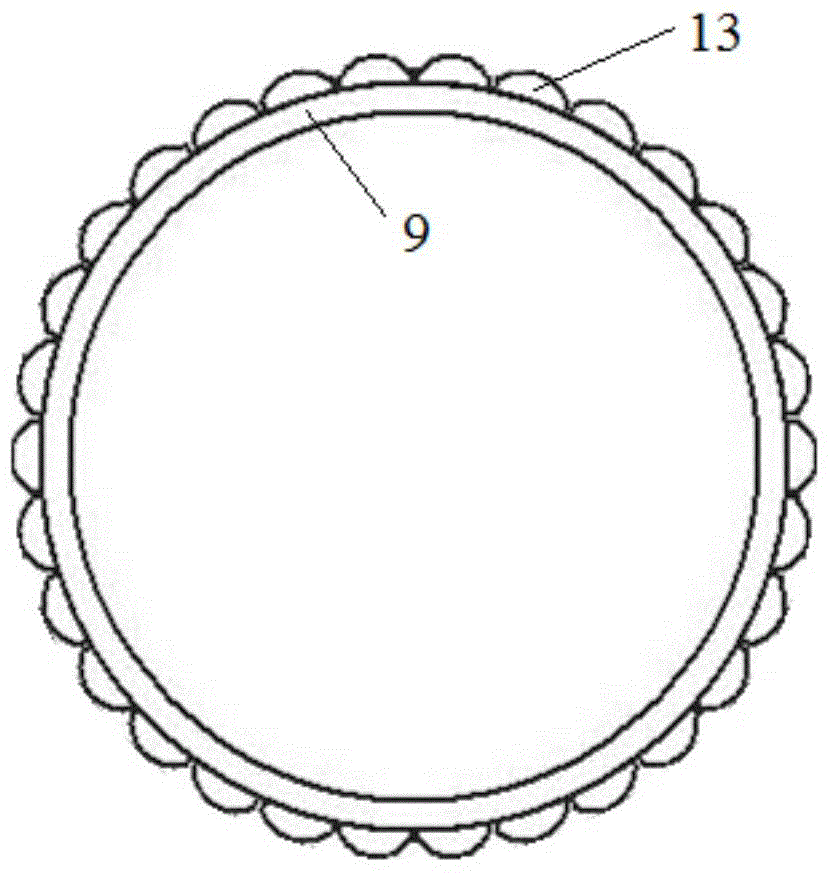

A rotary machine comprising a stator 2 composed of a stator iron core 3 having a plurality of slots formed in the direction of the rotation axis and stator windings inserted into the plurality of slots, wherein the stator windings are composed of a plurality of conductors 4 respectively inserted into the plurality of slots in the direction of the rotation axis and the stator 2 has a connection ring 1 having slots 13 into which the plurality of conductors 4 are inserted in the direction of the rotation axis.

