Sewing machine

A sewing machine and air supply mechanism technology, which is applied in the field of sewing machines, can solve the problems of poor cooling efficiency of the shuttle shaft, adverse effects of stitch formation, and heating of the bottom plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

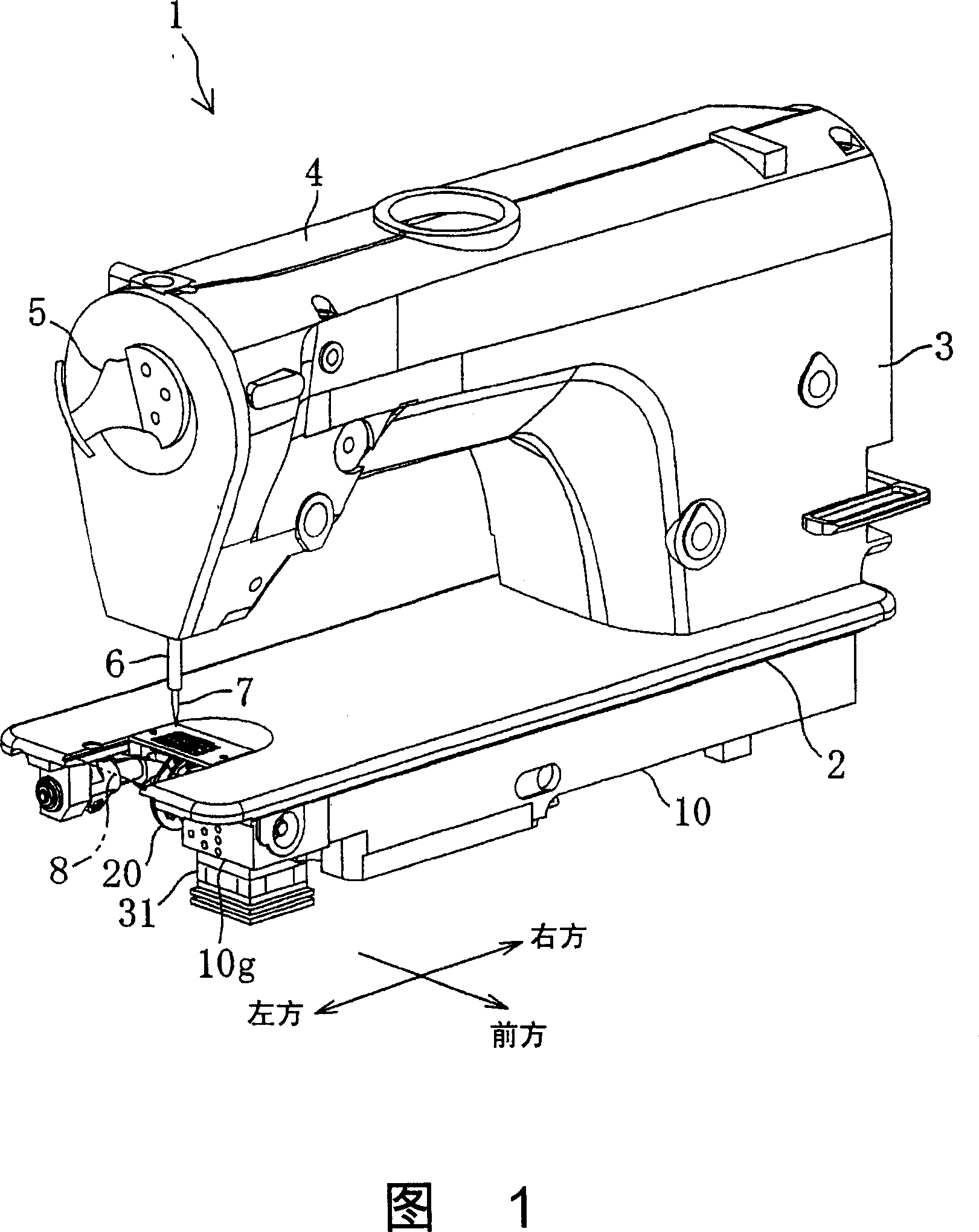

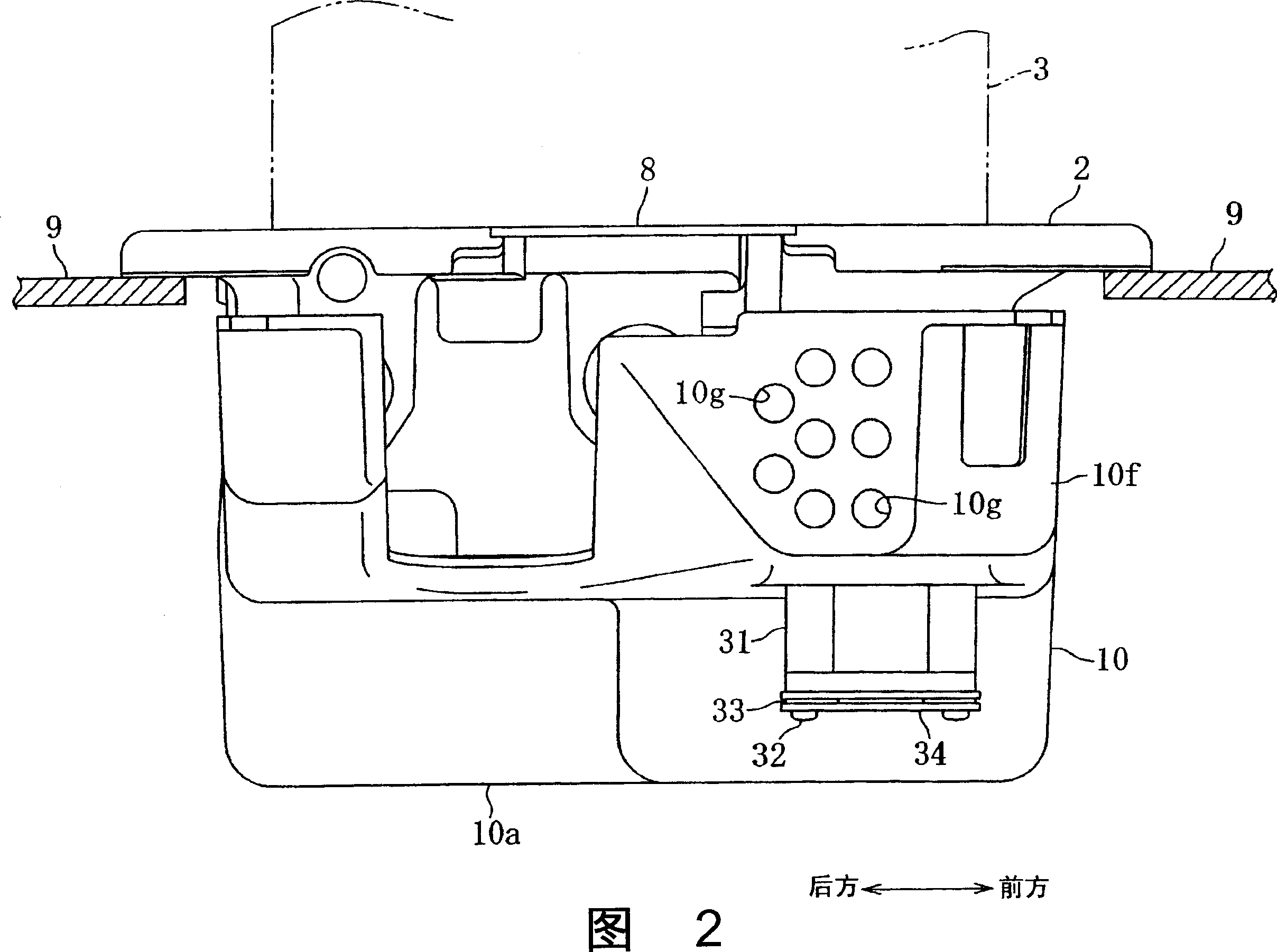

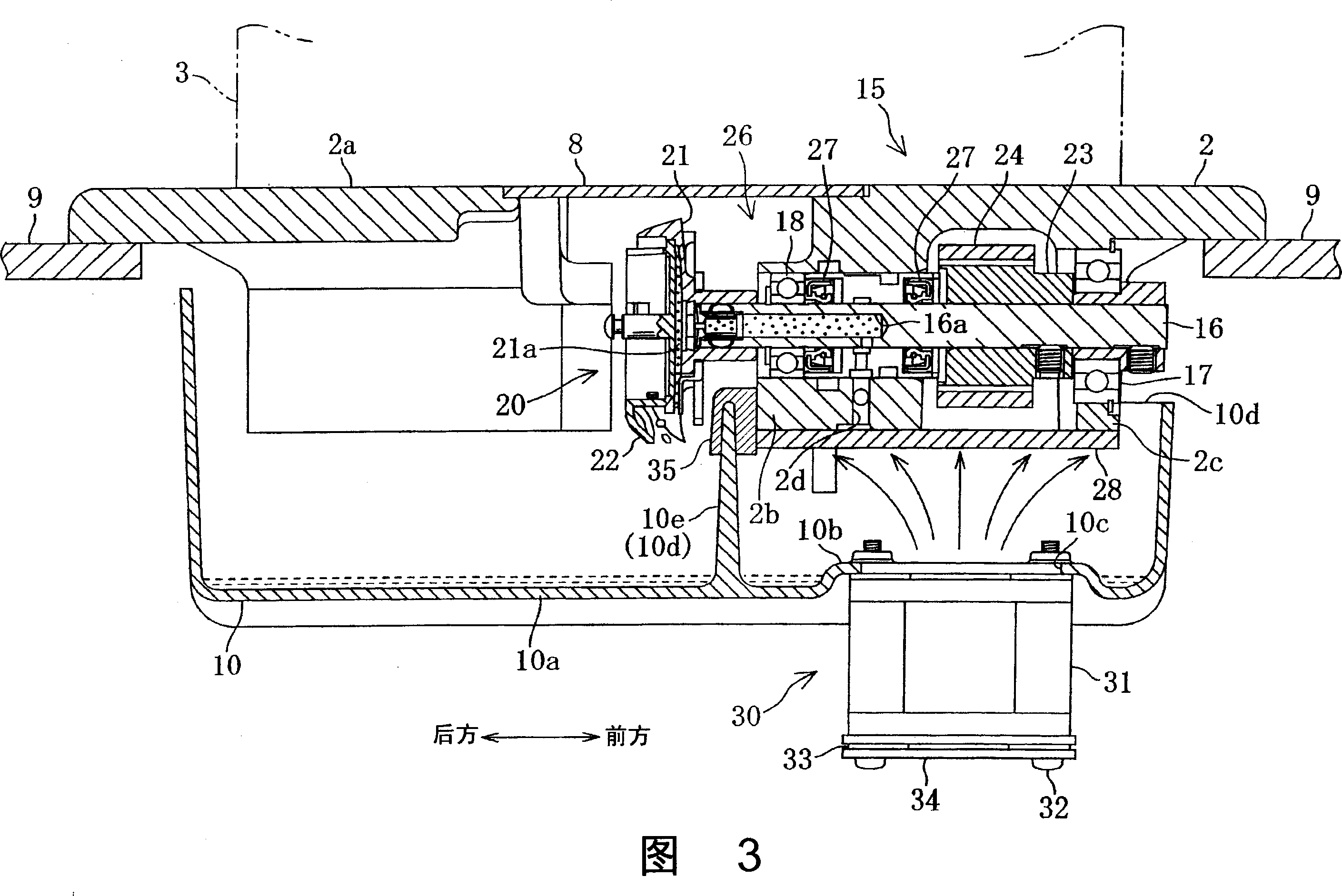

[0014] An embodiment in which the present invention is applied to a zigzag sewing machine will be described below with reference to the accompanying drawings.

[0015] As shown in FIG. 1 , the zigzag sewing machine 1 has a bottom plate 2 , a column 3 standing upright from the right end of the bottom plate 2 , and a casing extending leftward from the upper end of the column 3 facing the bottom plate 2 . part 4. This zigzag sewing machine 1 is fixed on a workbench 9 .

[0016] The casing part 4 is equipped with a sewing machine main shaft (not shown), a needle bar up and down drive mechanism, a rotary thread take-up mechanism (not shown), and the like. The main shaft of the sewing machine is arranged along the left and right directions, and a sewing machine motor (not shown) drives the main shaft of the sewing machine to rotate. The needle bar up and down drive mechanism makes the needle bar 6 with the sewing needle 7 installed at the lower end move up and down. The rotary th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com