Testing apparatus and method of data auto-acquiring stretching creep deformation

A technology of automatic collection and tensile creep, which is applied in the field of automatic data collection tensile creep test device and the test field of creep deformation of metal materials under different temperatures and tensile stresses, which can solve the difficulties of metallographic preparation and low hardness And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

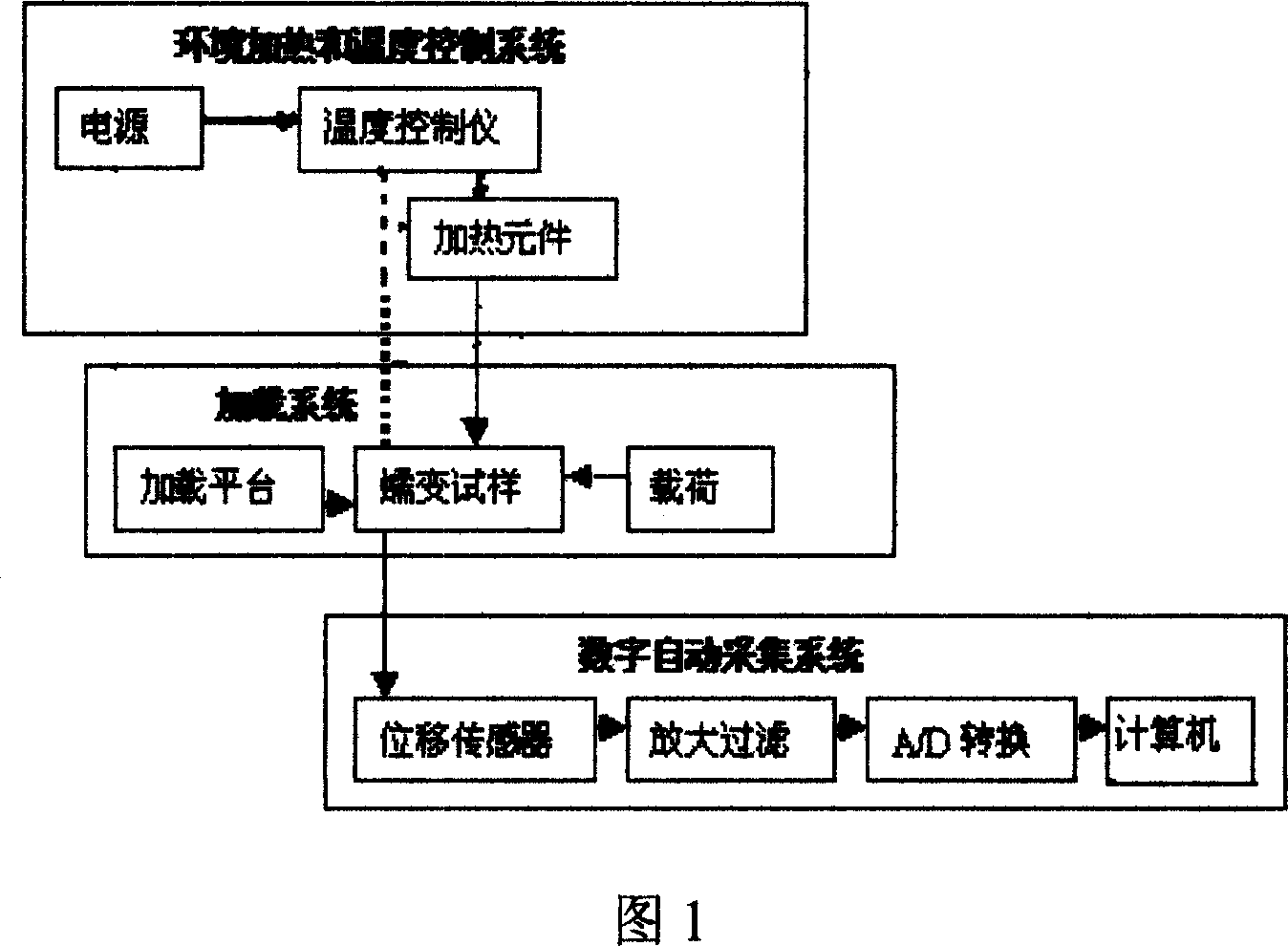

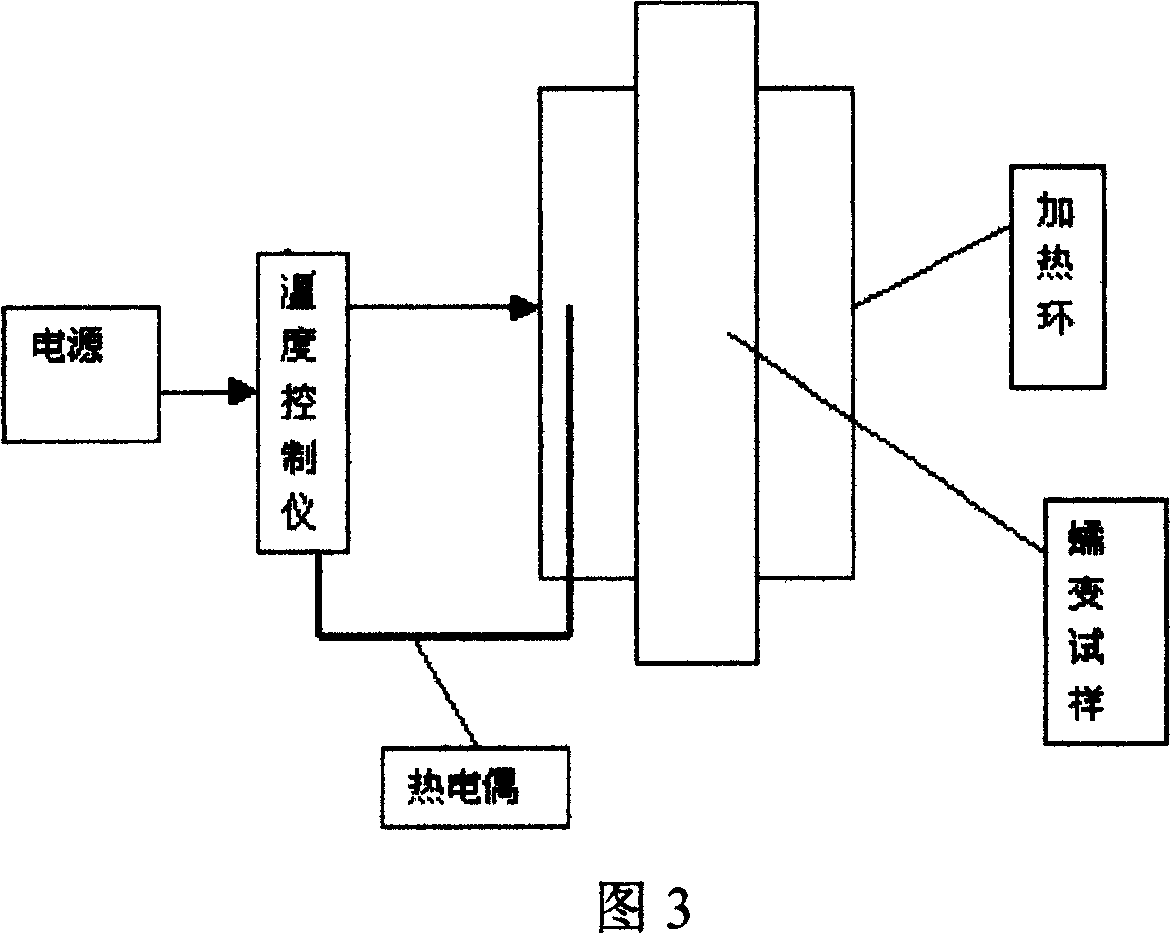

[0029] The tensile creep test device for automatic data collection of the present invention is mainly composed of the following three parts: a loading system, an environment heating and temperature control system, and an automatic data collection system.

