Rotor core structure of asynchronous starting permanent magnet synchronous motor

A technology for permanent magnet synchronous motors and rotor cores, applied to synchronous machines, magnetic circuit shape/style/structure, magnetic circuits, etc., to achieve the effects of shortening start-up time, improving performance indicators, and reducing harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

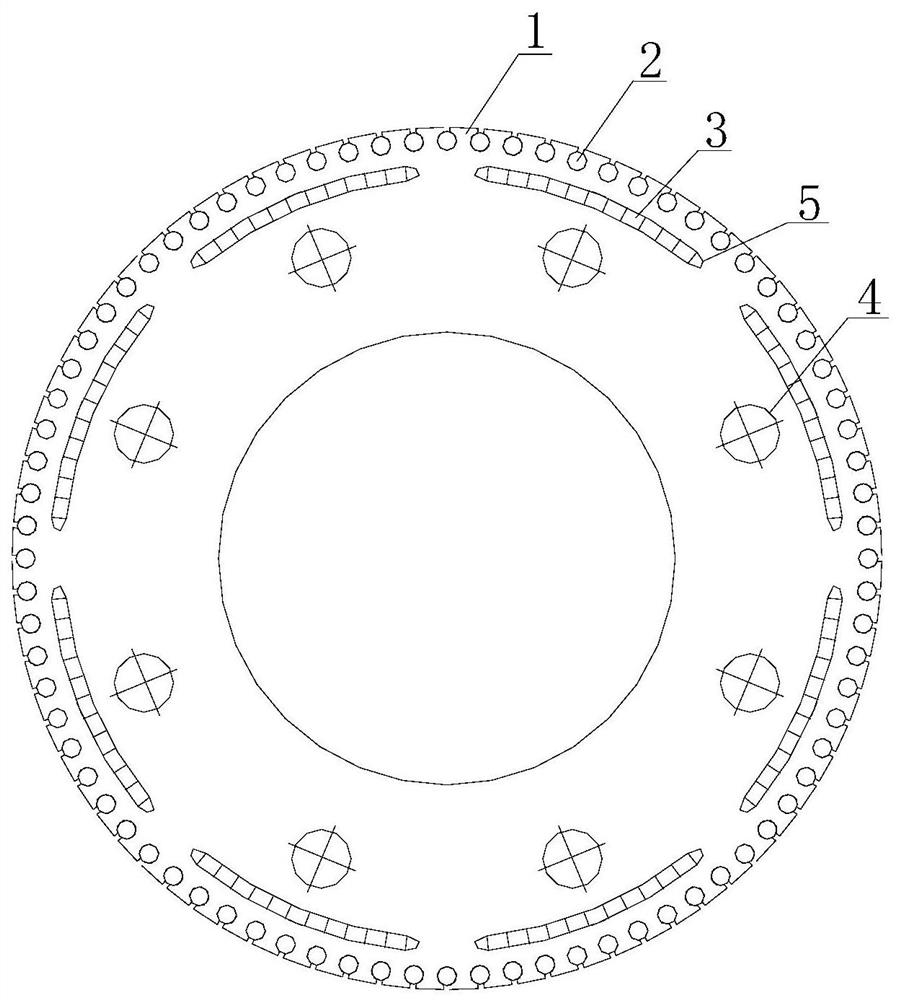

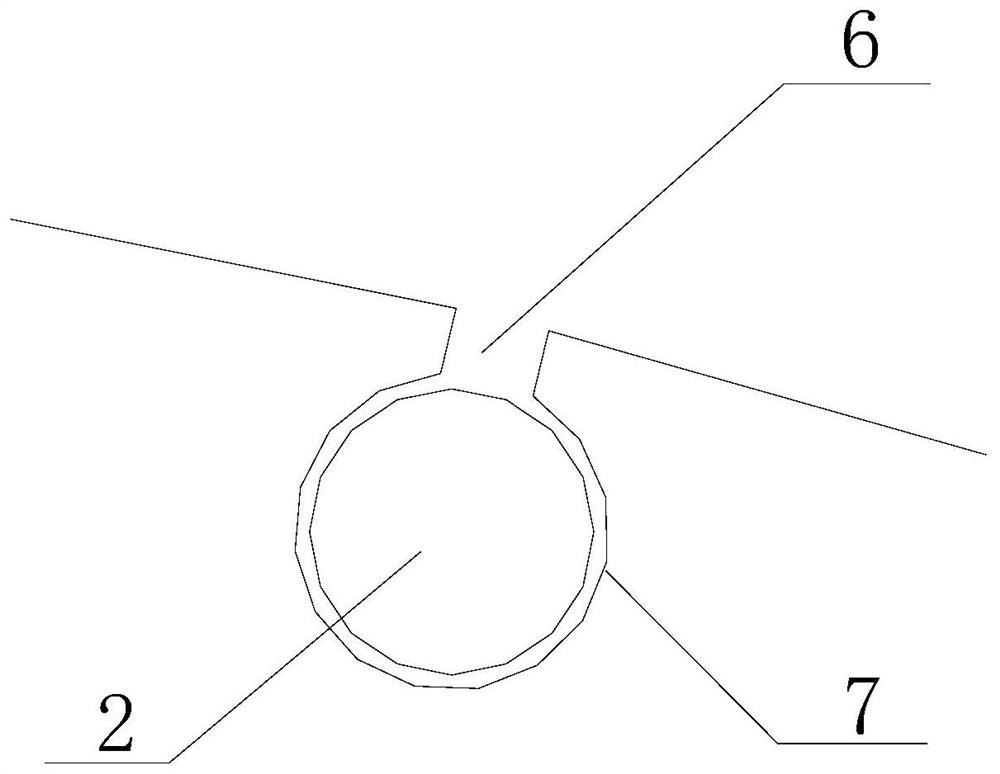

[0017] Such as figure 1 The rotor core structure of the asynchronously started permanent magnet synchronous motor shown includes a rotor punch group formed by overlapping several rotor punches 1 and a rotor magnetic steel 3 embedded on the rotor punch 1. The rotor punch 1 is ring-shaped , 80 damping holes 7 evenly distributed around the circumference are set on the rotor punch 1, and the damping holes 7 are located on the ring edge, and the damping strip 2 is pierced in the damping hole 7, and the damping strip 2 is made of brass rods, and the heat dissipation channel 6 is set on the damping hole 7 (Such as figure 2 As shown), the heat dissipation channel 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com