Control method for zero adjusting rollers in universal type rolling mill

A control method and rolling mill technology, applied in the direction of rolling force/roll gap control, metal rolling, metal rolling, etc., can solve the problem that the sliding resistance of the vertical roll and the upper horizontal roll bearing seat increases, and the pressure value cannot be given. , low efficiency and other problems, to achieve the effect of good robustness and fault tolerance, increase the pressing force, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

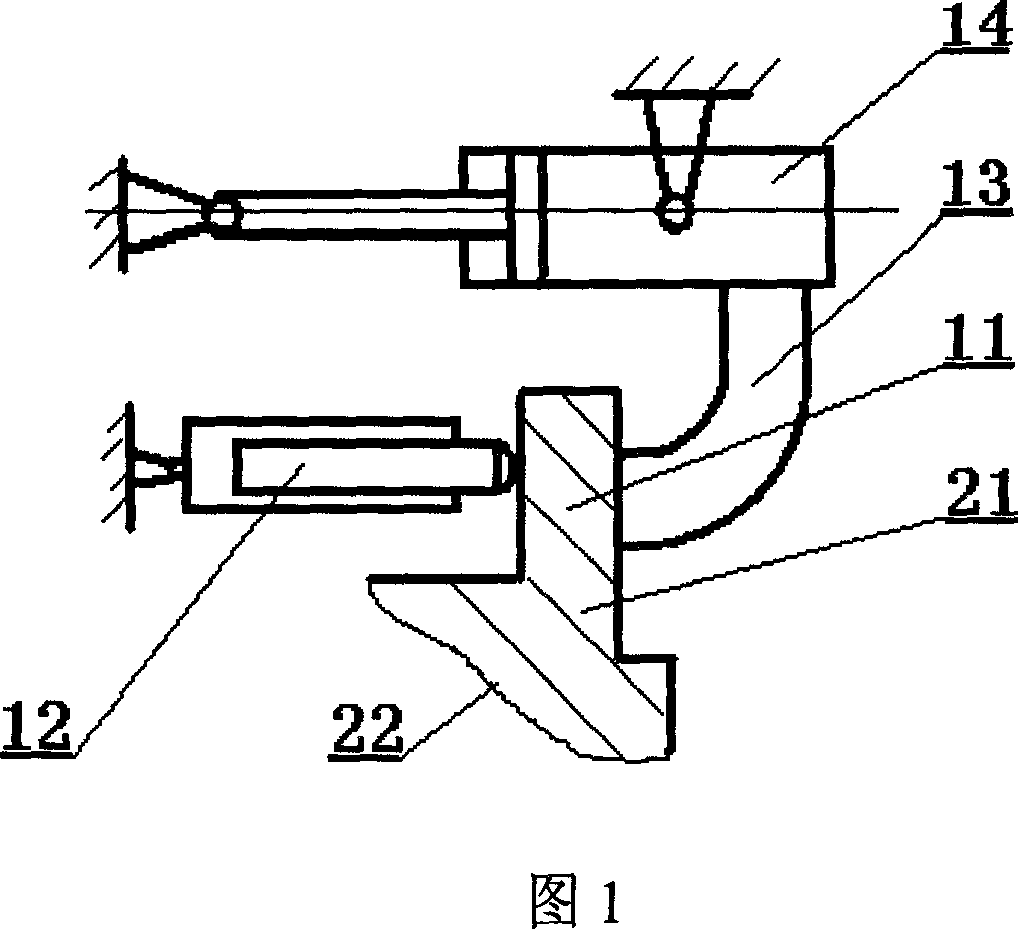

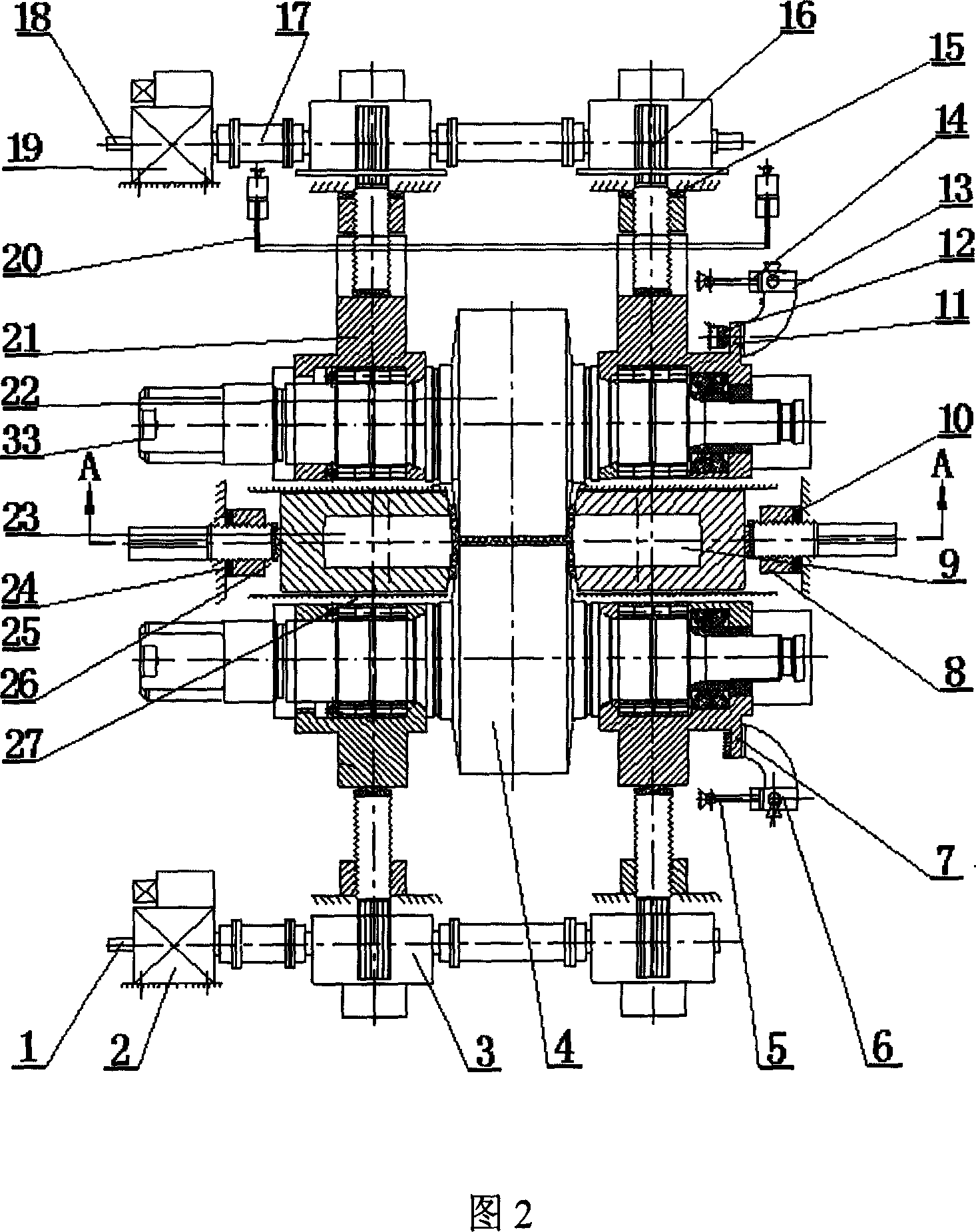

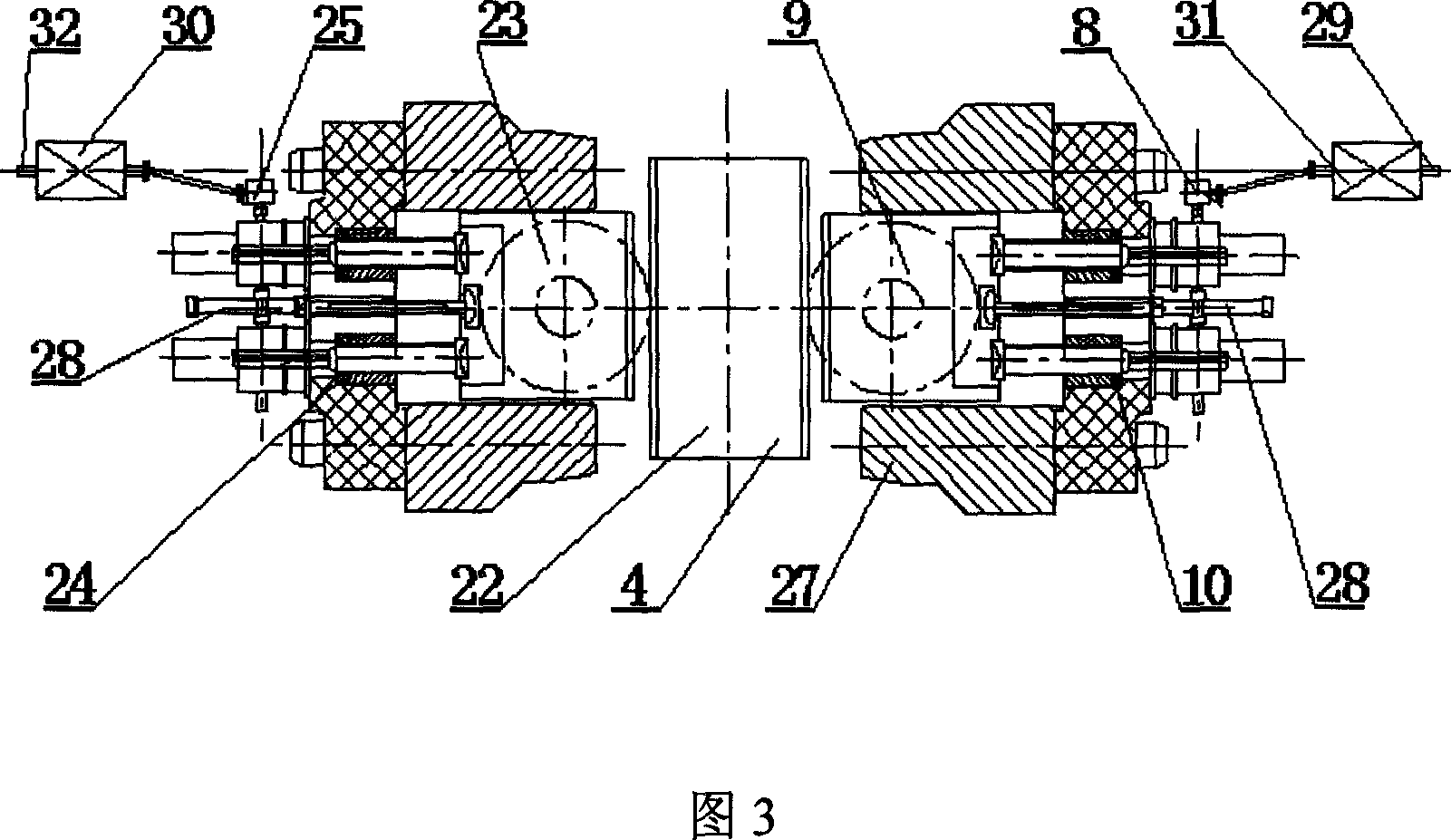

[0028] Referring to Fig. 1, Fig. 2 and Fig. 3 for the structure of the zeroing control process and related equipment of the present invention, the present invention provides a reversible universal section mill roll zeroing control method with dynamic axial adjustment of the upper roll.

[0029] As can be seen from Fig. 2 and Fig. 3, what the method provided by the present invention relates to is the reversible universal section steel rolling mill with the dynamic axial adjustment of the upper roll, including the upper horizontal roll 22, the lower horizontal roll 4, the operation side vertical roll 9 and Drive side vertical roller 23. The screw rod 16 is driven by the pressing motor 19 to move up and down the upper horizontal roller 22 through the two upper roller pressing mechanisms in the upper roller pressing mechanism 17; The lower roller pressing mechanism presses the screw mandrel to drive the up and down movement adjustment of the lower horizontal roller 4 . Pressing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com