[0030] Figure 1 is a schematic diagram of the tensile creep test device for automatic data collection. The working process of measuring the creep deformation of materials is as follows: fix the creep sample on the loading system and apply the test load, then start the ambient heating and temperature control system to make the ambient temperature reach the preset temperature, start the data acquisition system, and then measure The creep deformation of the material under the test conditions.

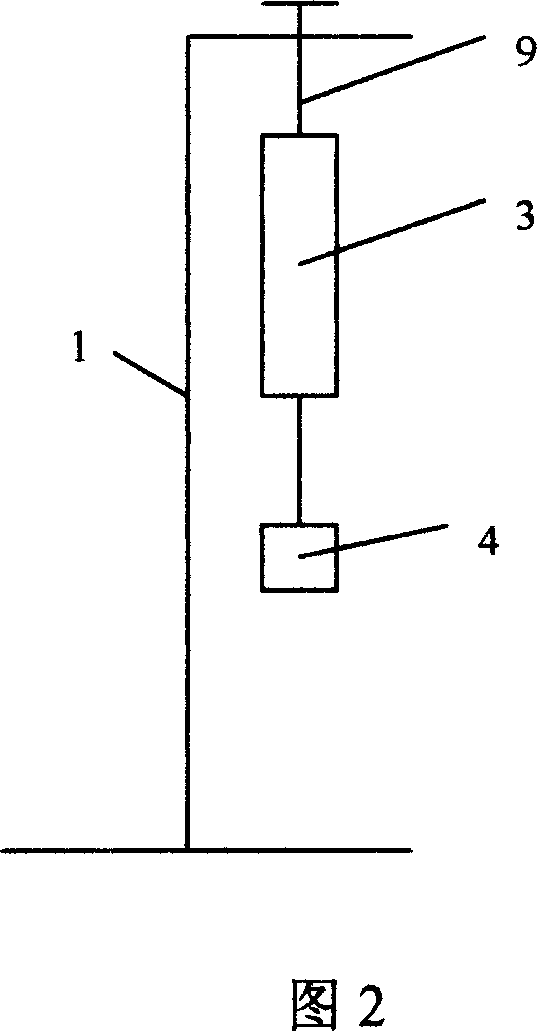

[0031] Referring to Fig. 6, the tensile creep test device for automatic data collection of the present invention includes: a loading system for fixing and loading the creep sample; a device for heating and controlling the ambient tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com