Device for treating fibrous materials

A pulping and pulping technology, which is applied in fiber raw material processing, paper recycling, textiles and papermaking, etc., can solve the problems of large space and area, and achieve the effects of space saving, manufacturing cost reduction and total length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

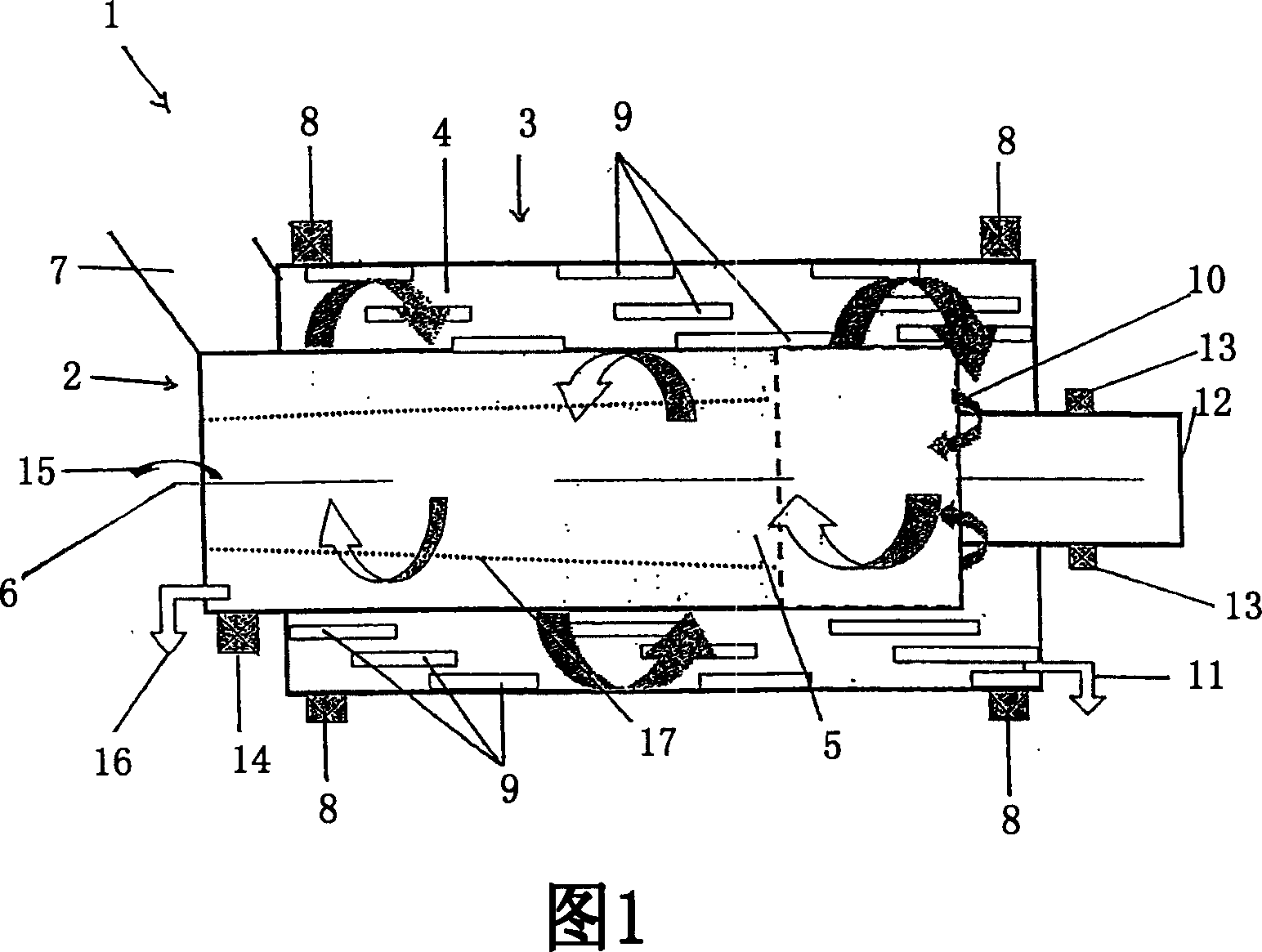

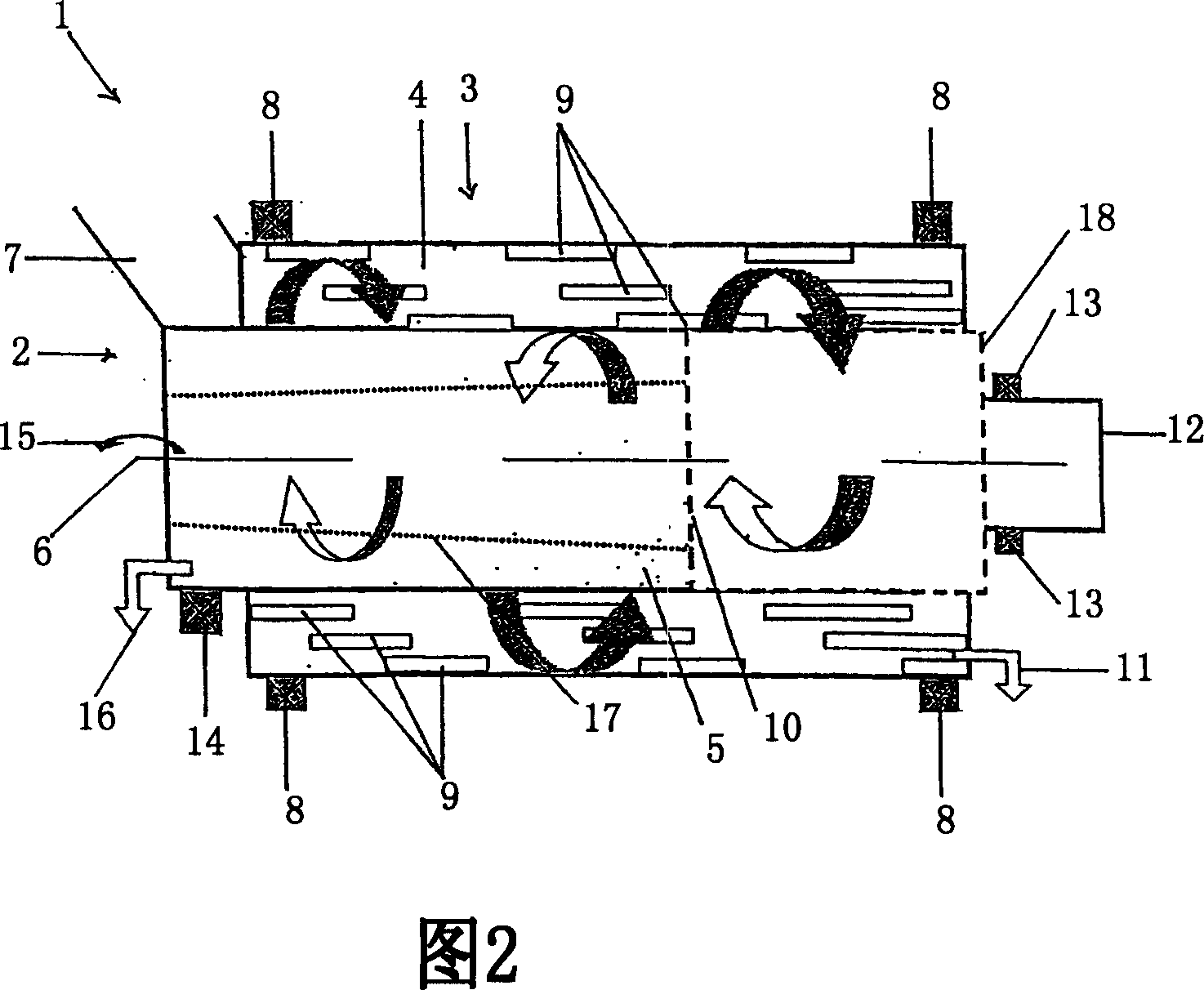

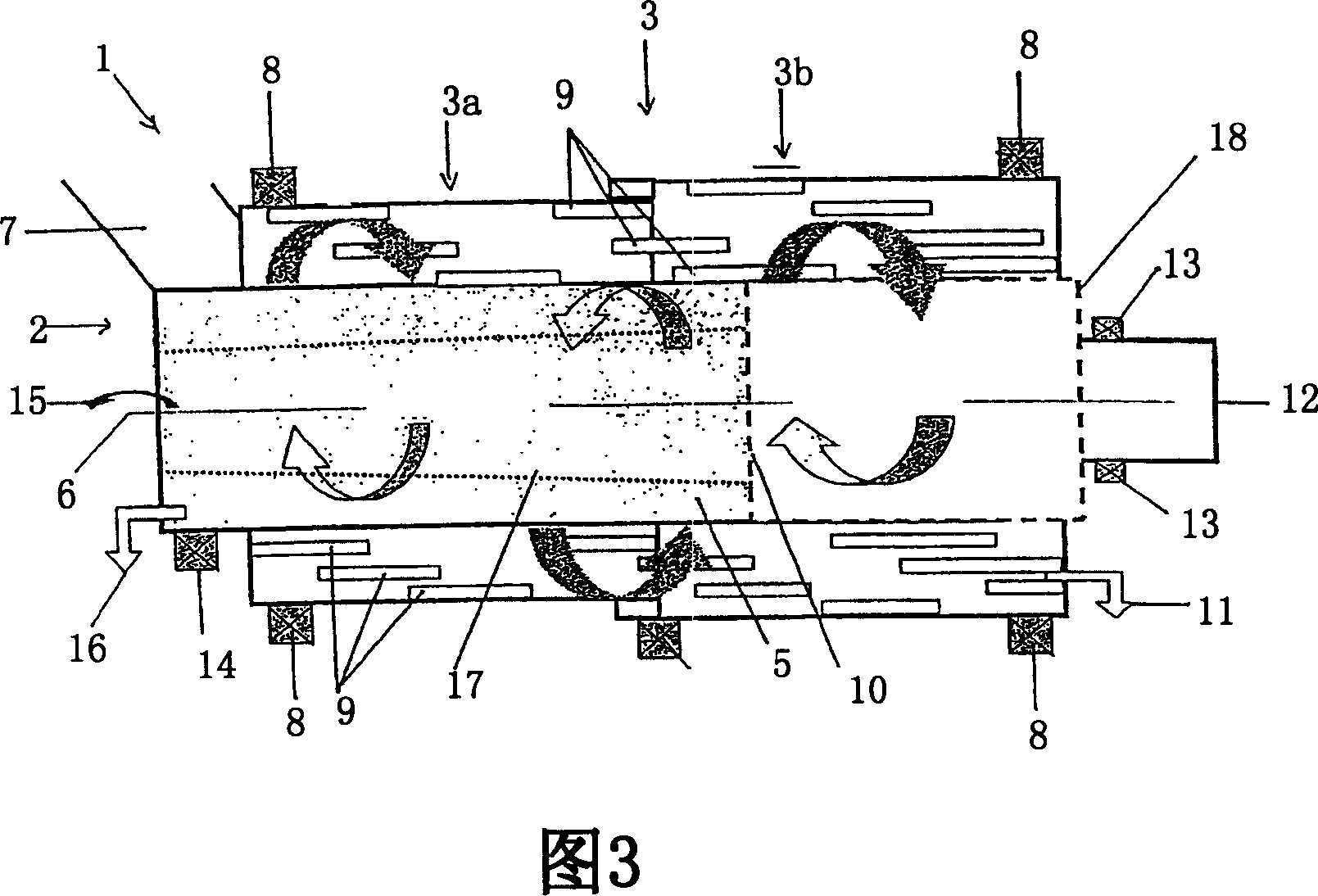

[0017] Figure 1 shows an embodiment of a device 1 according to the invention, which device 1 mainly comprises a combination of two main units, namely a pulping section 3 and a screening section 2, wherein the screening section 2 is arranged in the pulping section 3. Two units are formed by a pulping drum 4 and a screening drum 5 . As is well known in the art, the inner diameter of the pulping drum 4 is for example between 3.5 and 5.5 m.

[0018] Thanks to the arrangement according to the invention, that is, the screening section 2 is located inside the pulping section 3, a space saving of up to 50% can be achieved compared to a conventional arrangement of these two sections, i.e. the overall length required for the plant can be much reduced up to half.

[0019] The pulping drum 4 , which rotates about the axis of rotation 6 of the device 1 , is fed through the opening 7 the recycled paper to be pulped and cleaned. The pulping drum 4 is supported on bearings 8 and driven by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com