Bone ash jar surface pattern and character production method

A production method and technology for columbariums, which are applied in the fields of crafts and decorative arts for producing decorative surface effects, can solve the problems of inconvenient production and processing, primer oxidation, production troubles, etc., and achieve the effect of simple, convenient and fast production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

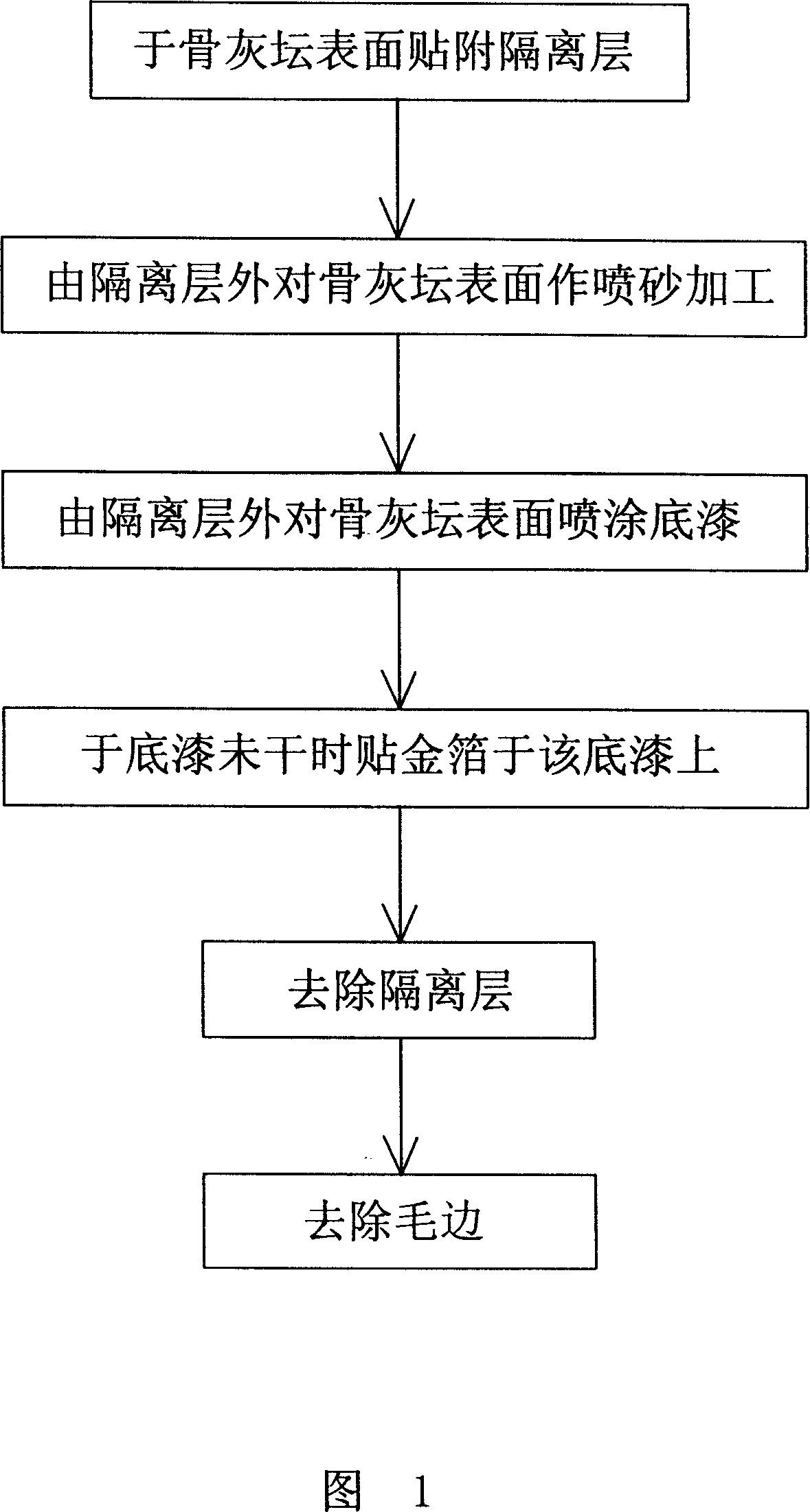

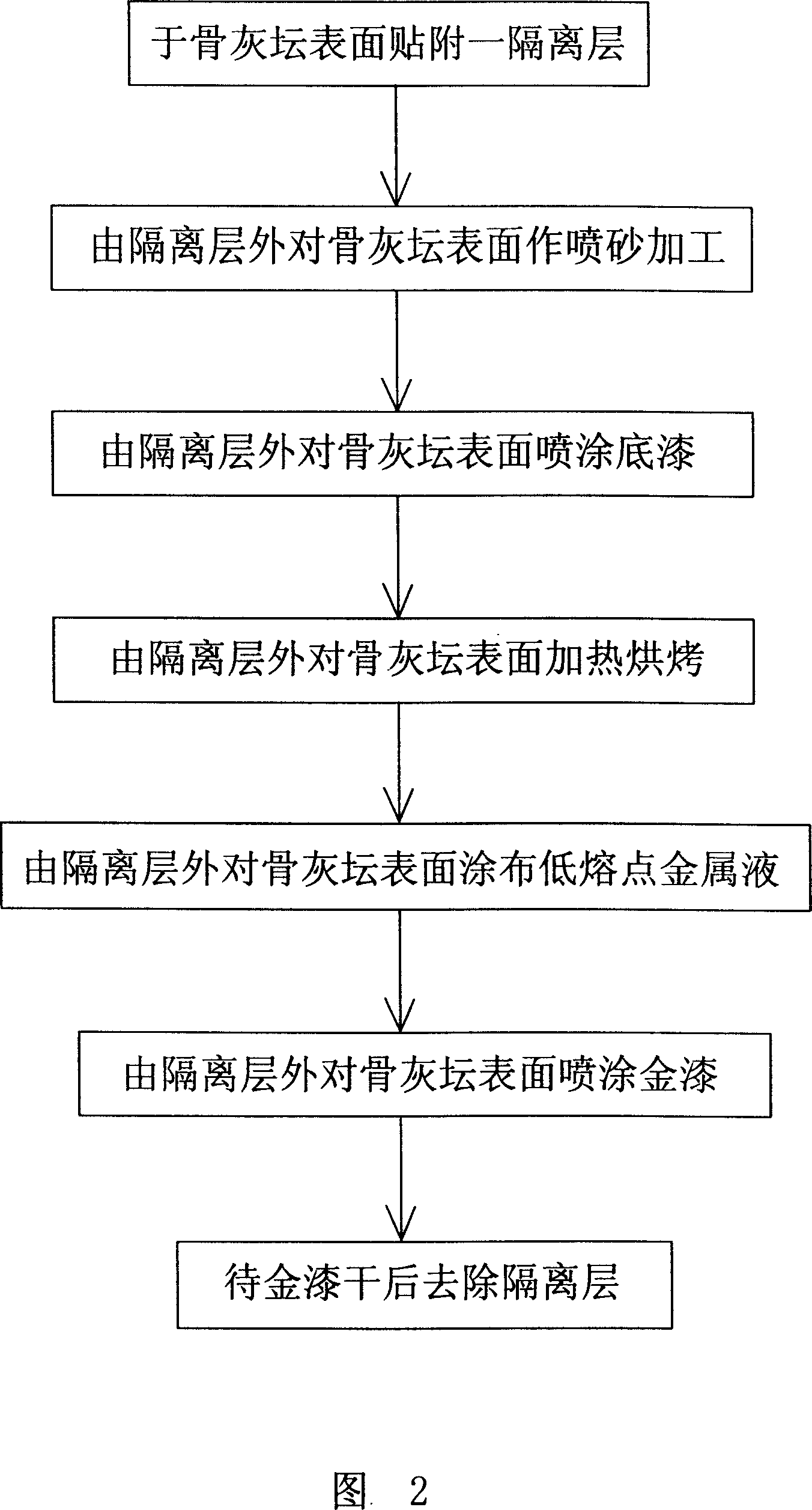

[0032] Embodiment 1, please refer to Fig. 2, the method for making the pattern and characters on the surface of the columbarium of the present invention, its specific steps are as follows:

[0033] a. Attach an isolation layer on the surface of the columbarium: the isolation layer has a barrier area and an erosion area, wherein the isolation area is not easy to wear and resistant to high temperature, while the erosion area is easy to be worn;

[0034] b. Sandblasting the surface of the columbarium attached with the isolation layer: place the columbarium attached with the isolation layer in the sandblasting room, so that the eroded area is worn away and the surface of the urn at the bottom of the eroded area Depressions that are etched to an appropriate depth;

[0035] c. Spray primer on the surface of the columbarium from the outside of the isolation layer: spray gold, red, blue or other colors of paint on the surface of the columbarium from the outside of the isolation layer,...

Embodiment 2

[0040] Embodiment 2, its manufacturing steps are referring to Fig. 2, and its specific implementation steps are referring to embodiment 1, and its difference is: the drying temperature in the d step is 120 ℃, and the time is 20 minutes; The low-melting point metal liquid in the e step is tin , and the method of coating the tin metal solution on the surface of the columbarium is chemical vapor deposition.

