Arc furnace power quality controller based on programmable logic controller (PLC)

A technology of electric energy quality and electric arc furnace, applied in flexible AC transmission system, AC network to reduce harmonics/ripples, harmonic reduction devices, etc. Sub-harmonic content, improved compensation effect, flexible control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Electric arc furnace power quality controller based on PLC

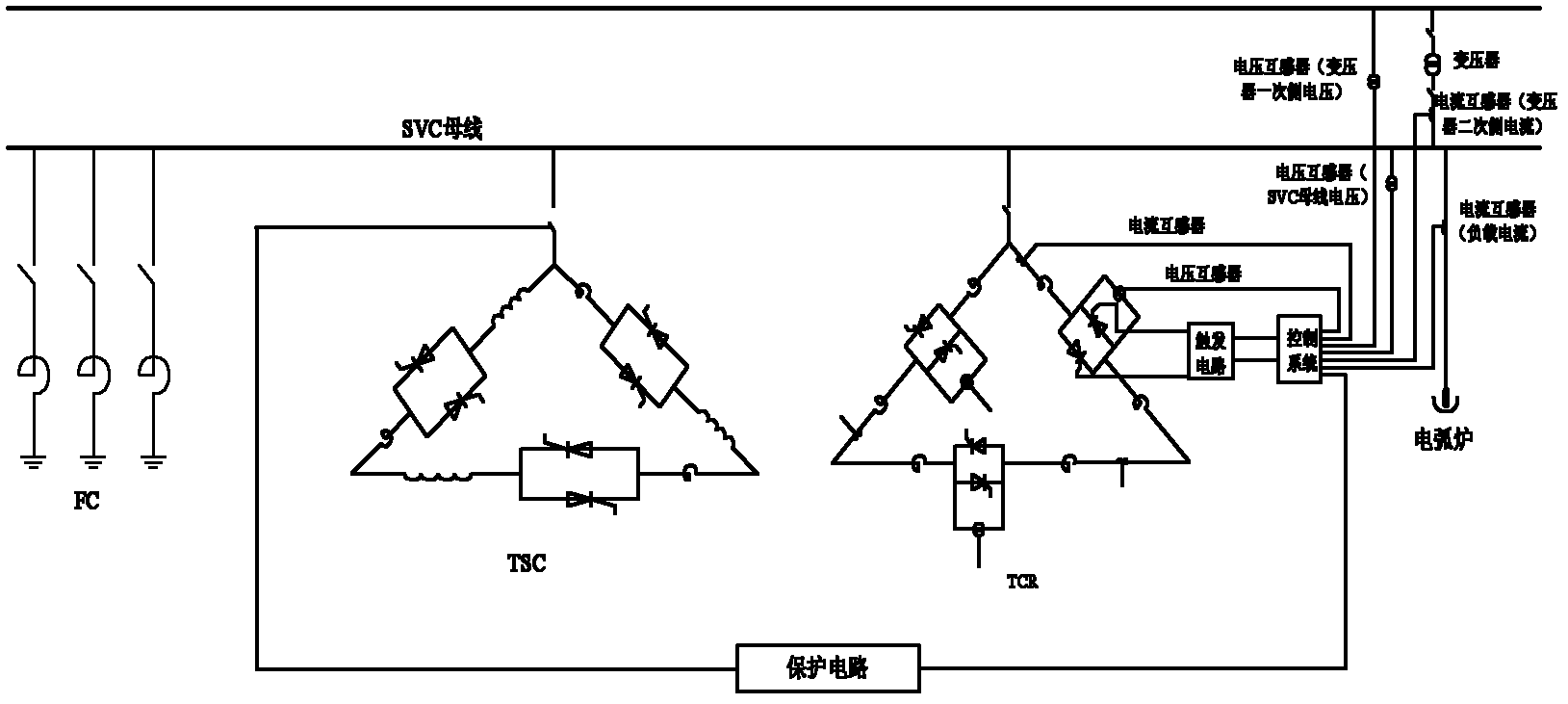

[0045] This example provides an electric arc furnace power quality controller based on S7-400PLC. The power quality controller system is as follows: figure 1 As shown, the electric arc furnace used in the present invention is a three-phase AC electric arc furnace, and the power quality controller is installed on the low-voltage side of the electric arc furnace transformer, and the detection unit transmits the detected three-phase instantaneous voltage and current data to the single control system, and the The control unit calculates and selects a control strategy to form a trigger pulse to control the reactive power compensation device.

