Practicing teaching system of flexible automatic production line based on network control

An automatic production line and network control technology, applied in the field of practical teaching systems, can solve problems such as low teaching efficiency, few training items, and low equipment utilization, achieve flexible and convenient control and management, improve learning interest and efficiency, and enhance monitoring. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

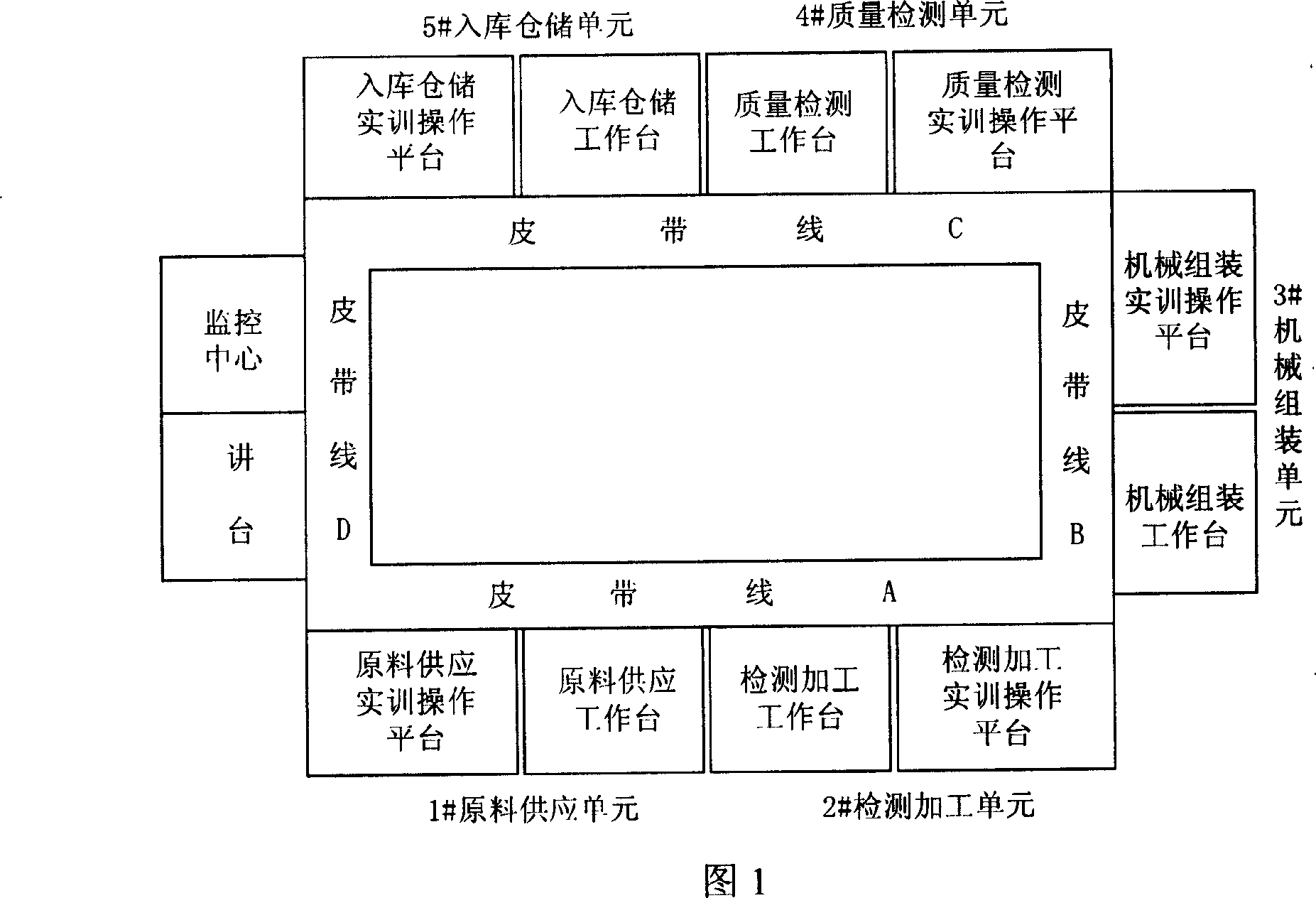

[0026] The practical teaching system of the flexible automatic production line of the present invention mainly includes a workbench and a training operation platform matched with the workbench. training platform.

