Examining apparatus for spot weld of steel shade thread

A technology of detectors and steel cords, applied in instruments, measuring devices, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

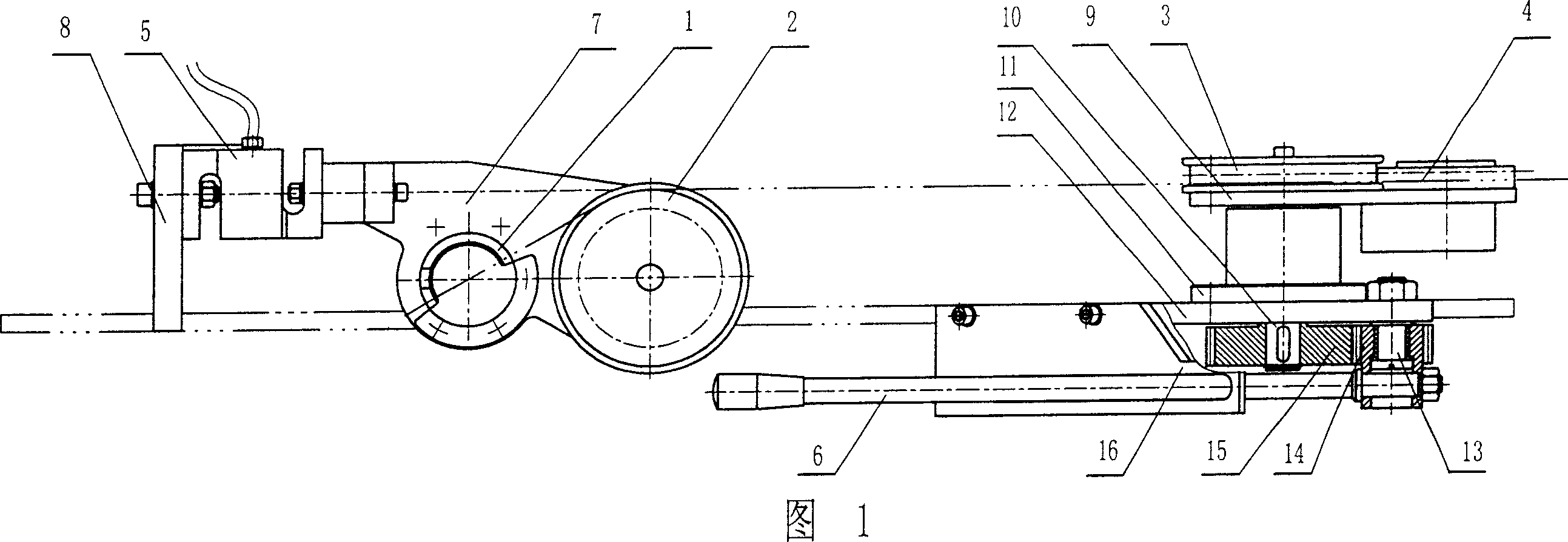

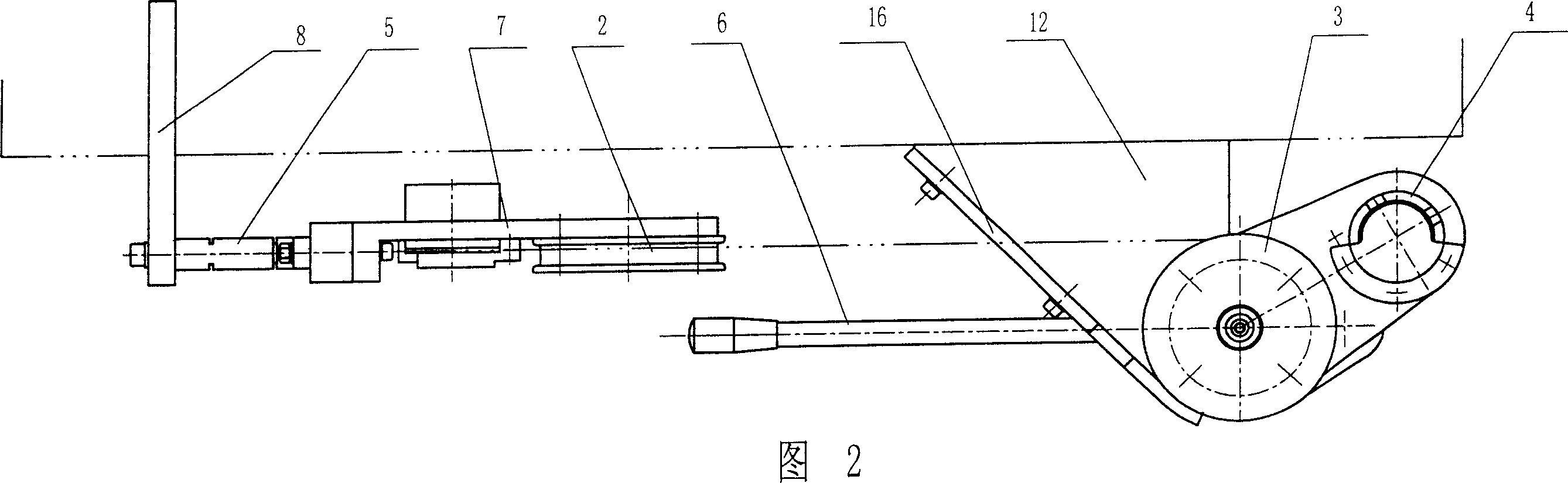

[0009] According to Fig. 1 and shown in Fig. 2, the present invention mainly is made up of left clamp 1, right clamp 4, left reel 2, right reel 3, load cell 5 and operating handle 6. The left clamp 1 and the left reel 2 are fixed on the wheel frame 7, the left end of the wheel frame 7 is fixed to the connecting plate 8 by the load cell 5, the wheel frame 7 is in a vertical state, the signal output line of the load cell 5 is connected to the Indicators are connected. The right winding wheel 3 and the right clamp 4 are fixed on the follower plate 9, and the follower plate 9 is horizontally installed on the upper end of the rotating shaft 10. The rotating shaft 10 is supported by bearings in an axle seat 11 , and the axle seat 11 is mounted on a horizontal support plate 12 . The rotating shaft 10 is connected with the operating handle 6 through a transmission member, and the transmission member includes a pin shaft 13 , a driving gear 14 and a driven gear 15 . The lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com