Wheel and automotive two-wheel vehicle with the same

A technology of wheels and hubs, which is applied in the field of motorized two-wheeled vehicles, can solve the problems of increasing the diameter limit of the axle sleeve and making it difficult to ensure the assembly space of drum brakes, etc., and achieve the effect of reducing abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below with reference to the accompanying drawings.

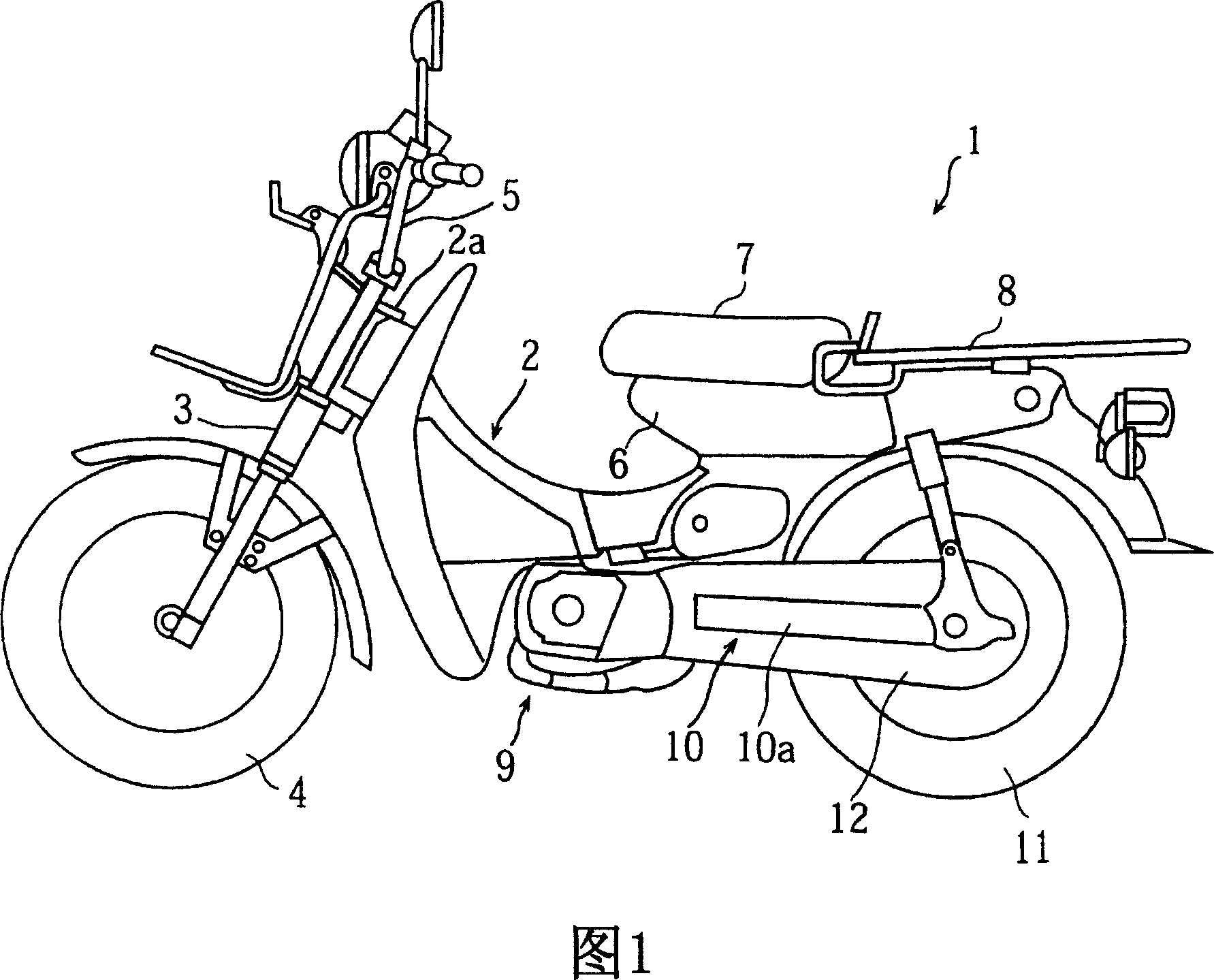