Owner:HITACHI LTD

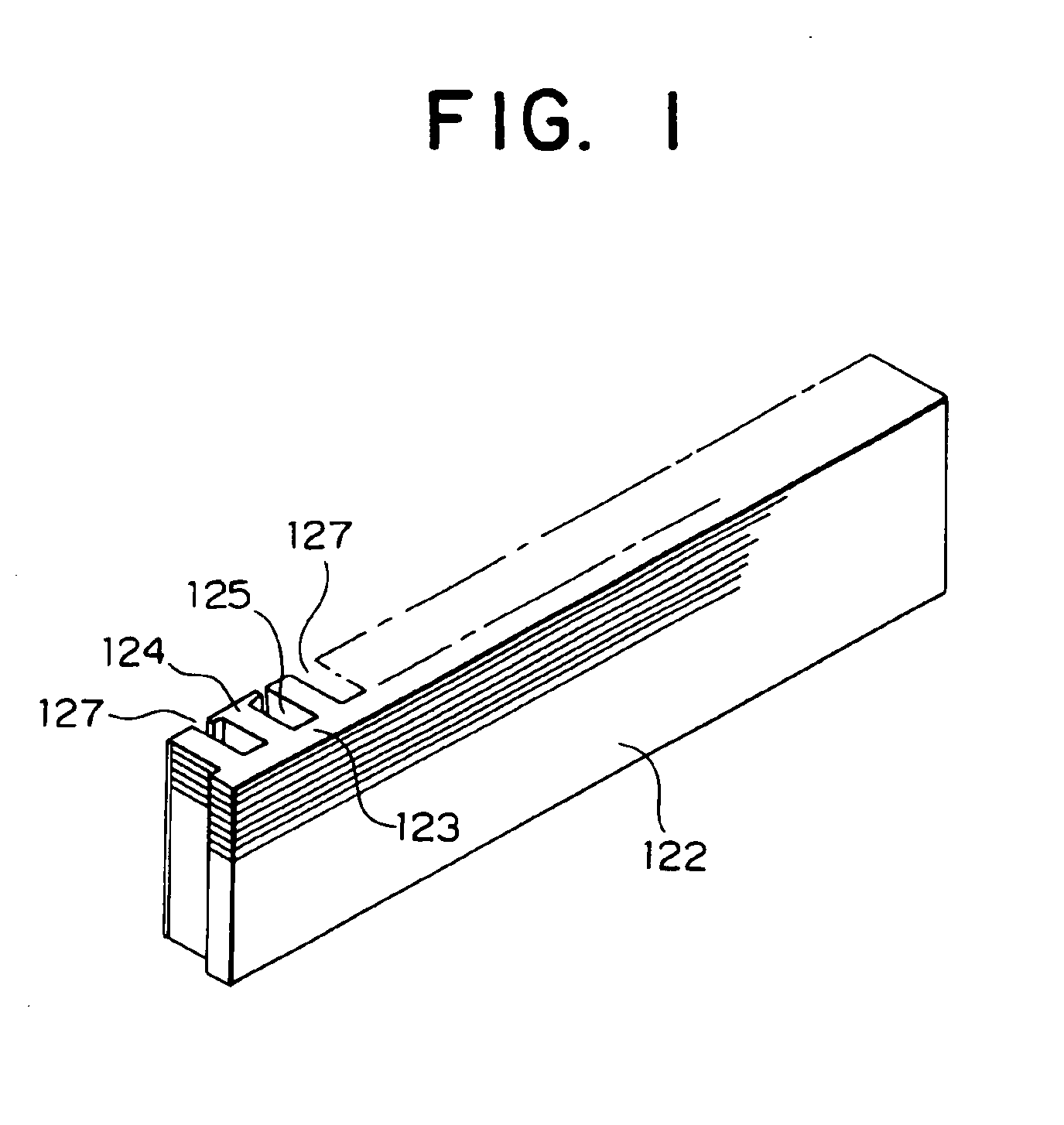

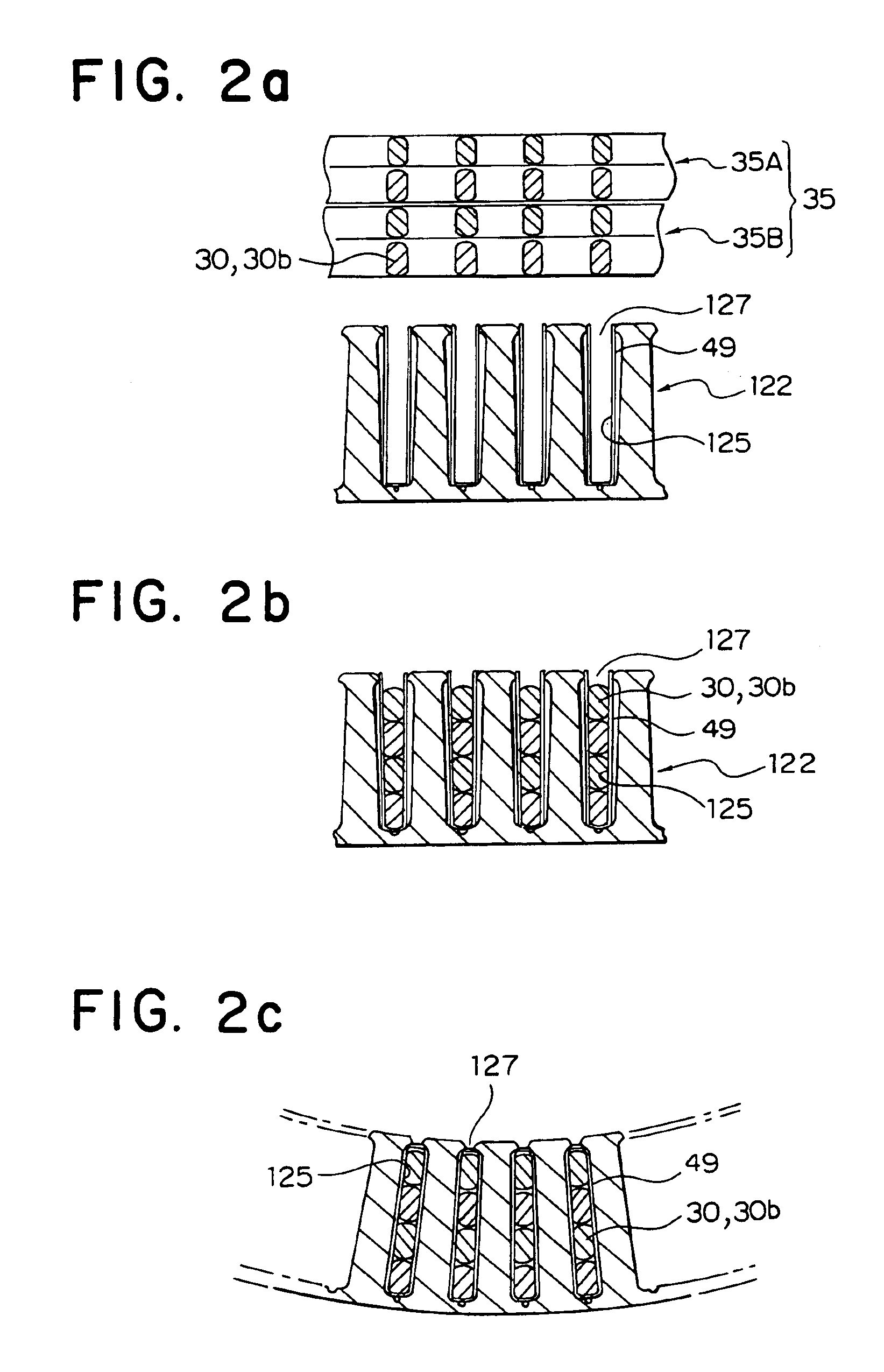

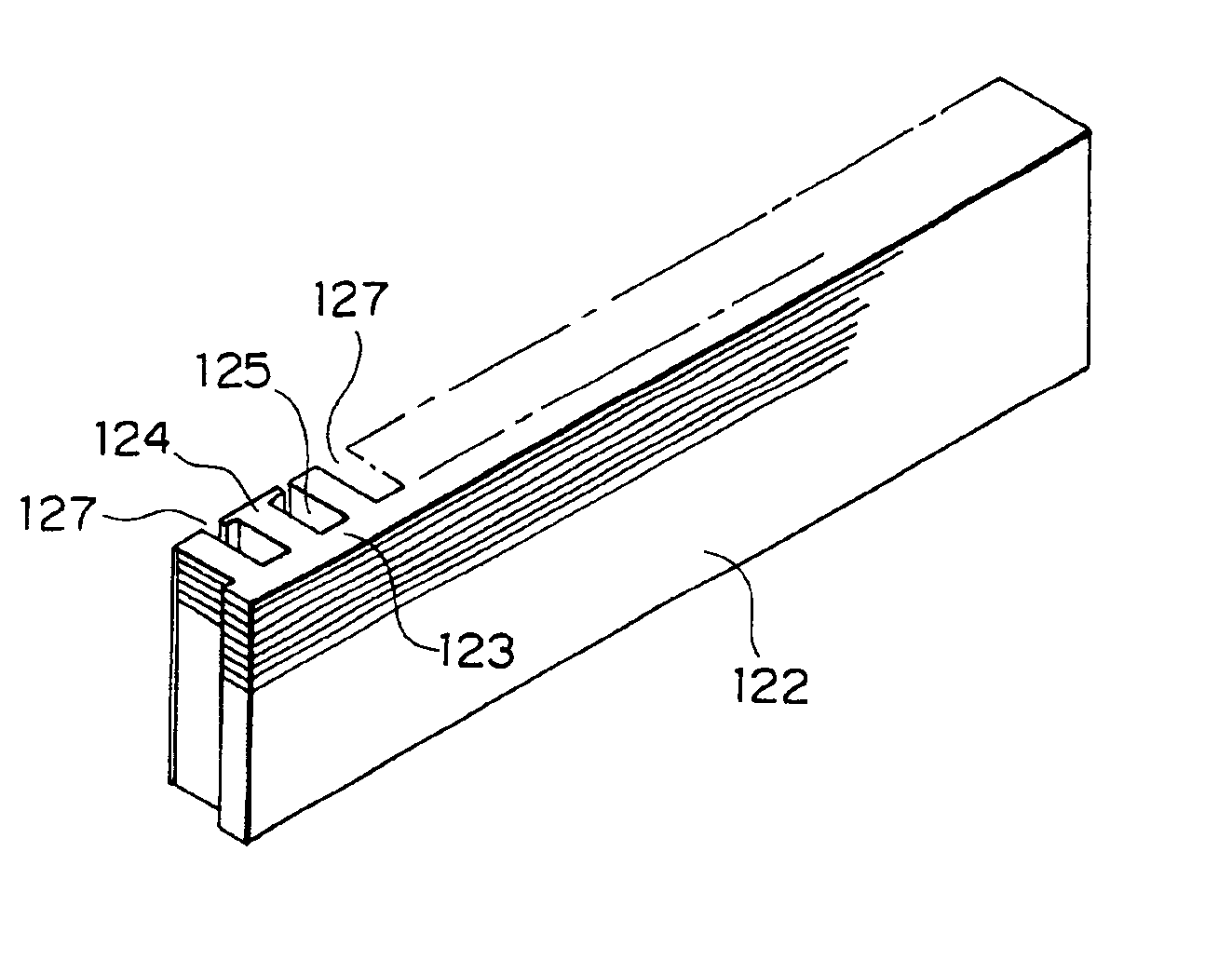

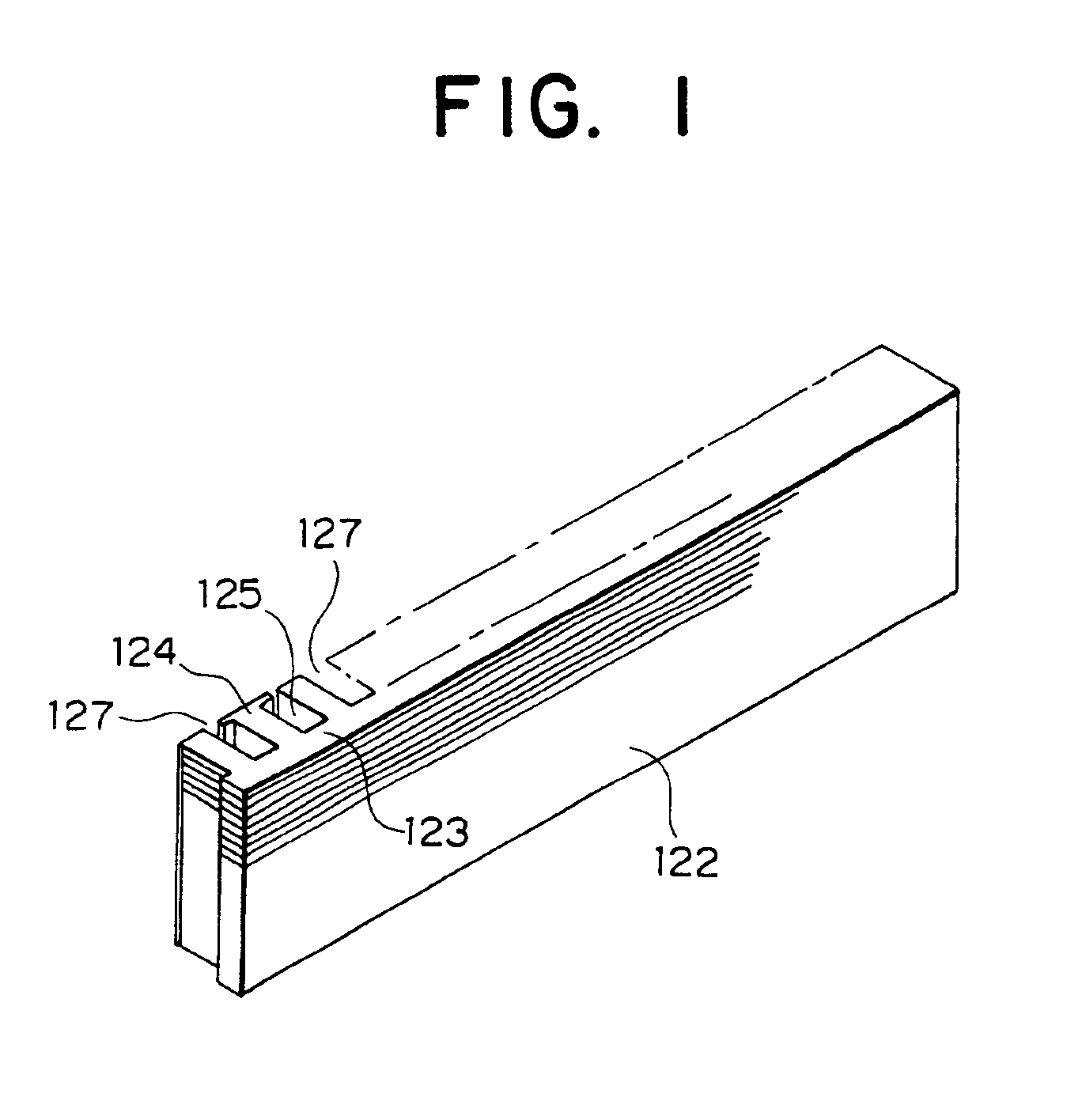

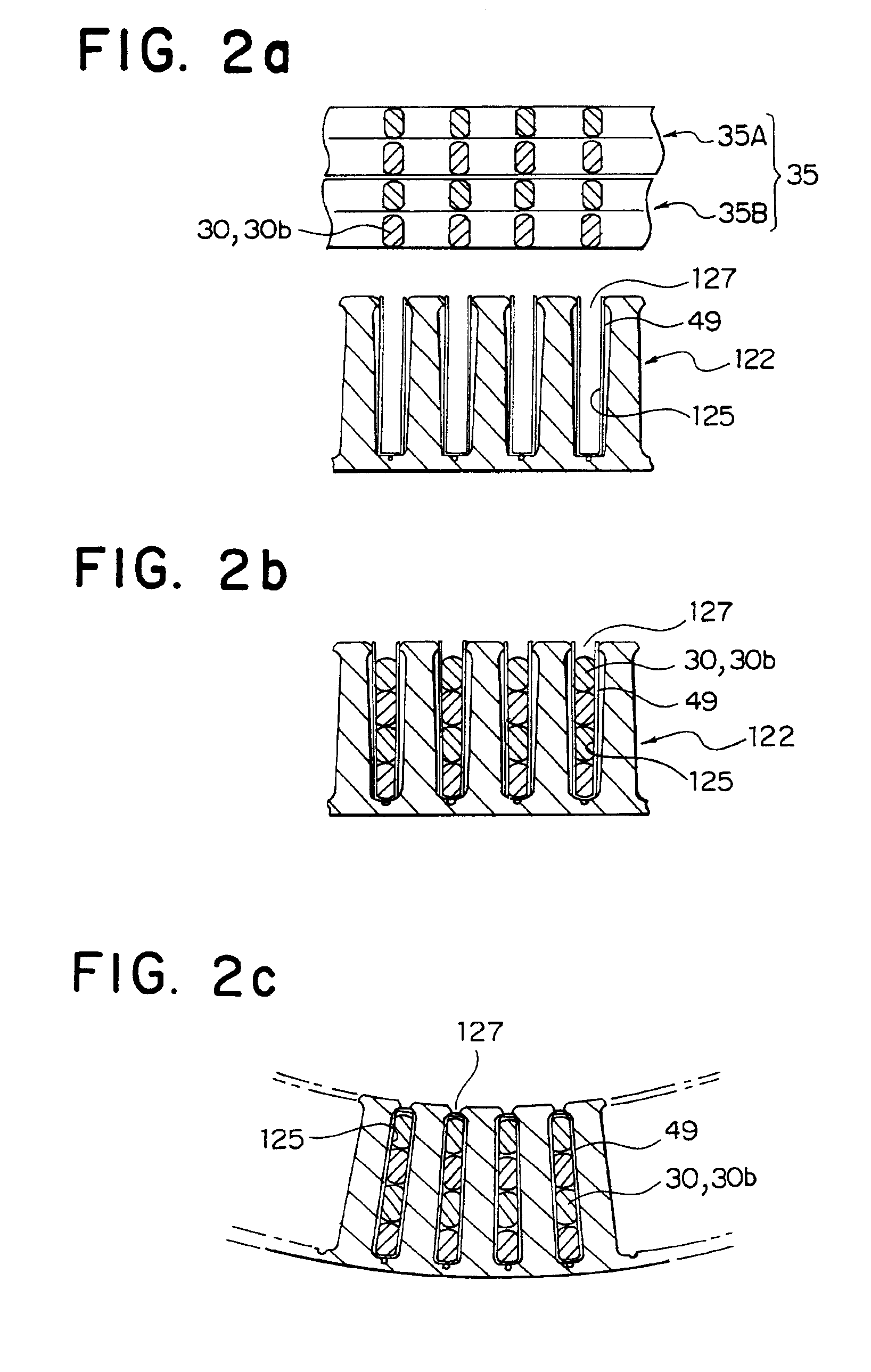

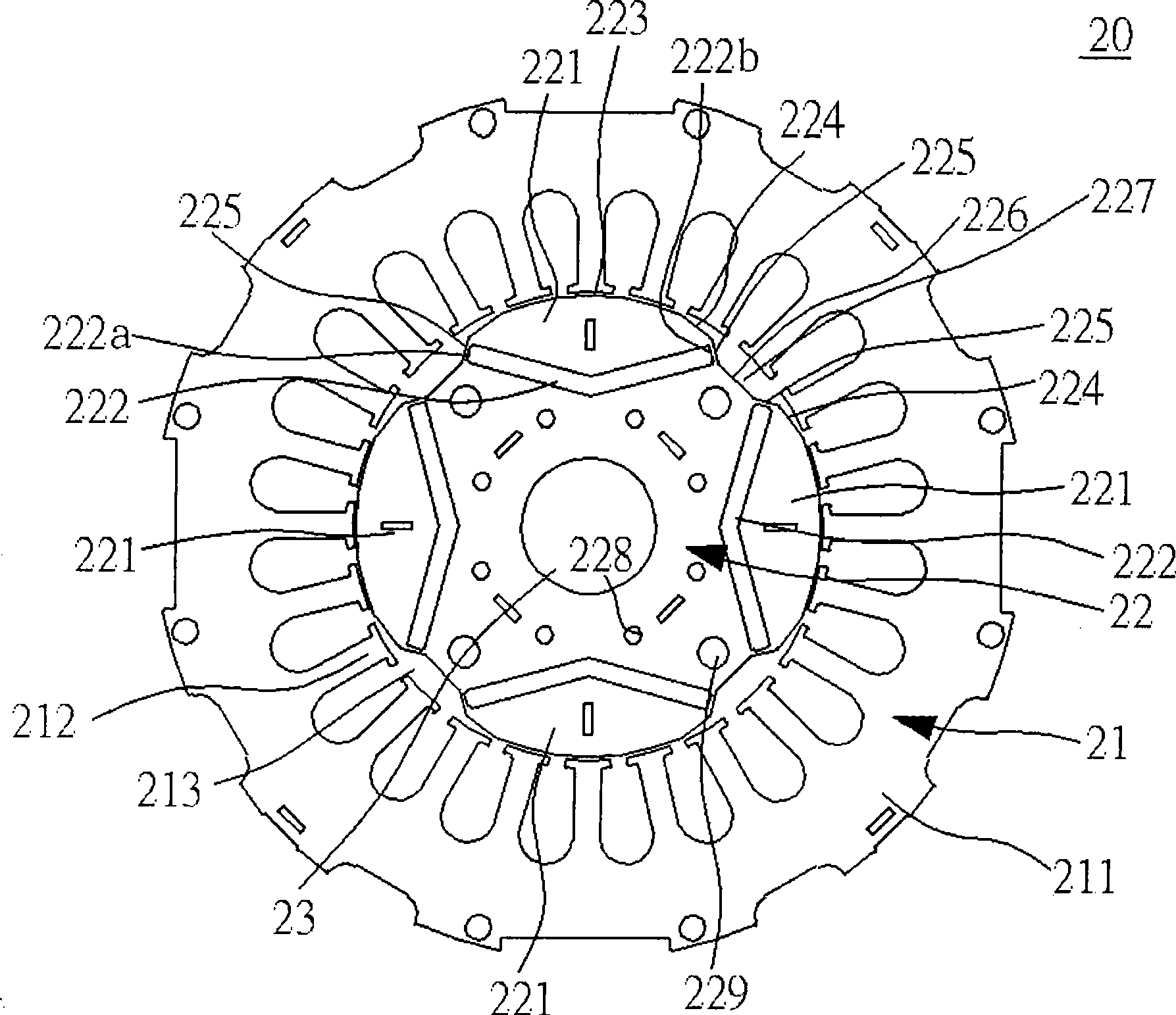

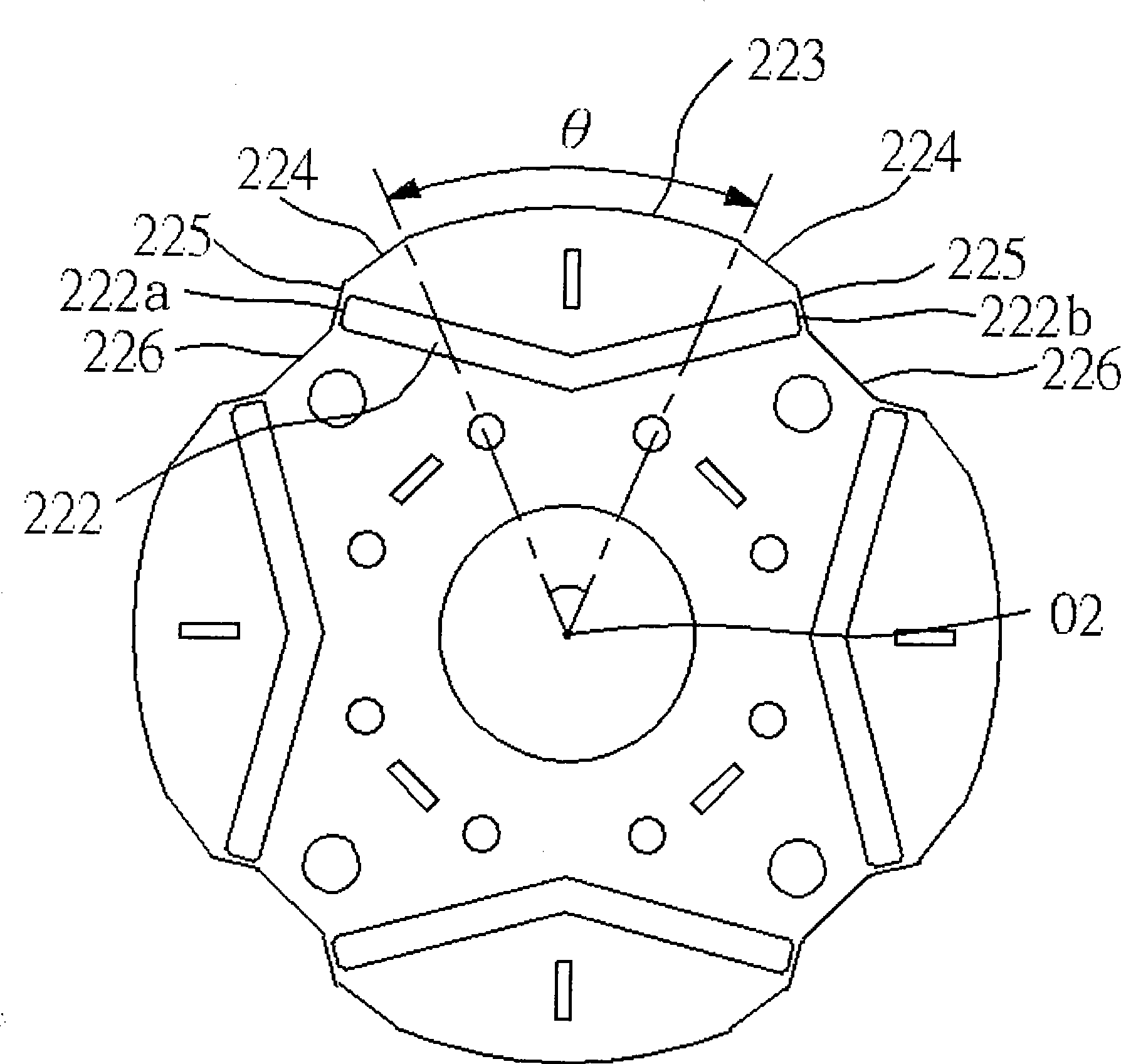

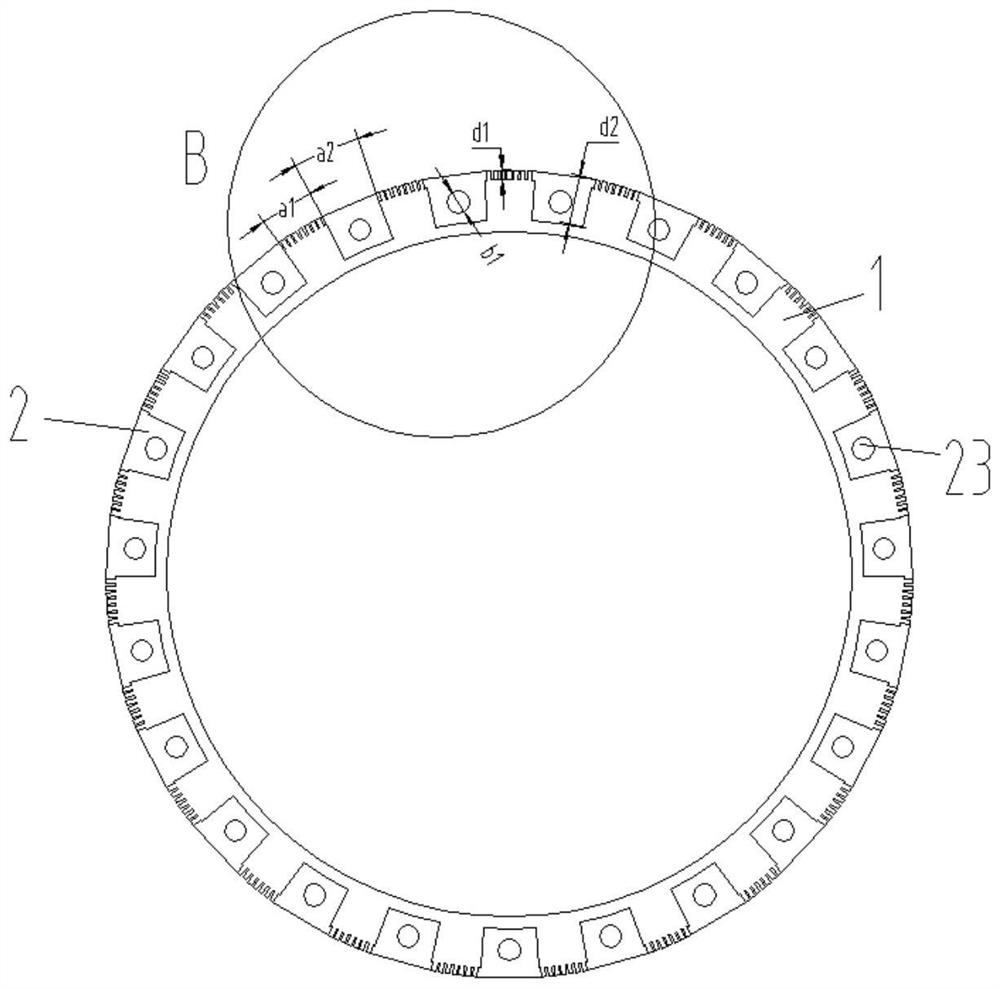

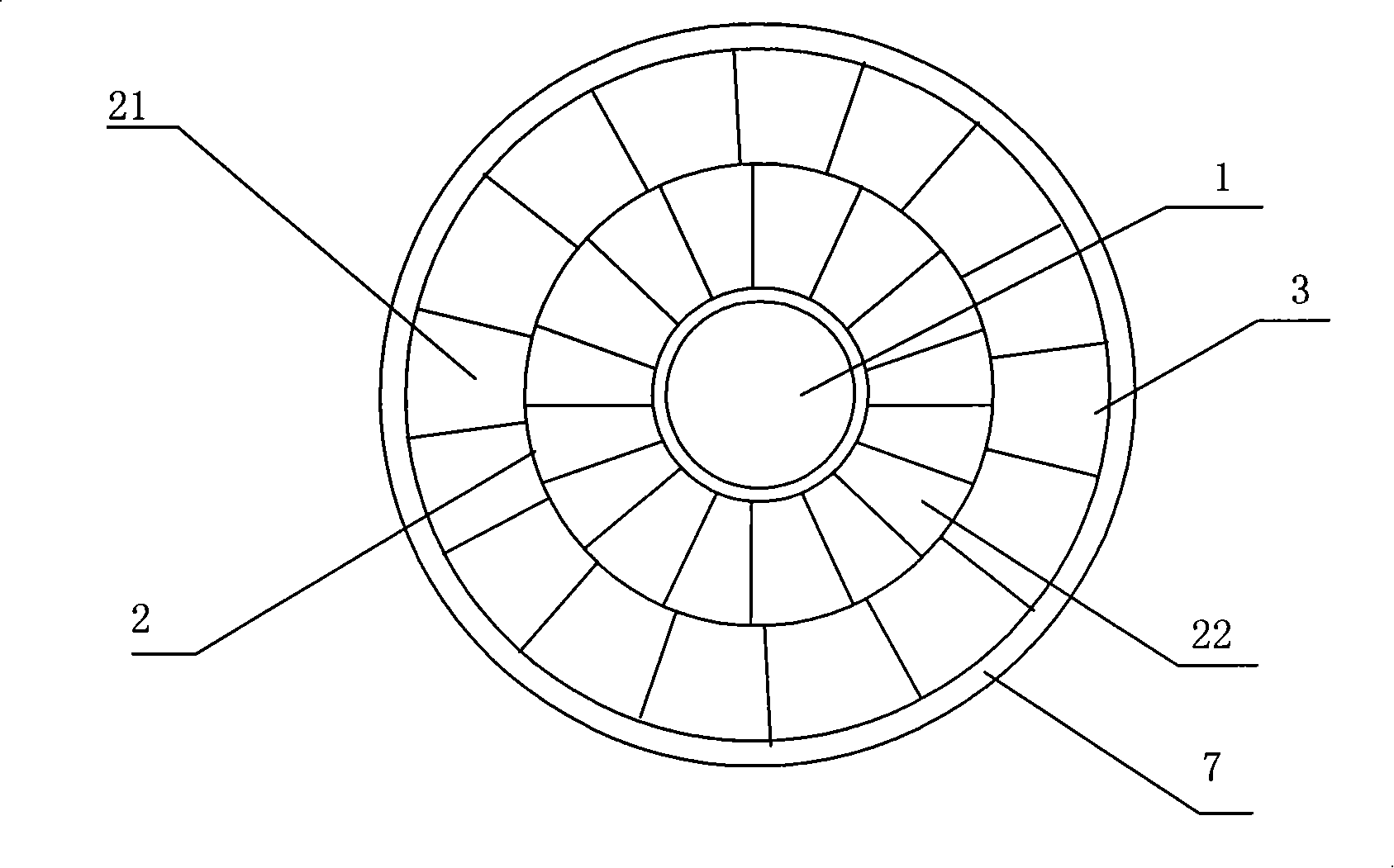

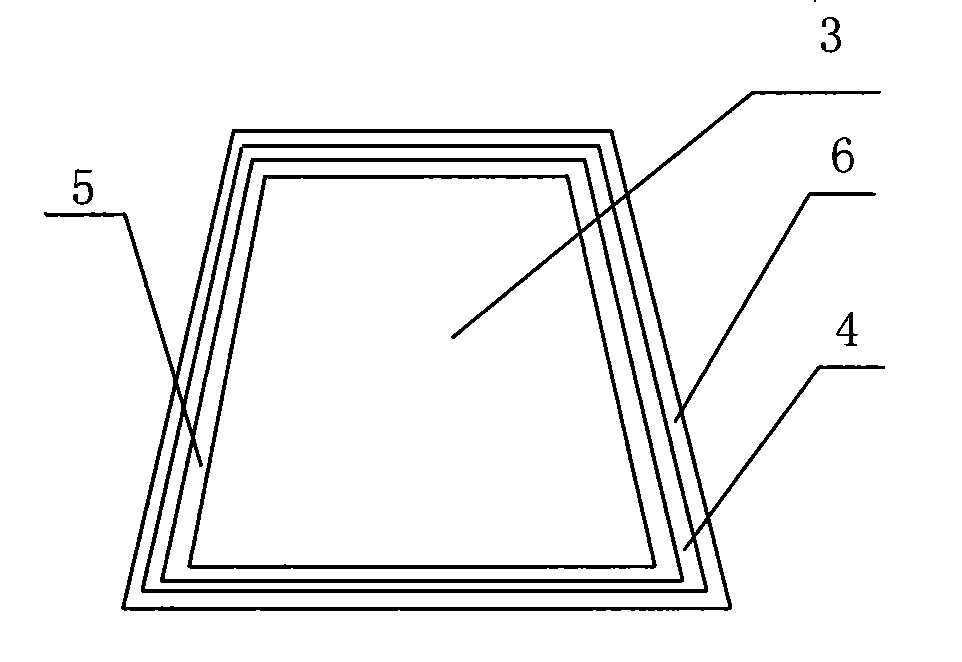

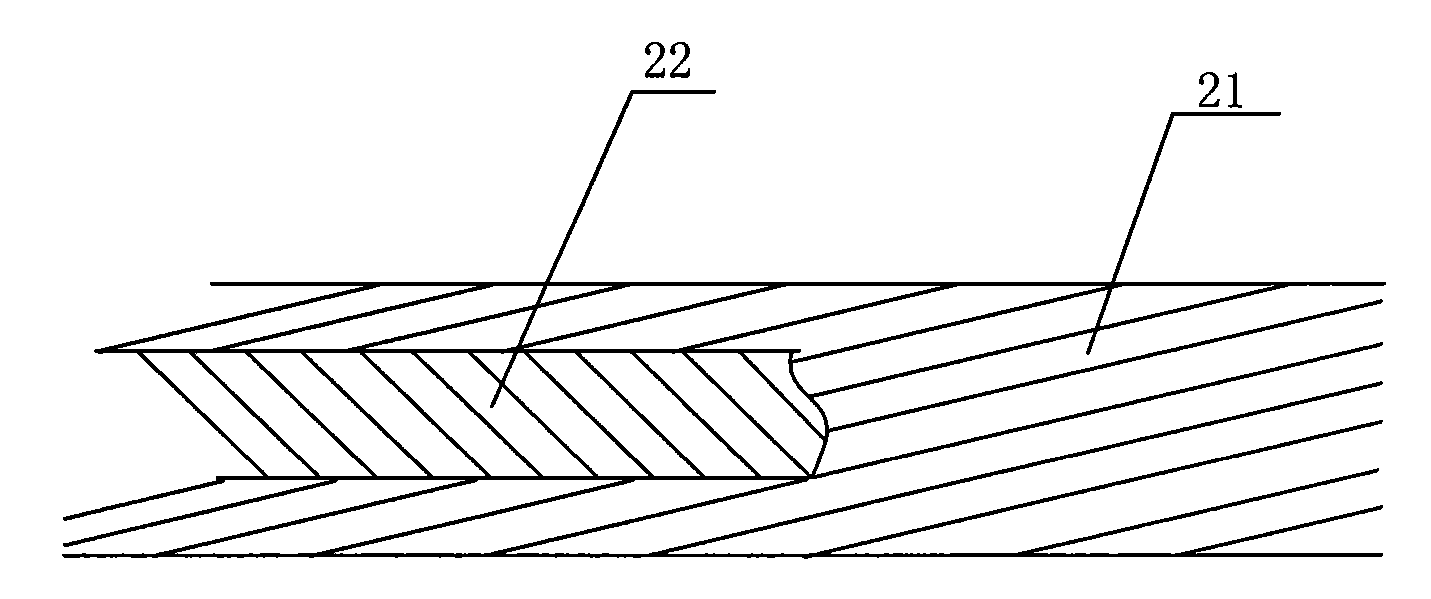

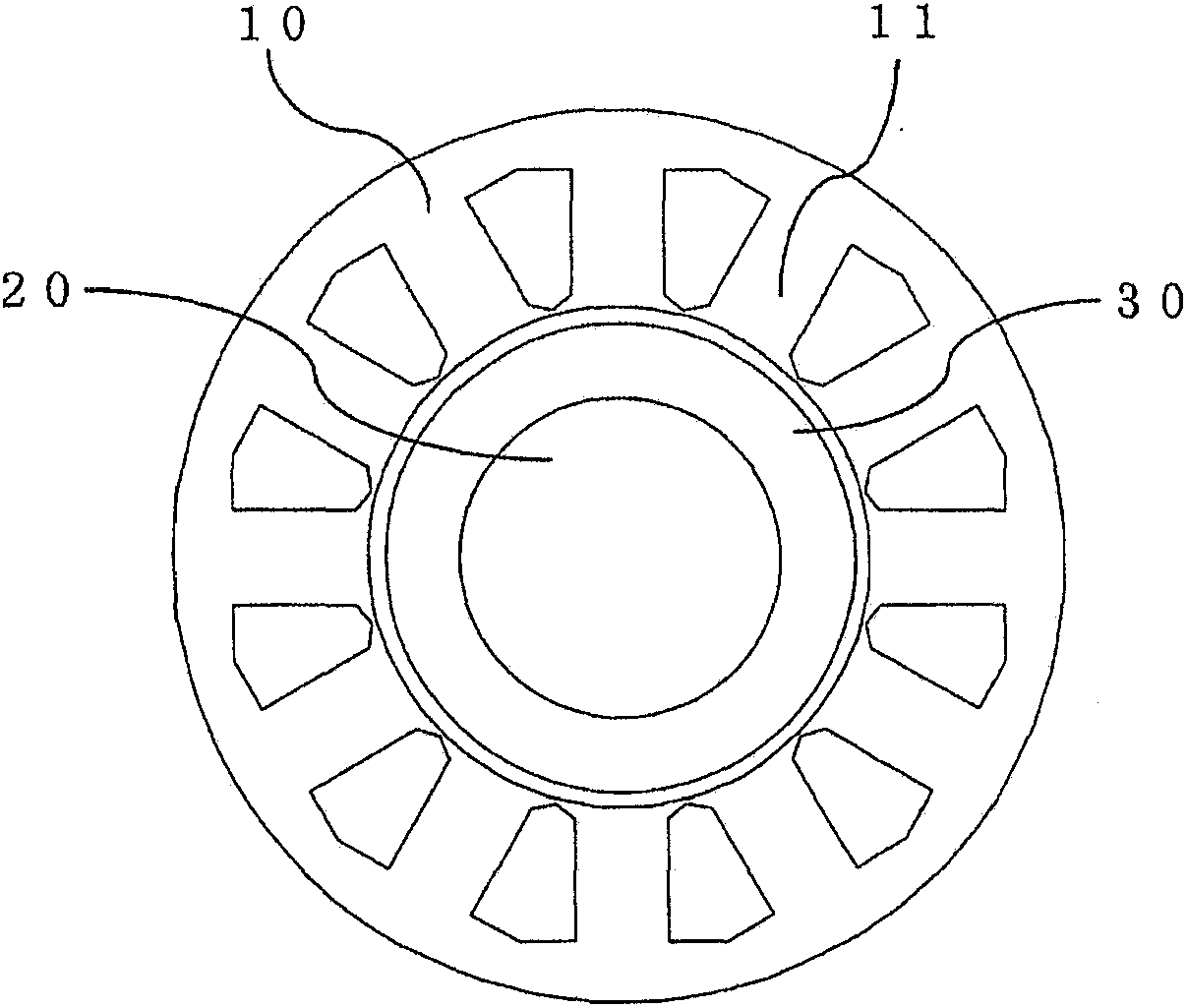

Stator for an automotive alternator

InactiveUS6885127B1Good stator coil installation characteristicRemarkable effectSynchronous generatorsWindings insulation shape/form/constructionAlternatorStator coil

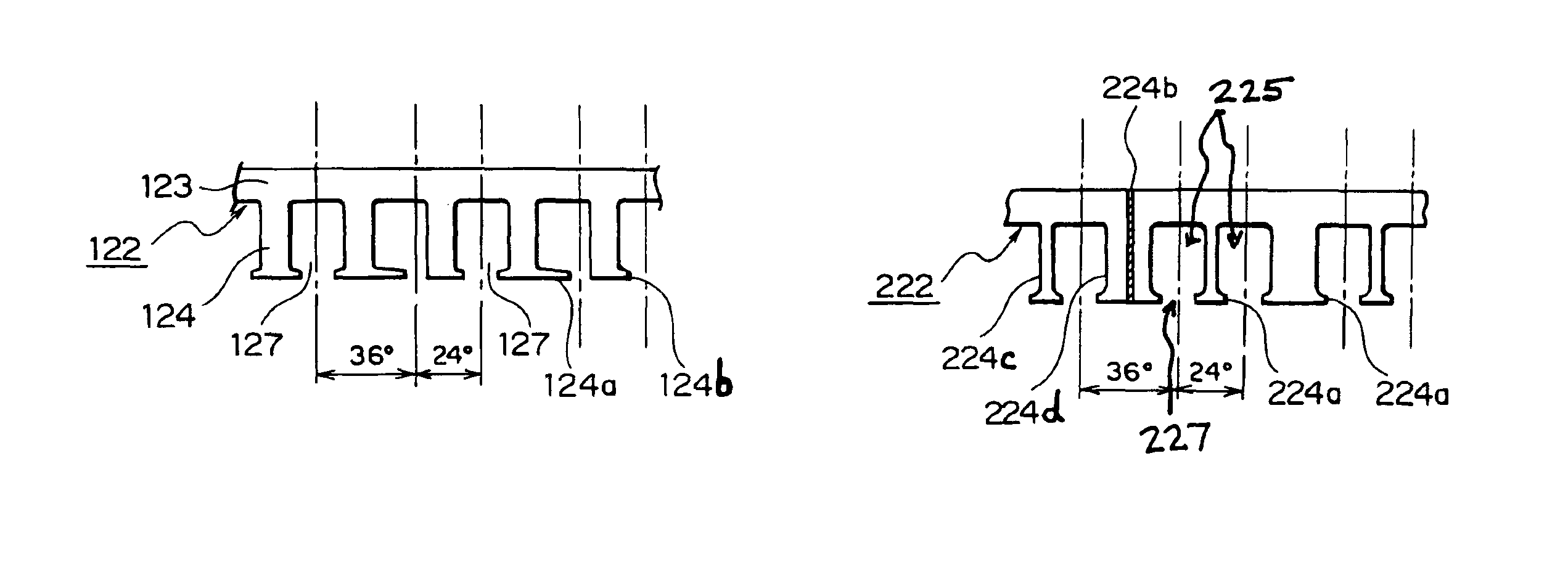

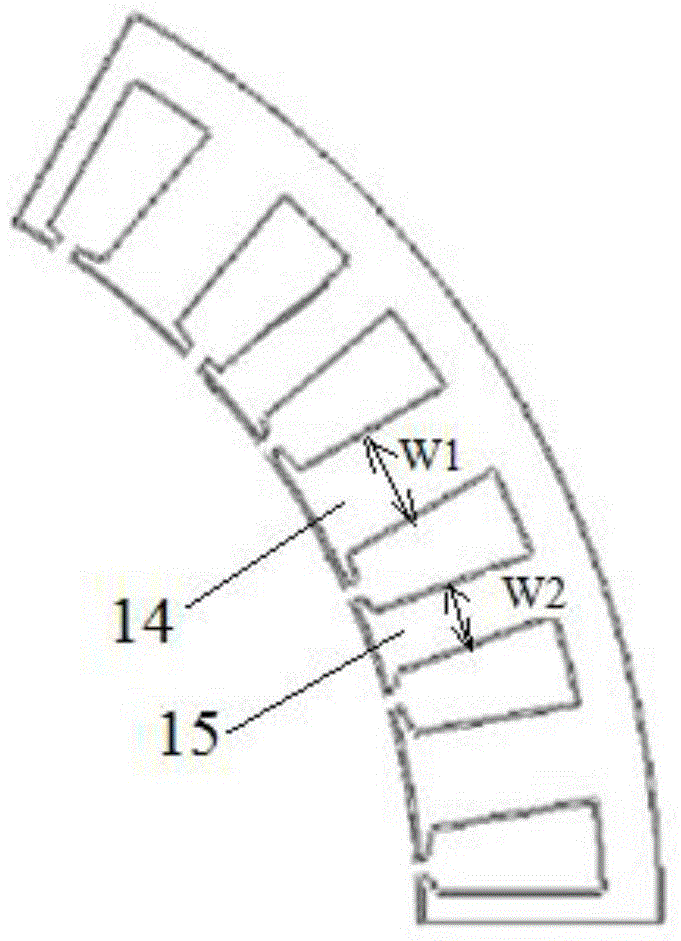

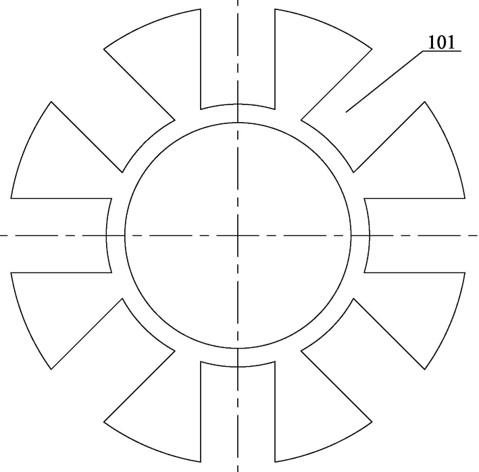

A stator for an automotive alternator is provided with good installation characteristics for stator coils and which can lower noise; the stator 8 including, a stator core 122 in which a plurality of slots 125 are formed at an inner circumference thereof and stator coils 23 which are fitted into the slots, and a rotor 6 provided inside the stator 8 so as to be capable of rotating, including, a rotor coil 15 for flowing a current to generate magnetic flux, and a pole core 16 for housing the rotor coil and forming a plurality of claw-shaped magnetic poles in accordance with magnetic flux, and, 2 slots 125 are provided for each set of stator coils, each phase and each magnetic pole and the total number of slots 125 is seventy-two (72) or more, the stator core 122 is such that a plurality of sheet-shaped magnetic members with a plurality of teeth 124 patterning the slots 125 at one side of a yoke 123 are laminated, the stator coils 23 are disposed in the slots 125, and the stator core 122 is rounded such that the stator coils 23 become the inner side thereof and both end surfaces thereof are contacted to connect the stator core 122 in an annular shape.

Owner:MITSUBISHI ELECTRIC CORP

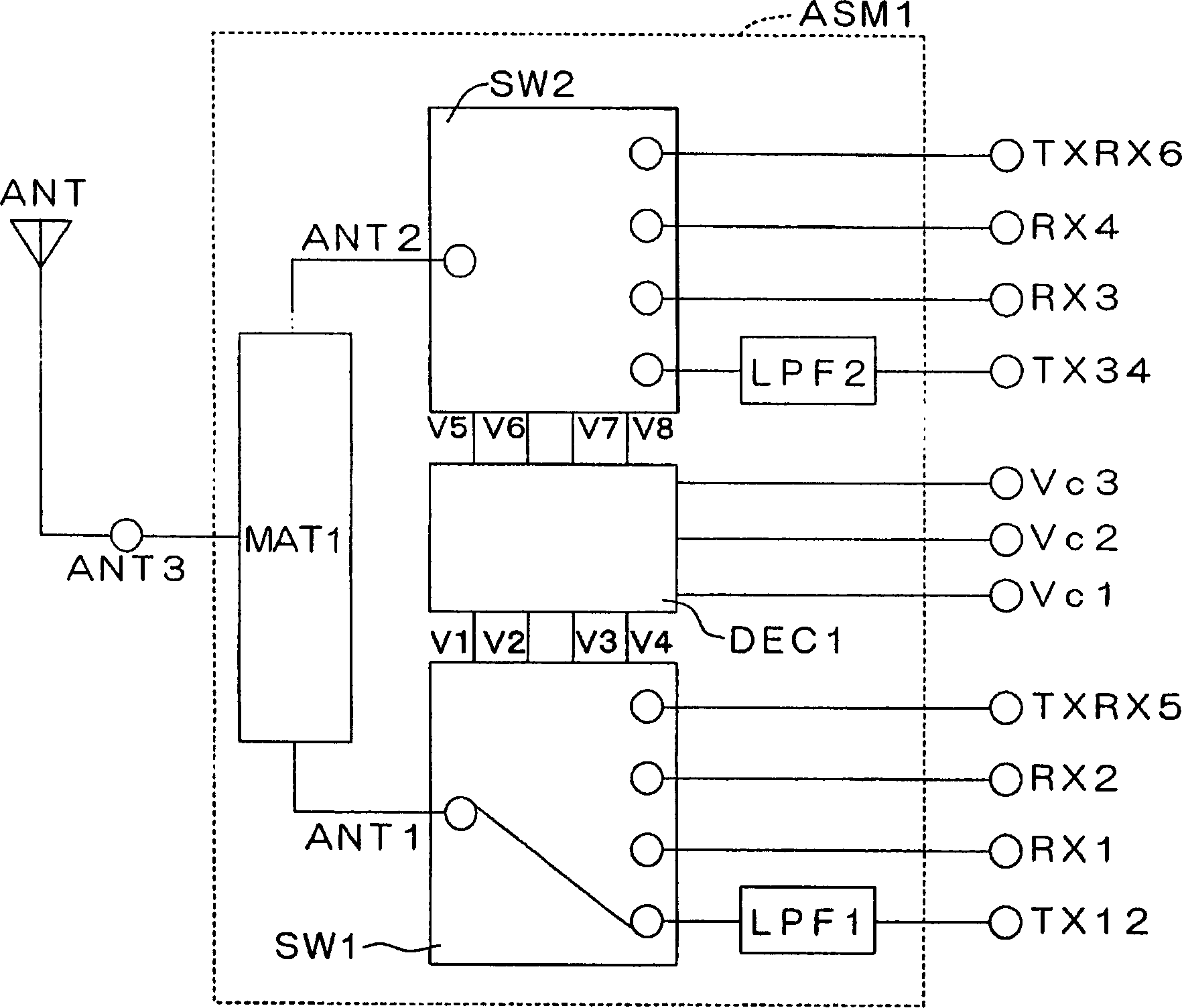

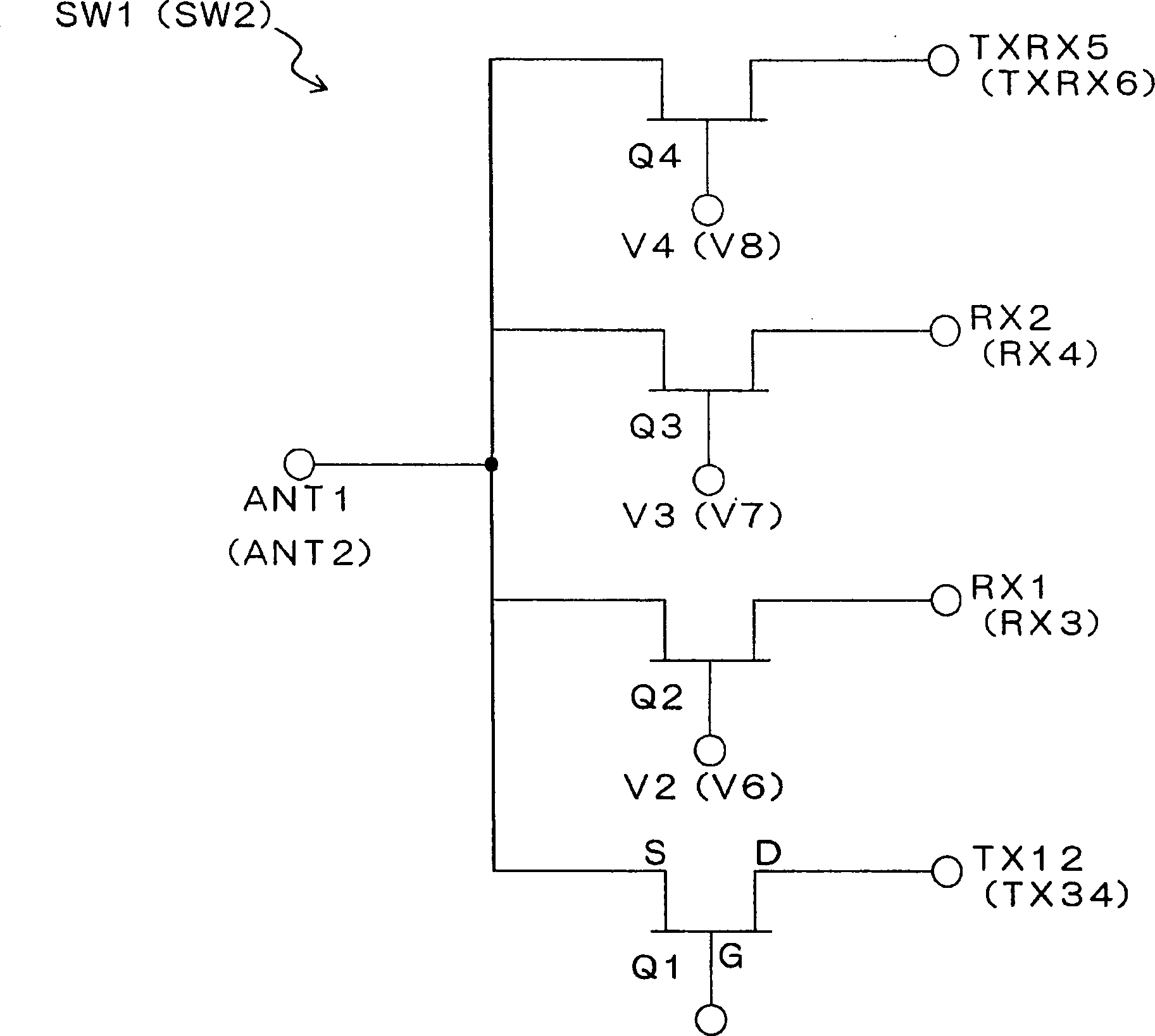

High-frequency switching circuit, high-frequency module, and wireless communications device

InactiveCN1661915AImprove functionalityReduce lossActive element networkRadio/inductive link selection arrangementsCommunications systemControl circuit

The present invention provides a high-frequency switching circuit comprising: two or more high-frequency switches SW1 and SW2 provided correspondingly to a plurality of communication systems having mutually different frequency bands; and a control circuit DEC1 adapted to control the switching of the two or more high-frequency switches SW1 and SW2, in which a common antenna terminal ANT3 and common terminals ANT1 and ANT2 of the respective high-frequency switches SW1 and SW2 are connected via a matching circuit MAT1 having a filtering function capable of allowing passage of direct current. When one path of the high-frequency switch SW1 is turned on, the other paths of the high-frequency switch SW1 and all paths of the high-frequency switch SW2 can be turned off.

