Testing method of flow ratio valve feature curve

A flow proportional valve and characteristic curve technology, which is applied in the field of flow proportional valve characteristic curve testing, can solve problems such as economic loss, low work efficiency, and high labor intensity, so as to ensure quality, improve work efficiency, and prevent misjudgment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

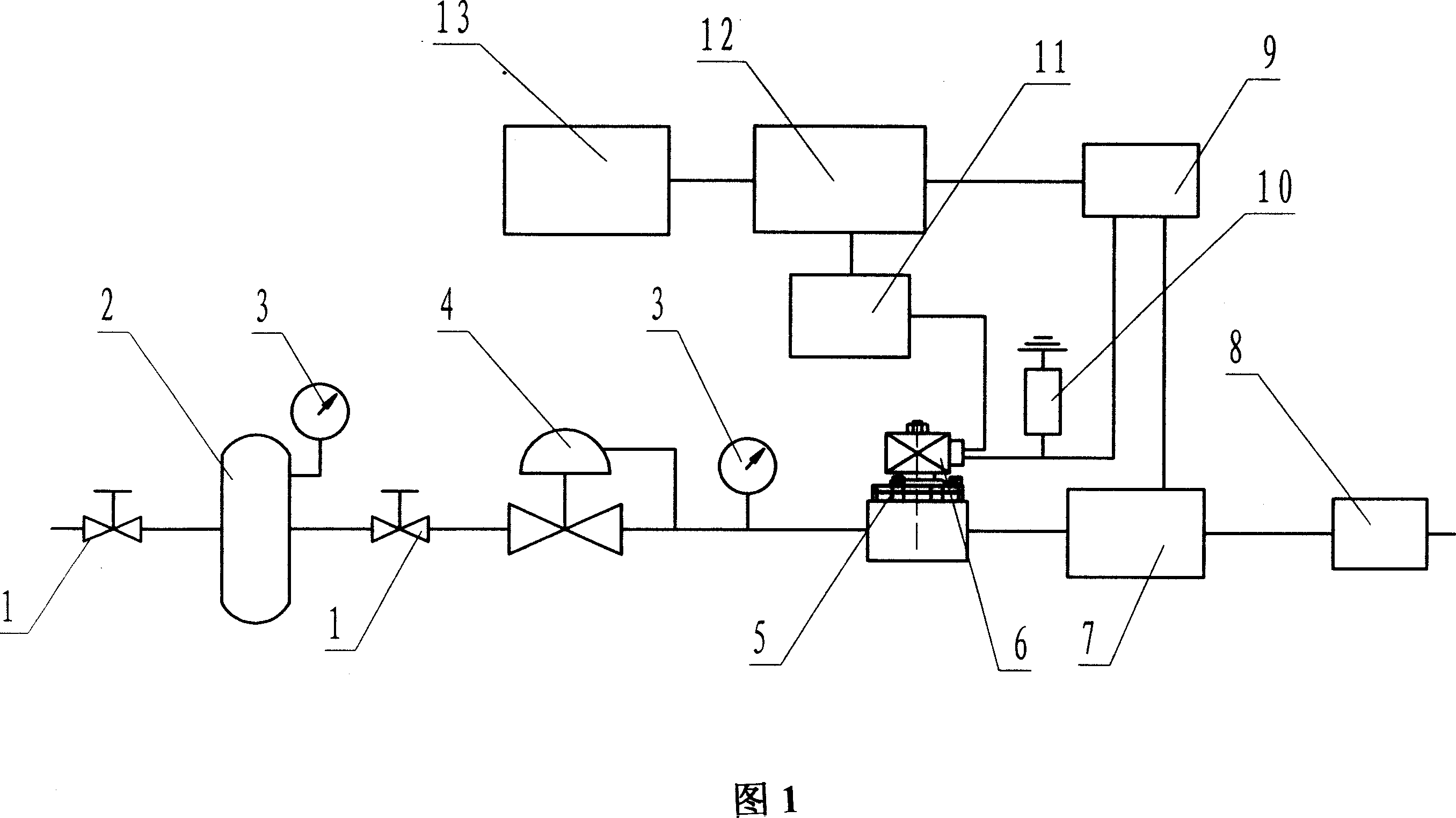

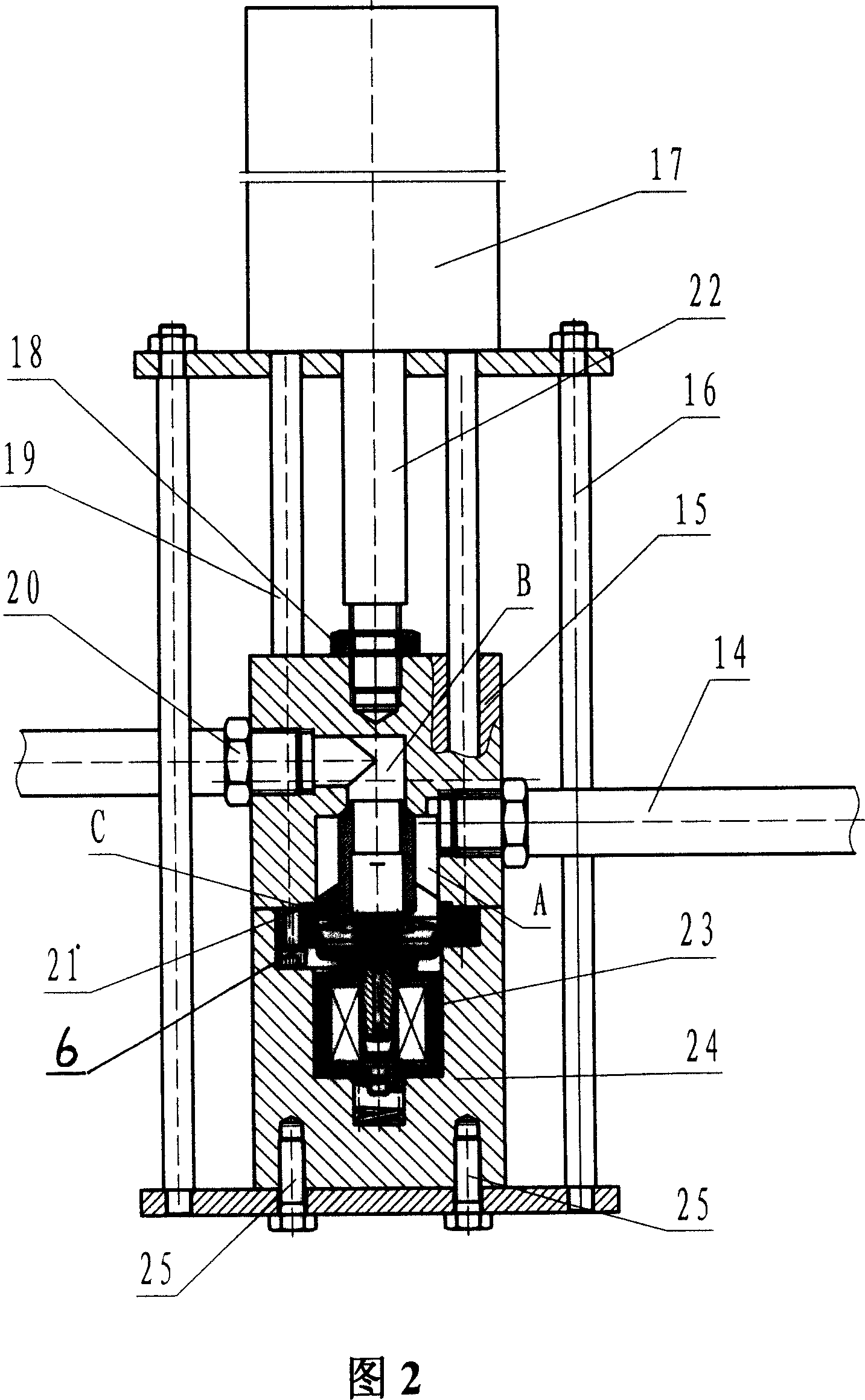

[0011] The equipment used in the present invention mainly includes a test platform and a flow test device. The test platform is composed of accumulator 2 with ball valve 1 and pressure gauge 3, pressure regulator 4 with pressure gauge 3, flow test device 5, flow meter 7, back pressure controller 8, data acquisition module 9, sampling resistor 10, driven Circuit 11, industrial computer 12 with display 13, etc. constitute; the flow test device consists of a lower valve seat 24 with a fixed bracket 16, a guide rod 19 placed on the top of the fixed bracket 16 and a cylinder 17 with a piston rod 22, fixed on the piston rod 22 The upper valve seat 15 with the inlet joint 14 and the exhaust joint 20 at the lower end is composed of an end face sealing gasket 21 placed between the upper valve seat 15 and the lower valve seat 24; the accumulator 2, the pressure regulator 4, The inlet joint 14 and the exhaust joint 20 on the flow test device 5, the flow meter 7, and the back pressure con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com