Rotary machine

一种旋转电机、旋转轴的技术,应用在旋转电机的定子,车辆用交流发电机领域,能够解决制造工序复杂、增加导体、复杂化等问题,达到制作容易、降低高次谐波成分、工艺的简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

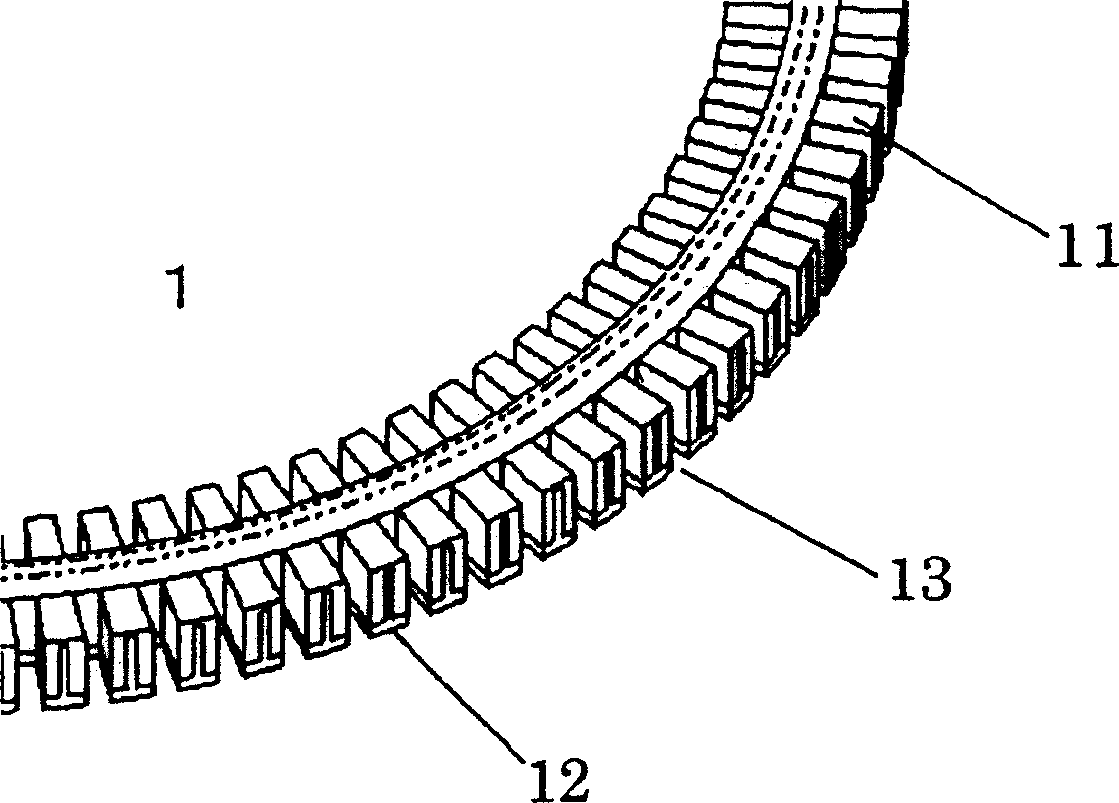

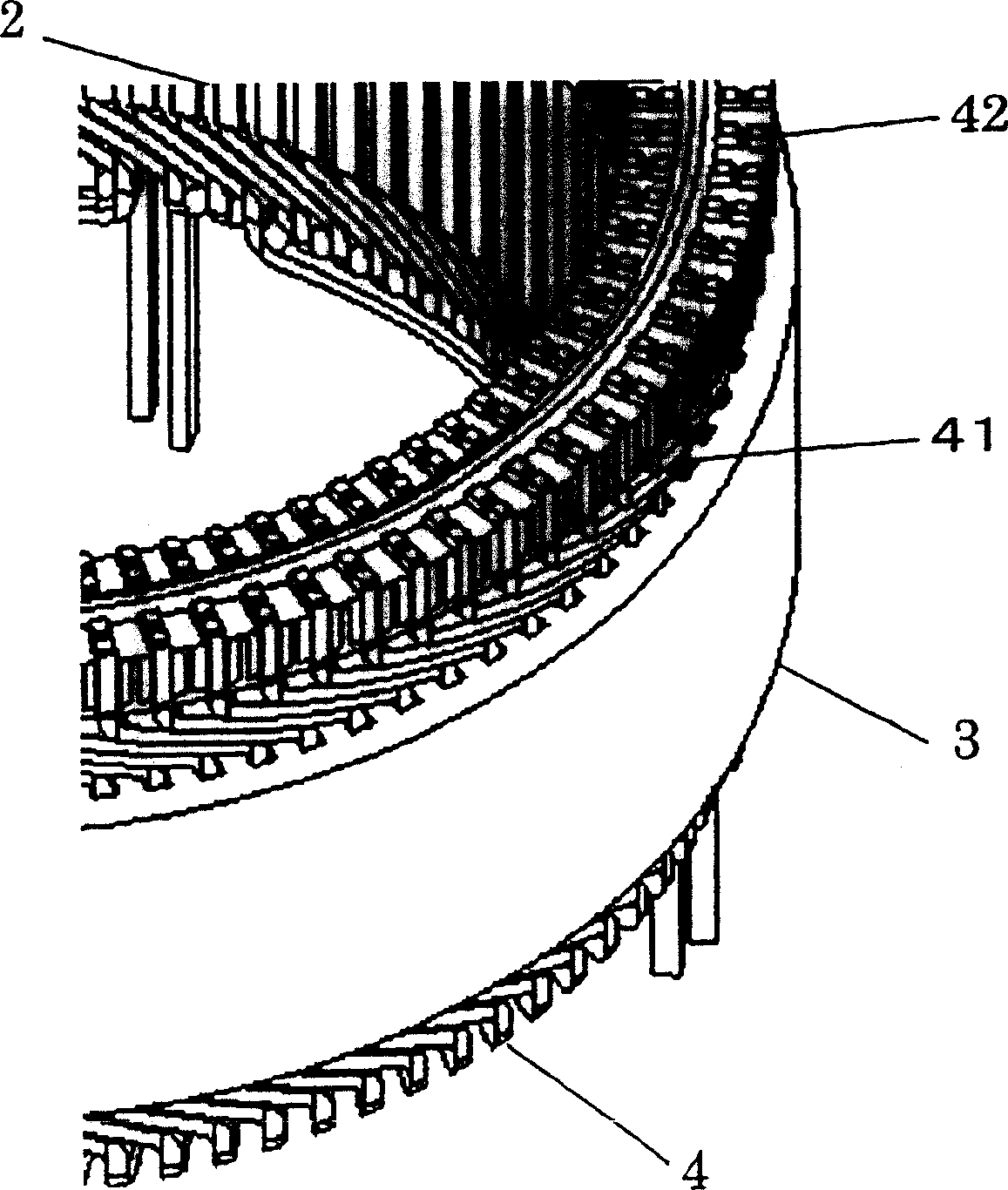

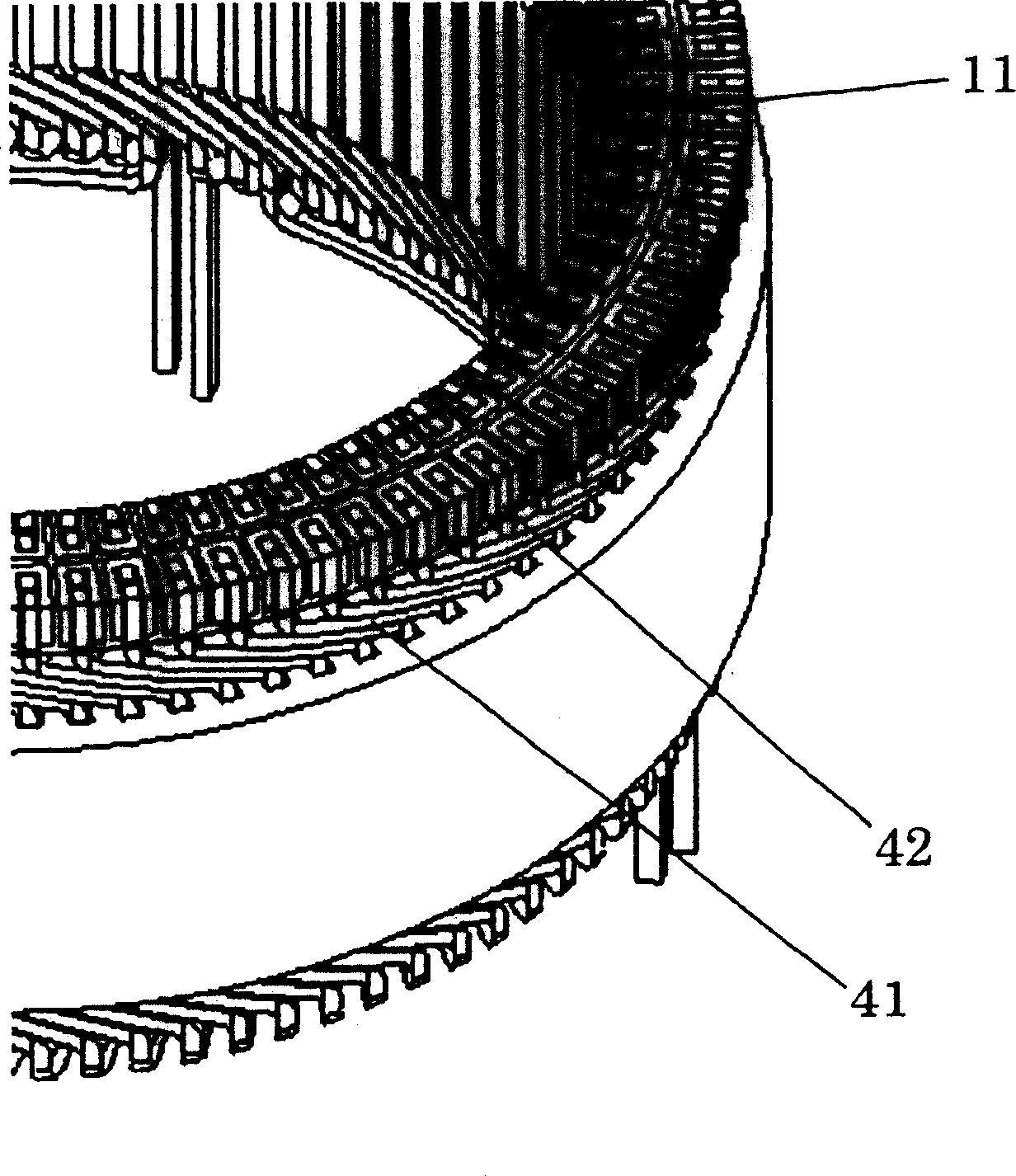

[0056] Example 1 will be described. Figure 1 shows an enlarged view of the connecting ring used in this embodiment, Figure 2 shows an enlarged view of the assembled state of the connecting ring, Figure 3 shows an enlarged view of the state after the connecting ring is divided, and Figure 4 shows a state diagram of the connecting ring after dividing. 1 to 4 above show an example in which the number of slots is 90, and each slot has four conductors.

[0057] In FIG. 1 , a connection ring 1 is composed of a conductor portion 11 and an insulating portion 12 . The connection ring 1 has a plurality of grooves 13 corresponding to the number of connection points of the terminal portions 42 of the plurality of conductors 41, and an insulating portion 12 is arranged