Owner:KYOCERA CORP

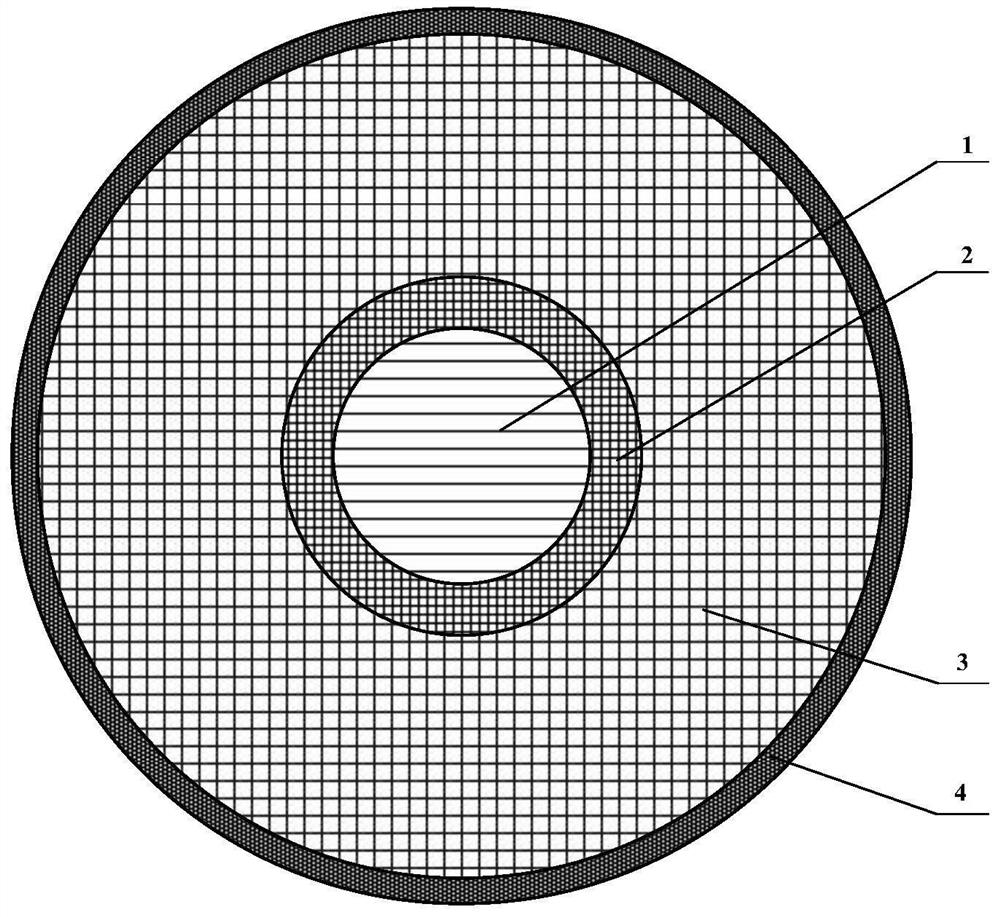

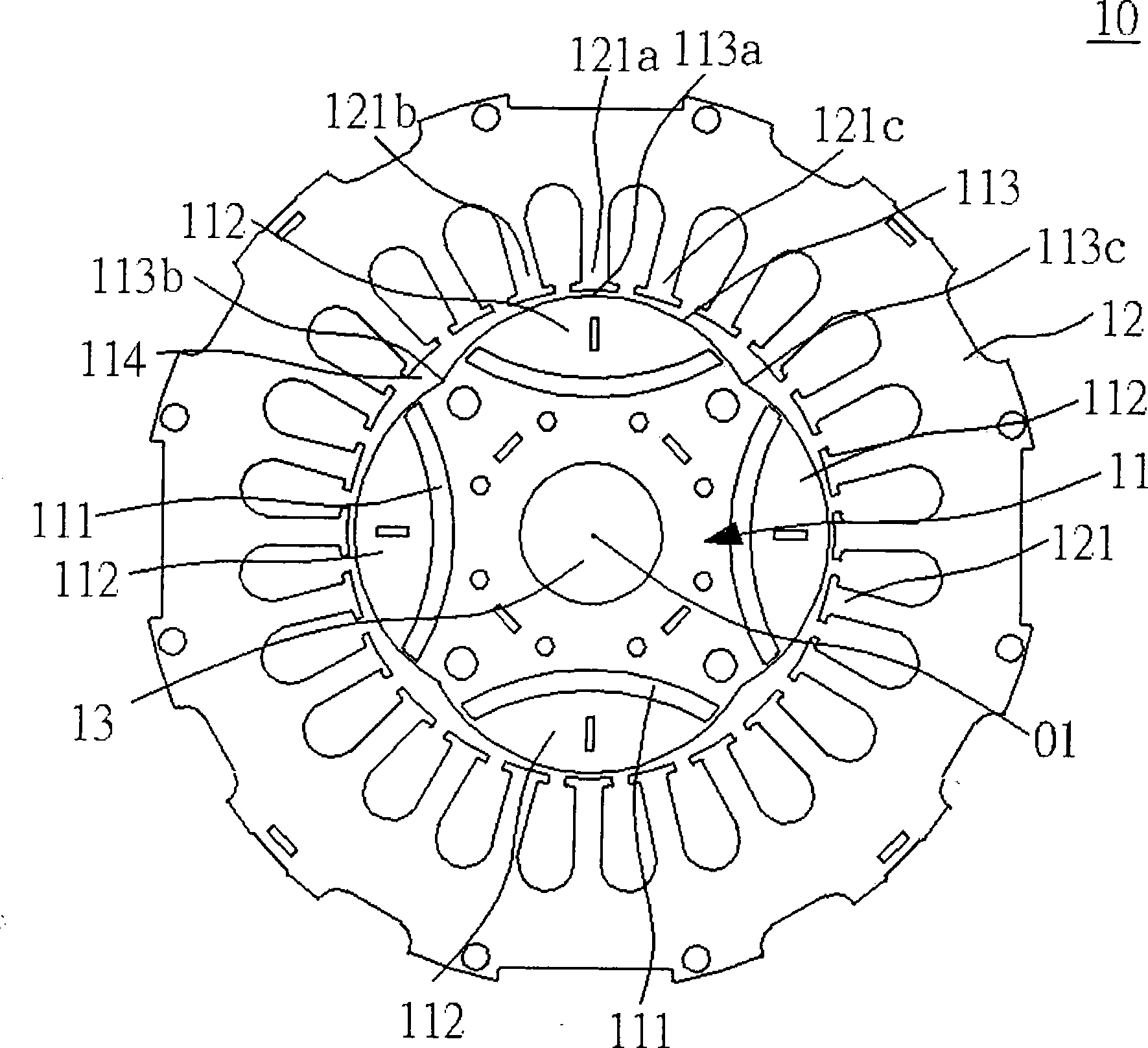

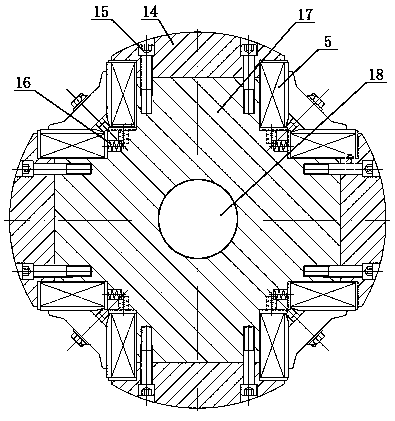

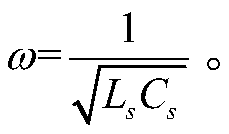

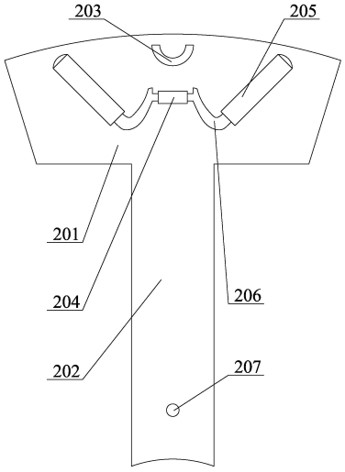

Hybrid excitation type high-speed permanent magnet motor rotor and manufacturing method

PendingCN112039240AReduce higher harmonic contentImprove power densityMagnetic circuit rotating partsManufacturing stator/rotor bodiesEpoxyFiber

The invention discloses a hybrid excitation type high-speed permanent magnet motor rotor and a manufacturing method. The hybrid excitation type high-speed permanent magnet motor rotor comprises a rotating shaft, a sintered permanent magnet unit, a magnetic powder adhesive film and carbon fiber composite unit and a rotor sheath which are sequentially arranged from inside to outside in the radial direction, wherein the sintered permanent magnet unit is composed of sintered permanent magnet blocks, epoxy resin filler and a carbon fiber layer, the sintered permanent magnet blocks are equal in axial length and unequal in radial thickness, and each magnetic pole of the high-speed permanent magnet motor rotor is formed by the sintered permanent magnet blocks in the circumferential direction according to the arrangement mode that the middle is high and the two ends are low; and the magnetic powder adhesive film and carbon fiber composite unit consists of a plurality of magnetic powder adhesivefilm and carbon fiber composite subunits composed of magnetic powder adhesive film layers and carbon fiber layers, the number of the magnetic powder adhesive film layers and the number of the carbonfiber layers are different, and the sum of the number of the magnetic powder adhesive film layers and the number of the carbon fiber layers is not changed. According to the hybrid excitation type high-speed permanent magnet motor rotor and the manufacturing method, the mechanical strength of the motor rotor can be improved, the eddy current loss of the motor rotor is reduced, and the allowable linear speed of the motor rotor is improved, thereby solving the problems of large eddy current loss, high temperature rise and low allowable linear speed of the traditional high-speed permanent magnet motor rotor.

Owner:SHENYANG POLYTECHNIC UNIV

Stator for an automotive alternator

InactiveUS6886236B2Good stator coil installation characteristicRemarkable effectWindings insulation shape/form/constructionManufacturing stator/rotor bodiesAlternatorStator coil

A stator for an automotive alternator is provided with good installation characteristics for stator coils and which can lower noise. The stator includes a stator core in which a plurality of slots are formed at an inner circumference thereof and stator coils which are fitted into the slots. A rotor is provided inside the stator and includes a rotor coil, and a pole core for housing the rotor coil. Two slots are provided for each set of stator coils, each phase and each magnetic pole and the total number of slots is seventy-two or more. The stator core formed by laminating a plurality of sheet-shaped magnetic members. The stator coils are disposed in the slots, and the stator core is rounded such that the stator coils become the inner side thereof and both end surfaces thereof are contacted to connect the stator core in an annular shape.

Owner:MITSUBISHI ELECTRIC CORP

Permanent-magnetic electric motor

InactiveCN101425708AImprove efficiencyReduce magnetic flux changeMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesPermanent magnet motor

The invention relates to a permanent magnet motor. The permanent magnet motor comprises a stator, a rotor and a rotating axle, wherein the rotor forms a plurality of rotor magnetic poles, each rotor magnetic pole is provided with an arc-shaped surface and first and second inclined sections extending from both sides of the arc-shaped surface, the second inclined sections of the adjacent rotor magnetic poles are connected via a tangent section to form a sunken space, a plurality of magnets are arranged in all the rotor magnetic poles, both end parts of each magnet are arranged adjacent to two second inclined sections, and the center part of each magnet is sunken toward the center of the rotor, so as to fully improve the efficiency of the motor.

Owner:RECHI PRECISION

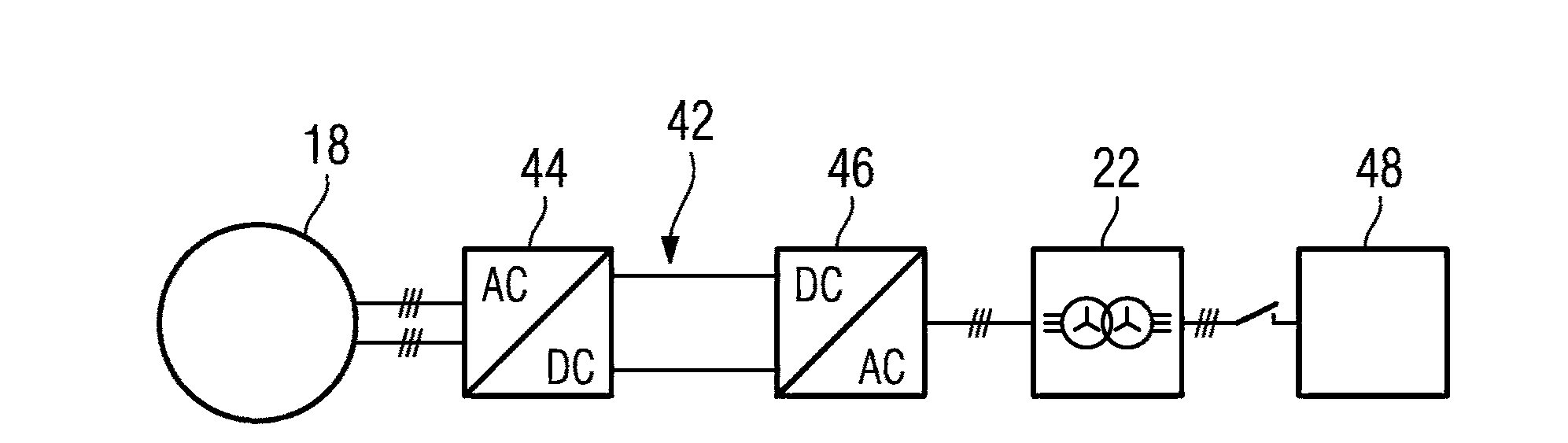

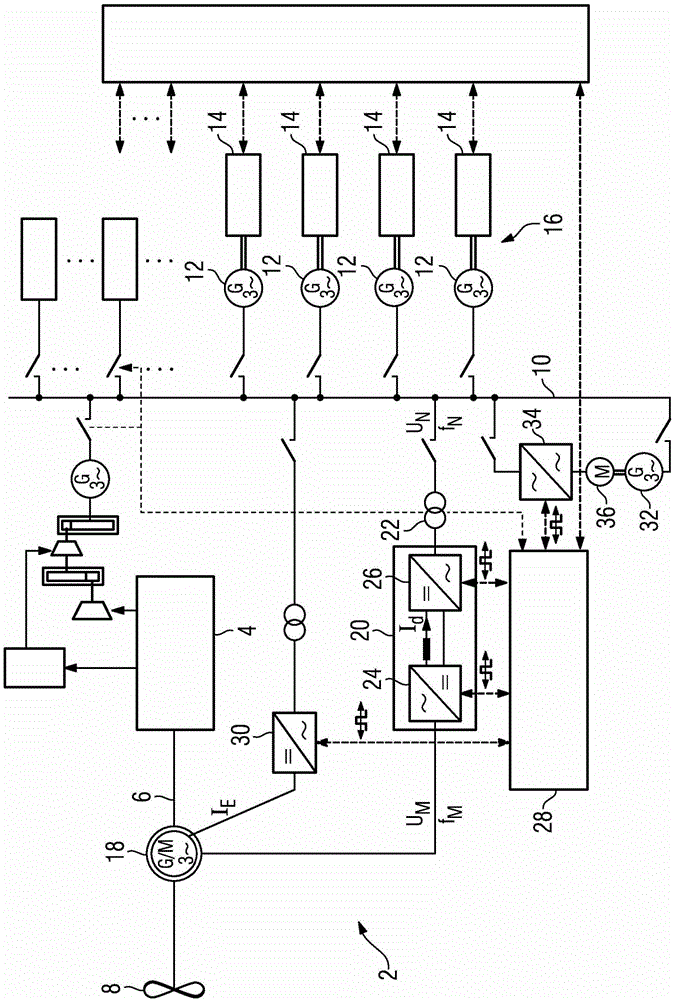

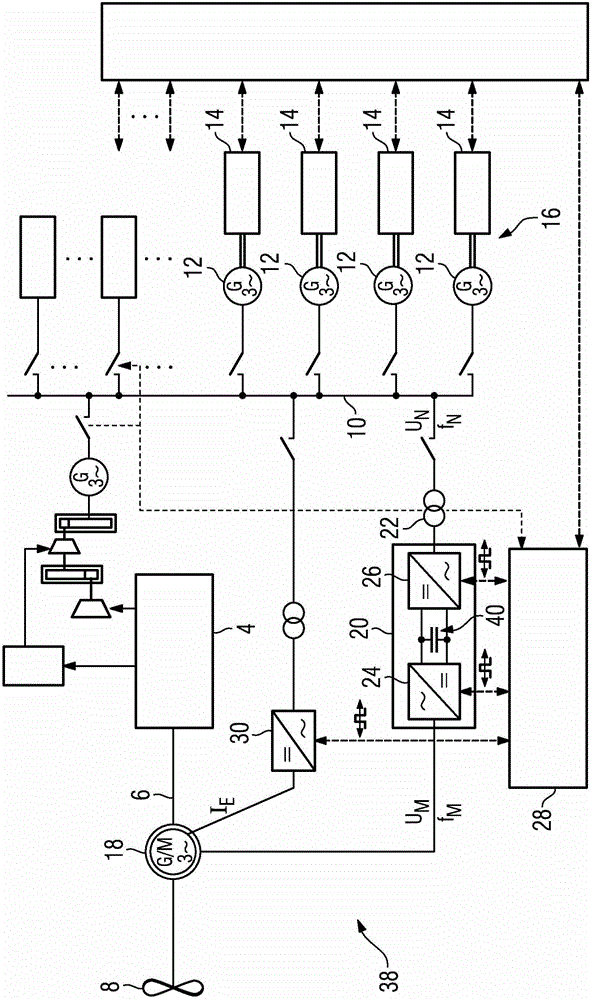

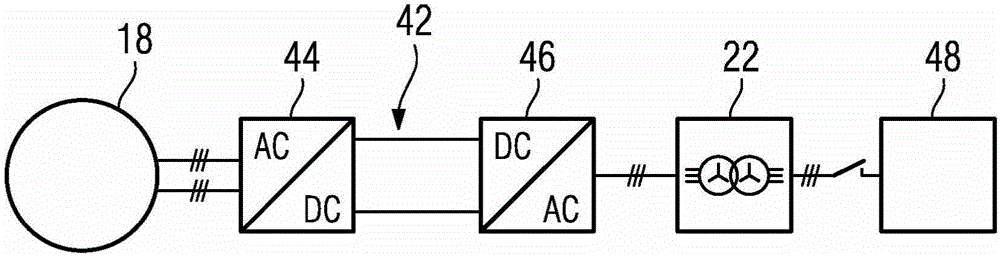

Shaft-driven generator system

ActiveCN102934343ASatisfy Reaction RequirementsMeet short-circuit-safetyGenerator control circuitsPropulsion based emission reductionFrequency changerElectricity

Owner:SIEMENS AG

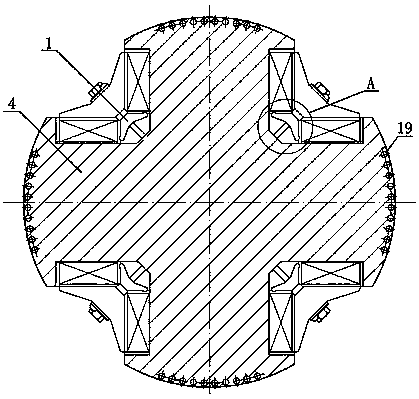

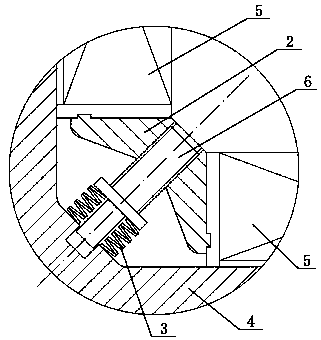

Salient pole synchronous motor rotor with integrated solid structure

ActiveCN107834798AReduce stressImprove safety and reliabilityMagnetic circuit rotating partsElectric machinesSynchronous motorElectric machinery

The invention discloses a salient pole synchronous motor rotor with an integrated solid structure. The rotor comprises a pole shoe, a magnetic pole, a rotation shaft and an exciting winding, wherein the pole shoe, the magnetic pole and the rotation shaft are machined into an integrated salient pole rotor structure by using a forge piece, the salient pole rotor structure is reserved with a space for arranging the exciting winding, the exciting winding is formed by directly winding on the rotor, and an elastic support device is arranged under the exciting winding.According to the salient pole synchronous motor rotor with the integrated solid structure provided by the invention, the pole shoe, the magnetic pole and the rotation shaft are machined into the integrated structure by using the forge piece with both excellent magnetic performance and mechanical property, without using a combining bolt, so that the whole carrying capacity is stronger, the rigidity is better, the capacity of themotor can become larger, and thus the rotor can bear larger centrifugal force, the stress of the rotor component is smaller under the effect of the same centrifugal force, and the security reliabilityis greatly improved; the surface of the pole shoe is a continuous curved surface without sharp corners and edges, so that the situation that local part heats seriously is eliminated, the magnetic field waveform is better, and the higher harmonic content becomes little.

Owner:东方电气(德阳)电动机技术有限责任公司 +1

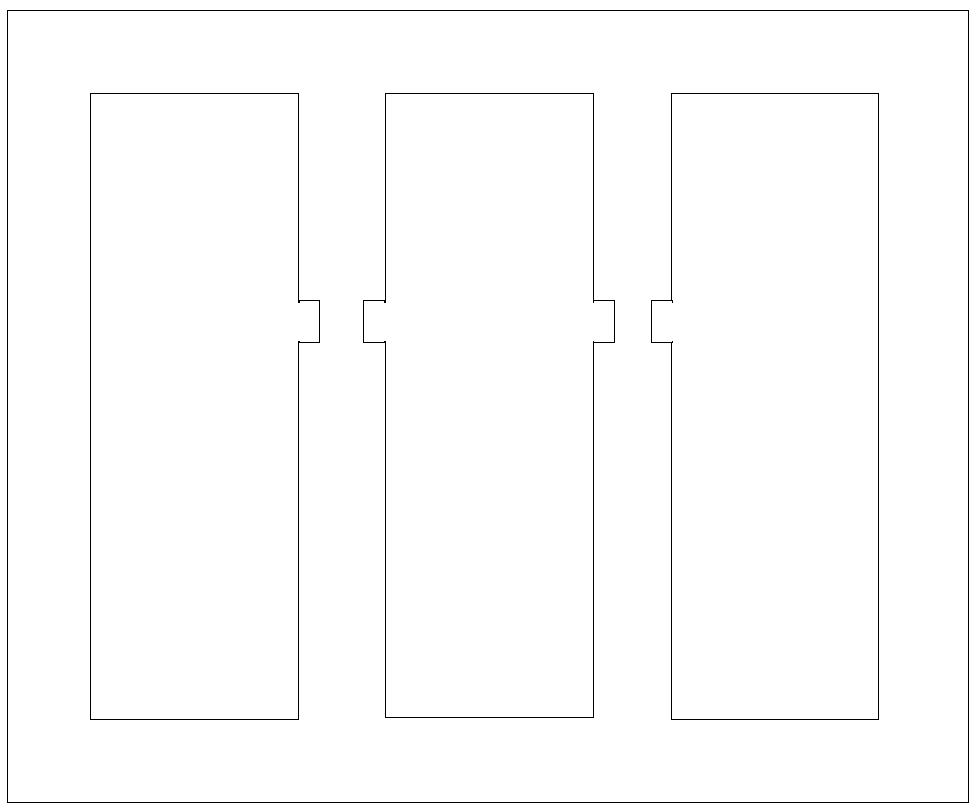

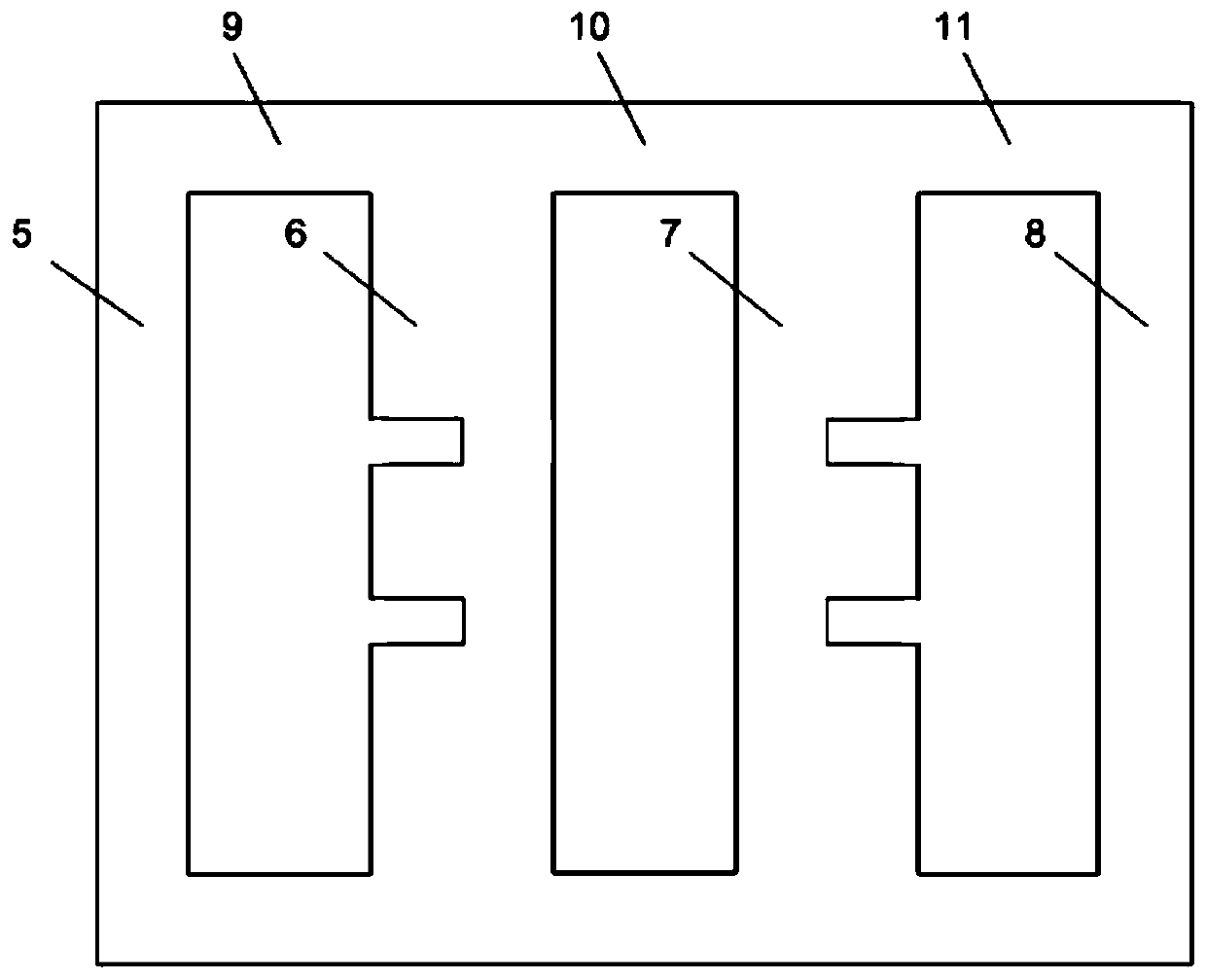

Core structure, core reactor and method

InactiveCN109273212AReduce vibrationReduce noiseTransformers/inductances noise dampingTransformers/inductances magnetic coresNuclear engineeringMagnetic valve

The invention provides an iron core structure, an iron core reactor and a method thereof. The iron core air gap structure composed of an iron core cake and an air gap cushion block of an existing ironcore reactor is replaced by a magnetic valve, so that vibration and noise effects during operation caused by the existing air gap structure can be reduced on the basis of maintaining the linear characteristics of the iron core reactor. By using the air gap at the magnetic valve, the magnetic flux will flow through the air gap to ensure the linearity at least for a certain period of time when theiron core is in operation. At the same time, because the iron core column in the coil of the iron core reactor is uninterrupted, the iron core cake and the air gap cushion block are not needed, the vibration and the noise of the iron core reactor in the operation process are small.

