Magnetism adjusting ring, magnetism adjusting ring assembly, magnetic gear and composite motor

A technology of magnetic gear and magnetic control ring, applied in the field of magnetic control ring, magnetic gear, magnetic control ring assembly, composite motor, can solve the problem of large output torque fluctuation, lack of magnetic control ring, high harmonic content, etc. problem, to achieve the effect of reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

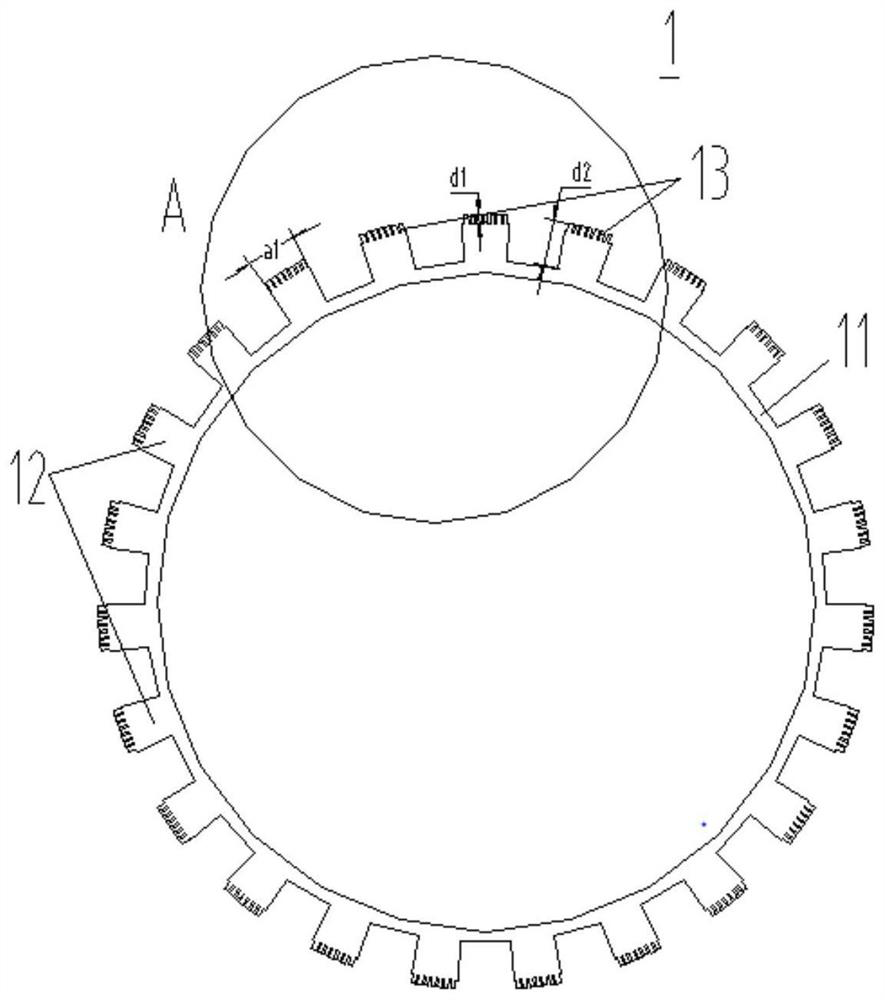

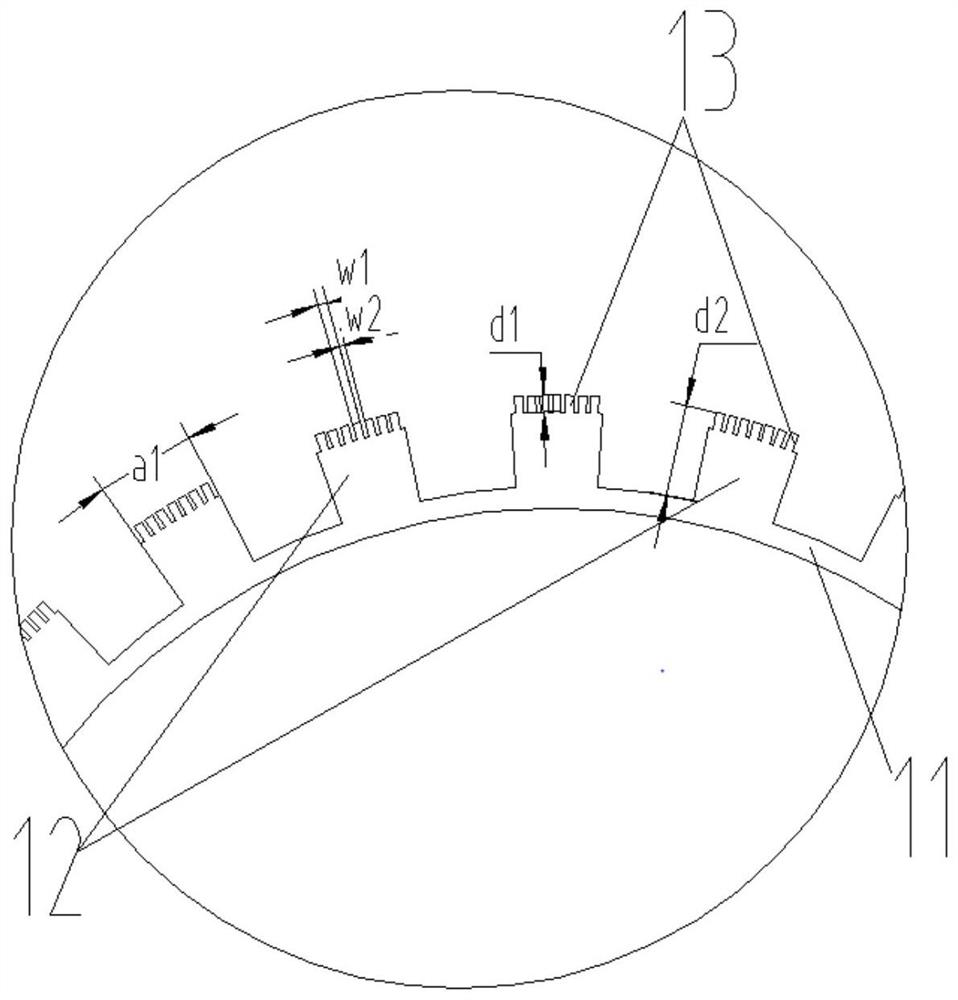

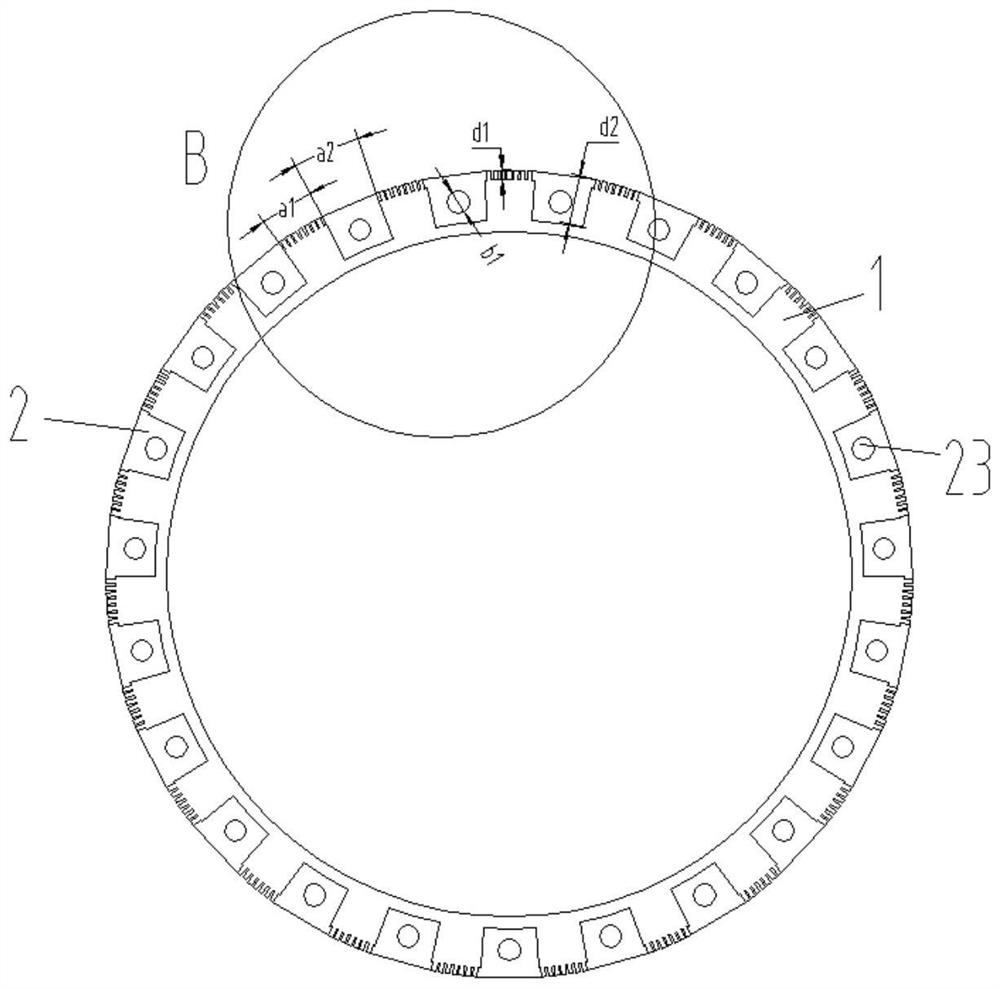

[0034] see in conjunction Figure 1 to Figure 13 As shown, according to an embodiment of the present invention, a magnetic modulation ring is provided, including an annular yoke 11 and a plurality of magnetic modulation protrusions 12 on the outer peripheral side wall of the annular yoke 11, and a plurality of magnetic modulation The protrusion 12 extends from the inside to the outside along the radial direction of the annular yoke 11, and the free end of the magnetic adjustment protrusion 12 has a plurality of teeth 13 on the side facing the outer rotor 200. The circumferential intervals of the yokes 11 are arranged. In this technical solution, by arranging a plurality of teeth 13 on the side of the free end of the magnetic adjustment protrusion 12 facing the outer rotor 200, the outer air gap (that is, the outer air gap of the magnetic gear during operation) can be effectively reduced. The higher harmonic content at the circumferentially extending gap between the free end a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com