Method for making thermal-insulating steel door window profile

A manufacturing method and technology for steel doors and windows, which are applied in the directions of windows/doors, building structures, wing fan frames, etc., can solve the problems of reducing the heat insulation effect of steel door and window profiles of thermal break bridges, and achieve good heat insulation effect, firm structure, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

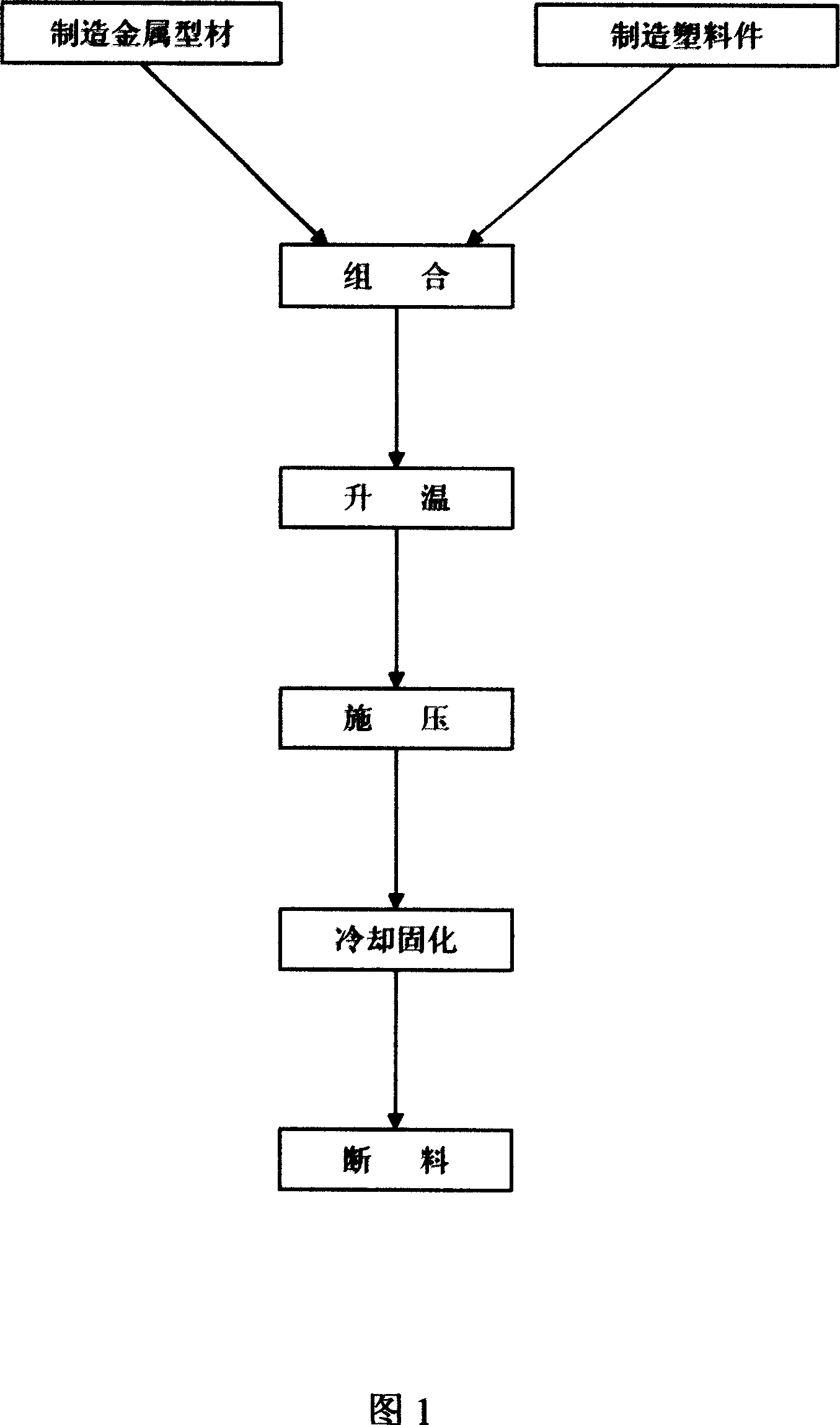

[0027] 1, a kind of manufacture method of thermal break bridge steel door and window profile, it is characterized in that according to process flow chart, the steps of its implementation are as follows:

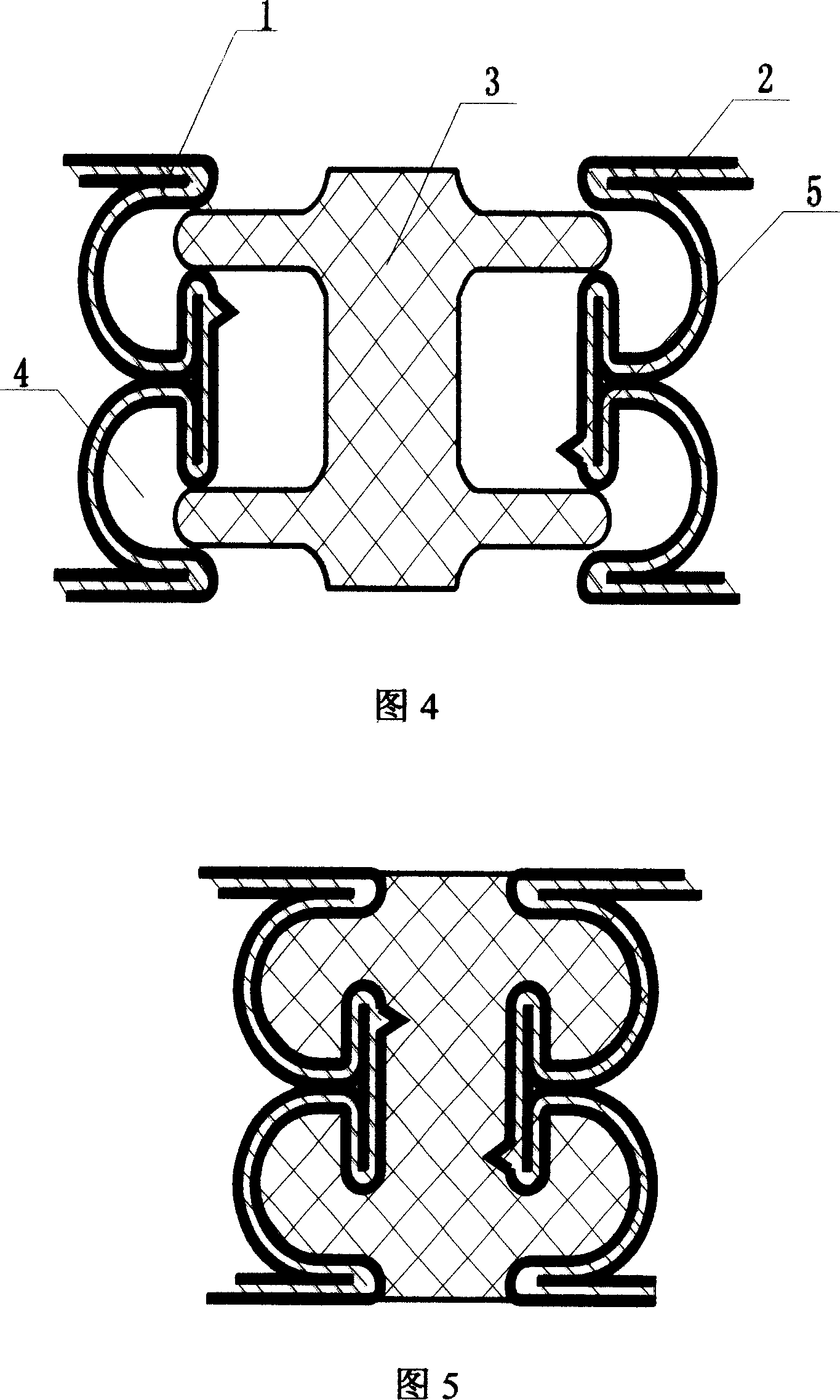

[0028] (1) Manufacture of metal profiles: steel profiles with cavities suitable for processing doors and windows are manufactured through a cold rolling mill;

[0029] (2) Manufacture of plastic parts: through the extruder, the plastic is made into a plastic part with a cross-section that meets the requirements;