Owner:李晓明

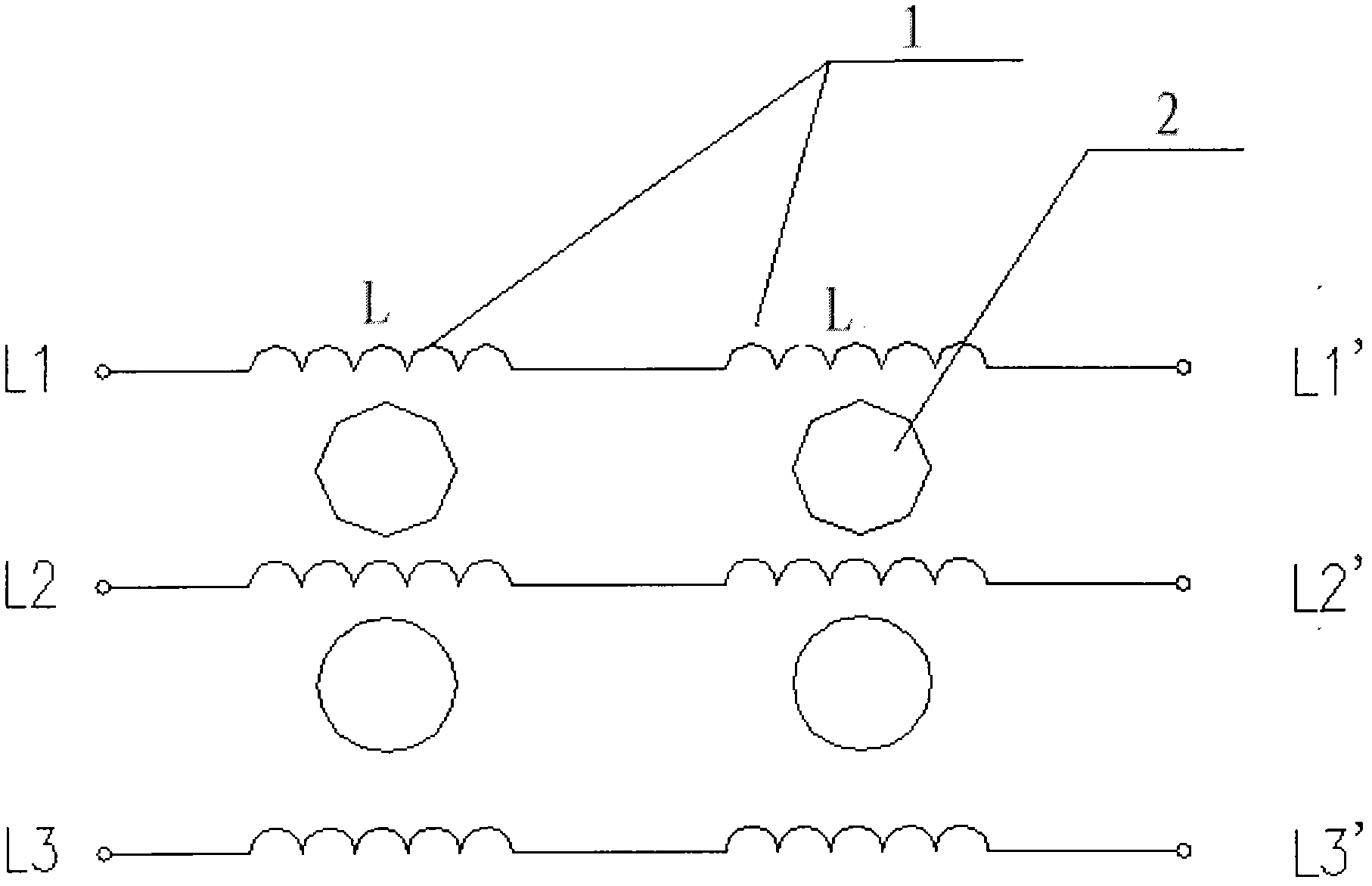

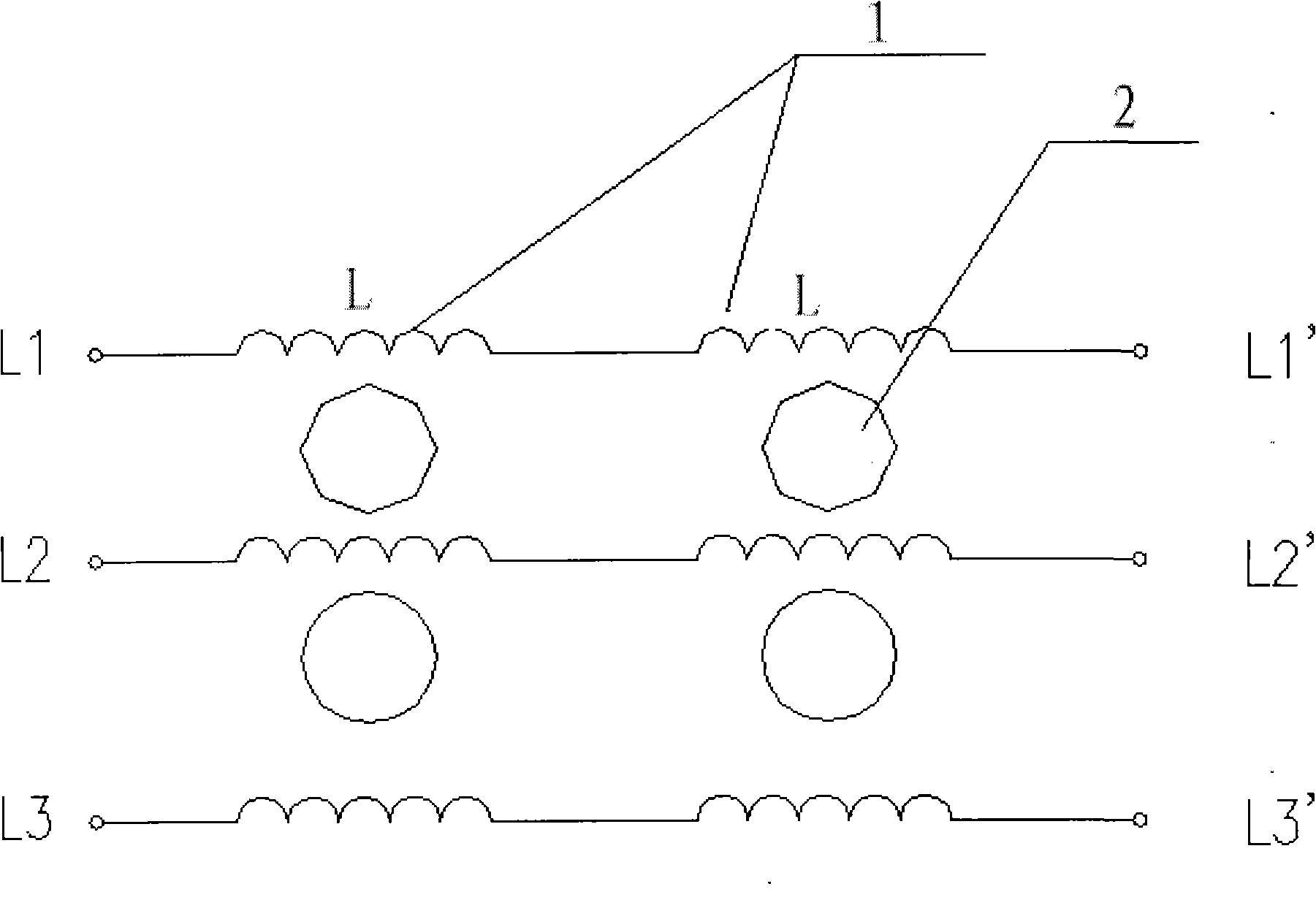

Coil

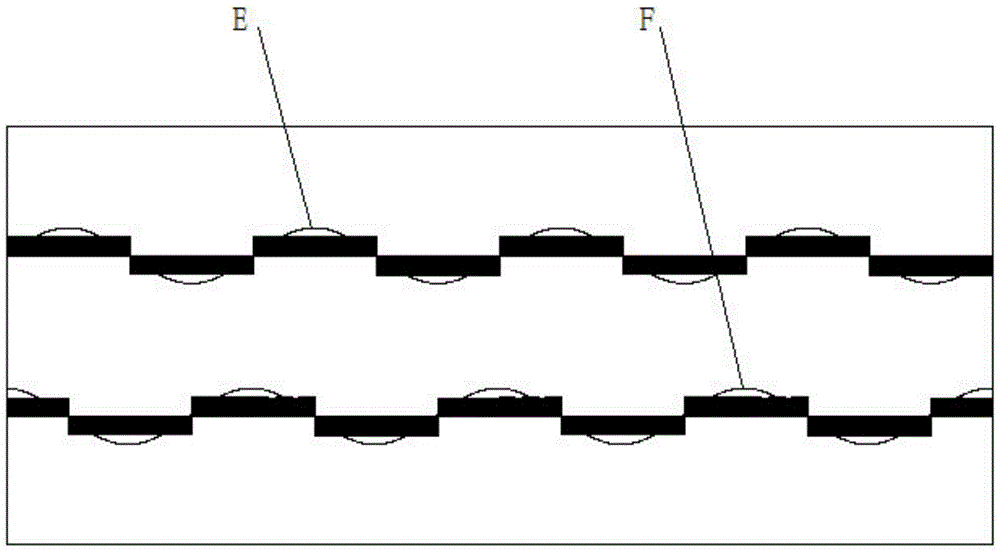

ActiveCN104185941AReduce higher harmonic contentReduce vibrationWindings conductor shape/form/constructionPower flowThree-phase

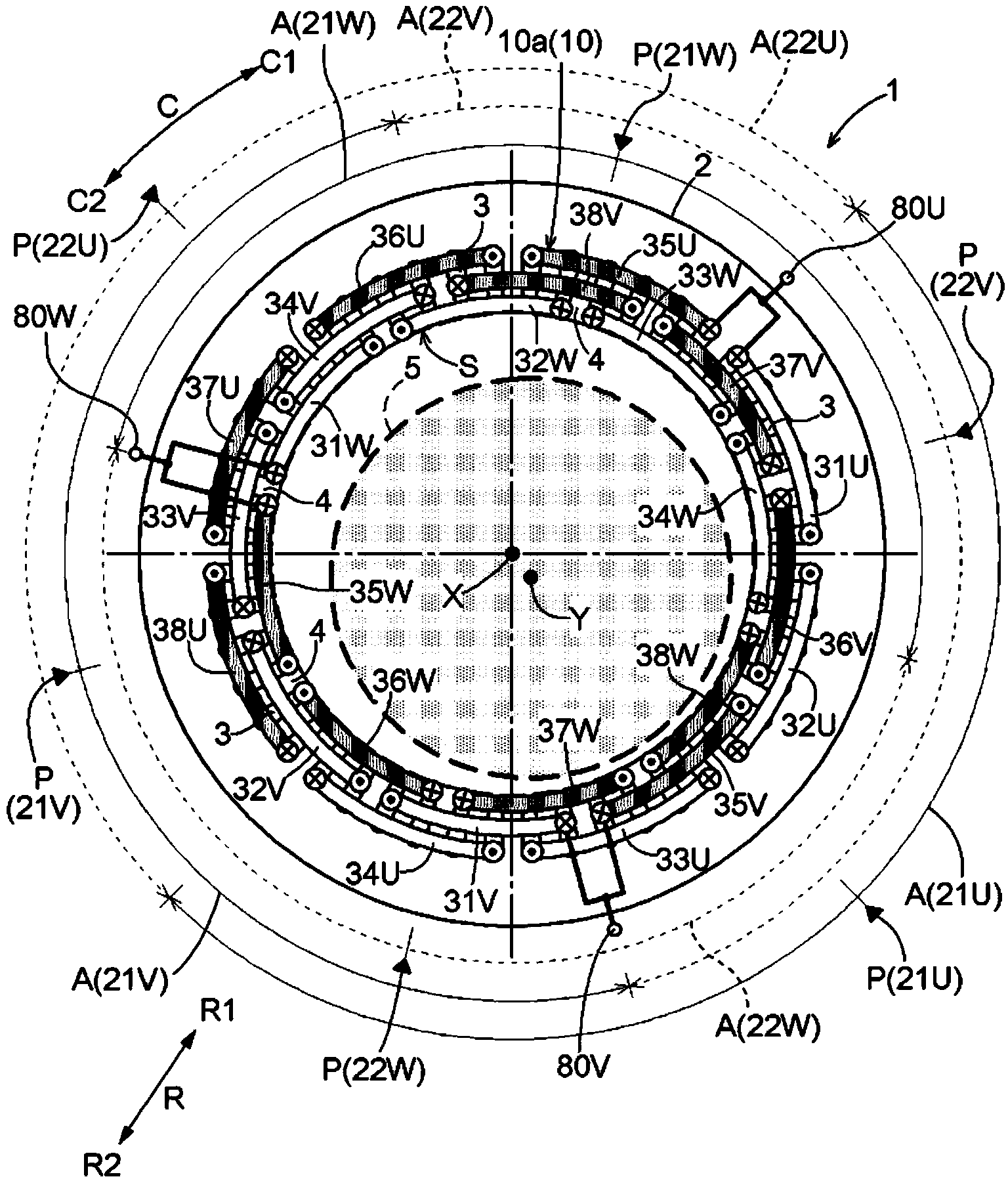

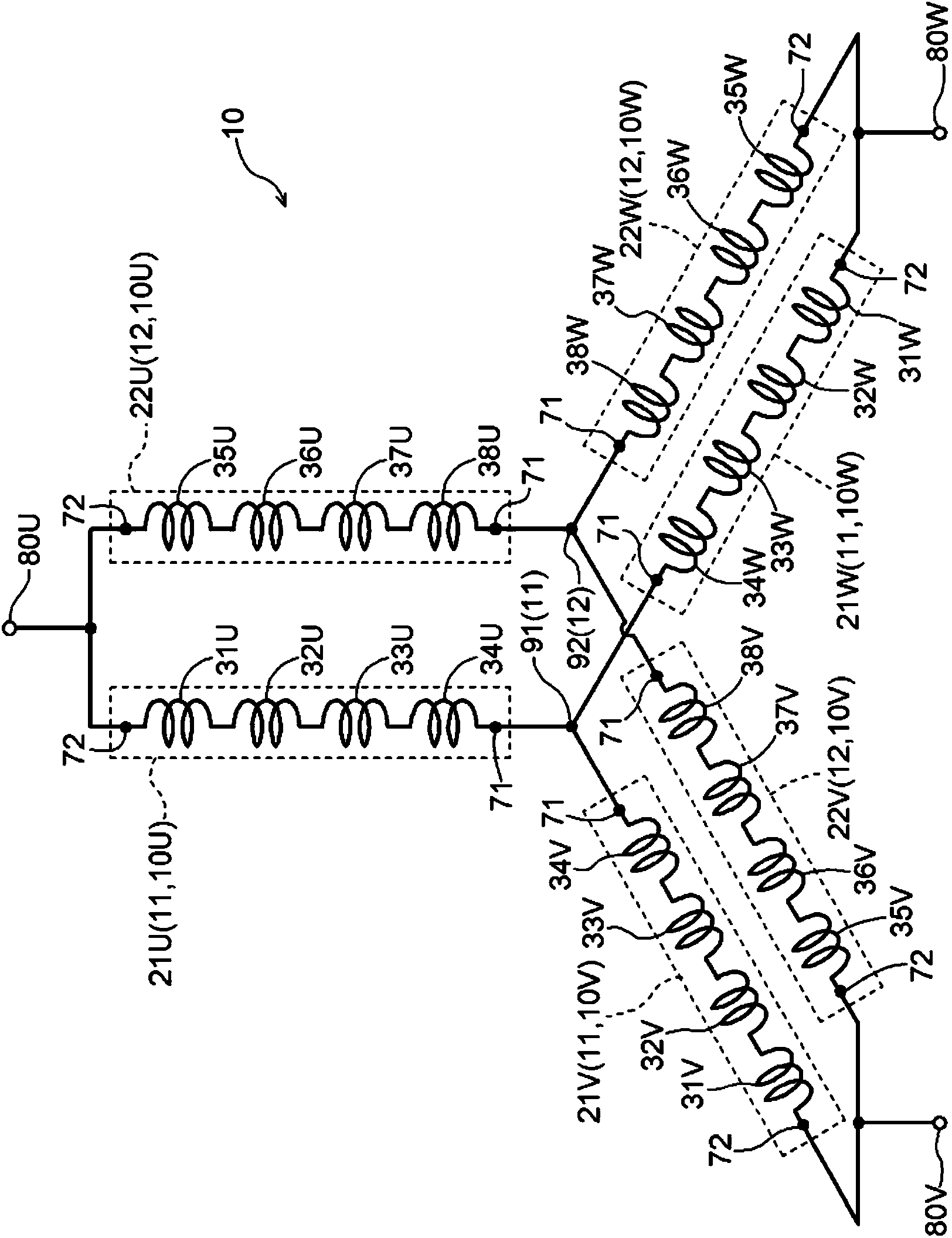

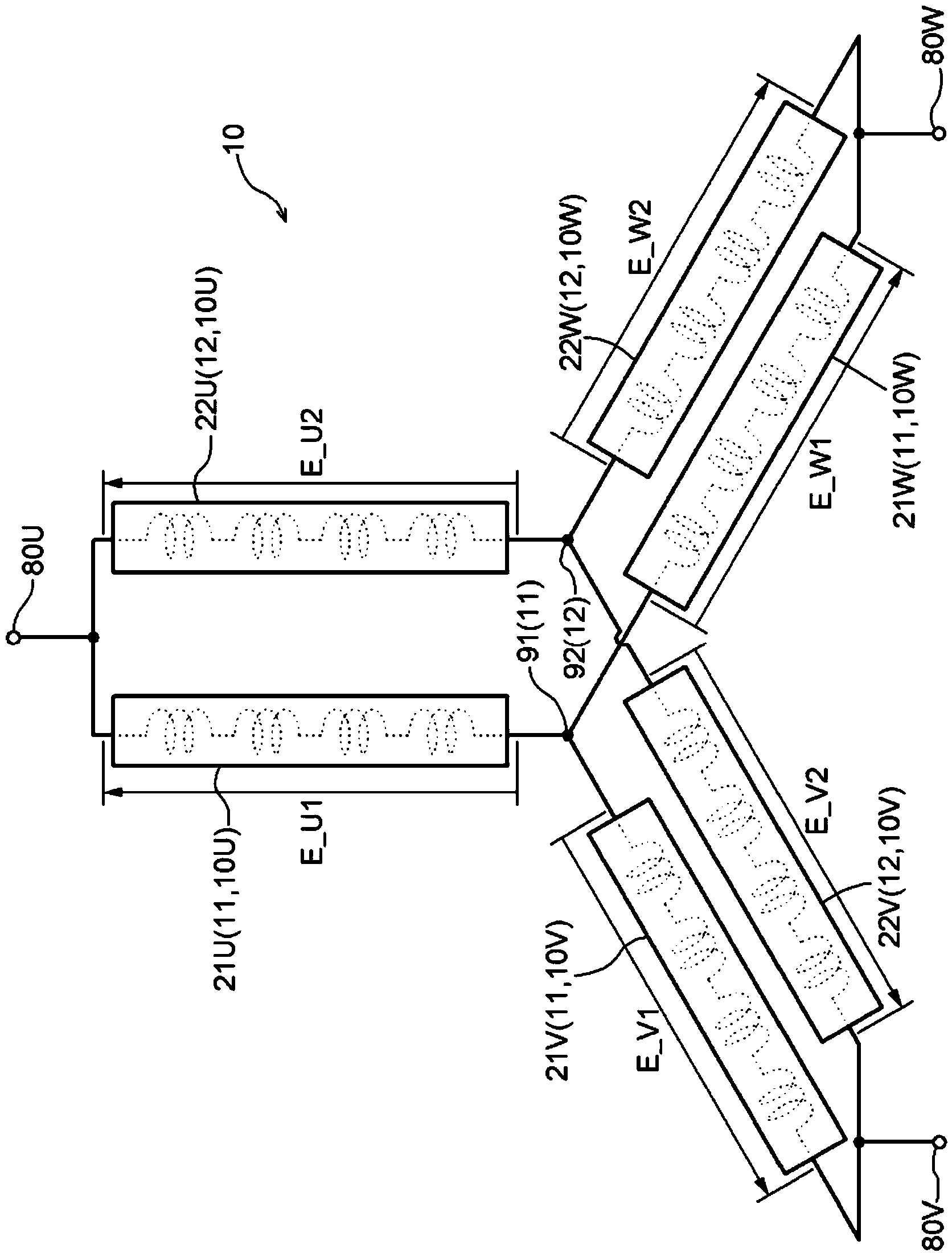

Provided is a coil that can suppress an increase in the time taken for a coil winding process and an increase in facility costs while suppressing the generation of a circulating current. Each of a plurality of star connection bodies includes three phase coil portions corresponding to each of three phases, and a first end portion of each of the three phase coil portions is connected using a neutral point which is independently formed by a star connection body. Second end portions of the phase coil portions of the same phase provided in the different star connection bodies are connected to each other. A phase coil arrangement area (A) where each of the phase coil portions is disposed is set to be continuous in a circumferential direction (C), and is arranged in such a manner as not to overlap the phase coil arrangement area (A) where the other phase coil portions of the same phase are arranged in a radial direction (R) view. A center position (P) in the circumferential direction of each of the phase coil portions is set at a position different by 120° in the circumferential direction (C) with respect to a center position (P) in the circumferential direction of the phase coil portion of another phase provided in the same star connection body.

Owner:AISIN AW CO LTD

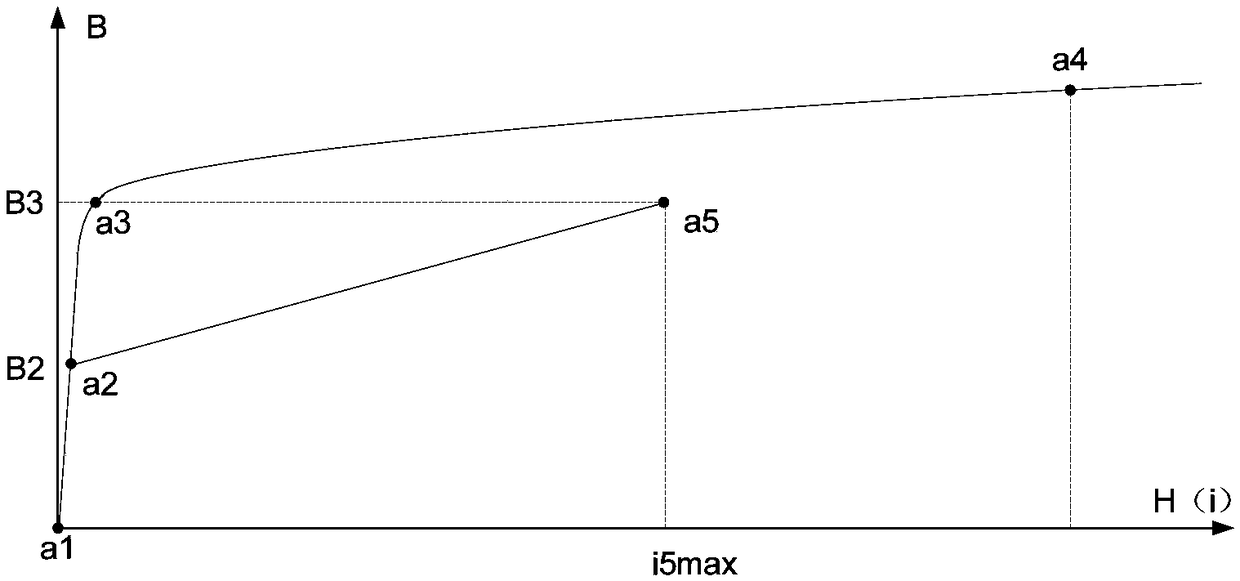

Magnetically controlled reactor and method

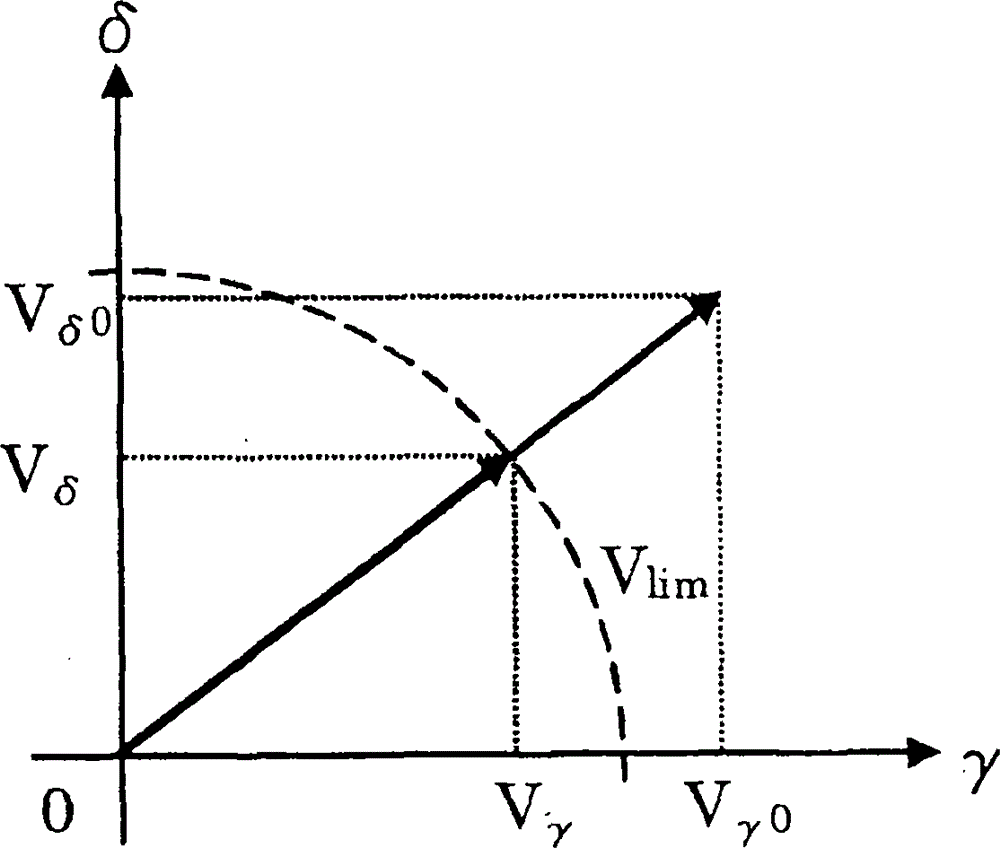

ActiveCN109326428AReduce higher harmonic contentReduce vibrationUnwanted magnetic/electric effect reduction/preventionLine segmentPeak value

The invention provides a magnetically controlled reactor and a method. Magnetic valves are arranged on one or more pairs of ironic core pillars with coils, under the condition that the shape and sizeof the magnetic valves are set to be capable of making a magnetized curve of an ironic core of the magnetically controlled reactor formed by sequentially connecting line segments a1, a2 and a5, wherein a1 is the starting point of the magnetized curve, and corresponding magnetic induction intensity is zero; a2 is a point between the starting point of the magnetized curve and a knee point, and magnetic induction intensity B2 corresponding to a2 is between magnetic induction intensity corresponding to zero and magnetic induction intensity corresponding to the knee point; magnetic induction intensity corresponding to a5 is equal to that corresponding to the knee point, and is the peak value of the maximum value of reactance current of the magnetically controlled reactor. By designing the magnetic values, the ideal magnetized curve of the ironic core of the magnetically controlled reactor can be obtained, so that the content of higher harmonic of the magnetically controlled reactor is minimum.

