Mounting structure of air separation device and gas turbine containing same

An air separator and installation structure technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of air leakage, easy vibration of air separators, etc., to prevent air leakage, improve sealing effect, and improve sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The best mode for carrying out the present invention will be described below with reference to the accompanying drawings.

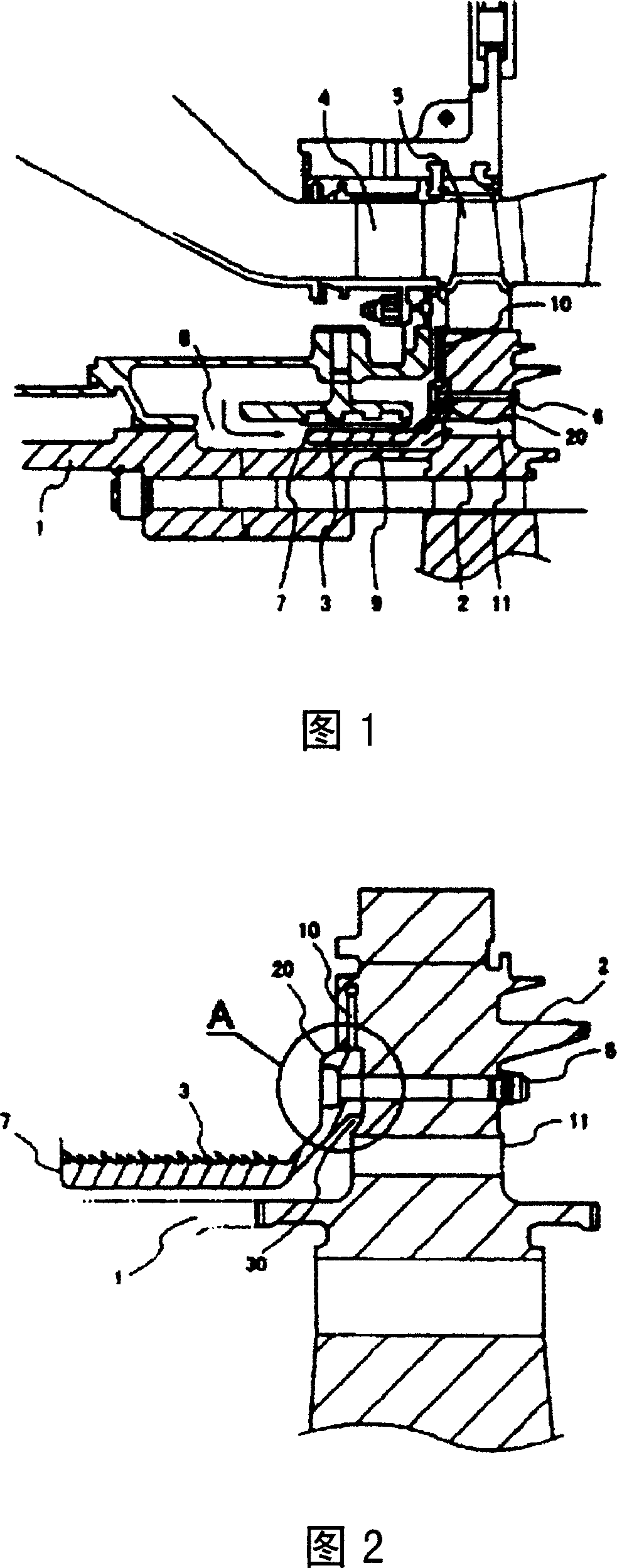

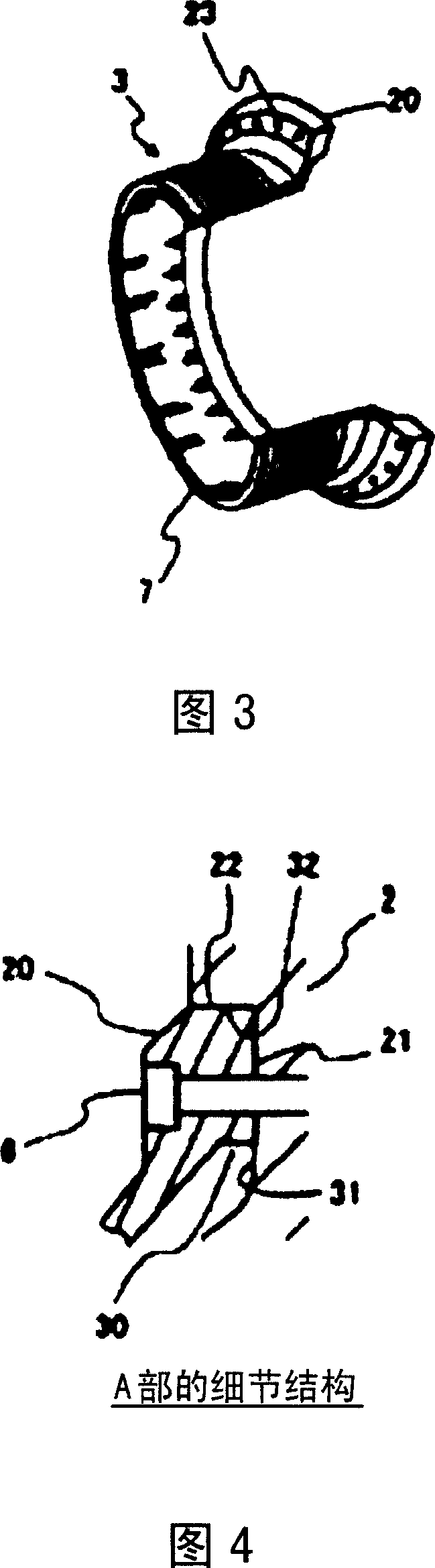

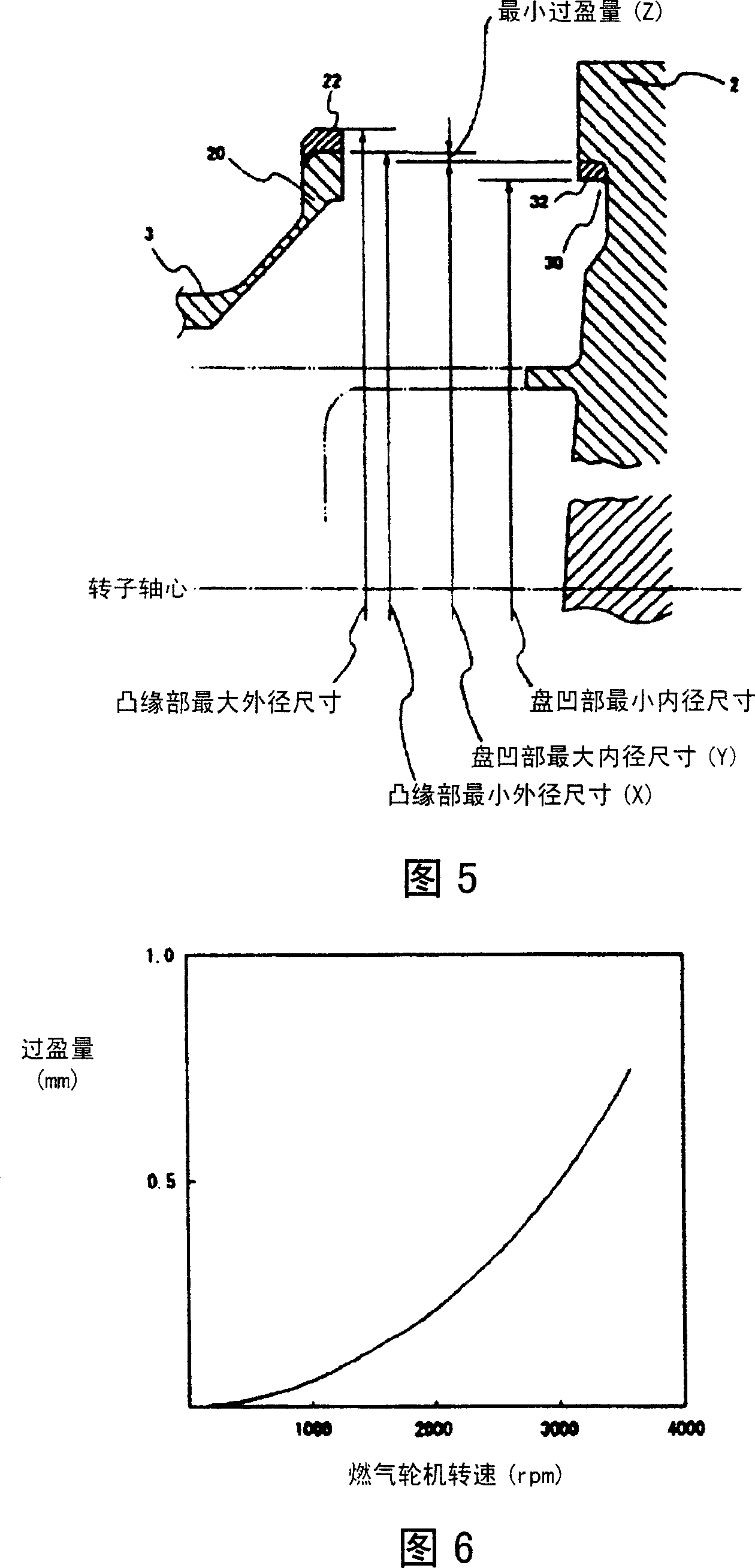

[0046] It only represents an embodiment of the present invention, and is limited to the structures involved in the present invention, not limited to this embodiment, and there are also similar methods. Fig. 1 is the overall structure of the air separator of the gas turbine of the present invention, Fig. 2 is a structural diagram around the installation structure of the air separator of the present invention, Fig. 3 is a perspective view of the air separator involved in the present invention, and Fig. 4 is an air separator of the present invention The details of the installation structure around the flange part, Figure 5 is the matching relationship between the flange part and the disc recess, Figure 6 is the interference relationship between the flange part and the disc recess due to the turbine speed and centrifugal force during the start-up operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com