Optical film

An optical film and optical technology, applied in the field of optical film, can solve the problems of impossible to expect light scattering effect, increased work difficulty, limited refraction direction, etc., to avoid optical coupling phenomenon, eliminate ripples, and improve productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the optical films shown in the drawings are exaggerated for convenience of description.

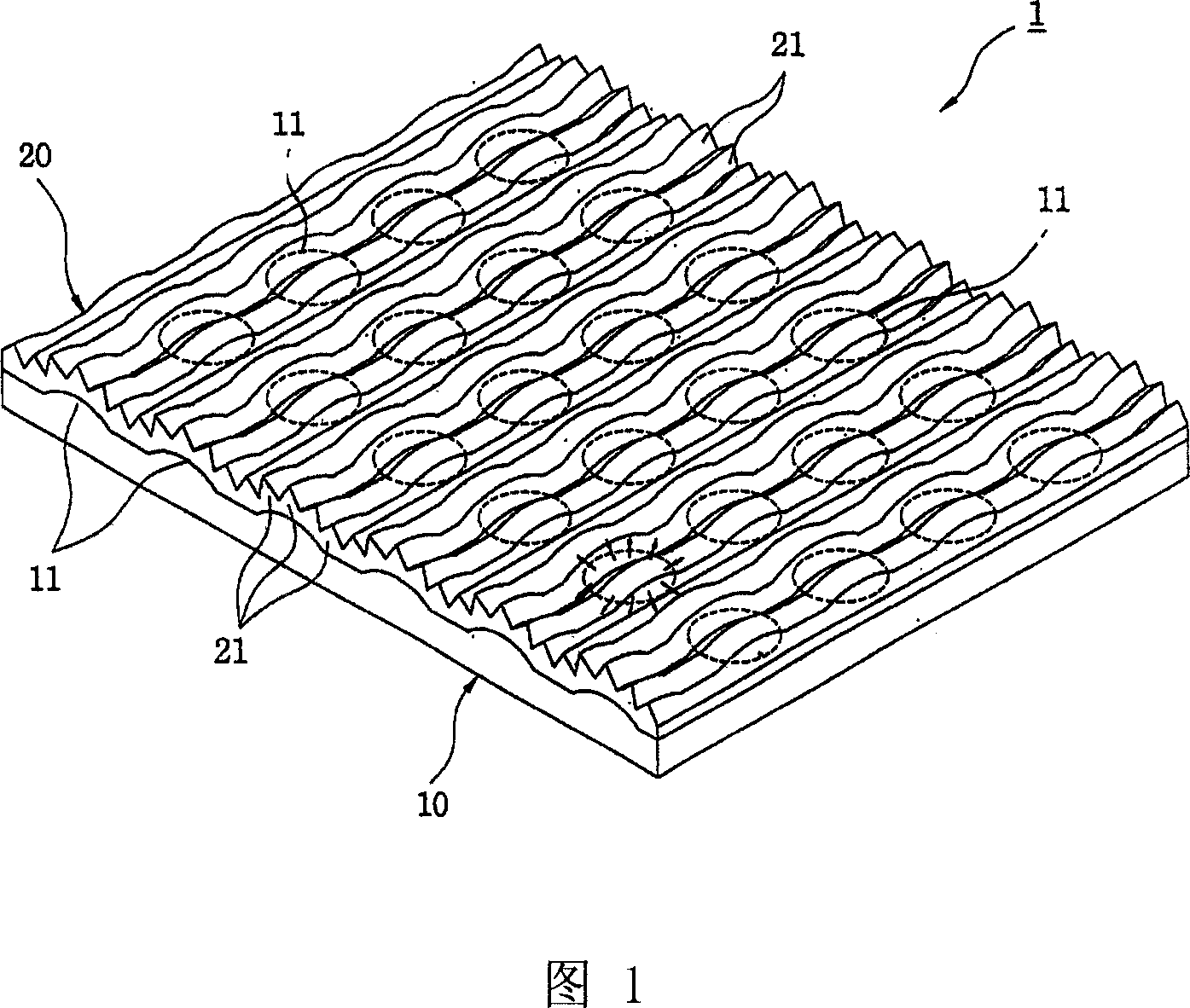

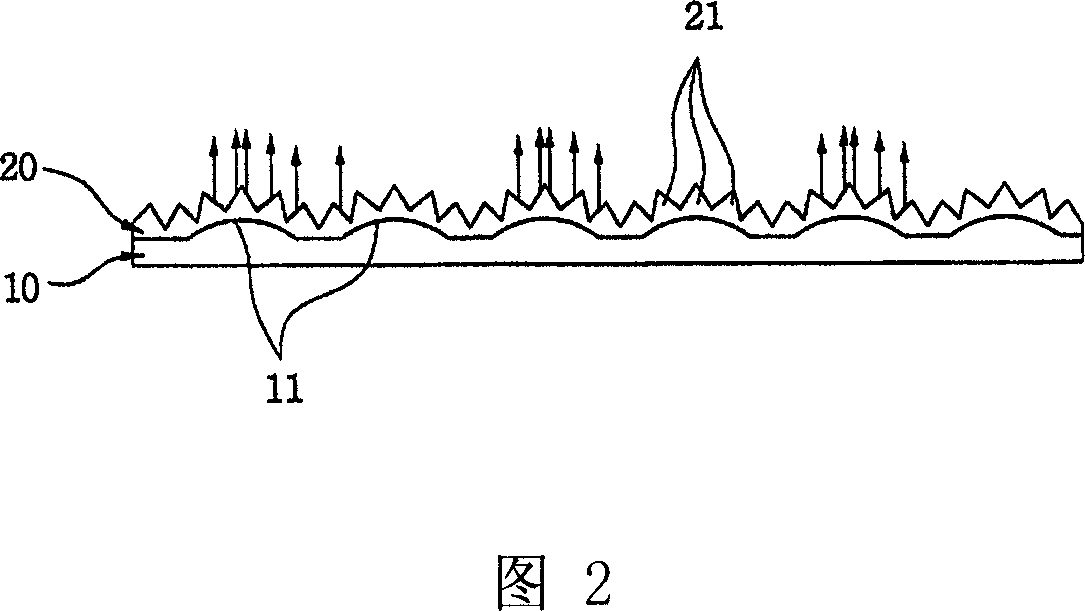

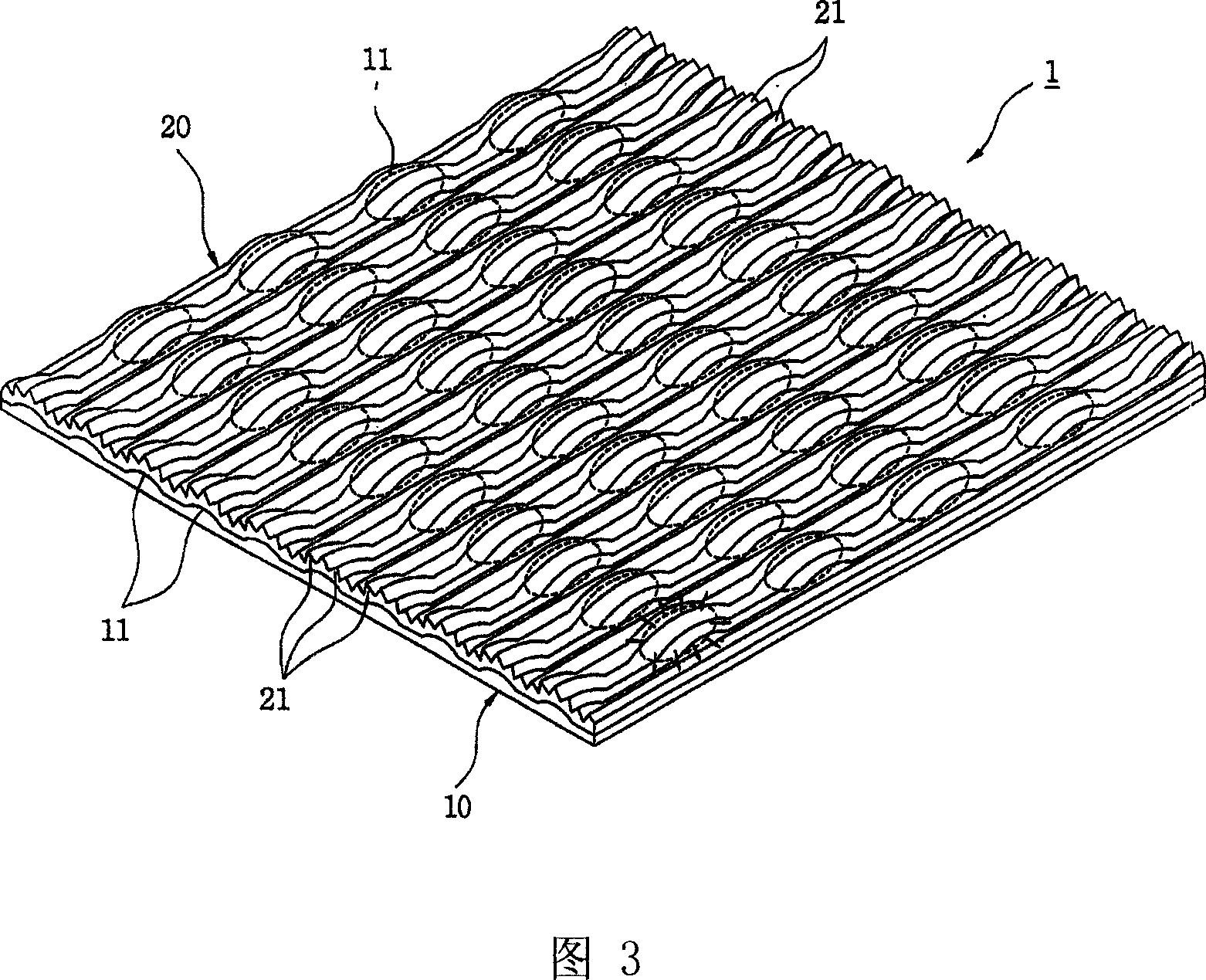

[0031] FIG. 1 is a perspective view of an optical film according to a first embodiment of the present invention, and FIG. 2 is a cross-sectional view of the optical film shown in FIG. 1 . As shown in the figure, the optical film 1 of the present embodiment includes a first refraction portion 10 having a plurality of first optical lens patterns 11 for collecting and diverging light emitted from a light source 105 at a predetermined angle. And incident on the first refraction part 10; And there is the second refraction part 20 of a plurality of second optical patterns 21, and this second optical figure collects the light that is diverged by the first refraction part 10, and the light that collects is vertically transmitted to Panel 107.

[0032] As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com