Owner:李晓明 +1

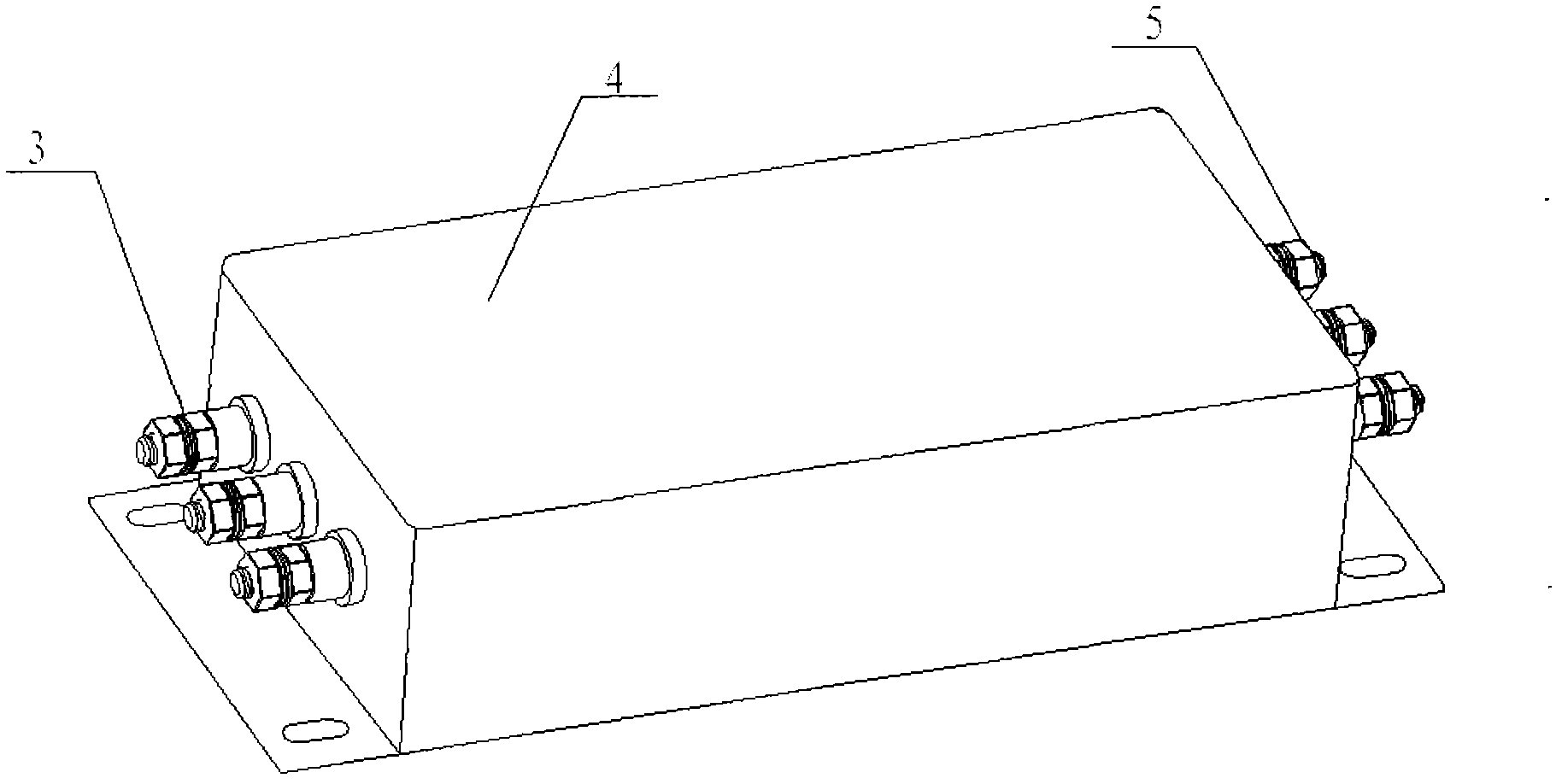

Design method of filter at output end of frequency converter

InactiveCN102570783AAvoid damageReduce higher harmonic contentPower conversion systemsFrequency changerConducted electromagnetic interference

The invention relates to filter technology, in particular relates to a design method of a filter at an output end of a frequency converter. The filter comprises a shielding shell, wherein nickel is plated on the surface of the shielding shell, and three groups of filter circuits are arranged inside the shielding shell provided with the filter circuits. The design method is characterized in that each group of filter circuit comprises two serially-connected common mode inductors which are electrically connected, the two common mode inductors in each group of filter circuit are wound on an iron core in a common mode manner, input and output wiring terminals of the three group of filter circuits are fixed on two sides of the shielding shell provided with filter circuits by using insulation terminals; and the two common mode inductors of each group of filter circuit are connected in series to form a pure-inductance common mode filter network, and the common mode inductors are made of non-crystalline nano metal materials in a winding manner. According to the design method, influences and interference on normal working of a system due to electromagnetic conducting of the output end of the frequency converter through a cable are reduced.

Owner:XIAN KAIRONG ELECTRONICS TECH

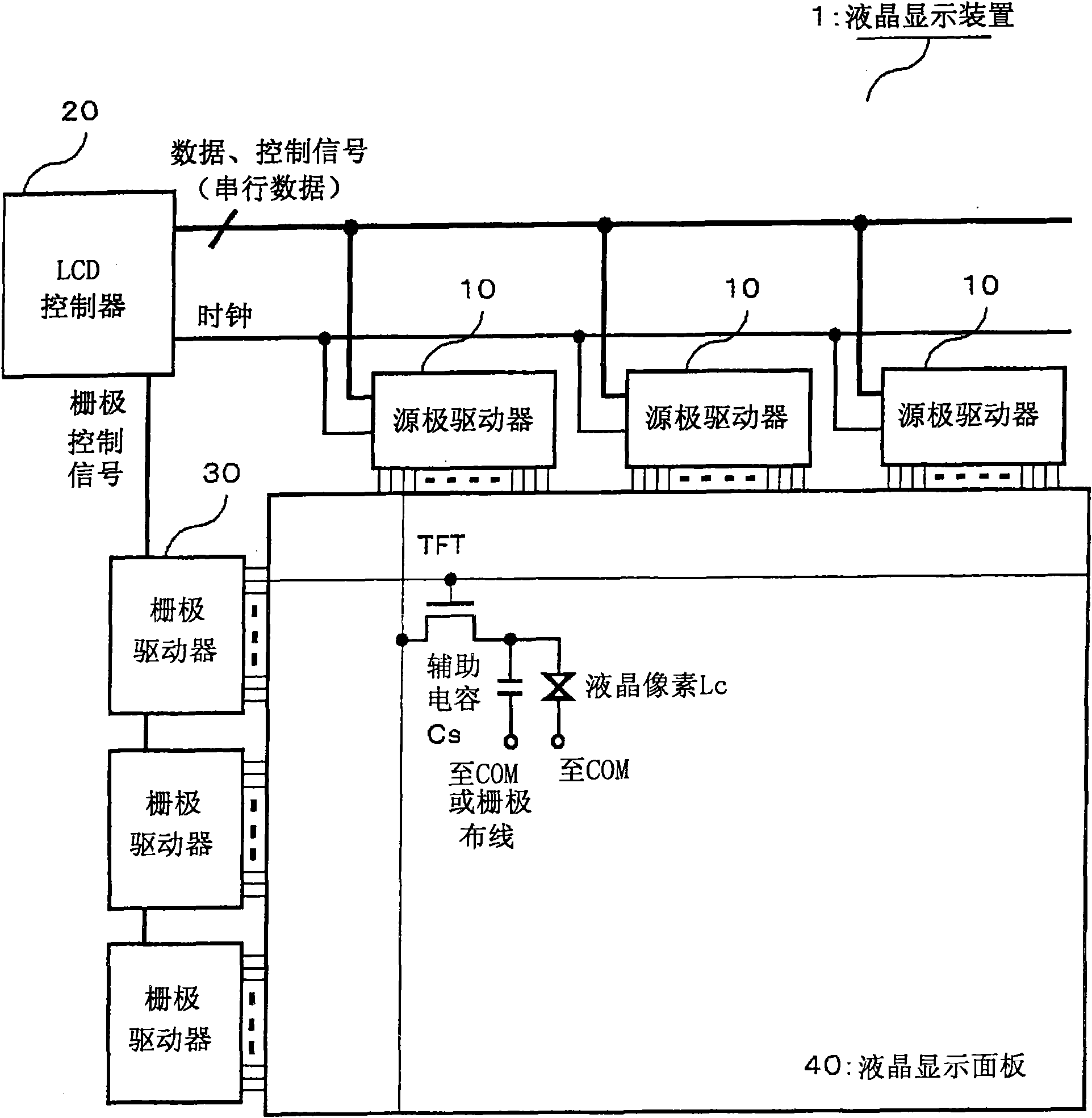

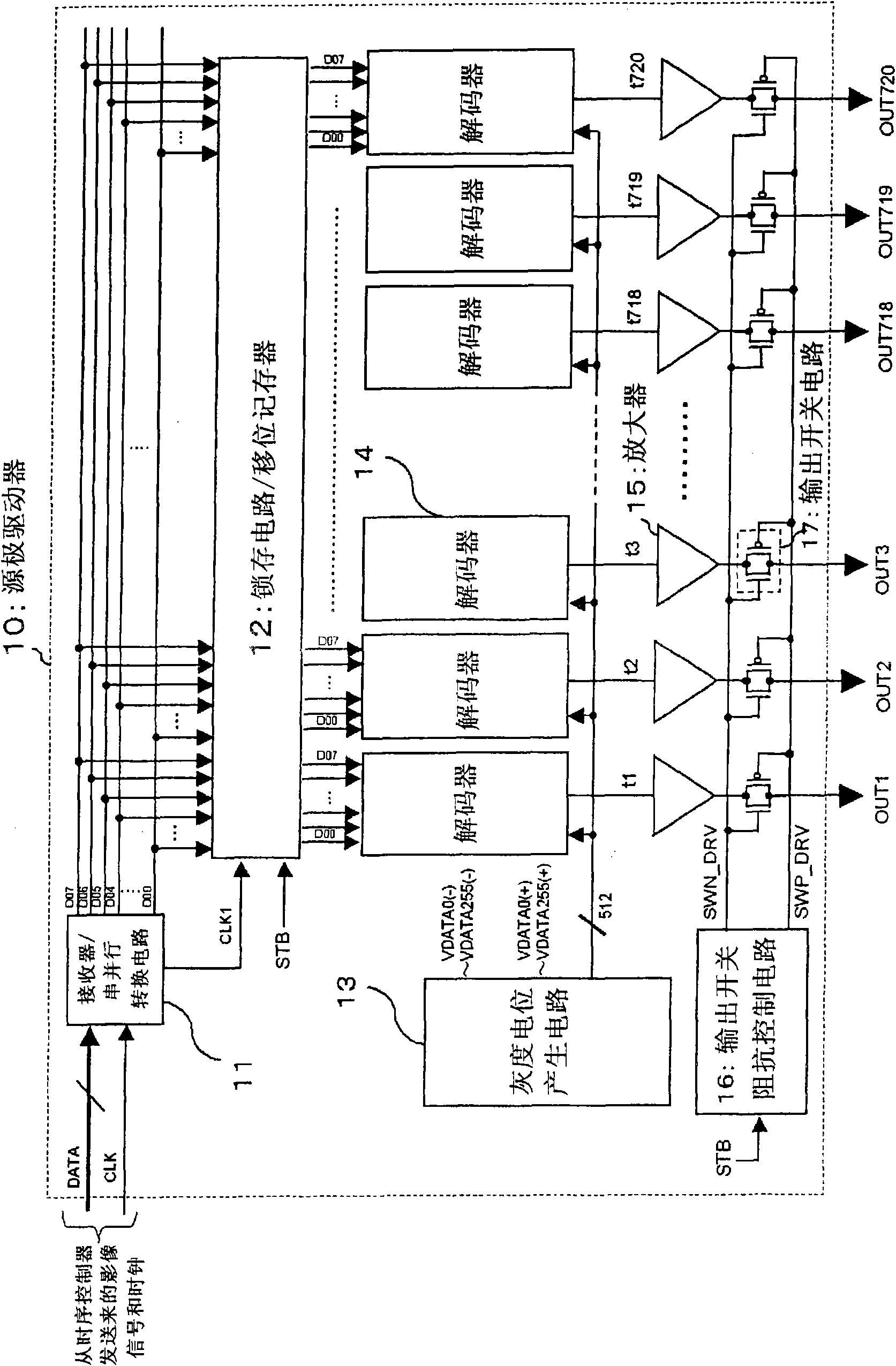

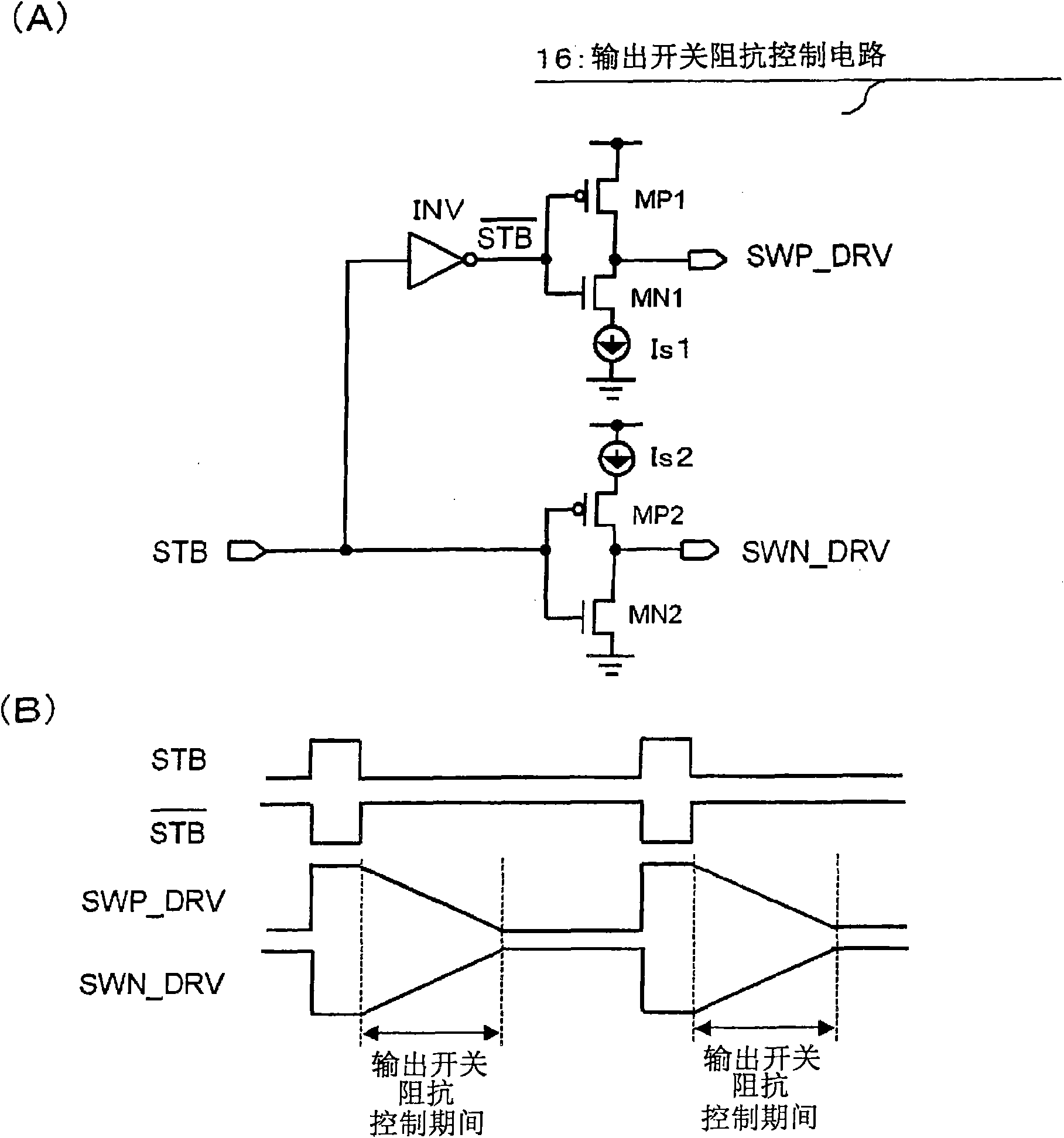

Driving circuit and display

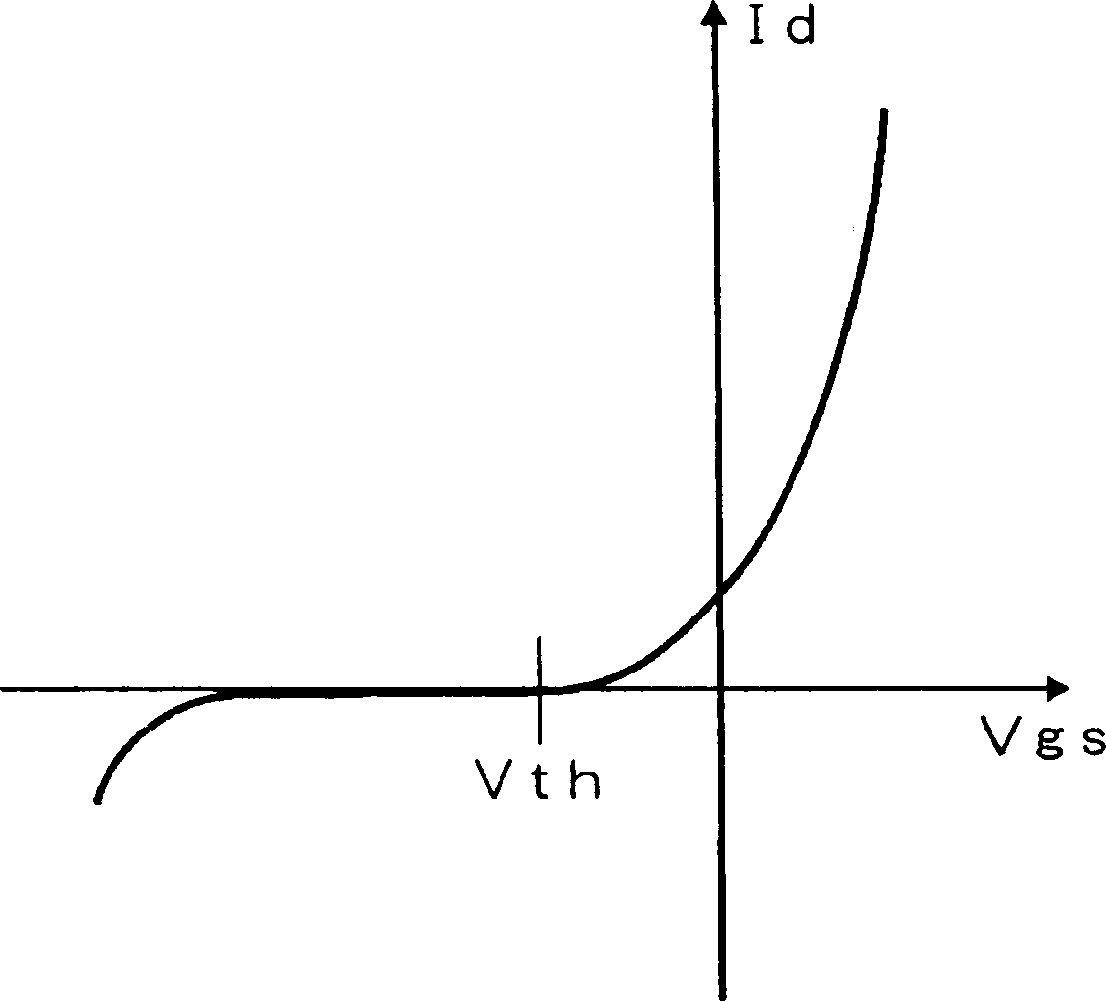

InactiveCN101609637AAvoid drastic changesReduce higher harmonic contentStatic indicating devicesAudio power amplifierLiquid-crystal display

A liquid crystal display in which it is possible to reduce the EMI noise ascribable to high harmonic contents in a charging / discharging current is disclosed. The liquid crystal display includes a source driver 10. The source driver includes output terminals (OUTn) that drive a liquid crystal panel, amplifiers 15 that amplify a video signal and output switching circuits 17 each connected between an output of the amplifier 15 and the output terminal. The source driver also includes an output switch impedance control circuit 16 that controls the switching operation of the output switching circuits 17. When turned on during the operation of switching the output switching circuit 17, the output switch impedance control circuit 16 exercises control to progressively lower the impedance of the output switching circuit 17.

Owner:RENESAS ELECTRONICS CORP

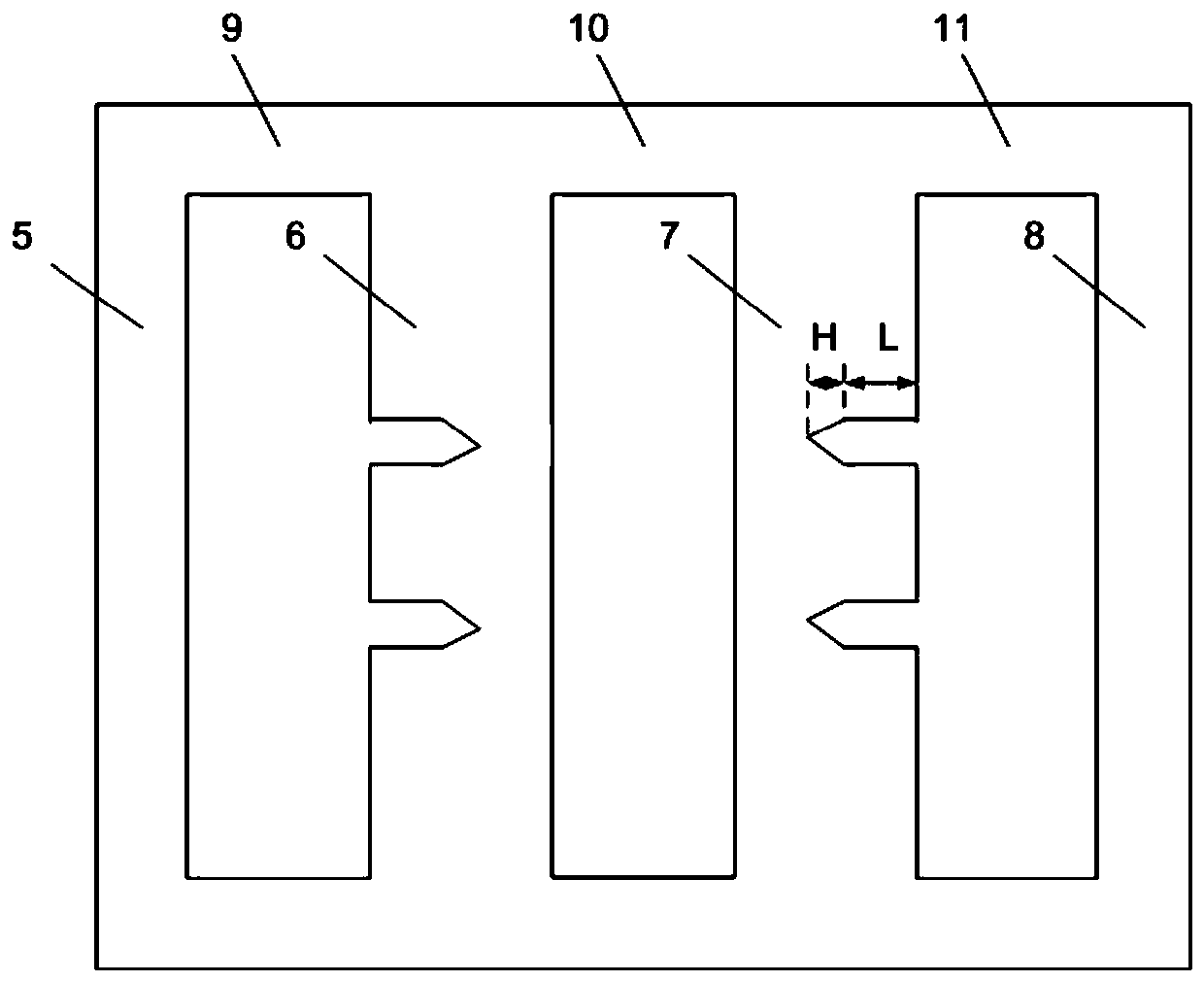

Magnetic controllable reactor core structure and design method

InactiveCN110415938AReduce higher harmonic contentOverall small sizeTransformers/inductances magnetic coresContinuously variable inductances/transformersMagnetization curveTransformer

The invention provides a magnetic controllable reactor core structure and a design method. The structure comprises an alternating current core column on both sides, and a number of coil core columns arranged between two alternating current core columns. Each alternating current core column and the adjacent coil core column are connected through an alternating current side yoke to form an alternating current closed loop flux loop. Adjacent coil core columns are connected through a direct current side yoke to form a direct current closed loop flux loop. Each coil core column is provided with a number of magnetic valves. The cross-sectional area of each alternating current core column and the alternating current side yoke is equal to S. The cross-sectional area of the direct current side yokeis greater than or equal to S and less than 1.2S. The remaining core cross-sectional area at the magnetic valves is equal to K3S. The cross-sectional area of a non-magnetic valve position is equal to(K3S+K4S). 1((K3+K4) is less than or equal to 2. K3 is less than or equal to 1. S is the cross-sectional area of a transformer core column of the same capacity. The magnetic controllable reactor corehas an ideal magnetization curve, and has the advantages of small volume and weight and small current higher harmonic content.

Owner:李晓明

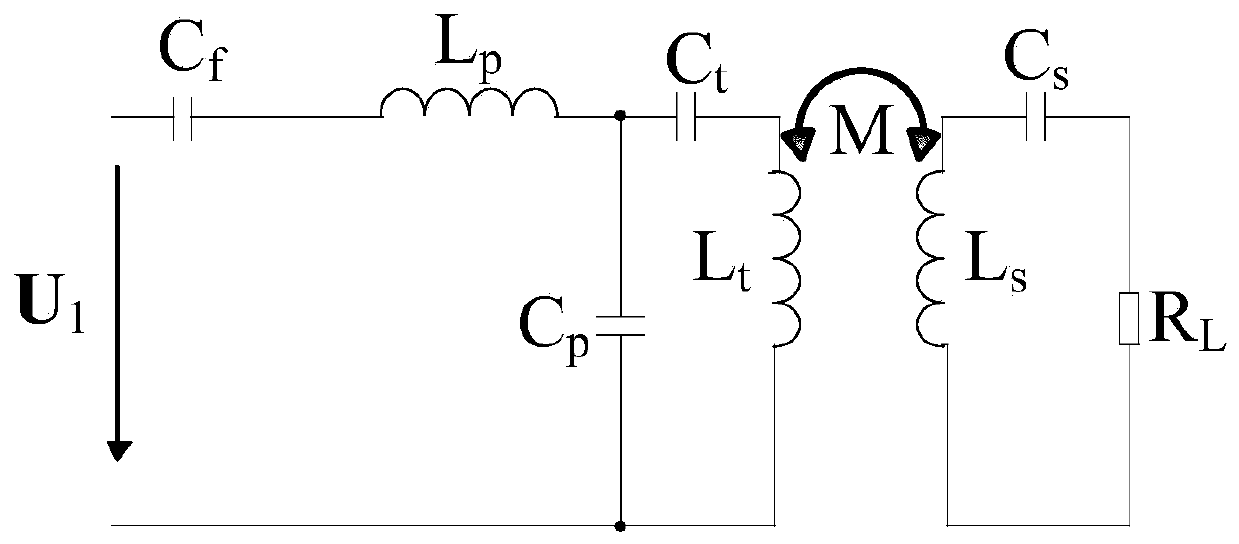

LCC-S topology, wireless power transmission system and harmonic content suppression method

InactiveCN111082539AReduce higher harmonic contentReduce the burden onBatteries circuit arrangementsElectric powerTransmitter coilCapacitance

The invention discloses an LCC-S topology, which is suitable for a wireless power transmission system and comprises a transmitting end and a receiving end, wherein the transmitting end comprises a voltage source U1, a first compensation capacitor Cf, a compensation inductor Lp, a transmitting coil Lt, a second compensation capacitor Ct and a third compensation capacitor Cp, and the first compensation capacitor Cf is sequentially connected with the compensation inductor Lp, the second compensation capacitor Ct and the transmitting coil Lt in series and then connected to the voltage output end of the voltage source U1; the third compensation capacitor Cp is connected in parallel with two ends of the transmitting coil Lt and the second compensation capacitor Ct which are connected in series;the receiving end comprises a receiving coil Ls and a fourth compensation capacitor Cs connected with the receiving coil Ls in series, and the receiving coil Ls is coupled with the transmitting coil Lt; the value of each inductor capacitor meets the following condition: [omega]Lp-1 / ([omega]Cf)=1 / ([omega]Cp)=[omega]Lt-1 / ([omega]Ct). According to the invention, the first compensation capacitor Cf isadditionally arranged at the transmitting end, and the high-order harmonic content of the current of the input end is effectively reduced by reasonably adjusting the value of the compensation inductor Lp, so that the burden of the power supply is reduced.

