Permanent-magnetic electric motor

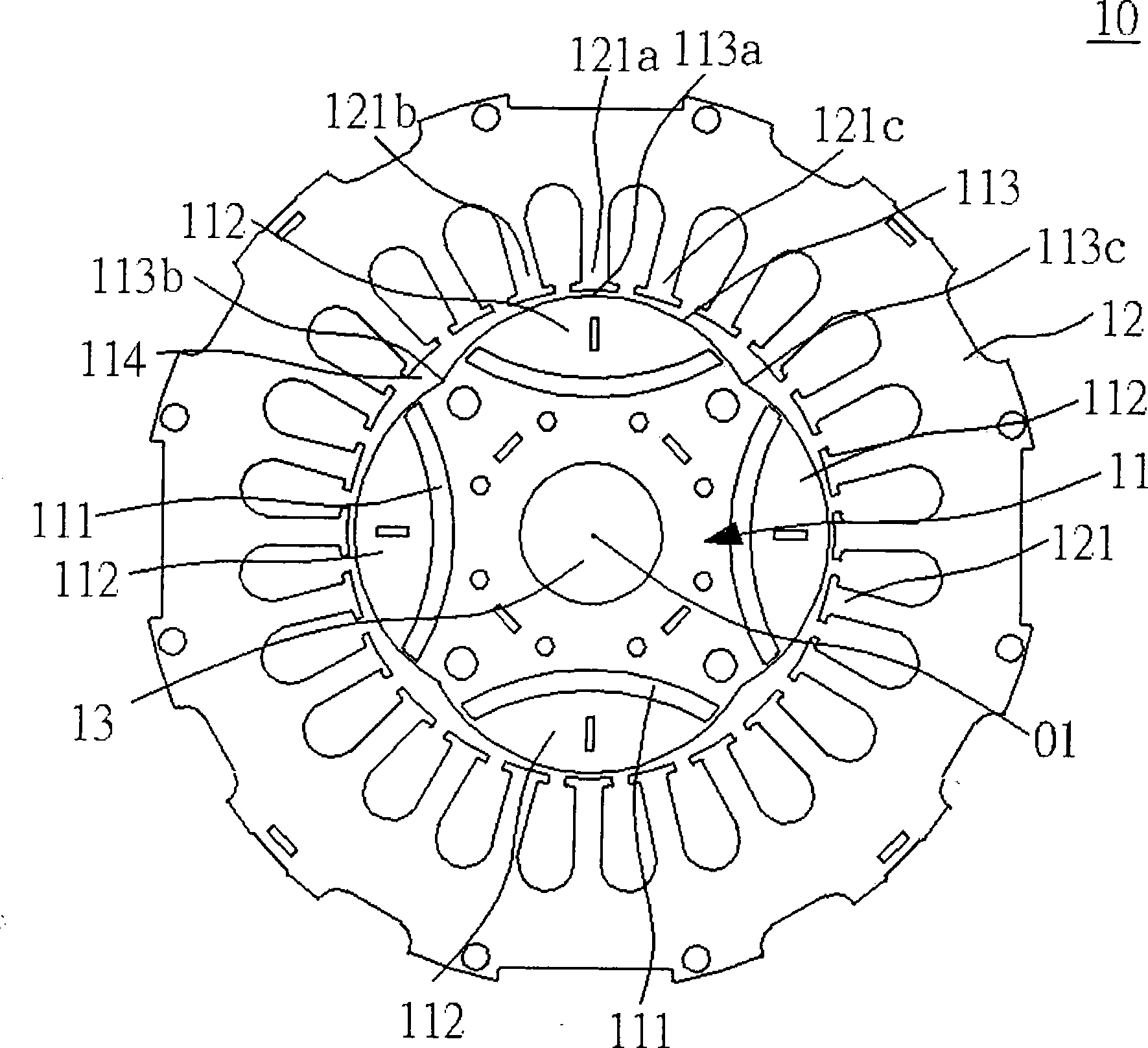

A motor, permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, manufacturing stator/rotor body, etc., can solve the problem of reduced stator winding electrification, increased copper loss, and inability to fully improve Motor efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

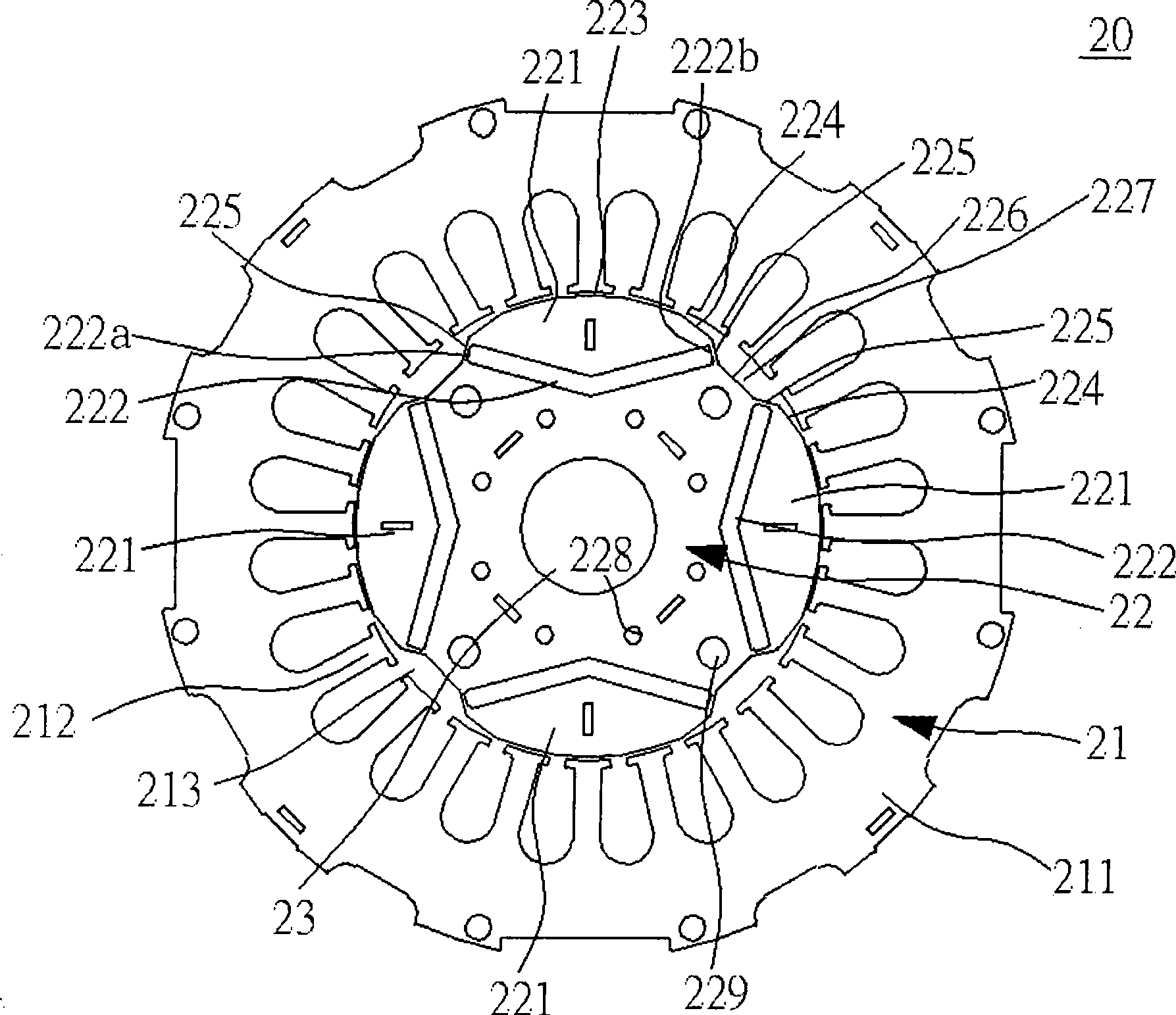

[0030] The present invention mainly improves the rotor in the general permanent magnet motor, such as Figure 2 to Figure 4 As shown, the permanent magnet motor 20 includes: a stator 21, a rotor 22 and a rotating shaft 23; wherein:

[0031] The stator 21 has an annular main body 211 and a plurality of stator poles 212 , each stator pole 212 protrudes inside the main body 211 , and each stator pole 212 forms an accommodating space 213 therein.

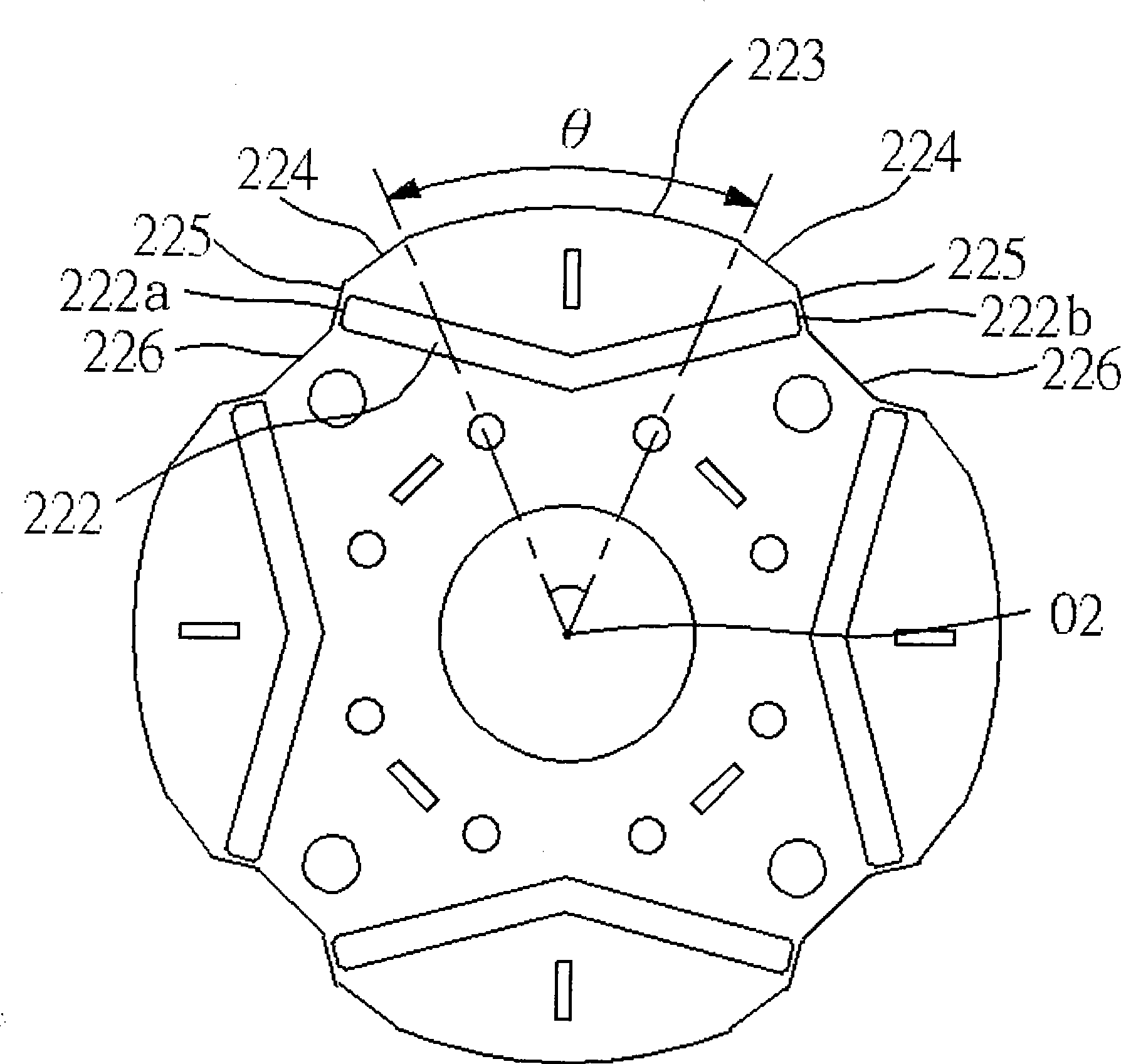

[0032] The rotor 22 is a slightly circular piece, is arranged in the accommodating space 213, and has an air gap with each stator pole 212, the rotor 22 is also formed with a plurality of rotor poles 221, and each rotor pole 221 is also provided with There are magnets 222 .

[0033] The number of the plurality of rotor poles 221 is set in an even number, and this implementation takes a four-pole motor as an example, so there are four rotor poles 221, and each rotor pole 221 is provided with an arc surface 223 and two sides of the arc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com