Variable capacity multi-cylinder rotary compressor and its running method

A rotary compressor, multi-cylinder technology, which is applied in the direction of pump combination, mechanical equipment, machine/engine, etc. for elastic fluid rotary piston type/swing piston type, can solve the problems of difficulty in improving refrigeration capacity and rising cost, etc. Achieve low cost, improve energy efficiency and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

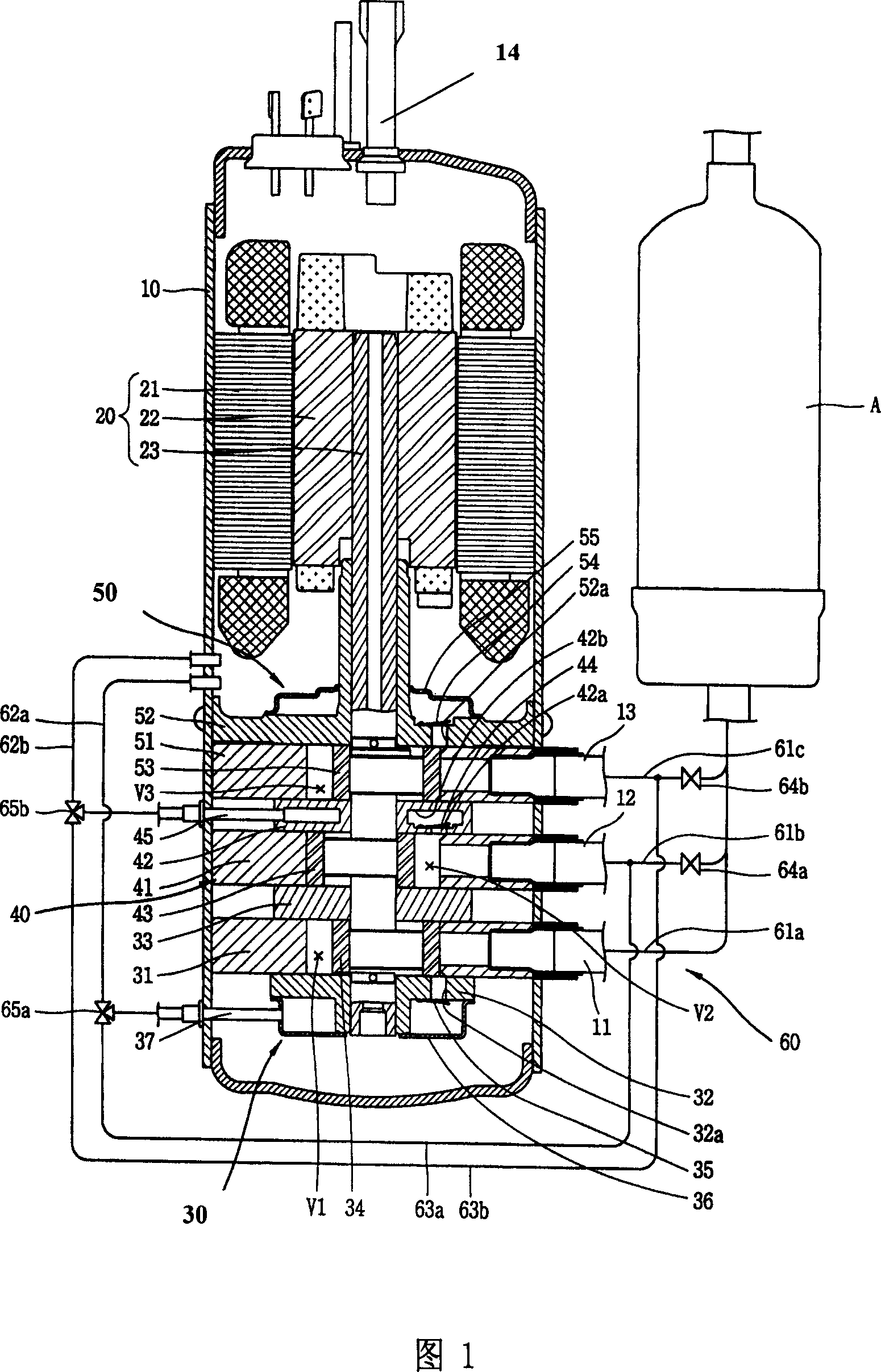

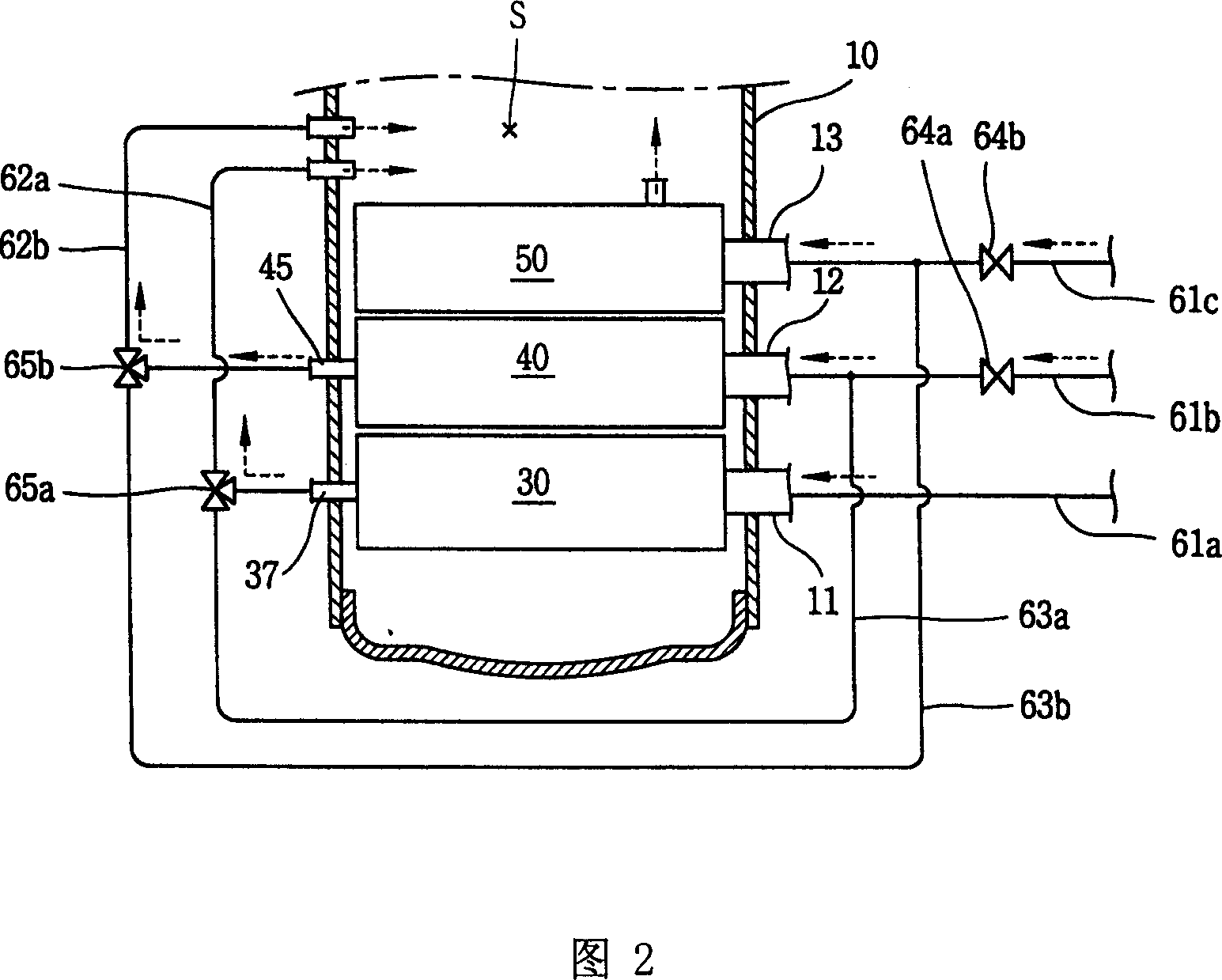