Owner:JIANGSU FRONTIER ELECTRIC TECH

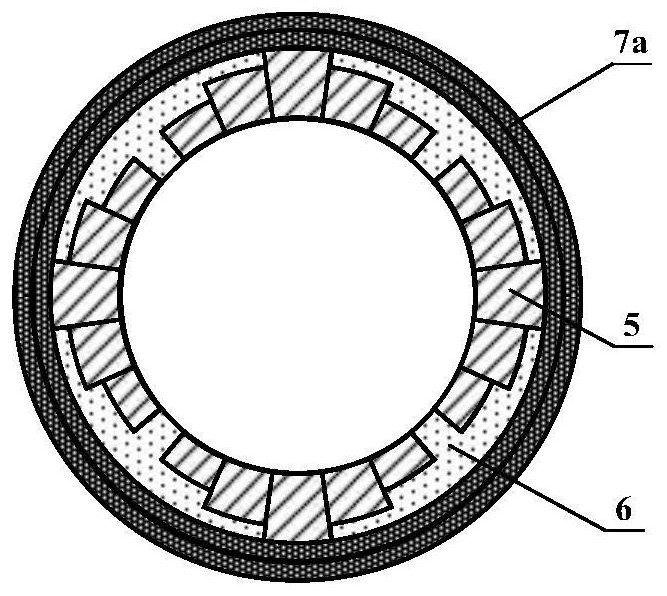

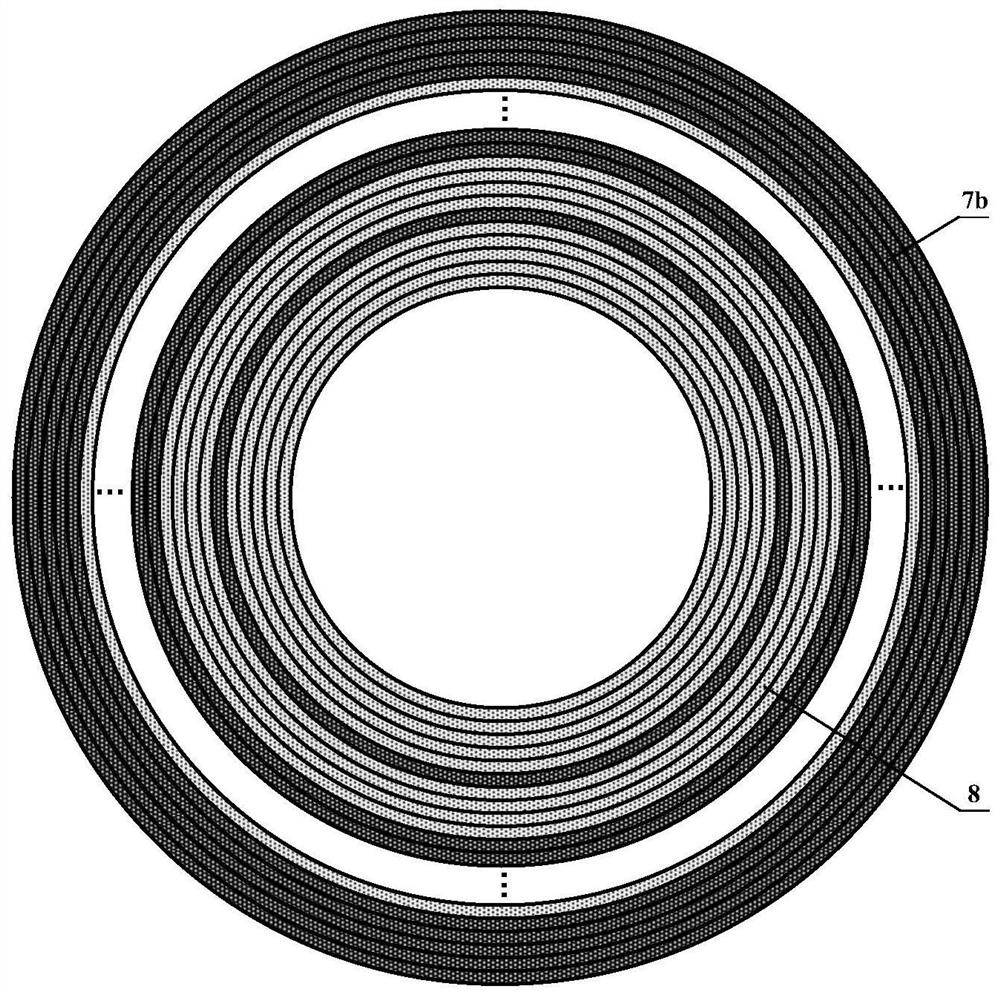

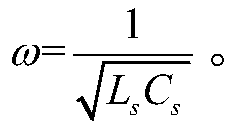

High-speed permanent magnet motor rotor with sine magnetomotive force distribution rule and manufacturing method

PendingCN112039241AIncrease sineReduce higher harmonic contentMagnetic circuit rotating partsManufacturing stator/rotor bodiesFiberAdhesive

The invention discloses a high-speed permanent magnet motor rotor with a sine magnetomotive force distribution rule and a manufacturing method. The high-speed permanent magnet motor rotor comprises arotating shaft, a sintered permanent magnet unit, a magnetic powder adhesive film and carbon fiber composite unit and a rotor sheath which are sequentially arranged from inside to outside in the radial direction, wherein the rotor sheath is formed by multiple layers of carbon fibers III, the magnetic powder adhesive film and carbon fiber composite unit is composed of a plurality of magnetic powderadhesive film and carbon fiber composite subunits, and each magnetic powder adhesive film and carbon fiber composite subunit is composed of a magnetic powder adhesive film layer block, an adhesive film layer block and a carbon fiber layer; and the number of the magnetic powder adhesive film layer blocks and the number of the adhesive film layer blocks are the same as the number of the sintered permanent magnet blocks, and the sum of the polar arc coefficients of the magnetic powder adhesive film layer blocks and the polar arc coefficients of the adhesive film layer blocks is always 1. According to the high-speed permanent magnet motor rotor, the mechanical strength of the motor rotor can be improved, the eddy-current loss of the motor rotor is reduced, and the allowable linear speed of the motor rotor is increased, so that the problems of large eddy-current loss, high temperature rise and low allowable linear speed of the traditional high-speed permanent magnet motor rotor are solved.

Owner:SHENYANG POLYTECHNIC UNIV

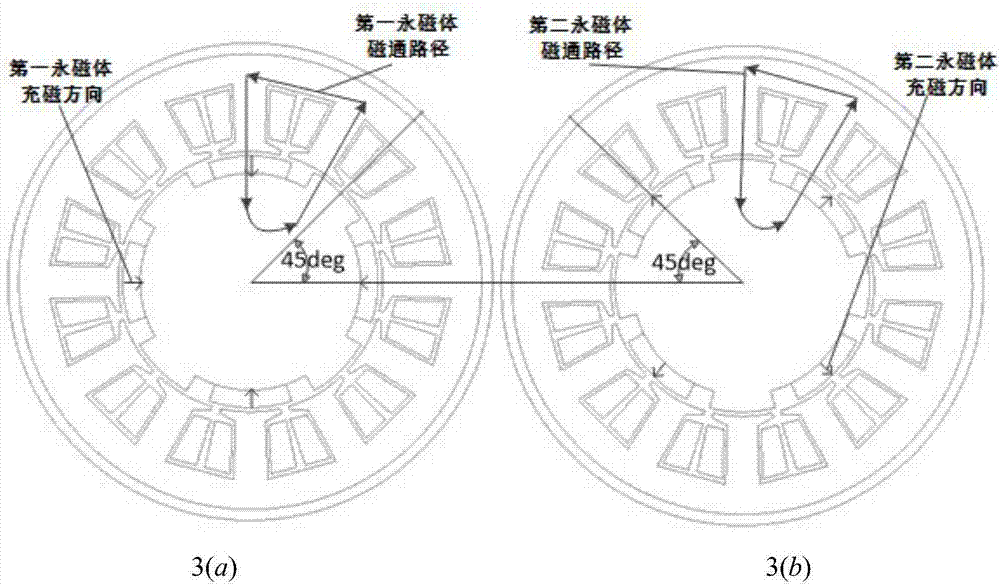

Rotor staggered structure motor

ActiveCN106981937AReduce copper consumptionReduce dosageMagnetic circuit rotating partsMagnetic circuit stationary partsConstant componentConductor Coil

The invention discloses a rotor staggered structure motor. The rotor staggered structure motor comprises a stator and a rotor, wherein the stator sleeves the outer side of the rotor; the stator comprises a first stator iron core, a second stator iron core, an armature winding, an exciting winding and a motor shell, the exciting winding is fixed on an annular exciting winding support, the first stator iron core and the second stator iron core are symmetrically arranged on two sides of the exciting winding, and teeth of the first stator iron core and teeth of the second stator iron core are not staggered in the peripheral direction; the rotor comprises a rotor iron core, a first permanent magnet and a second permanent magnet, a first groove corresponding to the first stator iron core and a second groove corresponding to the second stator iron core are staggered by Pi / n in the peripheral direction. According to the rotor staggered structure motor, through combined action of an iron core pole and a permanent magnet pole, the constant component and higher harmonic content of an air-gap field are reduced, so that the loss of iron cores is reduced, the fundamental current amplitude of the air-gap field is increased, and the utilization rate of the material is improved; and moreover, a rotor groove is filled with the permanent magnets, so that the wind drag and noise are reduced, the mechanical loss is reduced, and the operating efficiency of the motor is improved.

Owner:SOUTHEAST UNIV

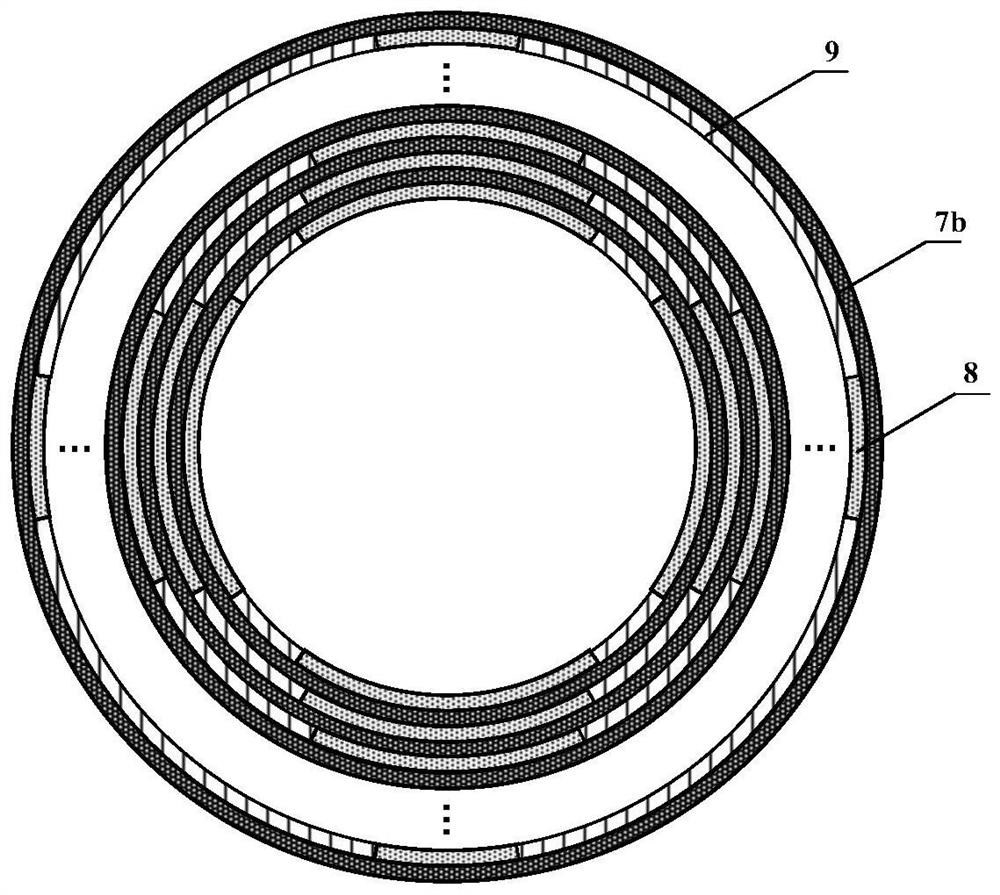

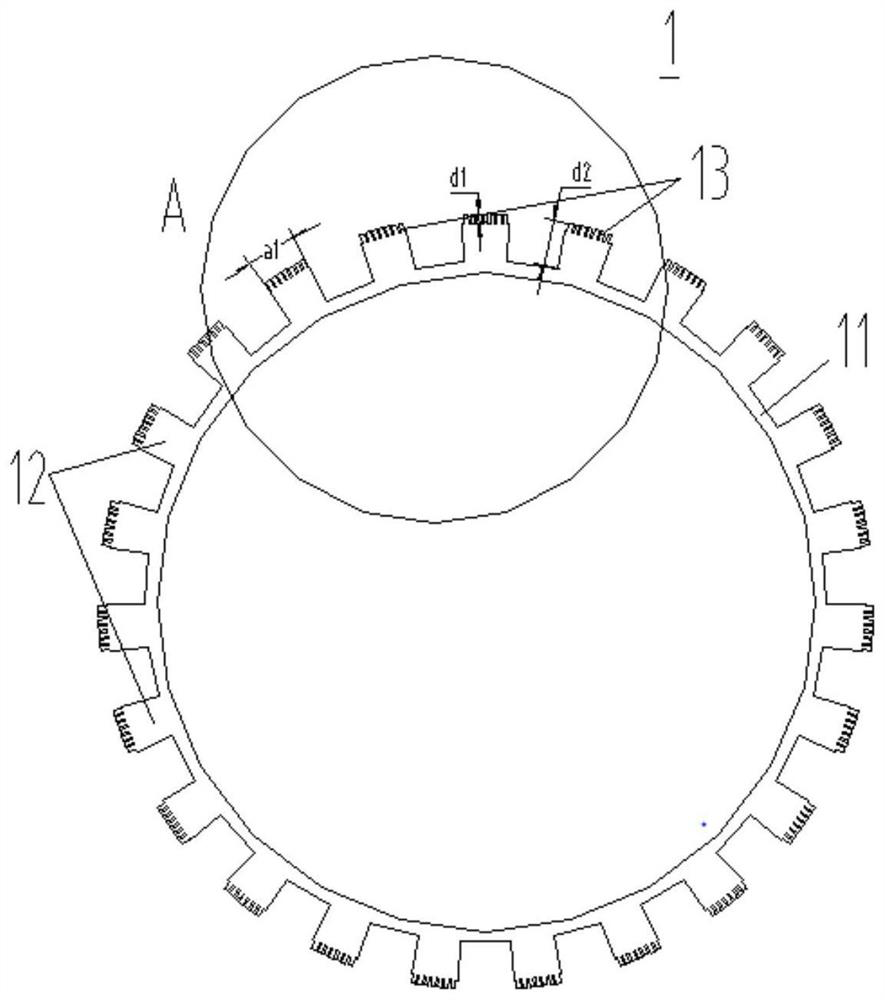

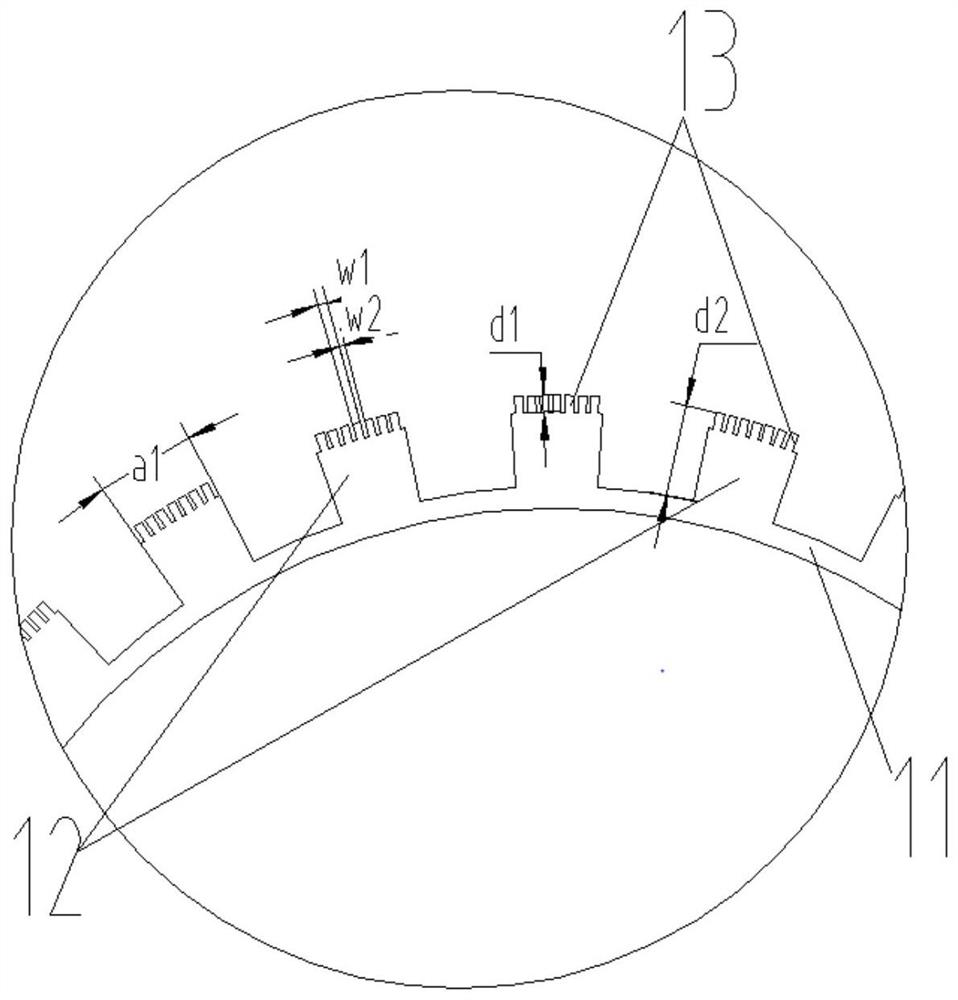

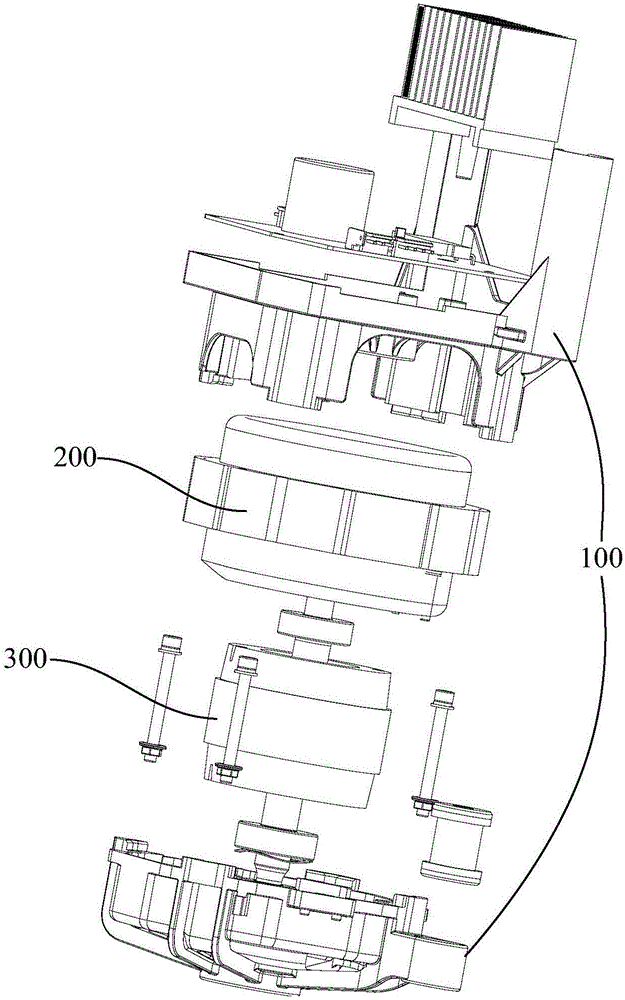

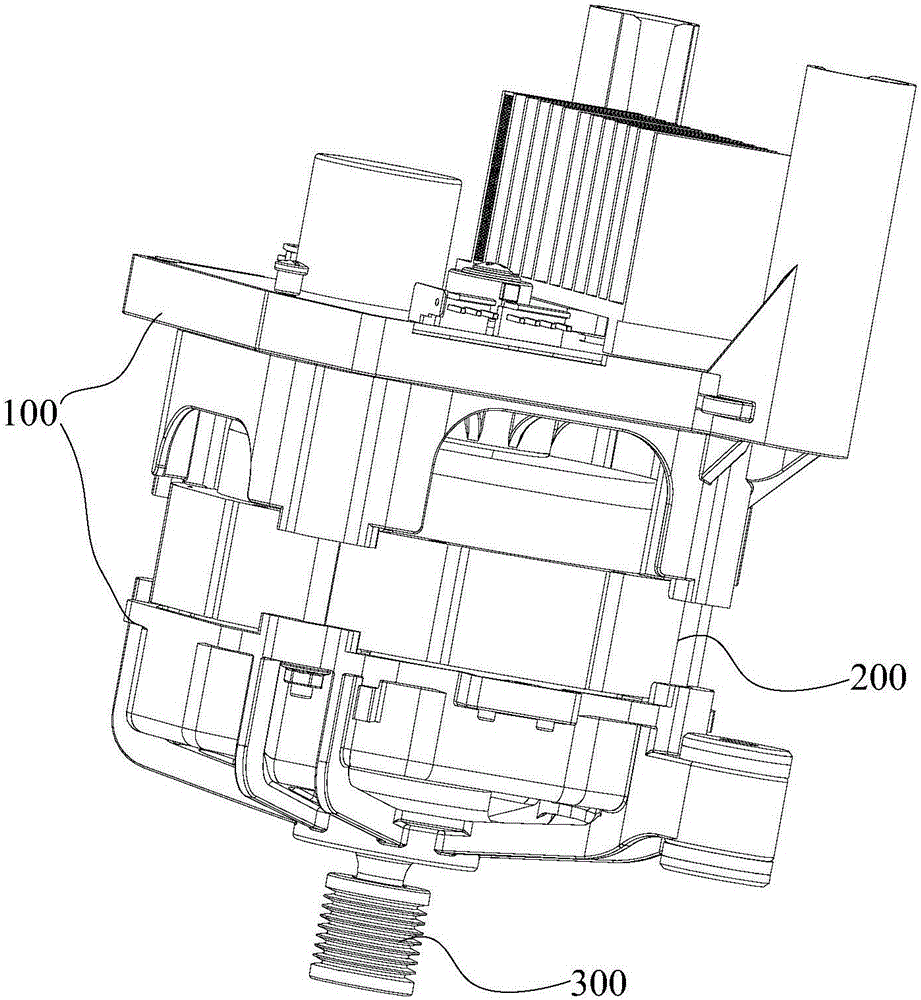

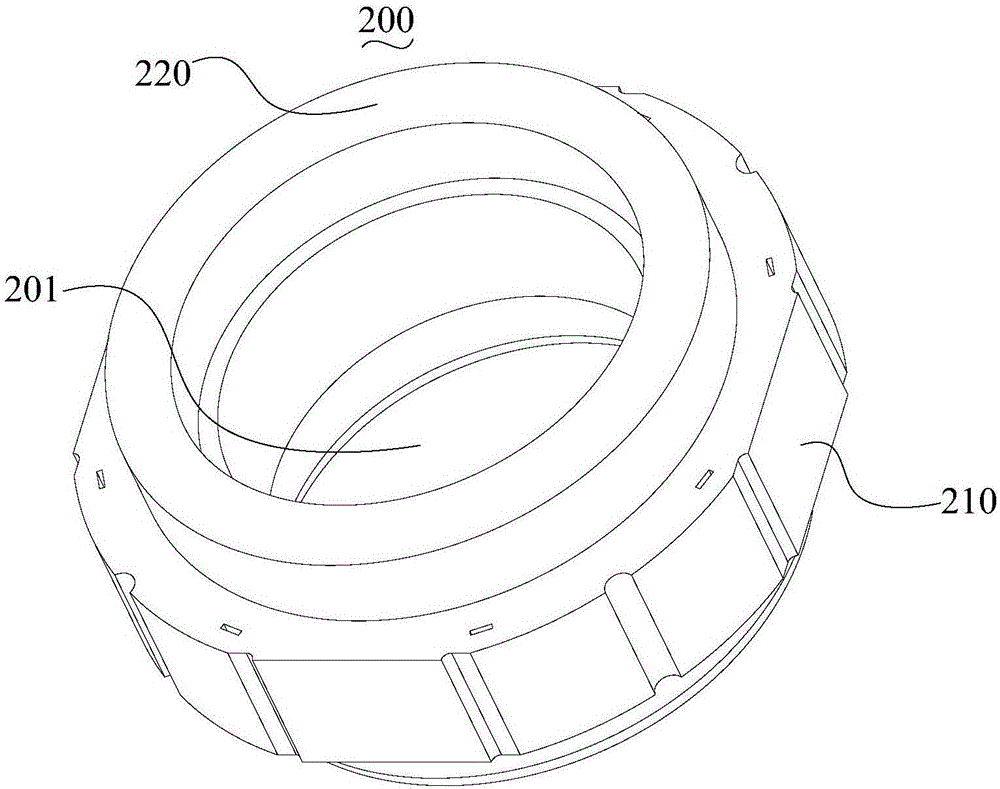

Magnetism adjusting ring, magnetism adjusting ring assembly, magnetic gear and composite motor

PendingCN112491248AReduce torque rippleReduce higher harmonic contentPermanent-magnet clutches/brakesElectric machineryEngineering

The invention provides a magnetism adjusting ring, a magnetism adjusting ring assembly, a magnetic gear and a composite motor. The magnetism adjusting ring comprises an annular yoke part and a plurality of magnetism adjusting protrusions located on the peripheral side wall of the annular yoke part, the multiple magnetism adjusting protrusions extend from inside to outside in the radial direction of the annular yoke part, the sides, facing an outer rotor, of the free ends of the magnetism adjusting protrusions are provided with a plurality of teeth, and the multiple teeth are arranged at intervals in the circumferential direction of the annular yoke part. According to the magnetism adjusting ring, the magnetism adjusting ring assembly, the magnetic gear and the composite motor, the multipleteeth are arranged at the free end of the magnetism adjusting protrusion, the higher harmonic content at the outer air gap in the operation process is effectively reduced, and therefore output torquefluctuation is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Direct-driving type torque motor

InactiveCN104539073AReduce torque rippleReduce vibration and noiseMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedTorque motor

The invention discloses a direct-driving type torque motor. The torque motor comprises a rotating shaft, a front end cover, a rear end cover, a machine shell, a rotor, a stator and a plurality of permanent magnets. The rotor is of a cylindrical structure and is mounted on the rotating shaft, the stator is fixed to the machine shell, the rotating shaft, the rotor and the stator are sequentially and coaxially arranged, the permanent magnets are of a strip-shaped structure, the cross section of each permanent magnet is a sealed pattern formed by sequentially connecting a first arc, a first straight line, a second arc and a second straight line, each closed pattern is symmetric relative to the straight line of the corresponding first arc and the straight line of the corresponding second arc, the curvature of each first arc is larger than that of the corresponding second arc, the permanent magnets are evenly arranged on the outer wall of the rotor, and are parallel to a central shaft of the rotor, and the face where the second arc in each permanent magnet is located is tightly attached to the outer wall of the rotor. According to the torque motor, the torque pulsation and the vibration noise of the motor can be effectively reduced, the demagnetization effect on the permanent magnets in flux-weakening control and torque output of the motor at low speed are ensured, the tooth groove torque ripple is effectively reduced, and the machining precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

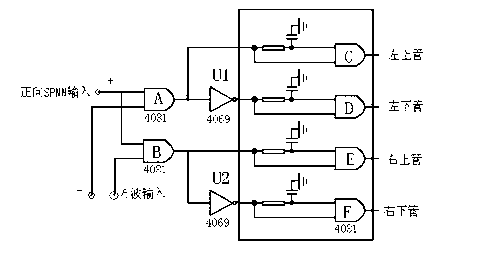

Precise inverter circuit

InactiveCN103178732AReduce higher harmonic contentDc-ac conversion without reversalVoltage pulsePulse-width modulation

The invention relates to a power inverter circuit, in particular to a precise inverter circuit. The precise inverter circuit adopts an arithmetic unit 4 to output biphasic sine pulse width modulation (SPWM) signals, the SPWM signals and output square signals together control a controllable inverter bridge to work, output pulse voltage area is equal to area of selected output sine wave in a corresponding interval, and by changing frequency and amplitude of modulating wave, frequency and amplitude of output voltage of the inverter circuit can be adjusted. The voltage pulse series can greatly reduce higher harmonic components in load current.

Owner:SHAANXI ZHONGXINLIAN ENERGY SAVING NEW TECHDEV

Aerial cable

InactiveCN101329928BIncrease the effective areaLower impedanceClimate change adaptationInsulated cablesAerial cableElectrical conductor

The invention discloses an aerial cable which comprises a reinforced core and an aluminum stranded wire layer, wherein, the aluminum stranded wire layer is divided into an outer aluminum stranded wire layer and an inner aluminum stranded wire layer which are respectively formed by the twisting of a plurality of aluminum wires; each single aluminum wire is coated by an insulation layer; the aerialcable has the advantages that each single aluminum wire is coated or covered by the insulation layer; therefore, currents do not influence each other due to magnetic fields produced by adjacent wiresduring the transmission process of an alternating current (adjacency effect refers to the phenomenon that wires get close to each other, and the current density in each wire is not even any more) so as to eliminate AC resistance caused by the said 'crowded current' and cause the current transmission to be distributed on each wire, thereby greatly increasing the effective area of a cable conductorand reducing the impedance of the conductor and electric power consumption.

