High-speed permanent magnet motor rotor with sine magnetomotive force distribution rule and manufacturing method

A permanent magnet motor with regular distribution technology, which is applied in the manufacture of motor generators, magnetic circuit rotating parts, and stator/rotor body manufacturing, etc. It can solve problems such as endangering the safe operation of the motor, difficulty in heat dissipation of the motor rotor, and temperature rise of the motor rotor. , to achieve the effect of solving the eddy current loss, large temperature rise, increasing the allowable line speed, and reducing the content of high-order harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described in detail below with reference to the accompanying drawings and examples.

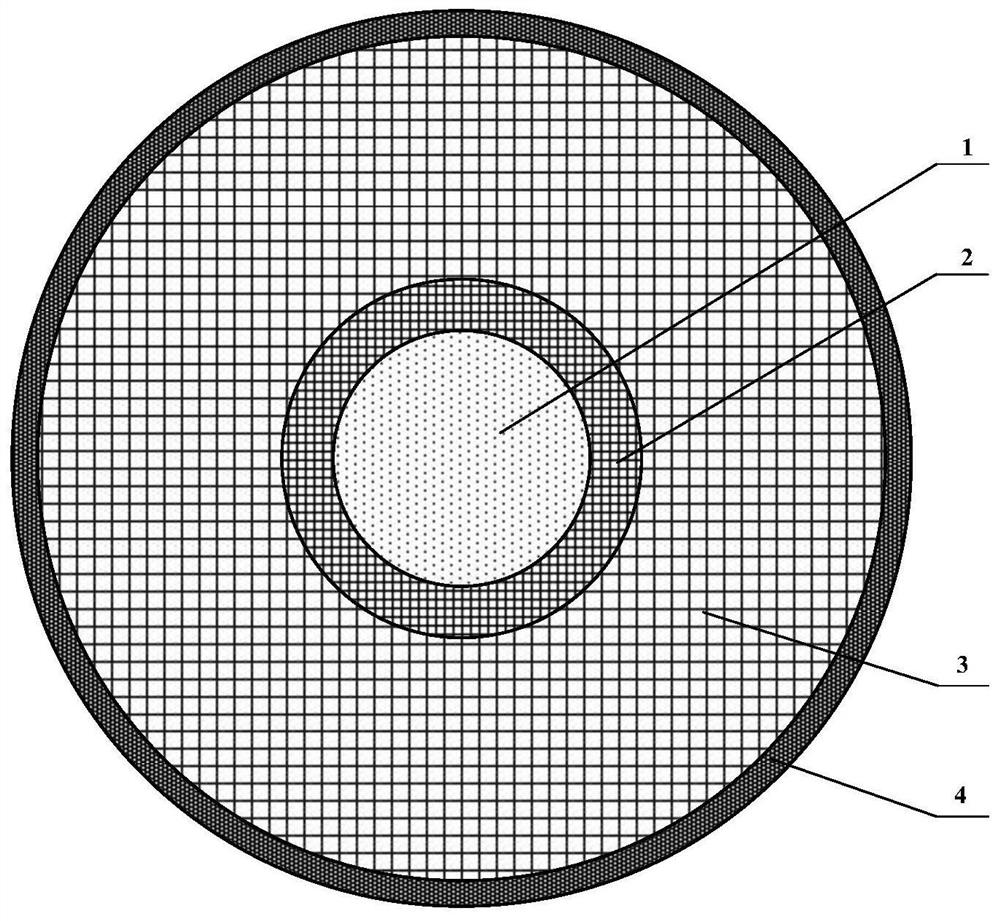

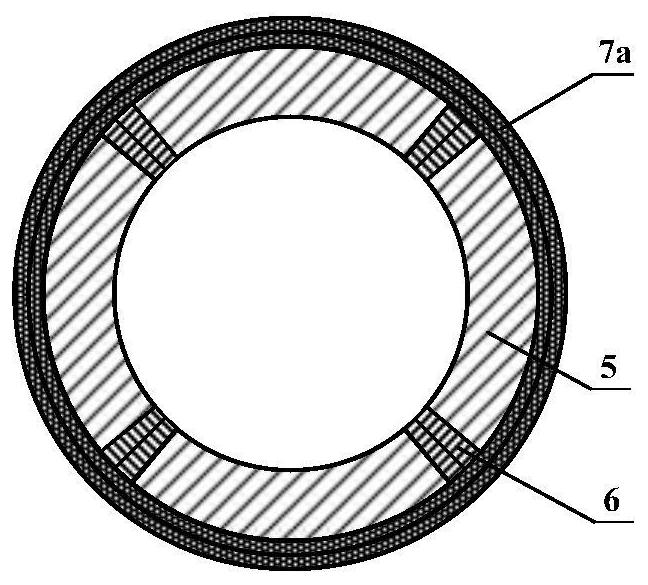

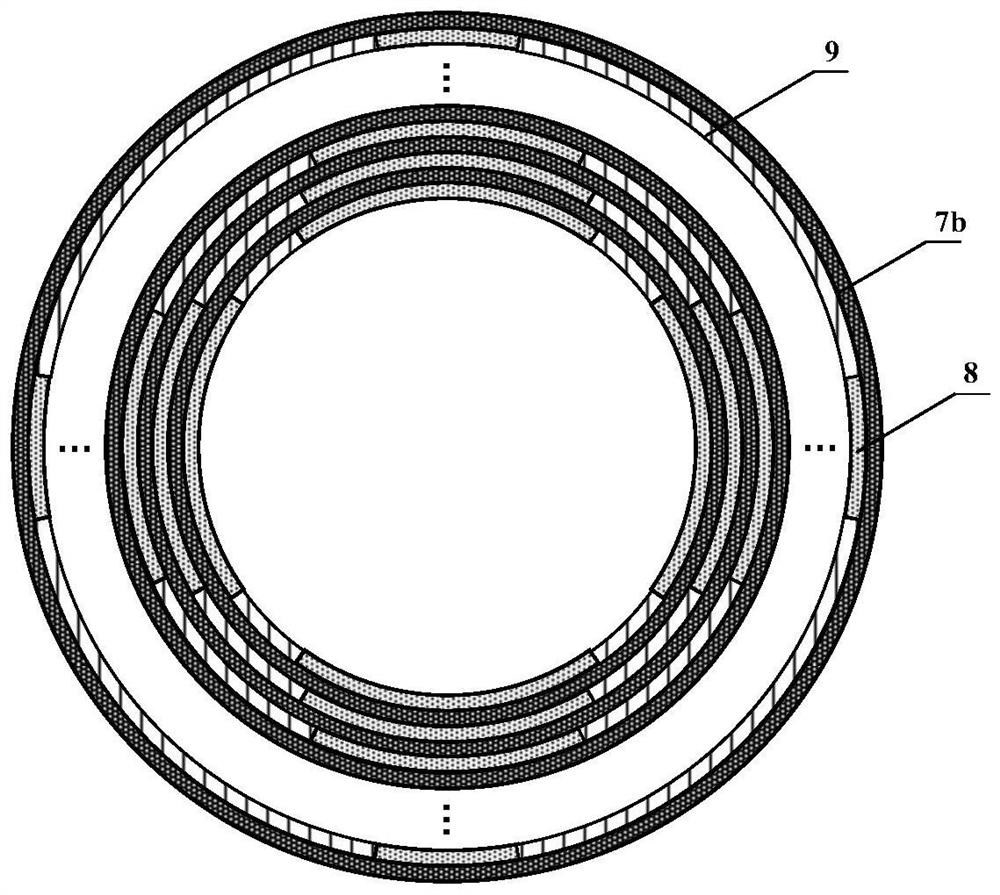

[0025] like figure 1 , Figure 5 and Image 6 , The high speed rotor of a sinusoidal magnetomotive potential distribution, comprises a shaft 1, a sintered permanent magnet section 2, the carbon fiber composite magnetic film unit 3 and the sheath 4 of the rotor; the high-speed permanent magnet motor shaft 1 is located innermost rotor, an outer shaft coaxially sleeved sintered permanent unit 2, the outer sintered permanent unit 2 by an interference fit with the wound carbon fiber composite magnetic film unit 3, and the winding process to ensure that the composition of the magnetic powder and carbon fiber film magnetic film layer 3 block of said magnetic film and a carbon fiber composite subunit composite unit 8 and the geometric centerline sintered permanent magnet block 5 geometric centerline coincides with the carbon fiber composite magnetic film unit 3 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com