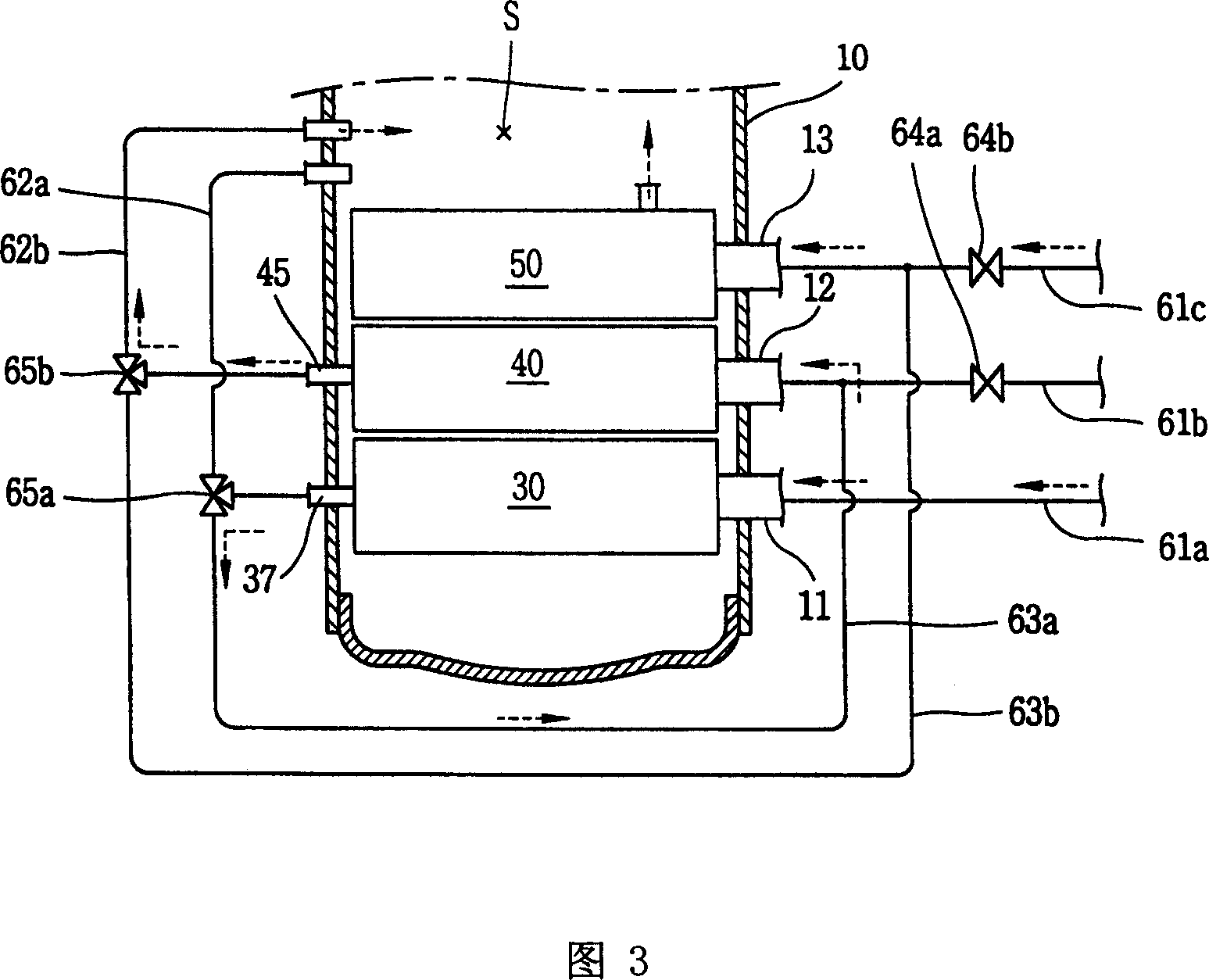

[0023]As shown in Figures 1 to 5, the variable capacity multi-cylinder rotary compressor provided by the present invention mainly includes a casing 10, a driving device 20, a first compression device 30, a second compression device 40, a third compression device 50 and A connecting device 60; a sealed space S is formed inside the casing 10; the driving device 20 is arranged inside the casing 10 and can generate driving force; the first compression device 30, the second compression device 40 and the third compression device 50 are installed Inside the casing 10 and connected with the driving device 20, it is used to compress the refrigerant; the connecting device 60 is connected between the outlet of the evaporator in the refrigeration cycle system and the suction side of each compression device 30, 40, 50, and simultaneously connects the The discharge side adjacent to each compression device communicates with the suction side of the other compression device or the closed space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com