Owner:NINGBO WANBO INNOVATIVE MATERIAL & TECH

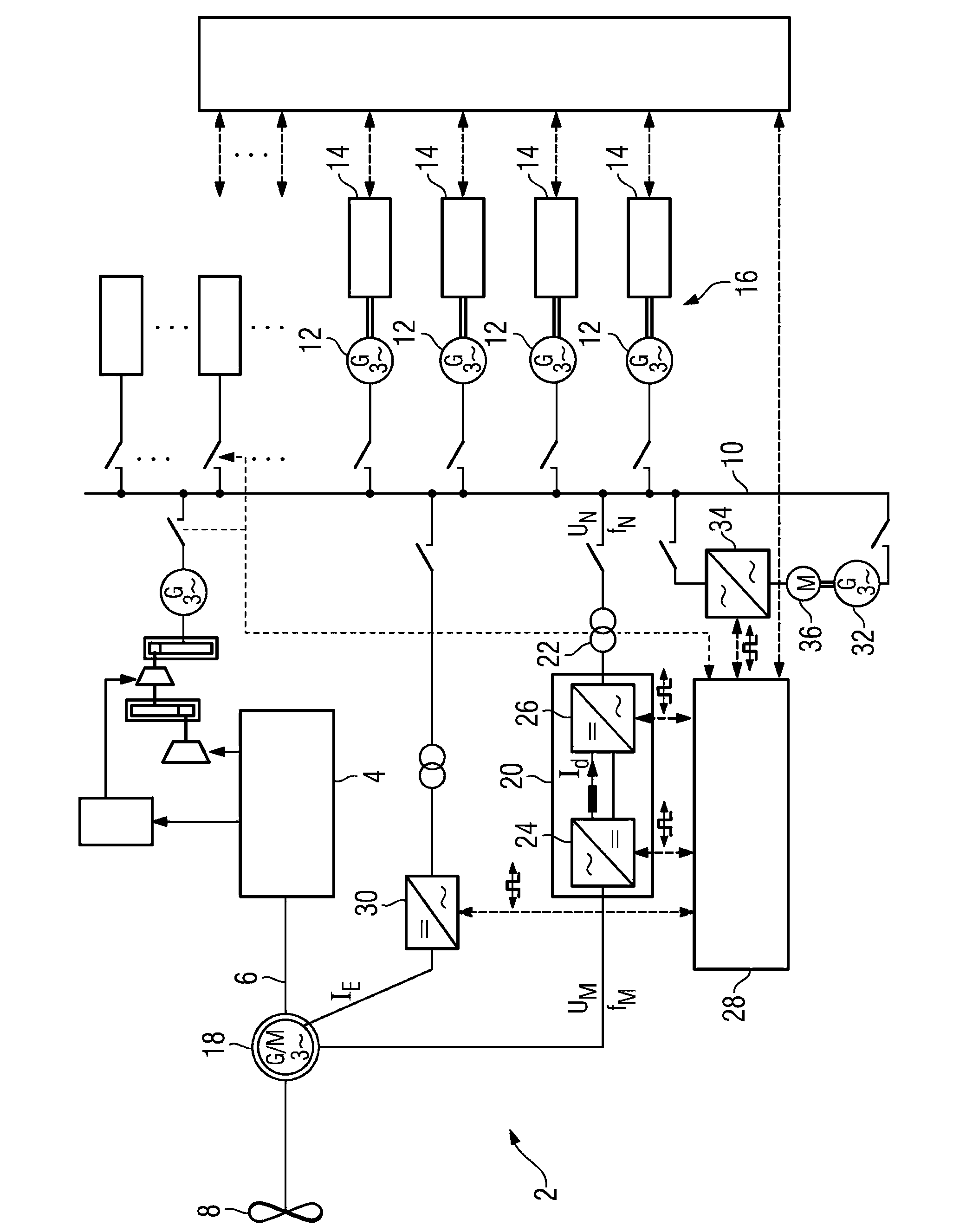

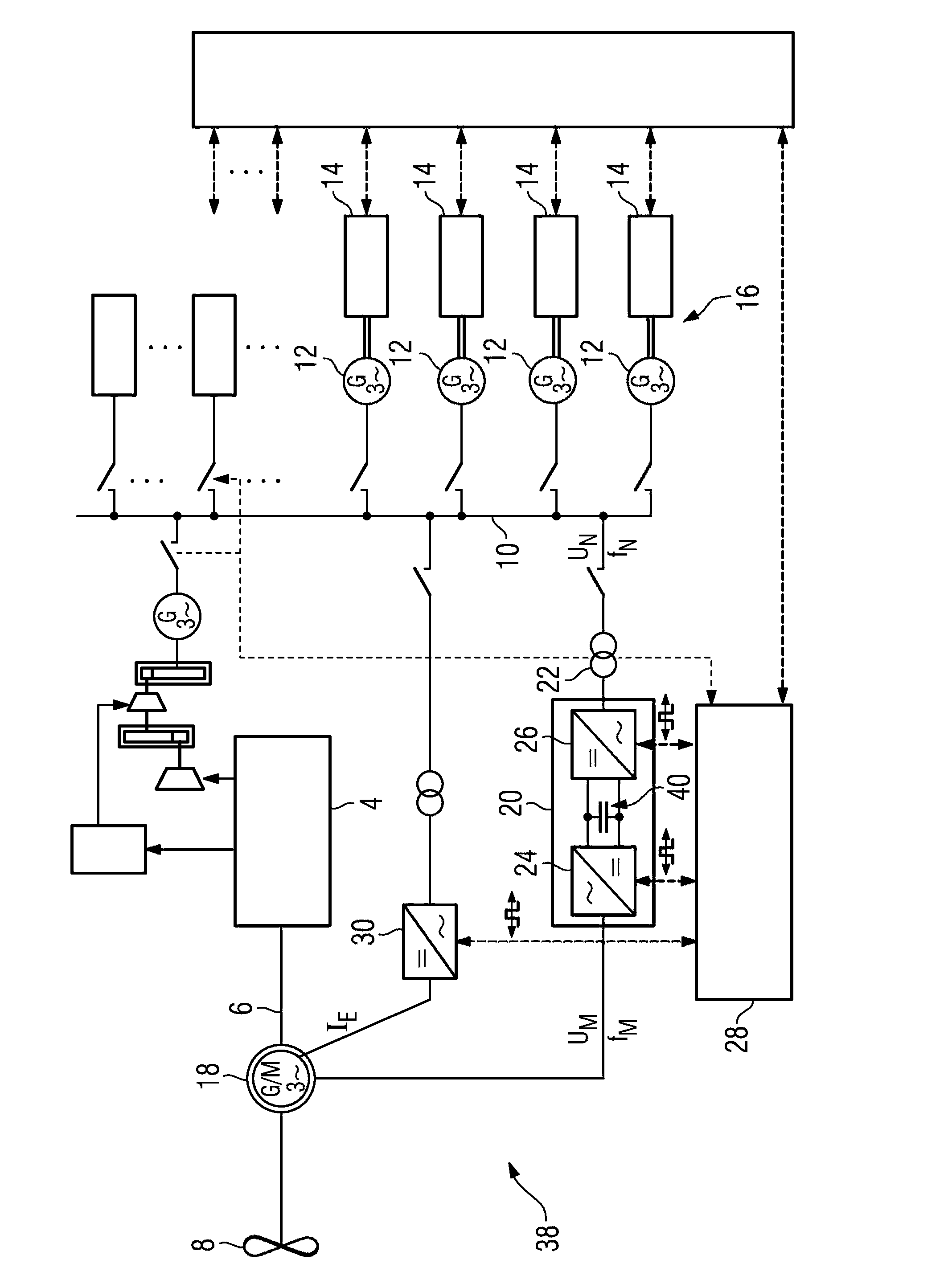

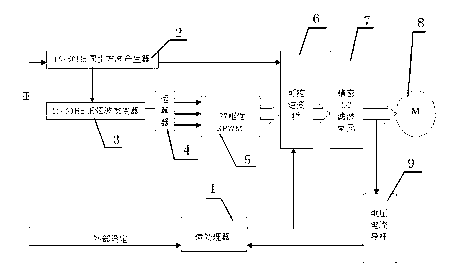

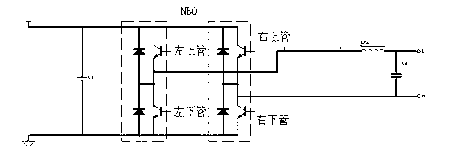

Shaft generator system

ActiveCN102934343BSatisfy Reaction RequirementsMeet short-circuit-safetyGenerator control circuitsPropulsion based emission reductionFrequency changerĆuk converter

A shaft-driven generator system has a generator connected to a converter. An inverter supplies an AC voltage on a network side. The converter and the inverter are linked via a DC link circuit. The inverter has at least two phase modules, which each have an upper and a lower valve branch, which each have a plurality of two-pole sub-systems connected electrically in series. Each sub-system has a unipolar storage capacitor, to which a series circuit of two gate-controlled turn-off semiconductor switches is connected electrically in parallel. Each semiconductor switch has a diode connected antiparallel therewith. Thus, a shaft-driven generator system is obtained that has a DC-link converter as a static frequency converter for complying with the required network feedback and for managing transient operating states.

Owner:INMONDA CO LTD

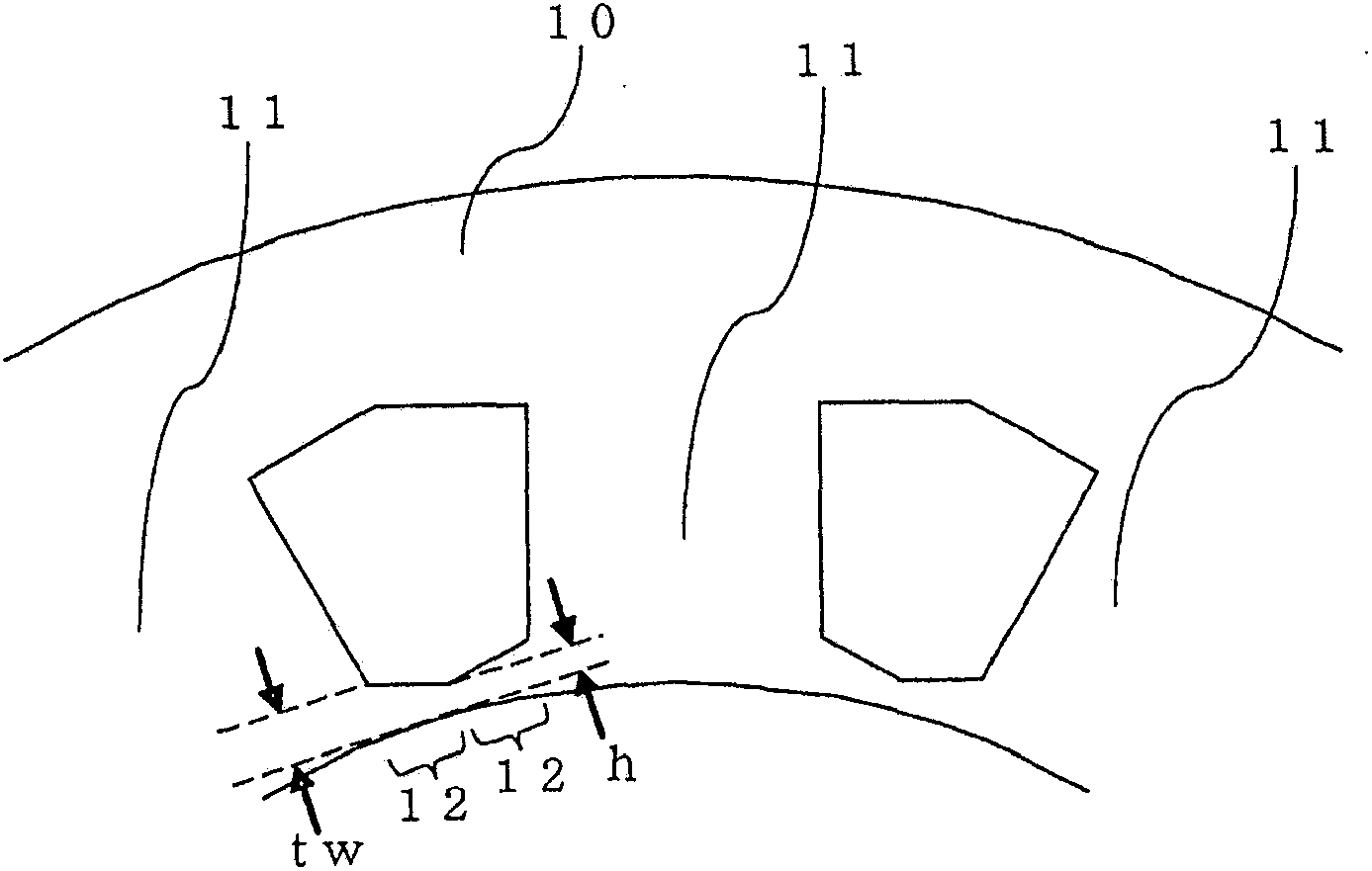

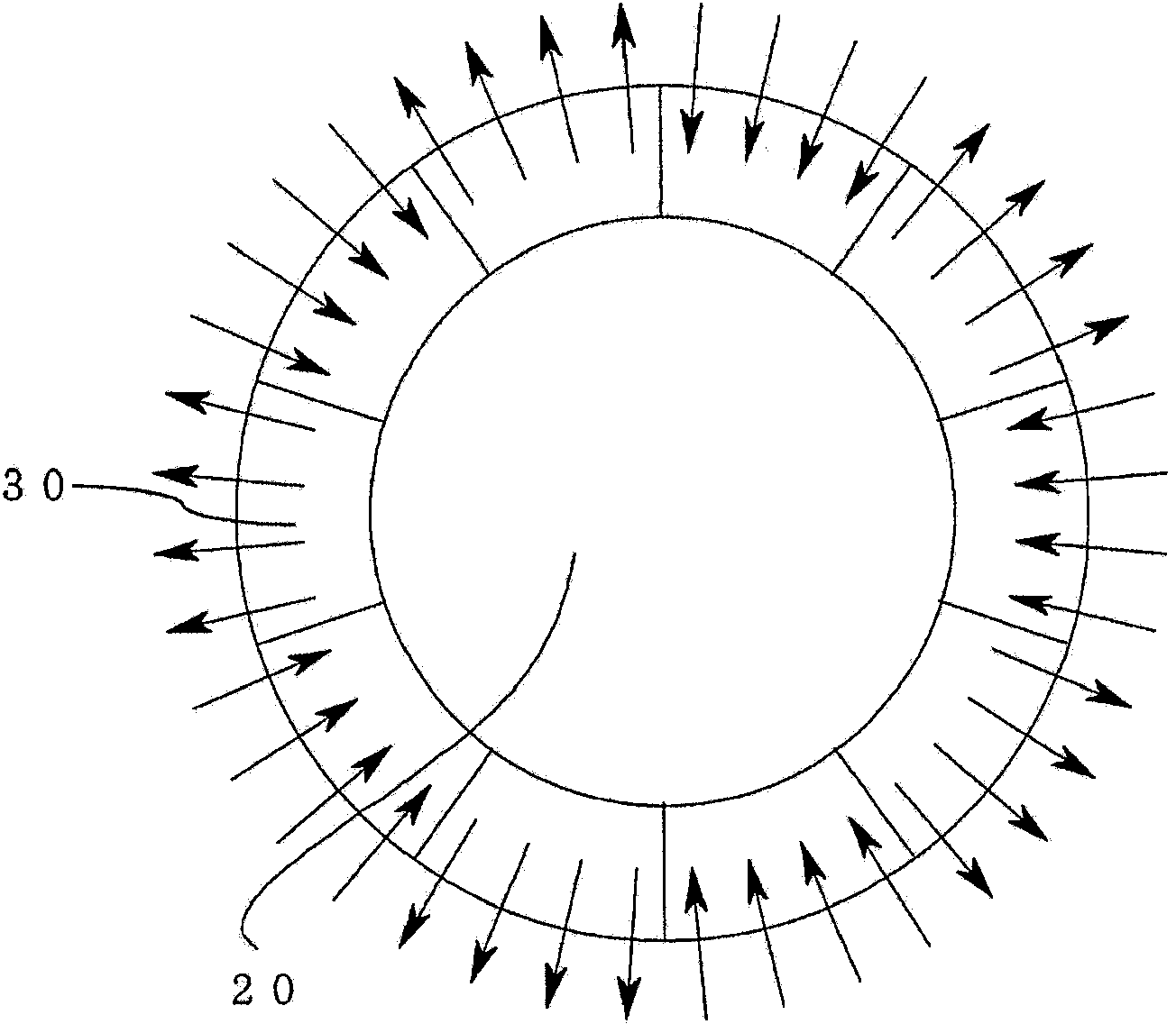

Permanent-magnet synchronous motor

ActiveCN102668329BReduce higher harmonic contentMagnetic circuit rotating partsManufacturing stator/rotor bodiesSynchronous motorPermanent magnet synchronous motor

Provided is a permanent-magnet synchronous motor whereby a 12f component of torque ripple can be minimized when using a radial anisotropic ring magnet in a small-diameter motor. Said synchronous motor has Z annular stators with wire windings and a permanent magnet with 2P poles, Z / (3·2P) being either 2 / 5 or 2 / 7 (3 being the number of phases). If a radial anisotropic ring magnet is used as the permanent magnet, a 12f component of torque ripple can be minimized by magnetizing the radial anisotropic ring magnet such that the ratio of a flat region to a transition region in the magnetization waveform of one magnetic pole has an appropriate value given tw / h, where h is the tip width of flange parts constituting the tip sections of the stators and tw is the base width of said flange parts.

Owner:MITSUBISHI ELECTRIC CORP

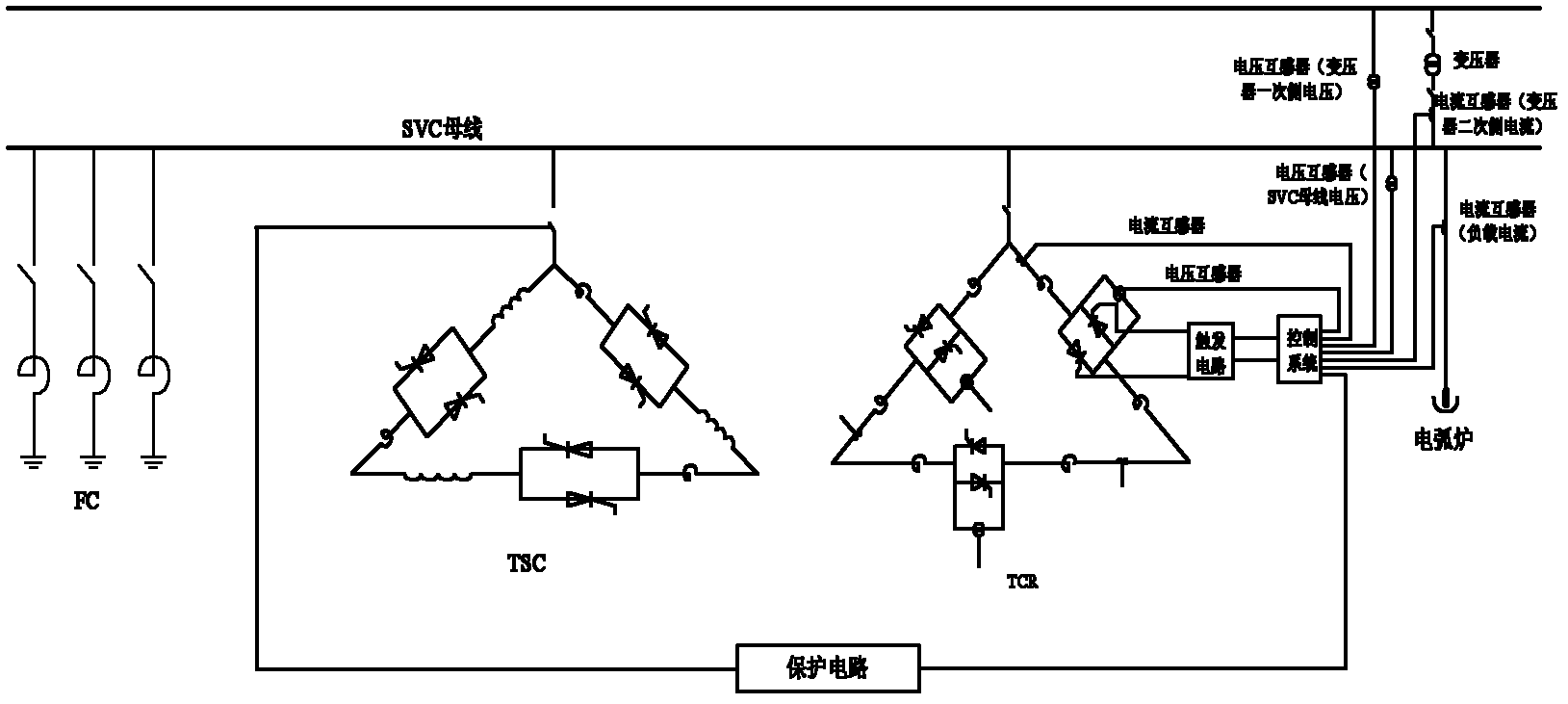

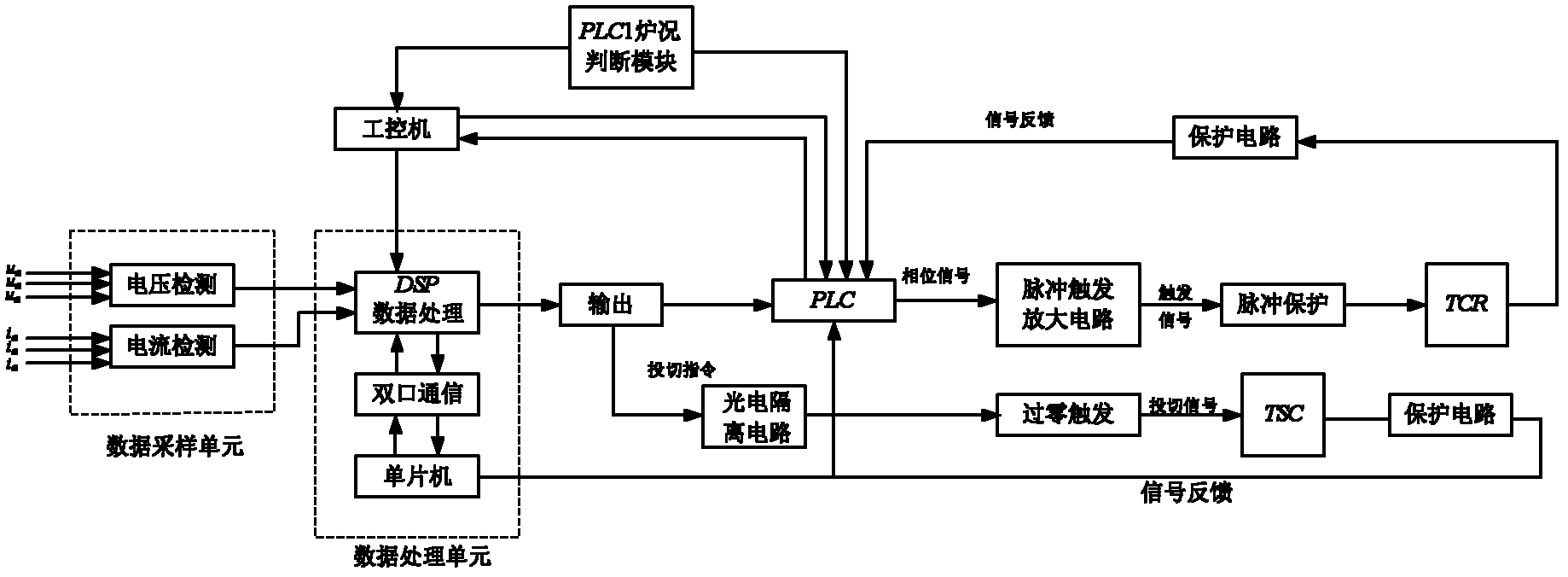

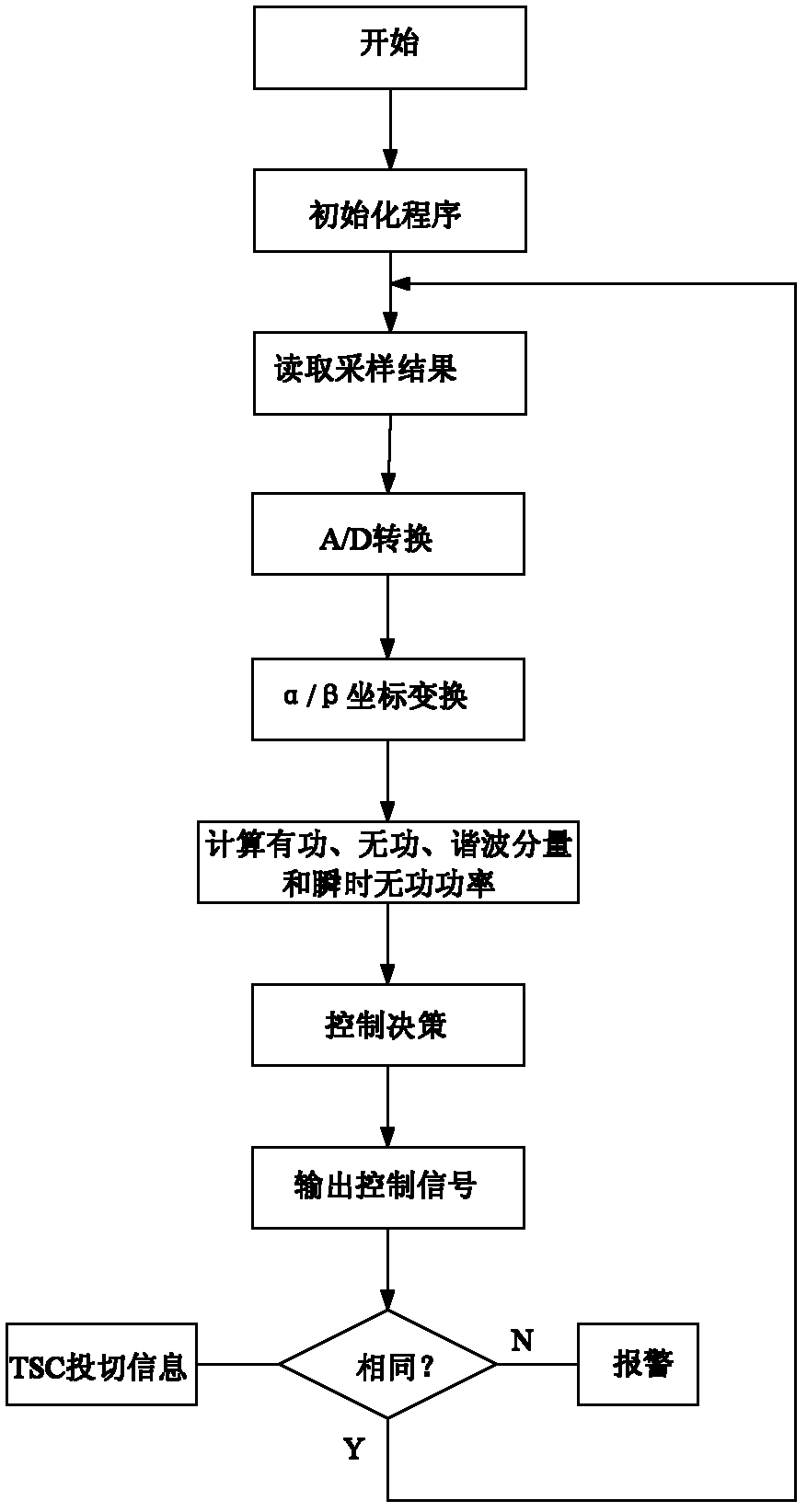

Arc furnace power quality controller based on programmable logic controller (PLC)

InactiveCN102354993BGood compensationReduce higher harmonic contentFlexible AC transmissionReactive power adjustment/elimination/compensationPower qualityElectric arc furnace

The invention relates to an arc furnace power quality controller based on a programmable logic controller (PLC), which mainly comprises a control system and a power quality improvement system, wherein the control system consists of an industrial personal computer, a PLC and a digital signal processor (DSP); and the power quality improvement system consists of thyristor switched capacitor - thyristor controlled reactor (TSC-TCR) reactive power compensation device and an auxiliary circuit. The controller can adjust compensation parameters in real time to improve compensation accuracy according to instantaneous reactive power in combination with furnace condition information. The arc furnace power quality controller based on the PLC has the advantages that the rapid real-time compensation can be realized aiming at the change of the reactive power and the power factor, the operating cost is low and the control stability is high.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

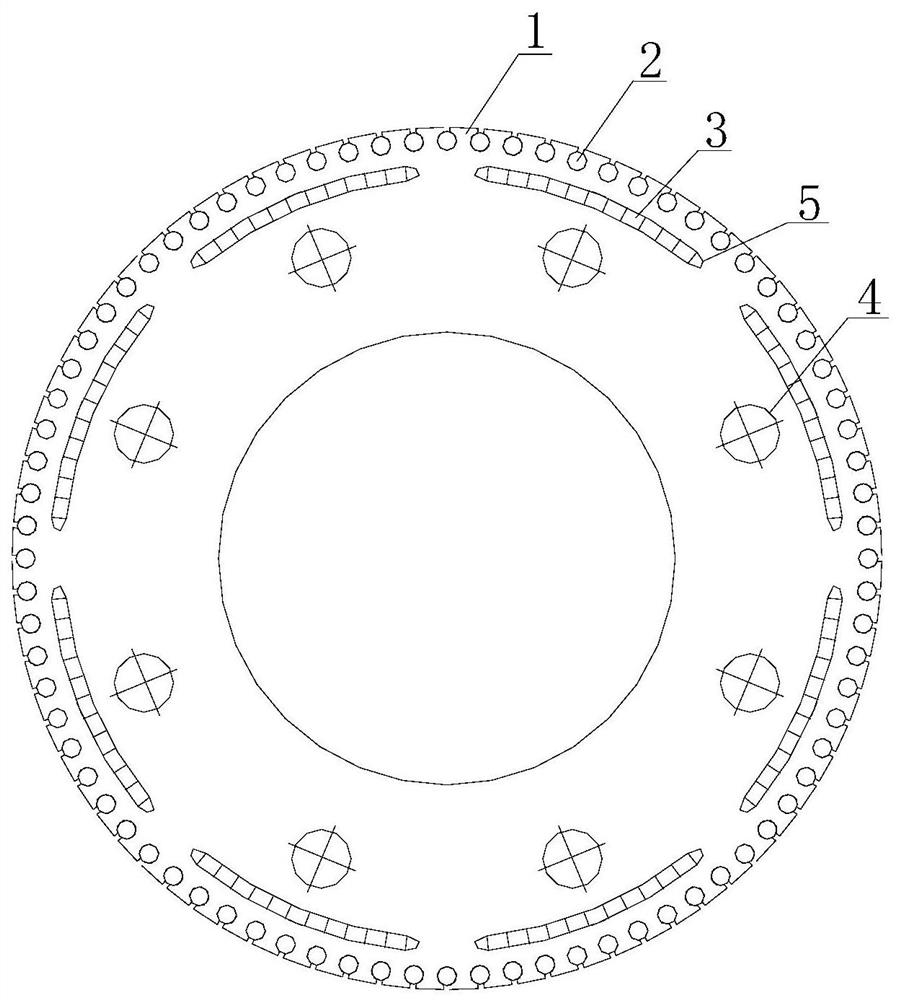

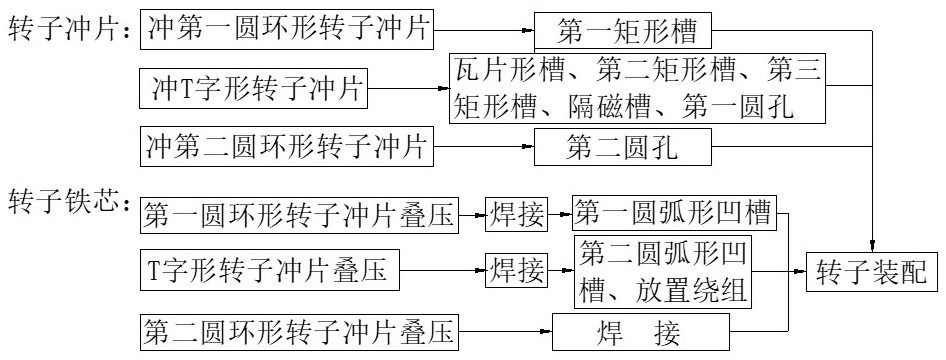

Rotor core structure of asynchronous starting permanent magnet synchronous motor

PendingCN111697724AReduce lossReduce higher harmonic contentMagnetic circuit rotating partsSynchronous machinesPunchingElectric machine

The invention discloses a rotor core structure of an asynchronous starting permanent magnet synchronous motor, and the structure comprises a rotor punching sheet group which is formed by superposing aplurality of rotor punching sheets, and a rotor magnetic steel which is embedded on the rotor punching sheets, wherein the rotor punching sheets are annular, the rotor punching sheets are provided with damping holes, and the damping holes are located in the annular edge; damping strips are arranged in the damping holes in a penetrating mode, heat dissipation channels are formed in the damping holes, the heat dissipation channels extend to the outer ring face of the rotor punching sheet, arc-shaped magnetic steel grooves are formed in the rotor punching sheet, rotor magnetic steel is embeddedin the magnetic steel grooves, the rotor magnetic steel adopts a magnetizing mode of a Halbach array, and axial ventilation holes are formed in the rotor punching sheet. According to the rotor core structure of the asynchronous starting permanent magnet synchronous motor, the 380V-8p-30kW motor has good operation performance, the noise and vibration of the motor can be reduced, and meanwhile, theworking performance of the motor is improved.

