Locking ring type modular double excitation drive motor rotor production method

A technology for driving motors and production methods, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., which can solve the problems of motor output torque, low efficiency, difficulty in winding coils, and high cost of motors, and achieve improved The effect of winding density, eliminating welding, and easy machine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

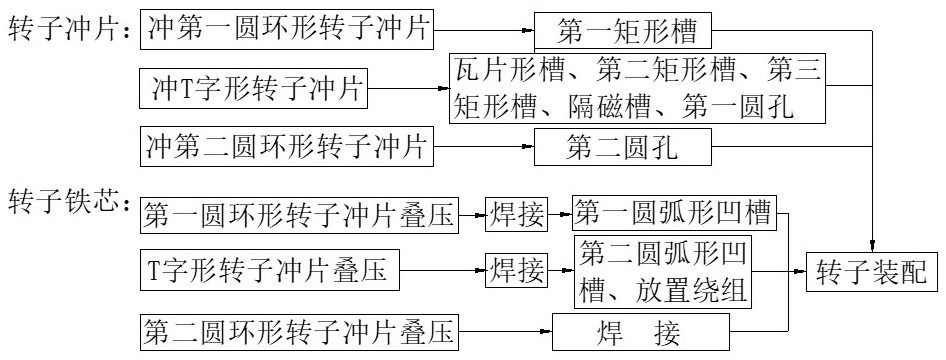

[0043] like Figure 1 to Figure 6 shown, including the following steps:

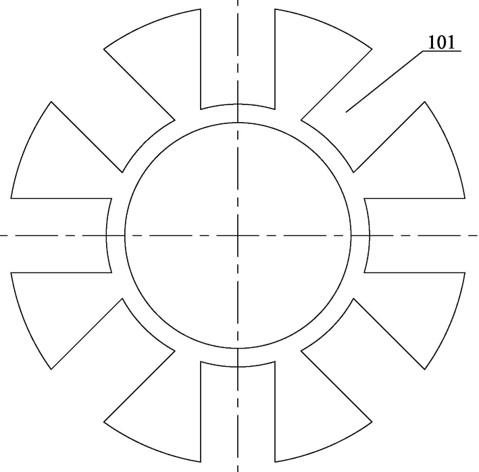

[0044] 1) Punching and cutting the first annular rotor punching piece 1, the first annular rotor punching piece 1 is evenly distributed with an even number of first rectangular grooves 101 penetrating through the axial thickness of the first annular rotor punching piece 1, the first The outer edge of a rectangular groove 101 is connected with the outer circle of the first annular rotor punch 1, the inner edge of the first rectangular groove 101 is not connected with the inner circle of the first annular rotor punch 1, and the inner edge of the first rectangular groove 101 is a concave surface Towards the arc shape of the center of the first annular rotor punch 1, a plurality of first annular rotor punches 1 are welded to form the first rotor core;

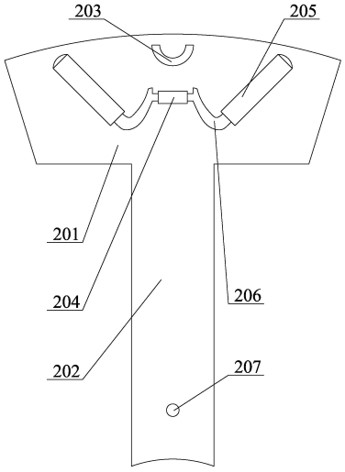

[0045] 2) Punching and shearing the T-shaped rotor punching sheet 2. The T-shaped rotor punching sheet 2 includes a transverse portion 201 and a longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com