Anti scrap-jumping device used in high-speed precise punching die

A precision stamping die, anti-jump technology, applied in the direction of perforation tools, manufacturing tools, forming tools, etc., can solve the problem of poor chip removal effect of suction air, so as to save manual anti-jump work, prevent chip jump, The effect of solving the problem of chip jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

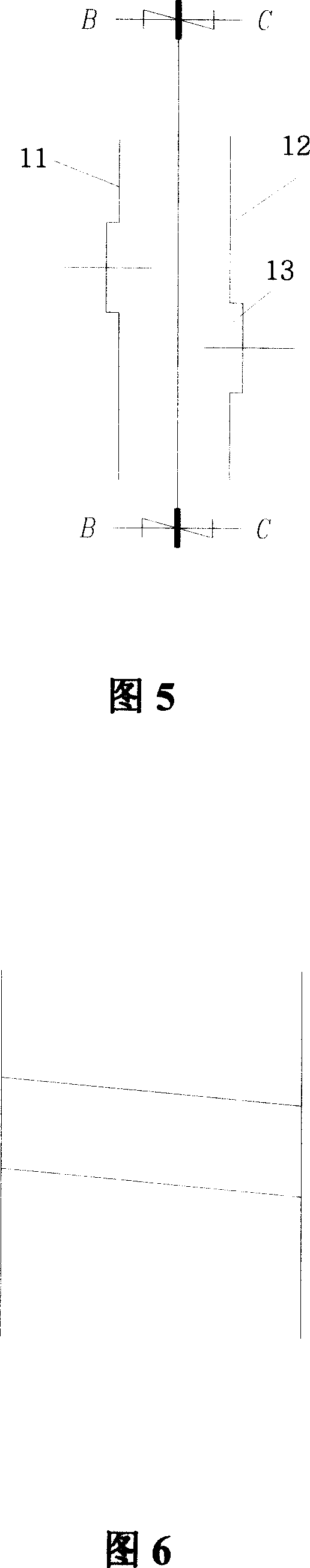

[0019] Visible by Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7: the present invention comprises punching edge 1; Described punching edge comprises left and right two edges (11,12); , 12) also includes 2-4 gaps 13 with a width of 0.005-0.008mm and a length of 0.5-1.0mm; the relative gaps 13 on the left and right sides (11, 12) are dislocated; the gaps 13 has a slope and the slope of the notch 13 on the left and right two knife edges (11, 12) is opposite;

[0020] The slope is between 2°-3°.

[0021] Due to the addition of the gap, the present invention makes the shape relatively complicated without affecting the shape of the stamped product, even if its resistance increases; and the original straight part of the knife edge is canceled, and the blanking slope is directly added as the cutting edge, so that After the waste material enters the knife edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap