Preparation process of high-stress-resistance self-repairing water-based paint

A technology of water-based paint and preparation process, applied in the direction of coating, etc., to achieve the effect of prolonging the service life, strong stability, and inhibiting the enlargement of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

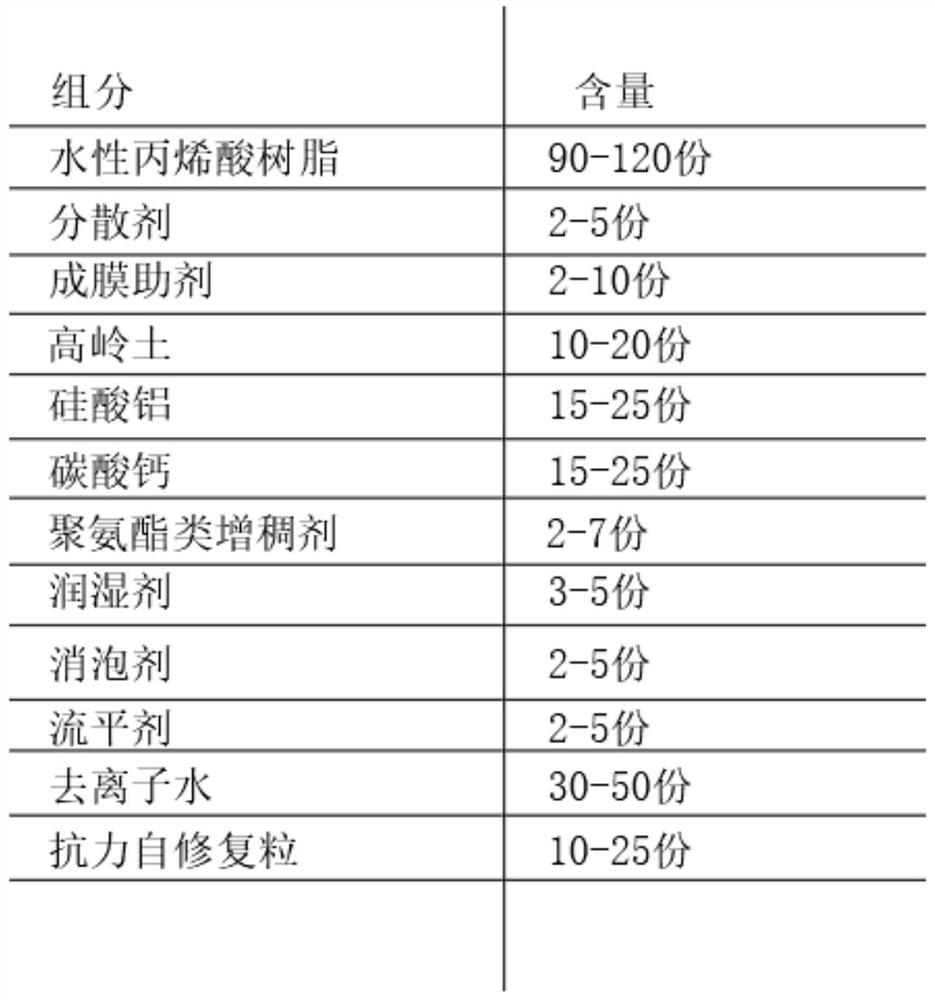

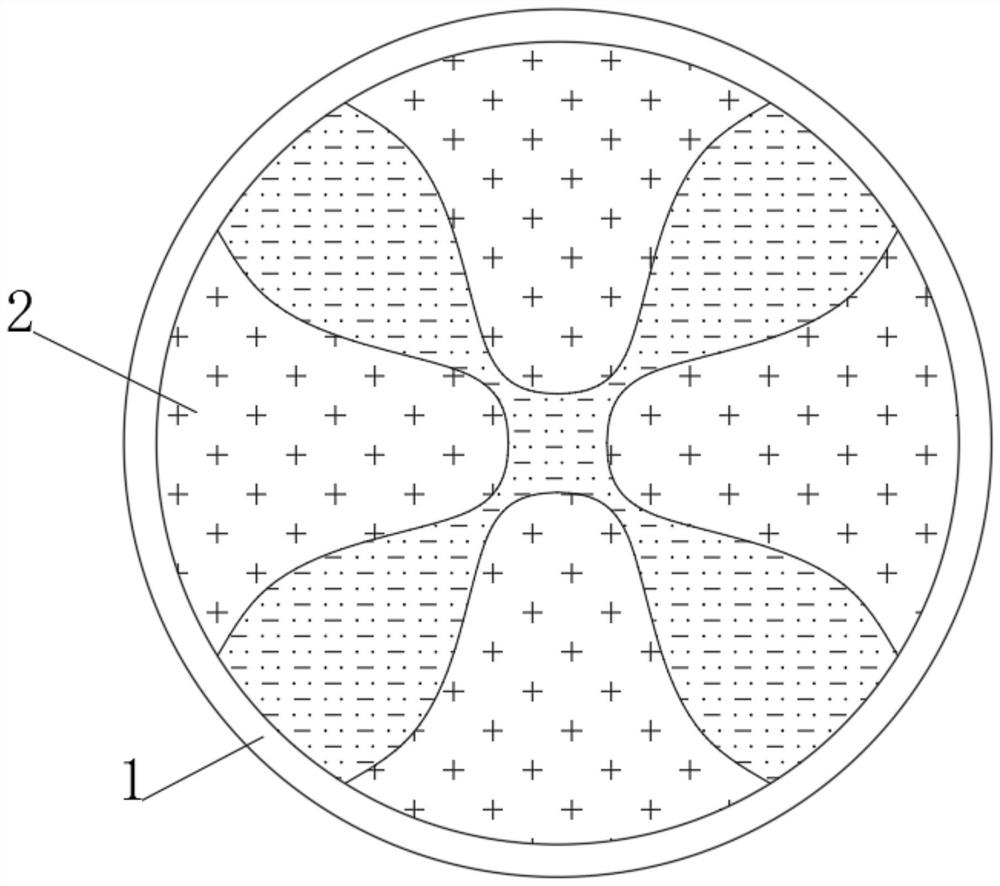

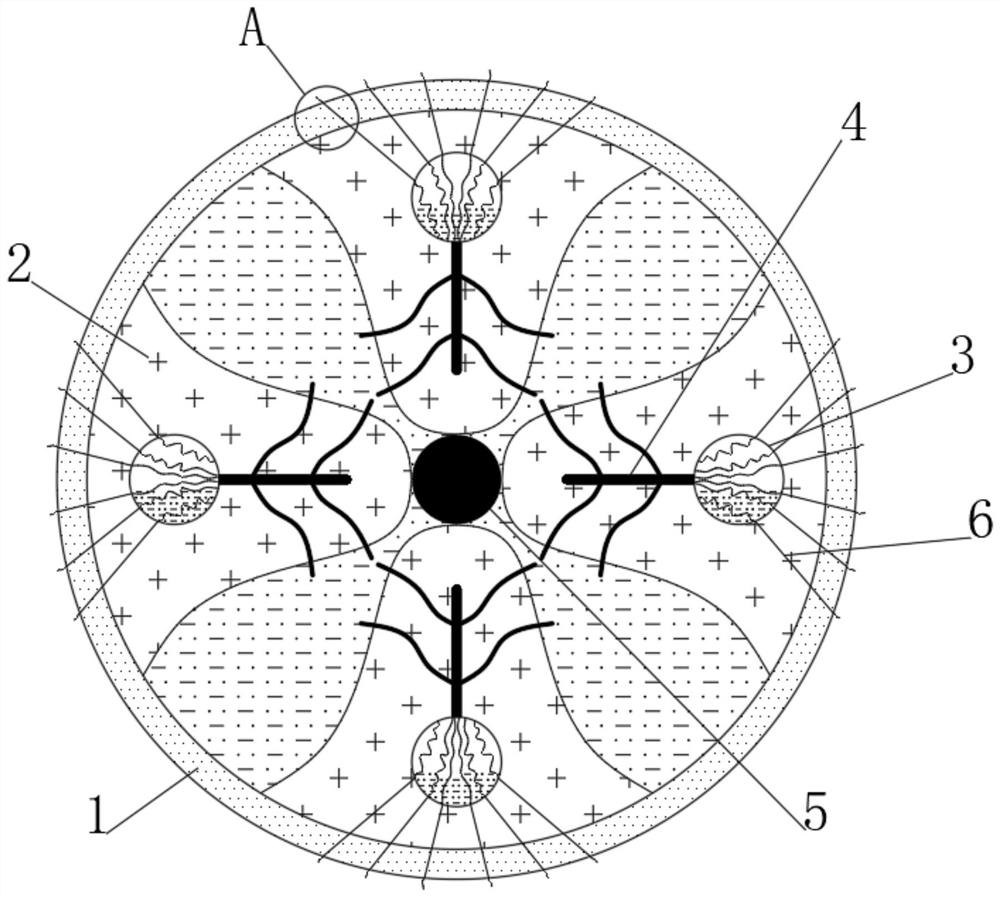

[0043] see figure 1 , a preparation process of high stress resistance self-healing water-based paint, the water-based paint includes the following ingredients in parts by mass: 100 parts of water-based acrylic resin, 3 parts of dispersant, 8 parts of film-forming aids, 15 parts of kaolin, silicic acid 20 parts of aluminum, 20 parts of calcium carbonate, 5 parts of polyurethane thickener, 4 parts of wetting agent, 4 parts of defoamer, 4 parts of leveling agent, 40 parts of deionized water and 15 parts of resistance self-repairing granules. The process includes the following steps:

[0044] S1. Put the above-mentioned water-based acrylic resin, dispersant and deionized water in a disperser, stir for 40 minutes, then add defoamer and wetting agent, and perform high-speed stirring at not less than 1000 rpm, stirring time Not less than half an hour to obtain a homogeneous mixture;

[0045] S2. Add film-forming aids, kaolin, aluminum silicate, and calcium carbonate to the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com