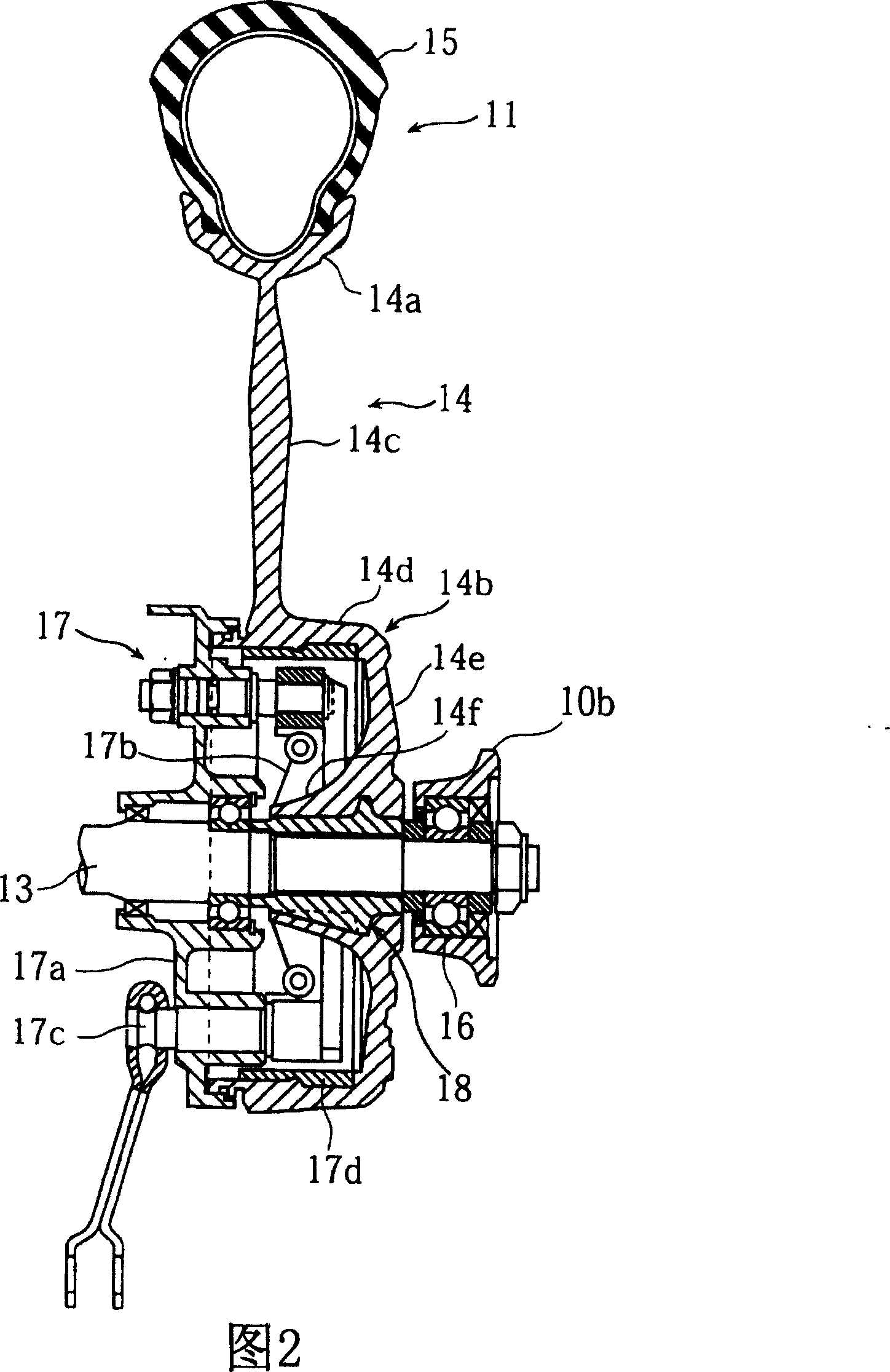

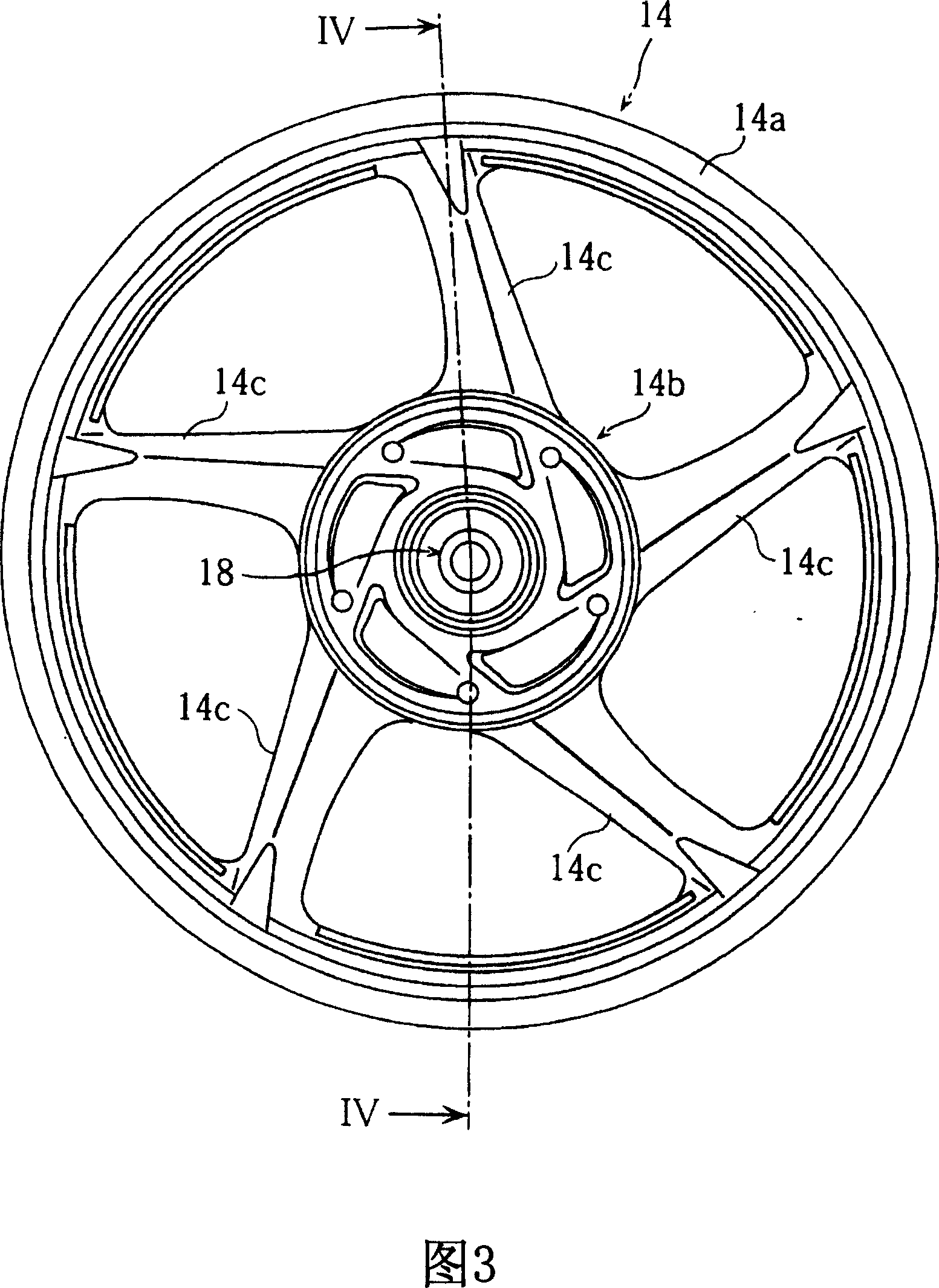

[0019] 1 to 7 are views for explaining an embodiment of the present invention. In these figures, 1 denotes a motorcycle having the wheel of this embodiment. This motorcycle 1 has the following structure. The front fork 3 is supported by the head pipe 2a at the front end of the vehicle body frame 2, and can turn freely left and right; In addition, a fuel tank 6 , a seat 7 , a luggage rack 8 , and the like are mounted on the upper portion of the above-mentioned vehicle body frame 2 .

[0020] The engine 9 is suspended and supported on the central lower part of the above-mentioned vehicle body frame 2 . A rear arm 10 is supported on the rear side of the engine 9 so as to be able to swing up and down. The rear arm 10 is connected to the front ends of the left and right arm bodies 10 a and 10 b at pivots, and the rear wheel 11 is supported between the rear ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com