Bedplate of industrial sewing machine fabricated by mixing sawdust, wood wool, and wood

A technology for industrial sewing machines and shavings, applied in sewing machine components, sewing equipment, wood processing equipment, etc., can solve the problems of easy deformation of slabs, large wood consumption, high sales price, etc., achieve good rigidity and stability, and save wood materials , The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

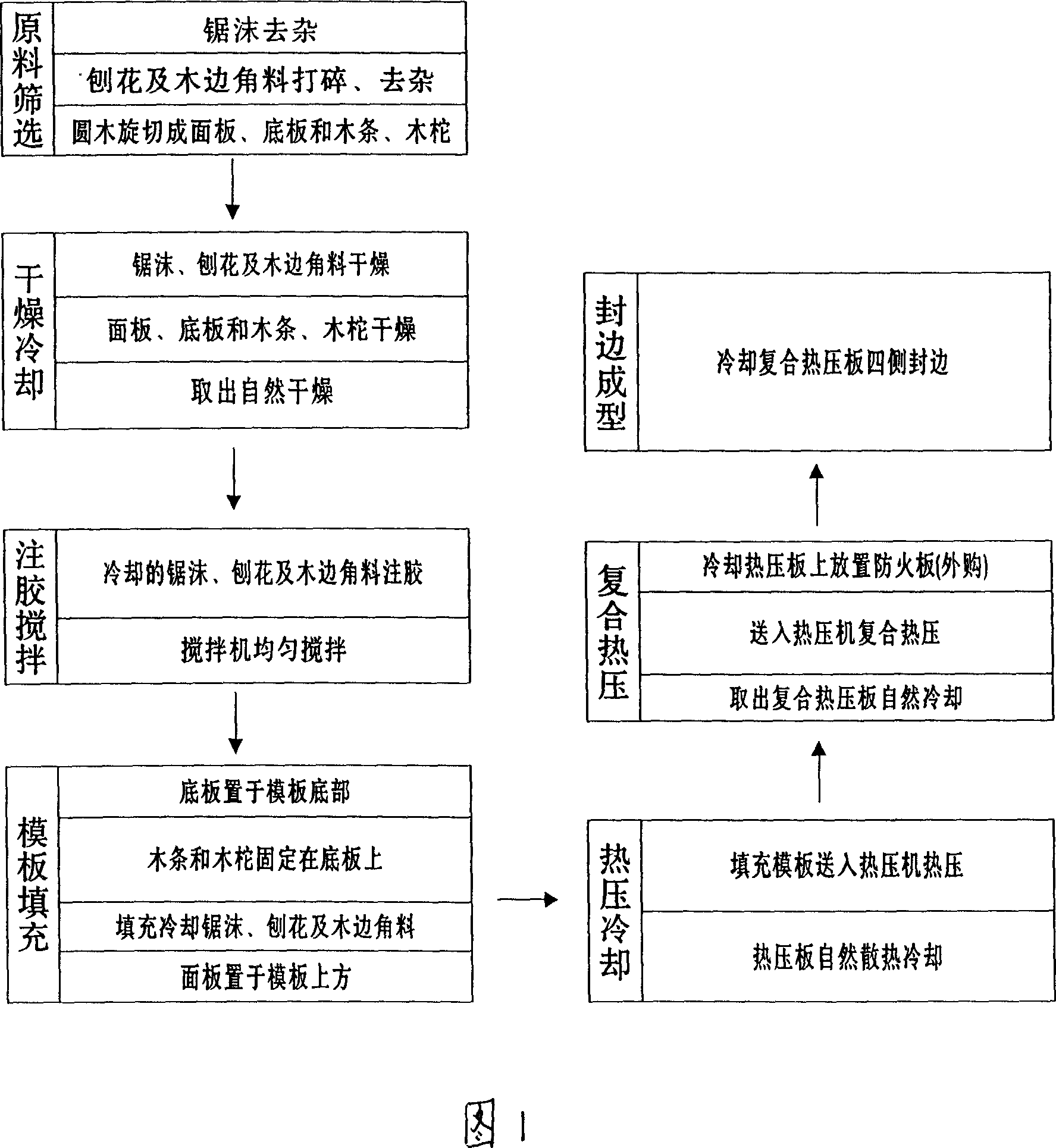

Method used

Image

Examples

Embodiment 1