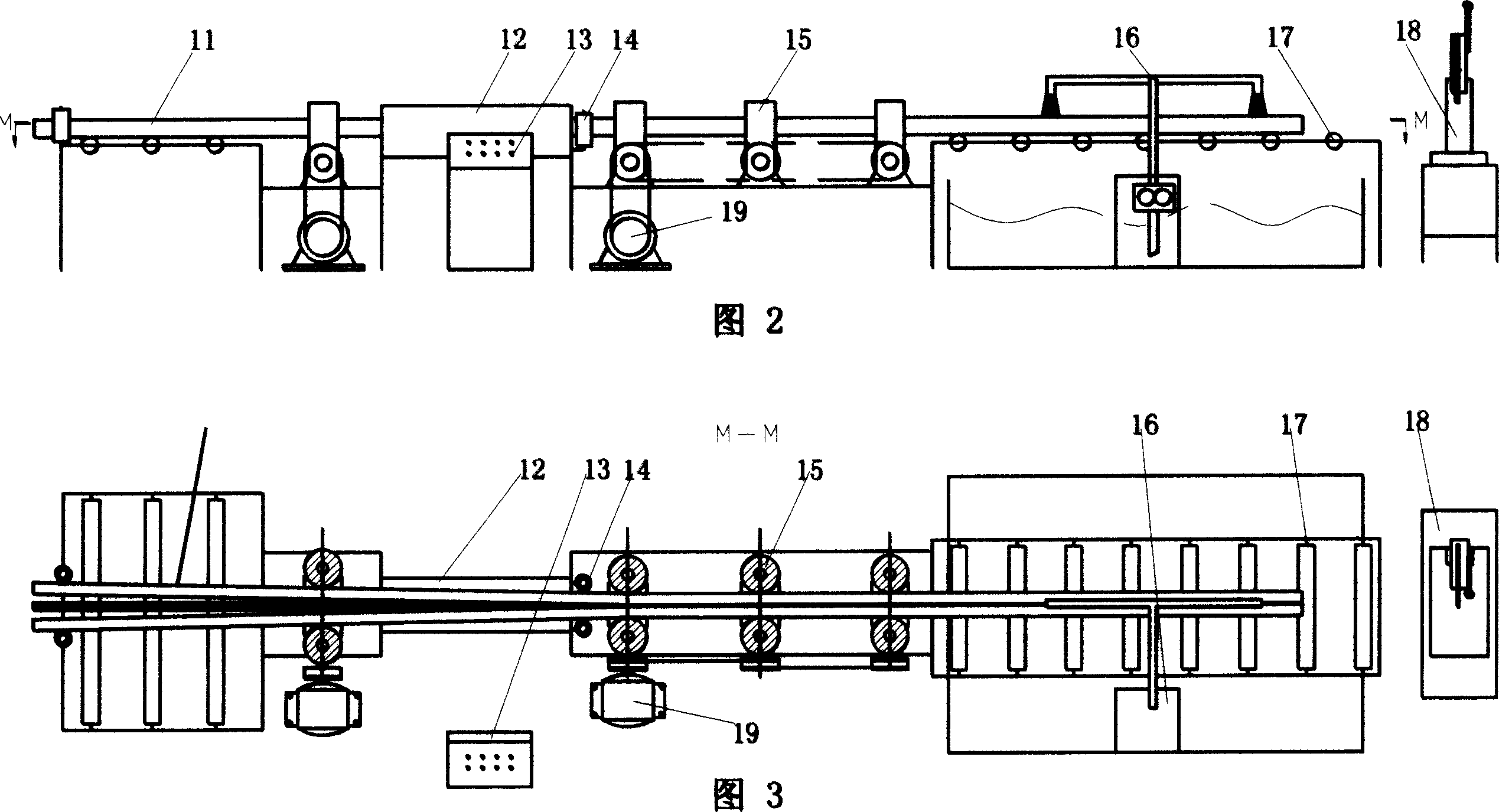

[0030] (3) Combination: put two steel profiles and a plastic part between them on the composite production equipment, and combine them according to the concave and convex of the steel profiles and plastic parts;

[0031] (4) Heating up: Send the assembly of steel profiles and plastic parts into the heating oven, heat for 3 minutes, and control the temperature at 180°C;

[0032] (5) Pressure application: heat to the softening point of the plastic, apply pressure to ...

Embodiment 2

[0036] 1, a kind of manufacture method of thermal break bridge steel door and window profile, it is characterized in that according to process flow chart, the steps of its implementation are as follows:

[0037] (1) Manufacture of metal profiles: steel profiles with cavities suitable for processing doors and windows are manufactured through a cold rolling mill;

[0038] (2) Manufacture of plastic parts: through the extruder, the plastic is made into a plastic part with a cross-section that meets the requirements;

[0039] (3) Combination: put two steel profiles and a plastic part between them on the composite production equipment, and combine them according to the concave and convex of the steel profiles and plastic parts;

[0040] (4) Heating up: Send the assembly of steel profiles and plastic parts into the heating oven, heat for 4 minutes, and control the temperature between 140°C;

[0041] (5) Pressure application: heat to the softening point of the plastic, apply pressur...

Embodiment 3

[0045] 1, a kind of manufacture method of thermal break bridge steel door and window profile, it is characterized in that according to process flow chart, the steps of its implementation are as follows:

[0046] (1) Manufacture of metal profiles: steel profiles with cavities suitable for processing doors and windows are manufactured through a cold rolling mill;

[0047] (2) Manufacture of plastic parts: through the extruder, the plastic is made into a plastic part with a cross-section that meets the requirements;

[0048] (3) Combination: put two steel profiles and a plastic part between them on the composite production equipment, and combine them according to the concave and convex of the steel profiles and plastic parts;

[0049] (4) Heating: Send the assembly of steel profiles and plastic parts into the heating oven, heat for 5 minutes, and control the temperature at 110°C;

[0050] (5) Pressure application: heat to the softening point of the plastic, apply pressure to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com