Owner:JIANGSU AEROSPACE POWER ELECTRIC

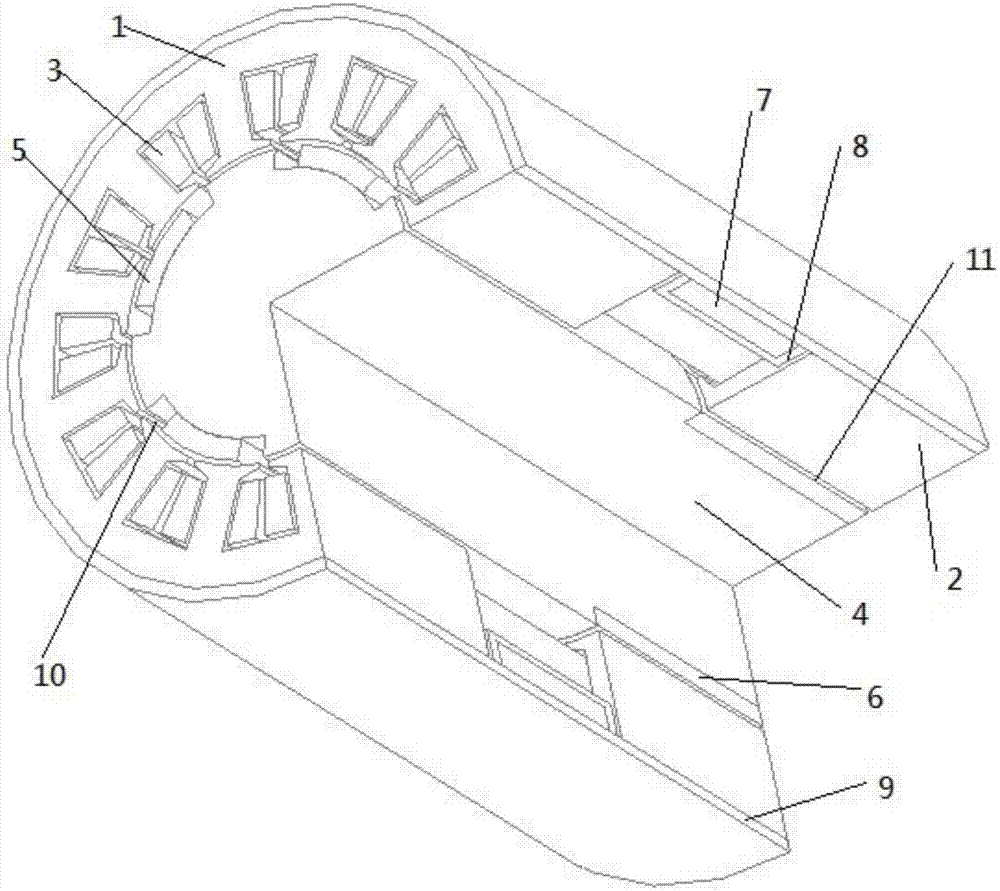

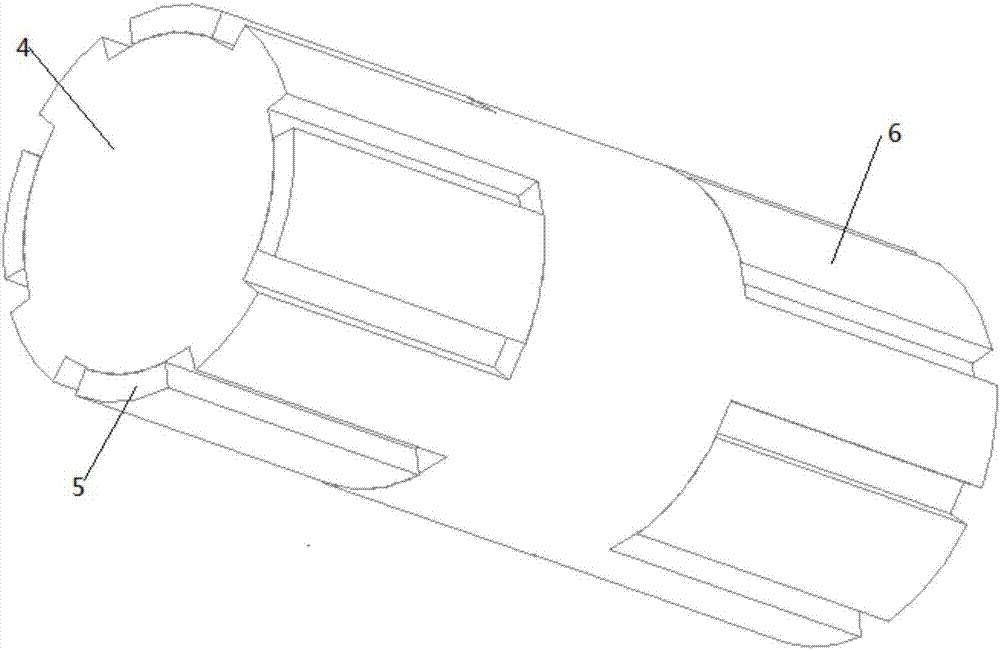

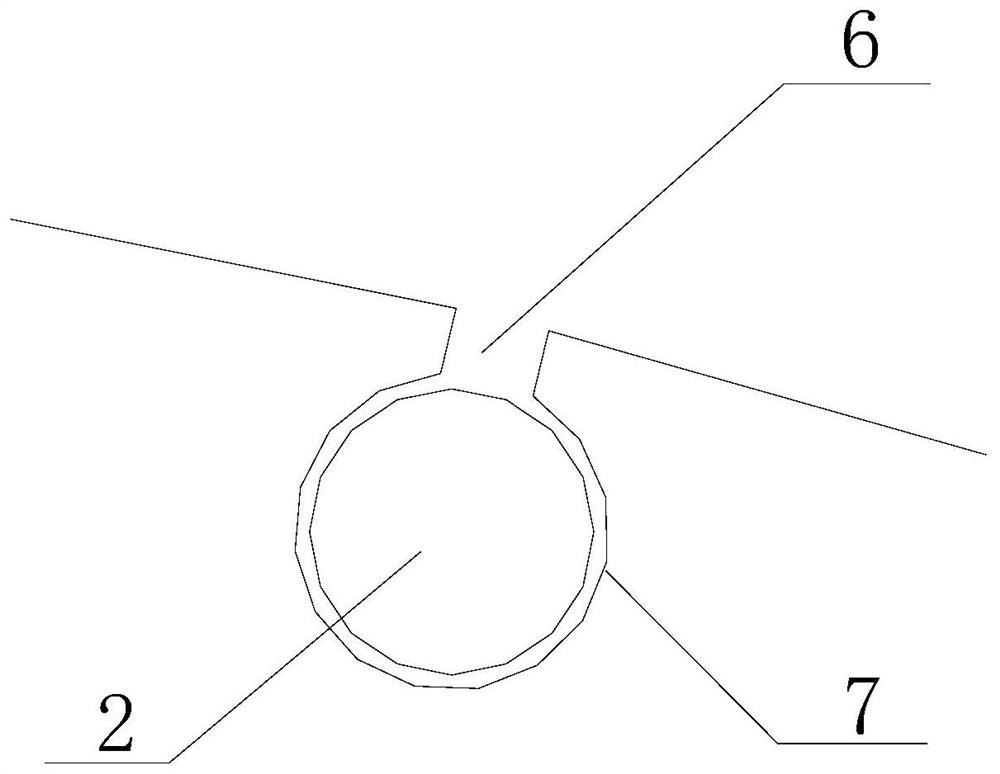

Locking ring type modular double excitation drive motor rotor production method

ActiveCN112600371BReduce manufacturing costEasy to manufactureManufacturing stator/rotor bodiesElectric machineWire cutting

The invention provides a locking ring type modular double excitation drive motor rotor production method, which belongs to the technical field of automobile motors and electrical appliances. The locking ring-type modular double-excitation drive motor rotor core punching is easy to process, and the wire cutting path is less complicated; the off-line winding is easy to machine operation, convenient and fast, and the third rotor core is used as a locking ring, which can be used as A part of the magnetic circuit can realize the axial fixation of the modular rotor, and the effect of multi-winding and multi-permanent magnets can be achieved in the limited space inside the motor, thereby improving the power density of the motor; the magnet in the rotor structure adopts three layers The structure, the second permanent magnet steel and the third permanent magnet steel combined with the magnetic isolation groove can better play the role of magnetic circuit blocking, the first permanent magnet steel can play its magnetic attraction role, and weaken the high-order harmonic content of the back electromotive force of the drive motor , to improve the performance of the motor.

Owner:SHANDONG UNIV OF TECH

Stator assembly and motor

InactiveCN106059133AGuaranteed pole distanceLow calorific valueMagnetic circuit stationary partsWindings conductor shape/form/constructionPhysicsMagnetic circuit

The invention discloses a stator assembly and a motor. The stator assembly comprises a stator core and a stator winding. The stator core has 36 stator slots. The stator winding comprises A, B, and C phases of stator windings, the common end of the A, B, and C phases of stator windings is in a star connection or triangular connection. The A, B, and C phases of stator windings comprise four sets of coil groups, and each set of coil groups comprises a large coil, a middle coil and a small coil. The large, middle and small coils of each set of coil groups of the A, B, and C phases of stator windings are uniformly embedded into the 36 stator slots according to a rule that the winding pitches of the large coils are 8, the winding pitches of the middle coils are 6, and the winding pitches of the small coils are 4, wherein the a double-winding design is employed by the A, B, and C phases of stator windings, and the elements of two different phases are placed in each one of the stator slots. According to the invention, the structure of the motor stator winding is improved, the magnetic saturation of a motor stator magnetic circuit is reduced, and the output performance of the motor is improved.

Owner:FOSHAN WEILING WASHER MOTOR MFG

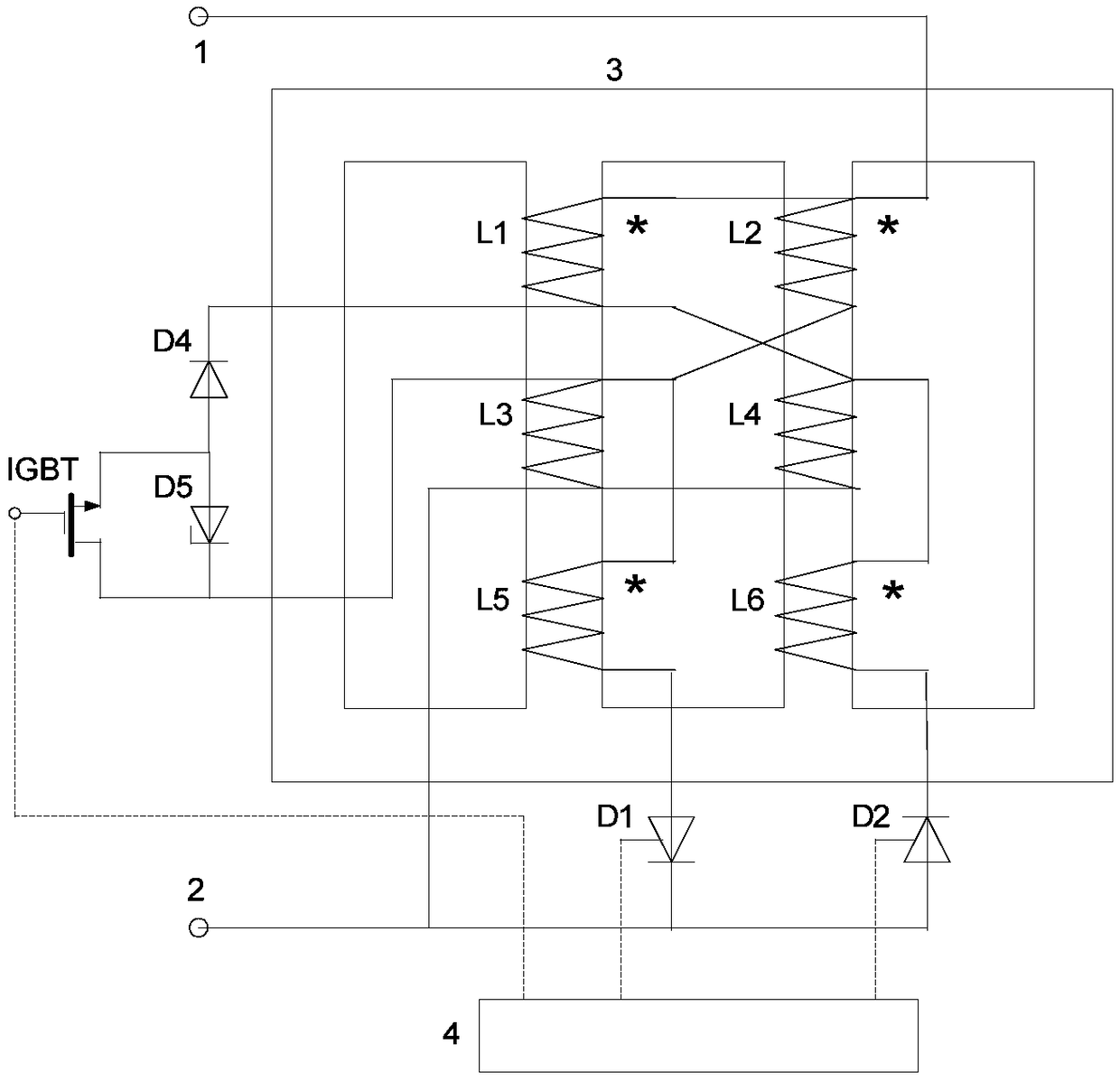

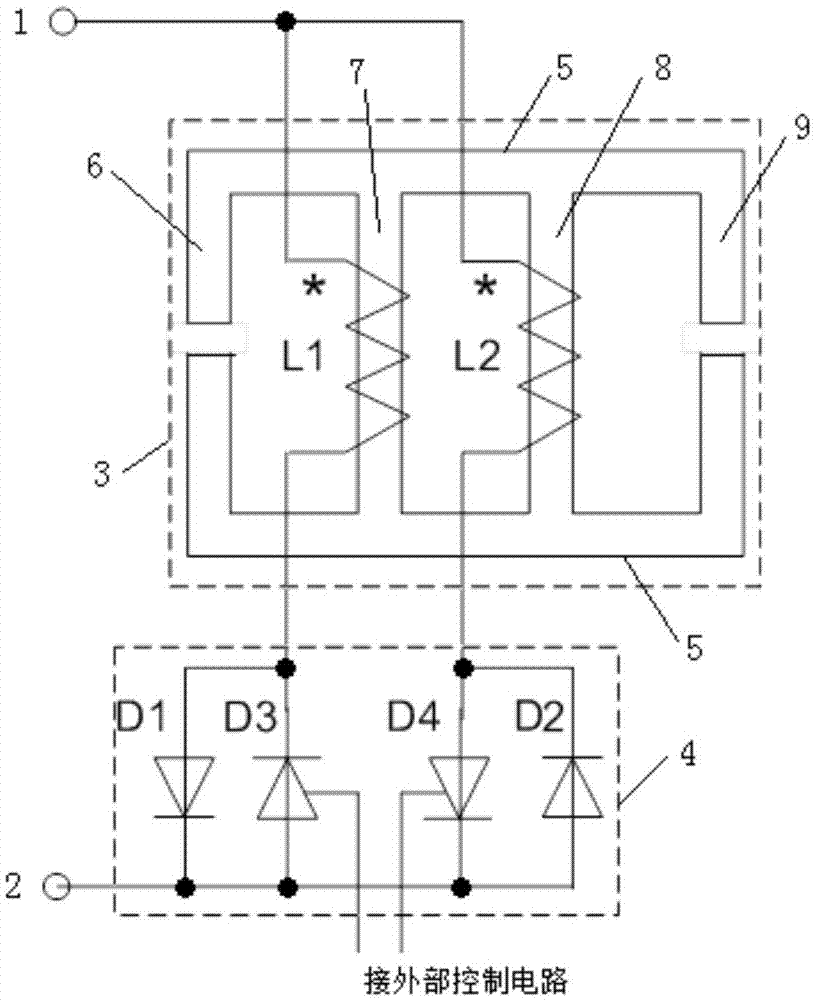

Magnetically controlled reactor

InactiveCN105448501ASimple structureContinuous adjustment of reactance valueTransformers/inductances coils/windings/connectionsConversion without intermediate conversion to dcHarmonicControl signal

The invention discloses a magnetically controlled reactor, comprising a first terminal, a second terminal, a closed-loop iron core and a controllable rectifying circuit, wherein the closed-loop iron core comprises four iron core legs, the sections of the four iron core legs have the same area, two ends of each two iron core legs are connected by magnet yokes, and two iron core legs placed in the middle portion of the closed-lop iron core are respectively wound with a coil; the dotted terminals of the first and second coils are respectively connected with the first terminal while the non-dotted terminals are respectively connected with the output end of the controllable rectifying circuit; the input end of the controllable rectifying circuit is connected with an external control circuit for rectifying under the control of control signals output by the external control circuit. The magnetically controlled reactor provided by the invention has the advantages of simple structure and fewer higher harmonic waves.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

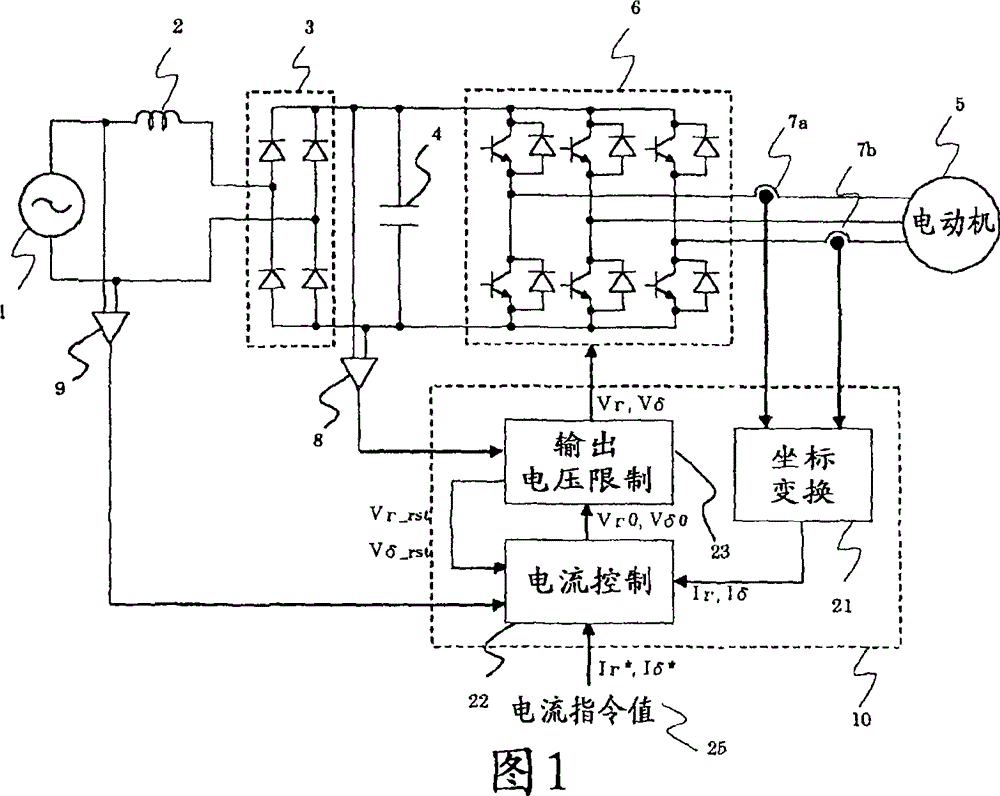

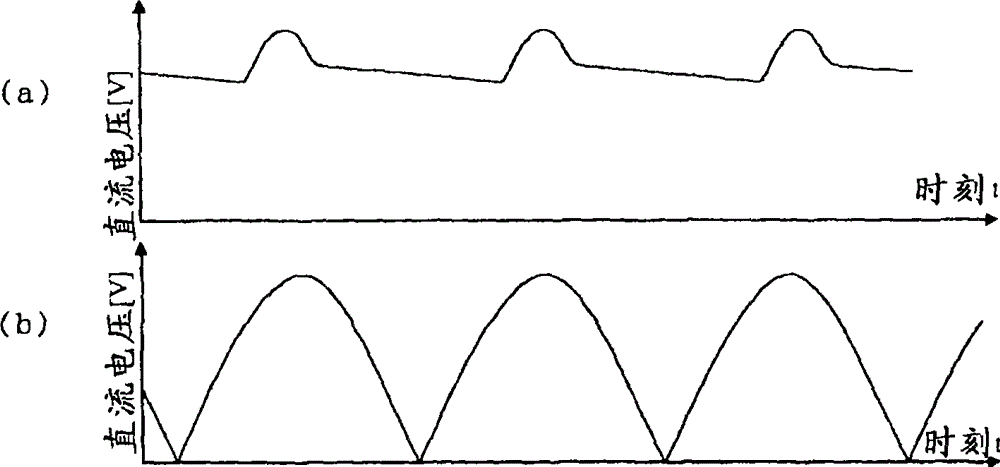

Electromotor driving device and compressor driving device

ActiveCN101449456BLow costReduce higher harmonic contentVector control systemsAc-dc conversionPower inverterPower flow

This invention claims an electromotor driver and compressor driver loading the motor driver. The motor driver makes the capacitor smoothing the commutated direct voltage of alternating current power be small capacity or do not be set. It realizes small size, light weight and low cost, furthermore, it can reduce higher harmonic current of input current effectively. The electromotor driver comprises a rectifying unit (3) for rectifying the AC voltage from AC supply to DC voltage, an inverter main circuit part (6) for transforming the DC voltage output by the rectifying unit (3) to AC voltage and applying the AC voltage to the electromotor (5); and a control unit (10) for controlling the voltage from the inverter main circuit part (6)applied to the electromotor (5), wherein the control unit (10) is provided with an output voltage limiting unit (23) for limiting the voltage applied to the electromotor (5) to let the scalar value of the voltage applied to the electromotor below the fixed maximum voltage output by the rectifying unit (3) and feed the voltage limitation of the output voltage limiting unit (23) to the control unit (10).

Owner:MITSUBISHI ELECTRIC CORP

Harmonic Elimination Radial Magnetic Circuit Multipole Resolver and Signal Winding Winding Method

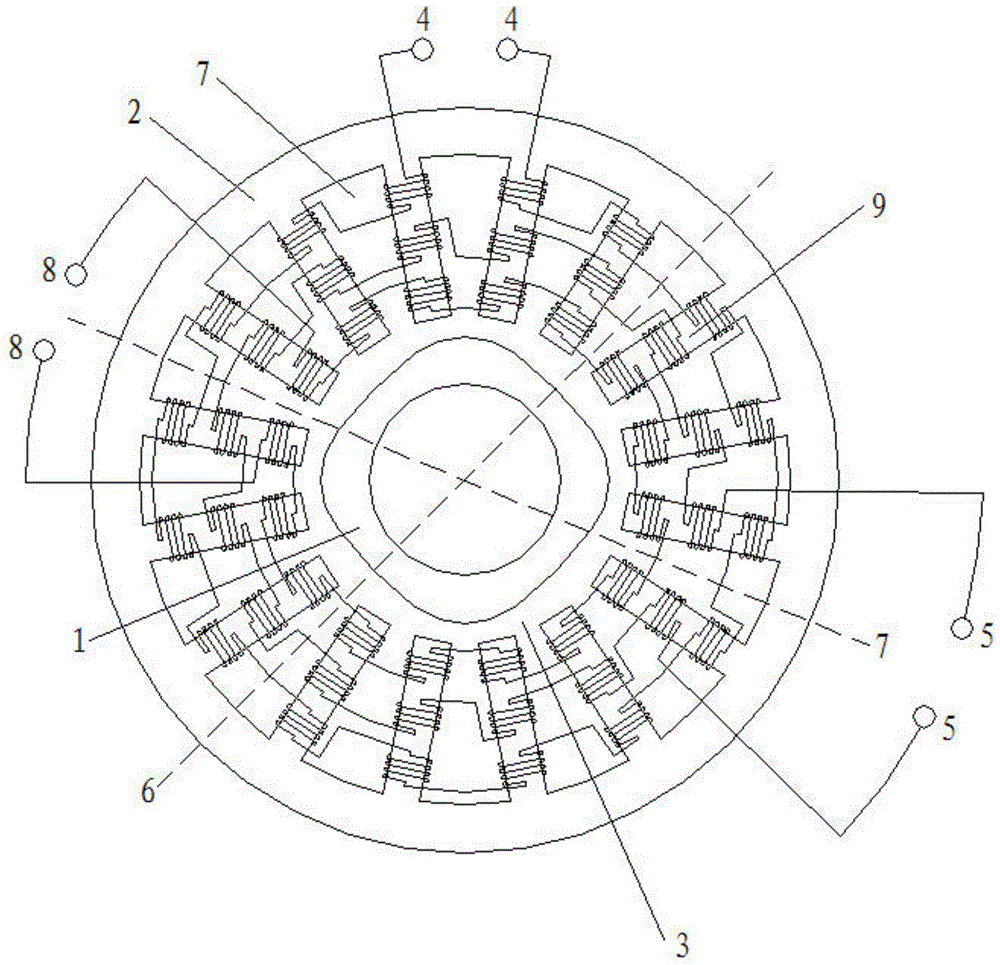

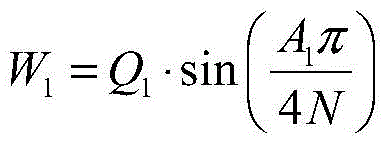

ActiveCN104200973BHigh measurement accuracyCompact structureMagnetic circuit rotating partsTransformersPhase differenceConductor Coil

The invention discloses a harmonic-wave eliminating type radial magnetic circuit multipolar rotary transformer and a winding method of signal windings, belongs to the technical field of transformers and aims to solve the problem that a radial magneto-resistive type rotary transformer is low in precision, enlarged in size with increase of number of pole-pairs and limited in application field. Unequal air gaps are arranged between a stator and a rotor, 4NP stator grooves and 4NP stator teeth are processed on the inner surface of the stator axially, an excitation winding is disposed in the 4NP stator grooves, and sine and cosine signal windings are wound on the 4NP stator teeth. The method includes: optionally selecting a plane passing an axis of the stator and not intersecting with the stator teeth, uniformly dividing the 4NP stator teeth into 4P groups clockwise, from the plane, and winding the first group of N adjacent stator teeth anticlockwise, winding the N adjacent stator teeth clockwise, wherein winding modes of the sine and cosine signal windings are identical, and phase difference between the sine and cosine signal windings is a 90 electrical degrees. The rotary transformer and the winding method are applied to fields such as electric vehicles, aviation, aerospace and the like.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com