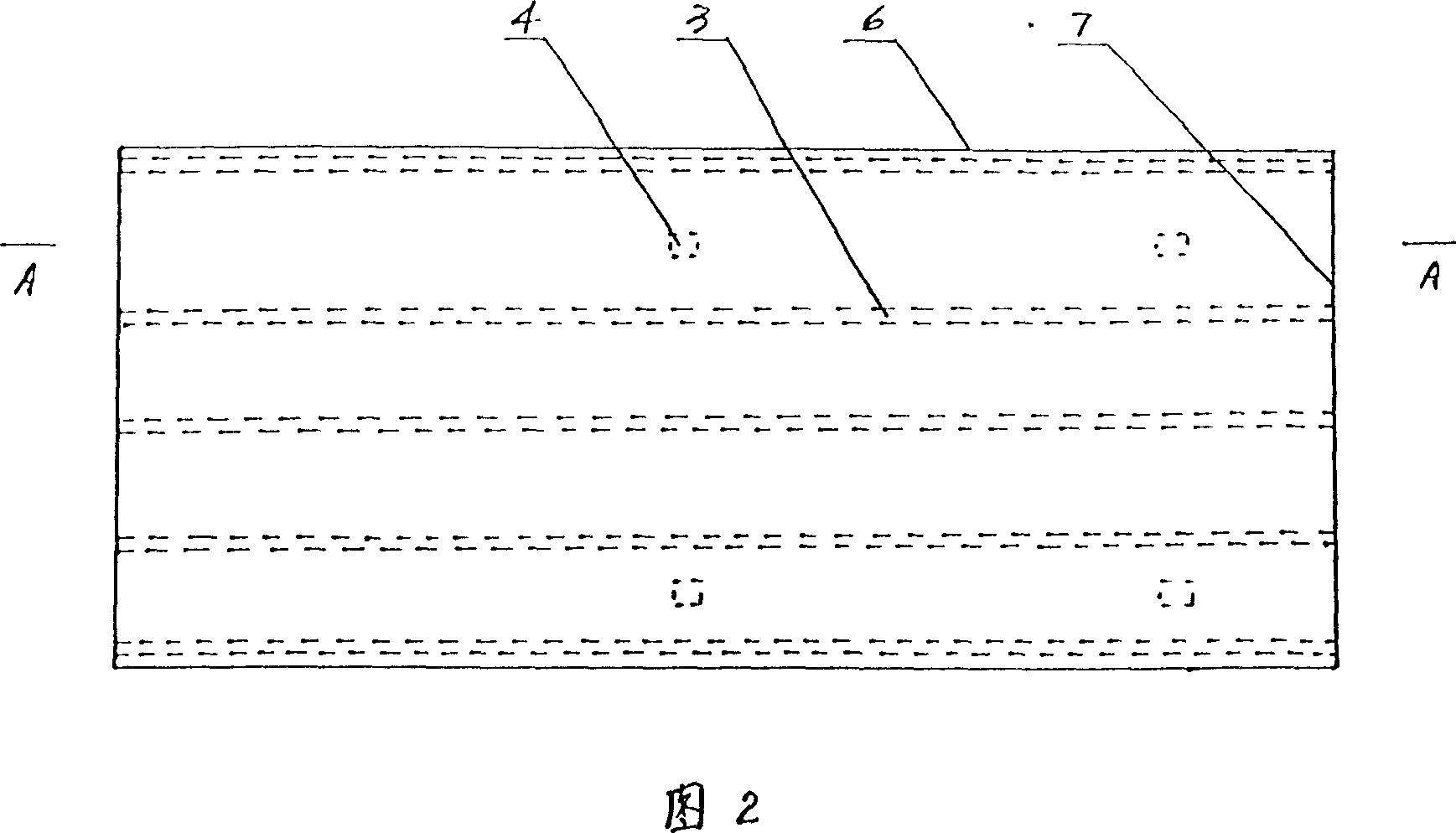

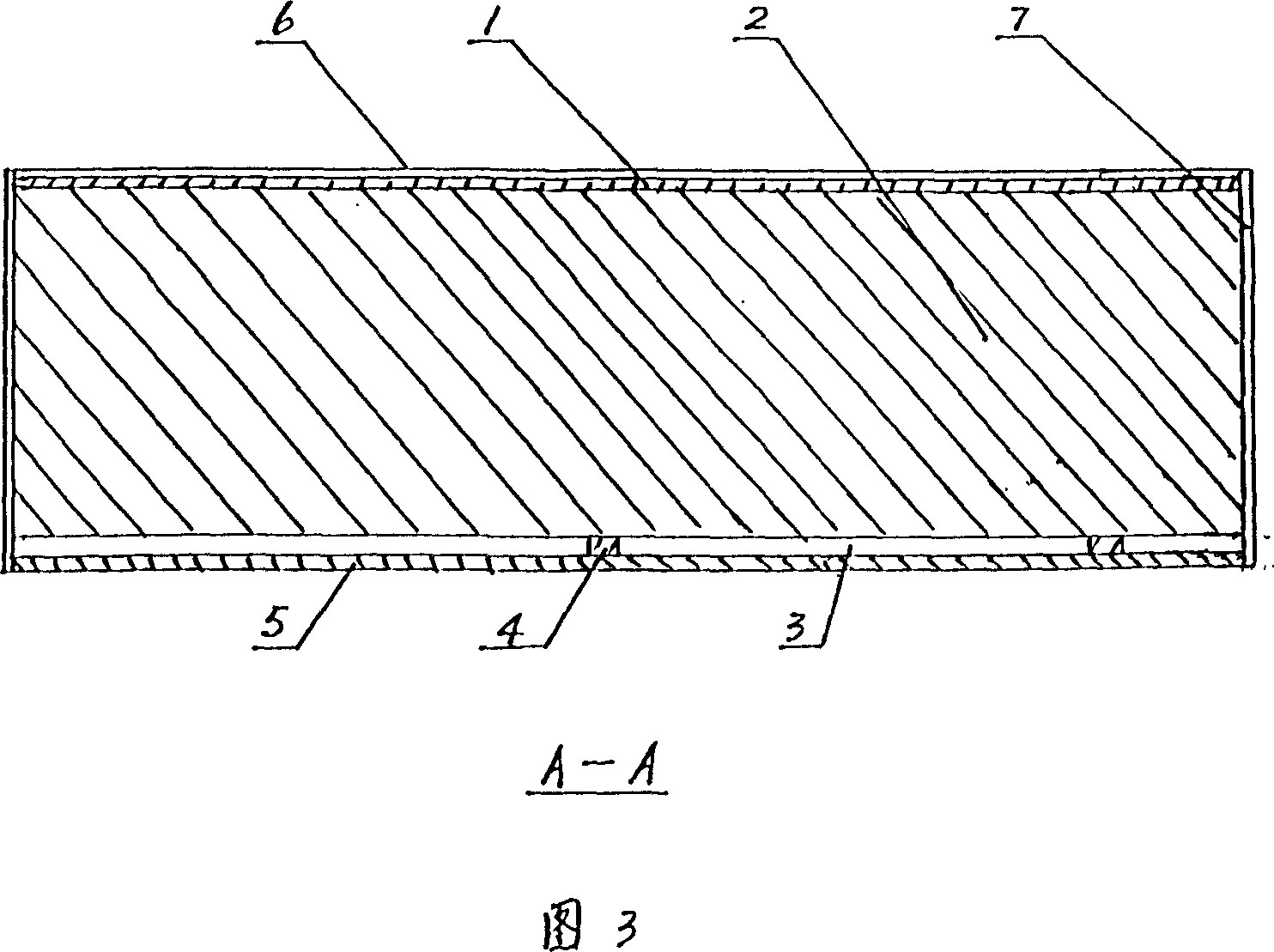

[0033] Embodiment 1: the present invention produced by the above-mentioned process, wherein: ① the outer dimensions of the table are 1200 × 540 × 40mm 3 ; ②The thickness of the panel (1) is 2.1mm, and the thickness of the bottom plate is 3.6mm; ③5 pieces of wood (3) are 1200×15×30mm 3 , 4 wooden watchtowers (4) are 50×50×30mm 3 ; ④ Use wooden strips to seal the edge of the composite hot-pressed plate.

Embodiment 2

[0034] Embodiment two: adopt the present invention that above-mentioned technological process is produced, wherein: ① table top external dimension is 1070 * 540 * 40mm 3 ; ②5 pieces of wood (3) are 1070×15×30mm 3 ; ③ The composite hot-pressed board is formed with a bendable fire-proof board.

Embodiment 3

[0035] Embodiment three: adopt the present invention that above-mentioned technical process is produced, wherein: ① platen external dimension is 1000 * 500 * 38mm 3 ; ②5 pieces of wood (3) are 1000×15×30mm 3 ; ③ Use rubber strips to seal the edge of the composite hot-pressed plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com