Embodiment 3

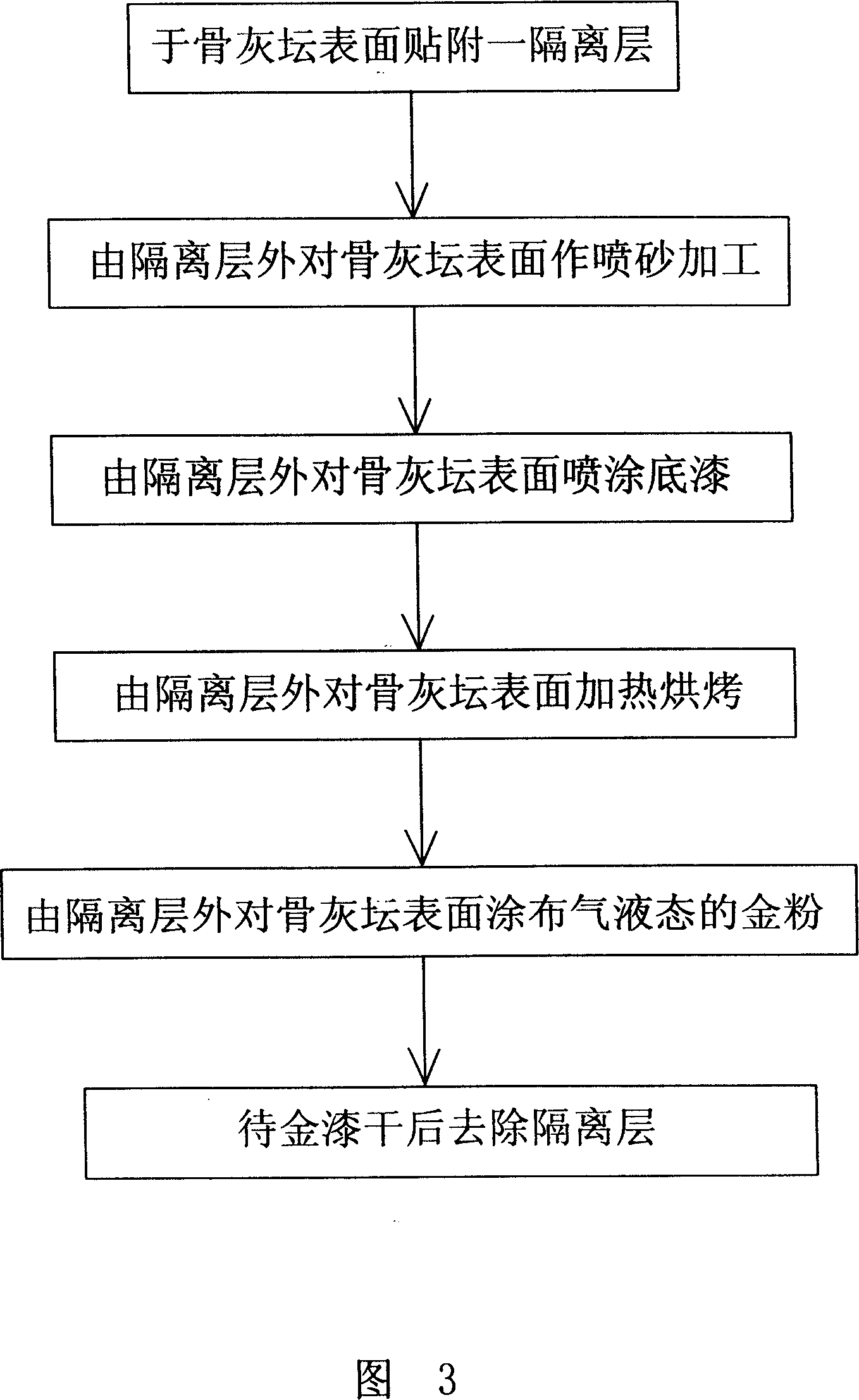

[0041] Embodiment 3, please refer to Fig. 3 for its manufacturing steps, its processing steps are roughly the same as in Embodiment 1, the only difference is that step e of Embodiment 1 is changed to be formed by spraying gold powder on the surface of the columbarium from the outside of the isolation layer. Gas-liquid metal liquid, the coating method is the dipping coating method, and the subsequent f step is omitted, directly jump to the g step to tear off the isolation layer, and at the same time, the drying temperature in the d step is 60 ℃, the time for 2 hours.

[0042] The structure of the isolation layer mentioned above has a barrier area and an erosion area, and one side of it is sticky and can be directly pasted on the surface of the columbarium, wherein the barrier area is made of a material that is not easy to wear and resistant to high temperature For example, rubber film, etc., its wear resistance is so high that even if the columbarium is sandblasted to a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com