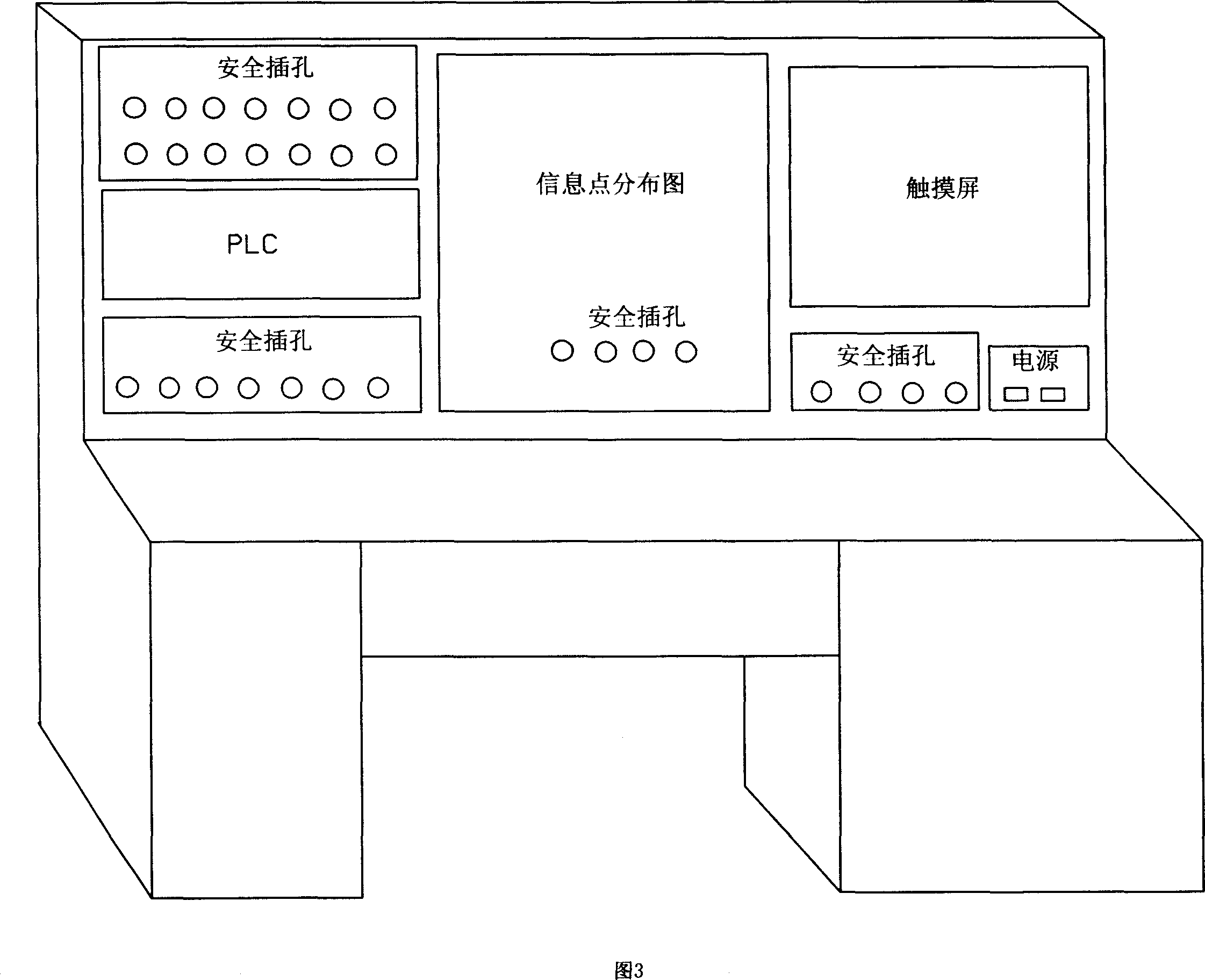

[0027] The training console includes a table body, a power supply, a control unit, an information point distribution map and a safety jack located on the table body; the power supply, the control unit and the safety jack are interconnected.

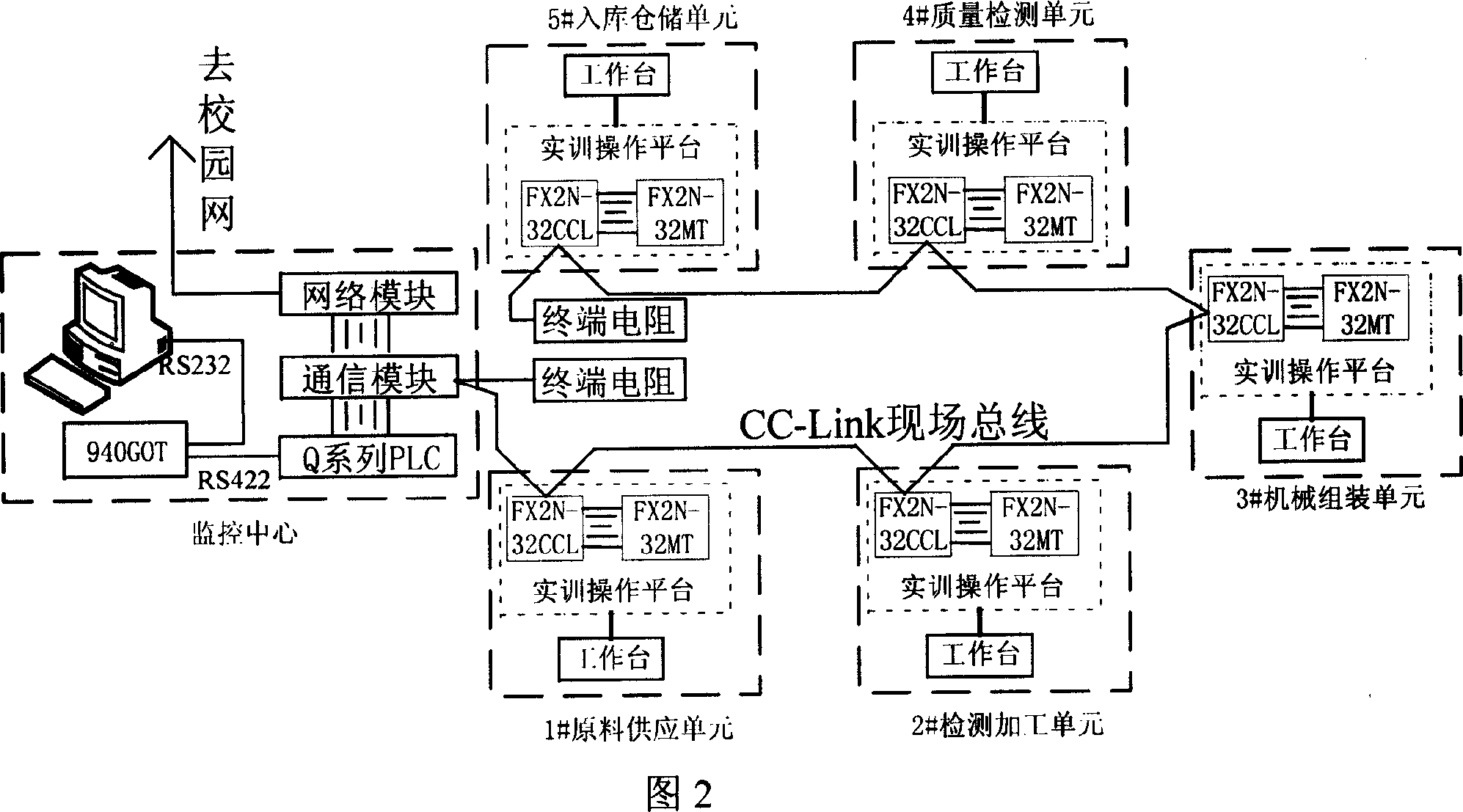

[0028] The control unit includes a PLC, a touch screen, a computer, a communication module and / or a frequency converter, which are interconnected and interconnected. The PLC is used to process various logic and digital operations, and the touch screen is used as a human-computer interaction interface to send various control commands. , parameter setting and running parameters and status display; the computer is monitored through the configuration software; the communication module is used for the communication of multiple work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com