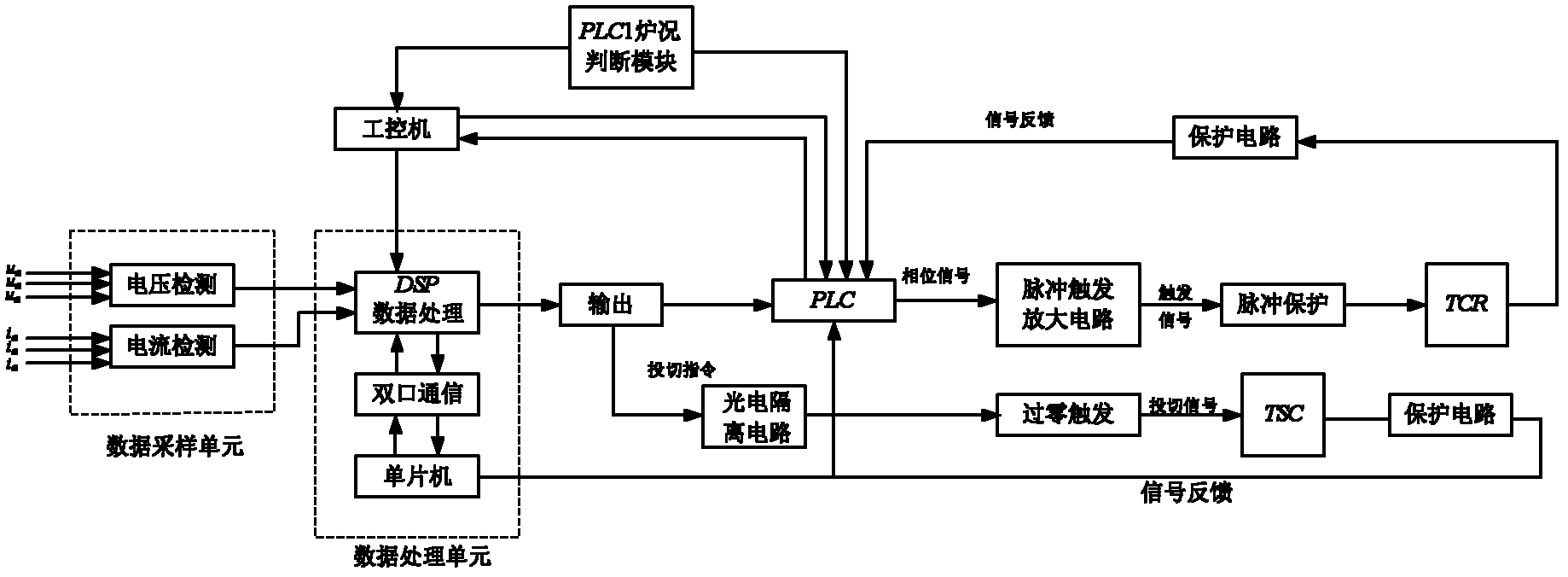

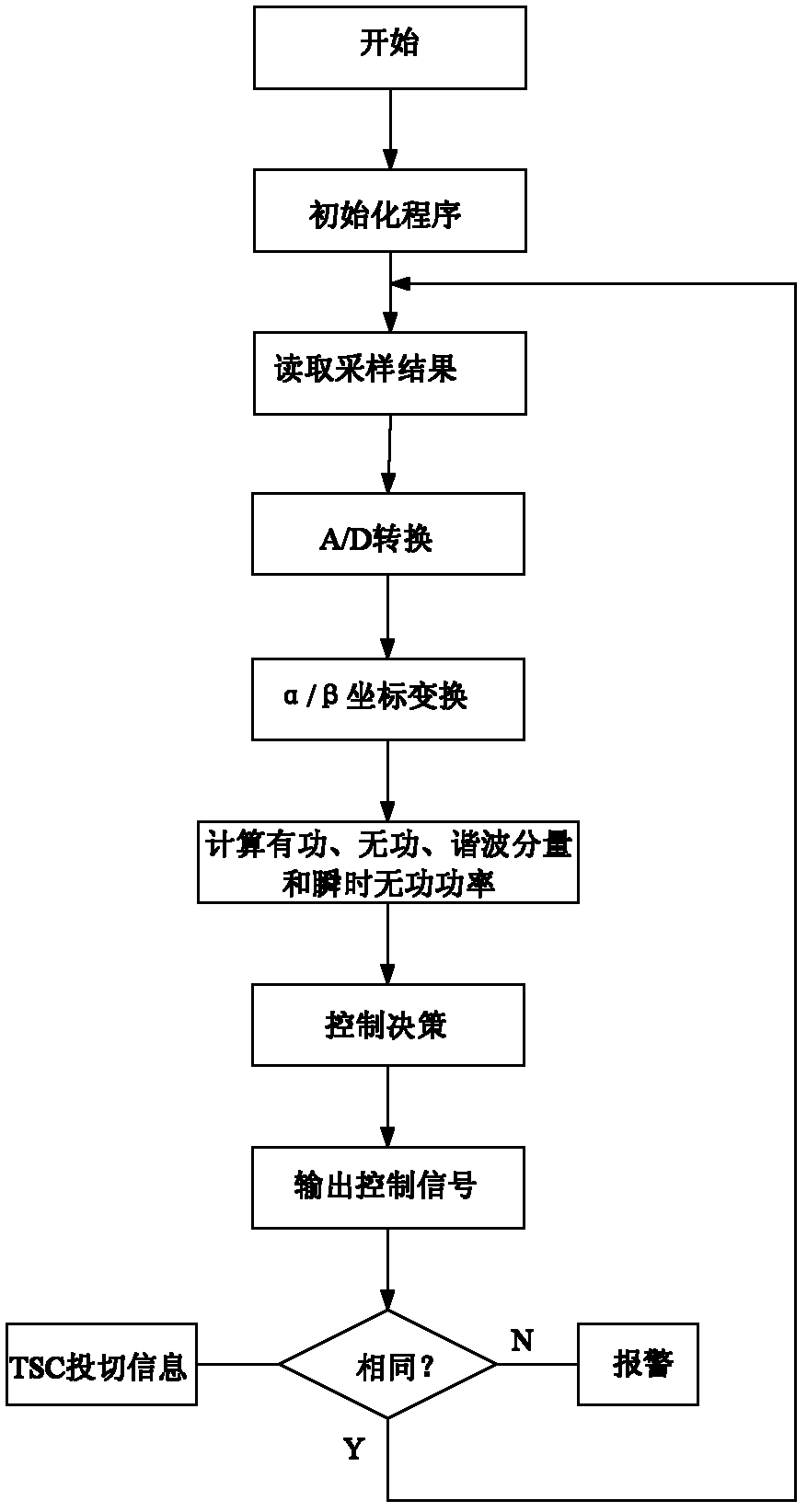

[0046] The principle of the control system is as figure 2As shown, the DSP receives and processes the collected instantaneous voltage and current values, calculates the number of TSCs required to be invested in combination with the furnace condition informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com