Improved permalloy sensor

一种坡莫合金、传感器的技术,应用在磁场控制的电阻器、仪器、测量磁变量等方向,能够解决限制等问题,达到增加灵敏度、扩展感测范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

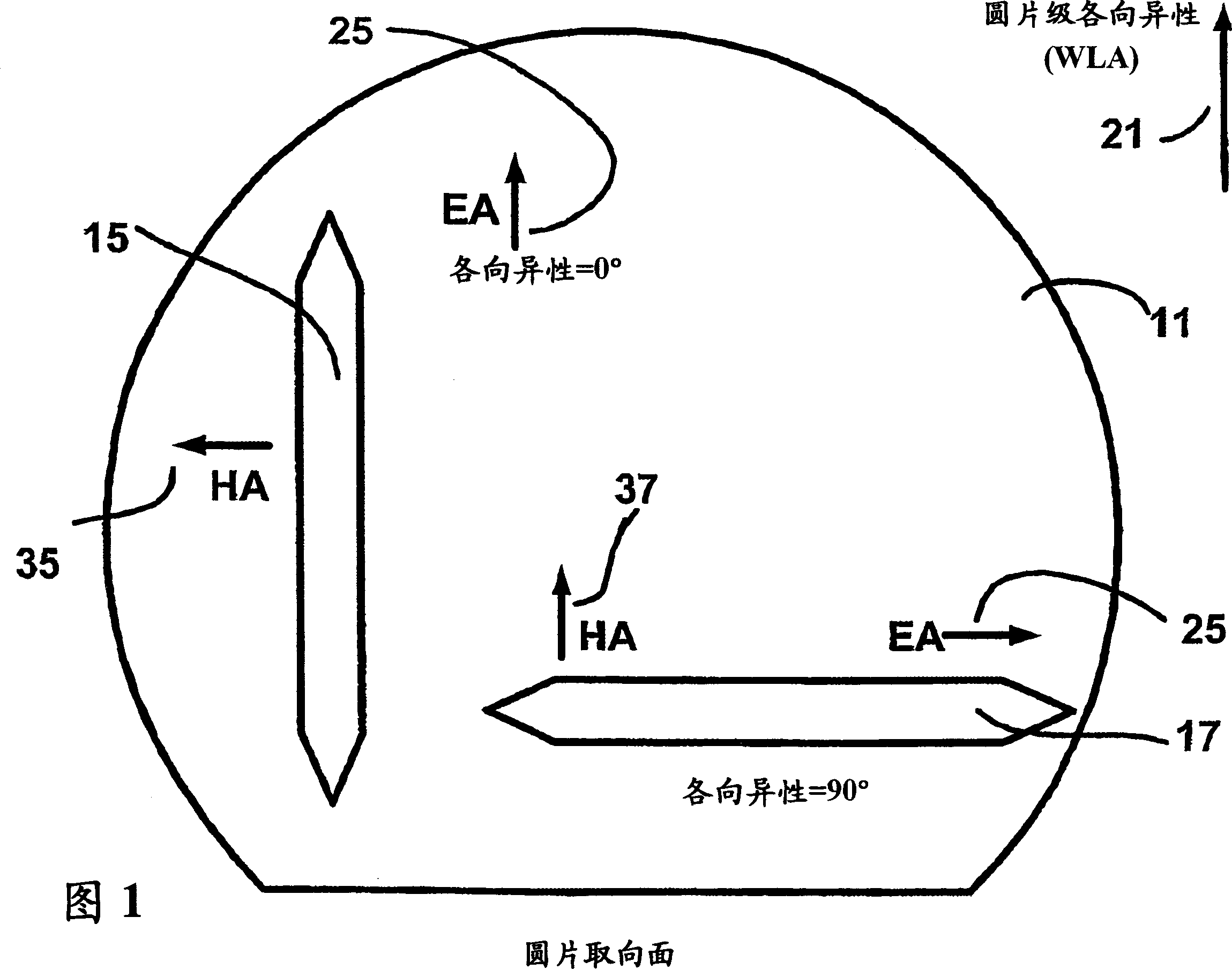

[0013] Referring to Figure 1, it should be understood that there may actually be thousands of permalloy deposits on a wafer, of which only two are shown for illustration. This is conventional in sputtering techniques, by using permanent magnets to bias the magnetic permalloy particles into alignment of the particles as they land on the substrate. This allows many permalloy resistors to be deposited and aligned in one direction. Also, when the resistors are deposited, they all have the same general orientation. Figure 1 is purely for illustration purposes.

[0014] In Figure 1, wafer 11 is shown having two different permalloy resistors 15 and 17 deposited thereon. In practice, the aspect ratio of permalloy resistors is very large, on the order of 100 or more, so permalloy resistors 15 and 17 are only schematic, as lines 100 times longer than their width cannot be clearly used as illustrate. The easy axis EA is always in the length direction of the resistor, so that permallo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com