between the plurality of grooves 13 and adjacent grooves 13 to ensure a uniform insulation. Since four conductors are arranged in one slot, and the No. 1 and No. 2 of the end portion 42 counted from the outer peripheral si...

Embodiment 2

[0060] Example 2 will be described. In FIG. 5 , which is an enlarged view showing a state after being connected by reversely twisted conductors, an example in which the number of slots is 90 and 4 conductors per slot is shown. Since each slot is equipped with 4 conductors, the phase winding consists of: an outer circuit 6 composed of a plurality of No. 1 and No. 2 conductors 41 counted from the outer peripheral side, and a plurality of No. 3 and No. The inner circuit 7 composed of two conductors 41 is formed by connecting the tail end conductor 46 of the outer circuit and the head end conductor 48 of the inner circuit. The connection of the tail end conductor 46 of the outer circuit and the head end conductor 48 of the inner circuit can be canceled by using the anti-twisted conductor 43 .

Embodiment 3

[0062] Example 3 will be described. Figure 6 is an enlarged view of the state of connecting conductors with different pitches, showing that the number of poles is 12, the number of slots is 90, the number of phases of the stator winding is 3, and the number of slots per pole and phase determined according to the number of poles is 2.5, An example of a winding circuit with 5 conductors per pole and 4 conductors per slot.

[0063] In this winding circuit, 4 conductors per slot are arranged in a row along the diameter direction, and are divided into the first and second conductors and the third and fourth conductors counted from the outer peripheral side. The outer circuit 6 constituted by two conductors and the inner circuit 7 constituted by the third and fourth conductors of the plurality of slots are constituted by a combination.

[0064]In the outer circuit 6, 15 slots are arranged corresponding to each pair of magnetic poles of the rotor (a pair of magnetic poles of N pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com