Composite drying machine with rotating hanger

A dryer and rotary technology, applied in the field of dryers, can solve problems such as inconvenience for users, increase indoor ambient temperature and humidity, damage clothes, etc., and achieve the effect of shortening drying time and uniform drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

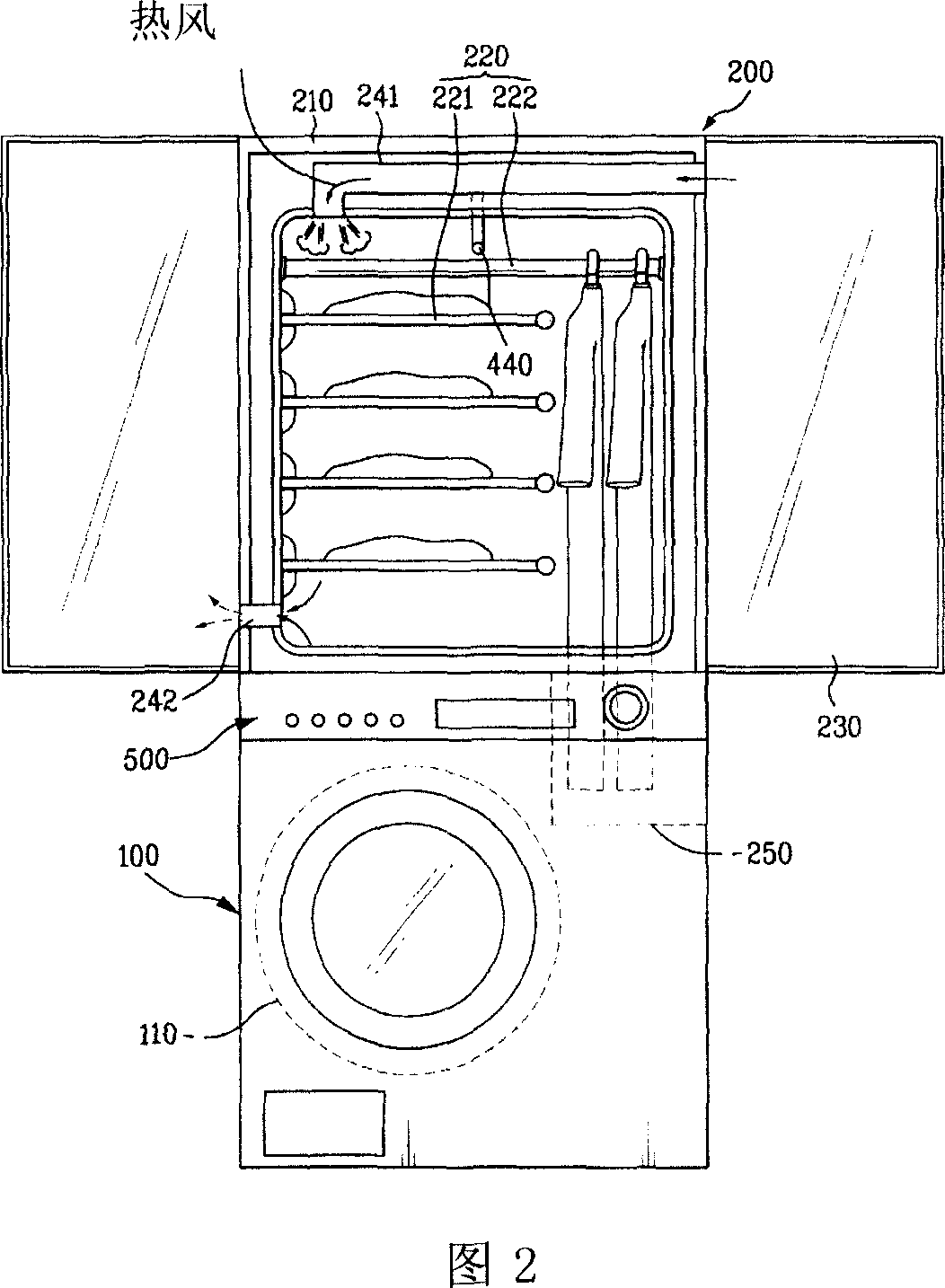

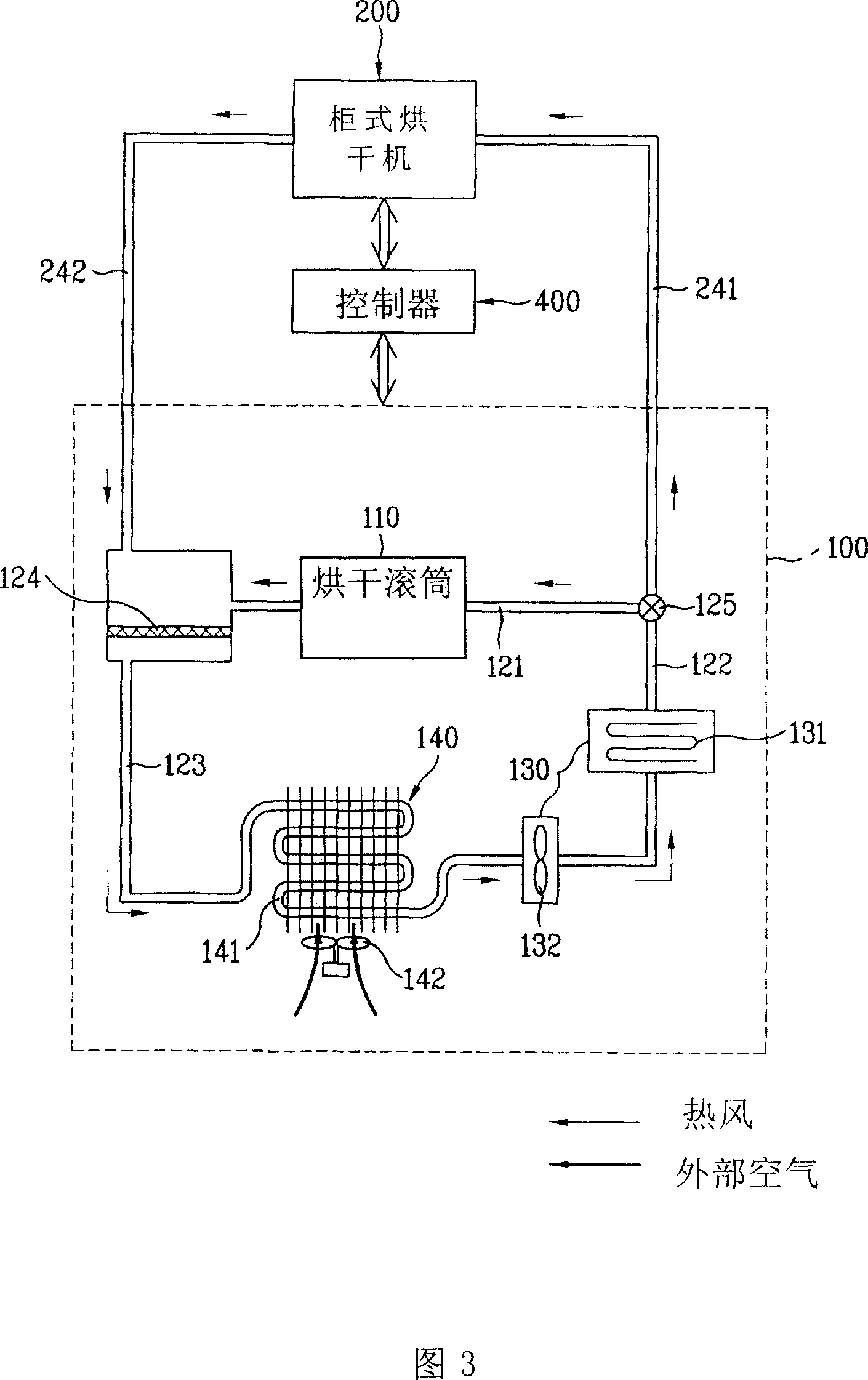

[0056] Fig. 2 is a schematic appearance diagram of an embodiment of a composite dryer with a rotary clothes hanger in the present invention; Fig. 3 is a structural block diagram of an embodiment of a composite dryer with a rotary clothes hanger in the present invention.

[0057] As shown in FIG. 2 and FIG. 3 , the composite dryer with a rotary clothes hanger of the present invention includes: a tumble dryer 100 , a cabinet dryer 200 , a rotary clothes hanger 300 , a rotary device and a control 500 .

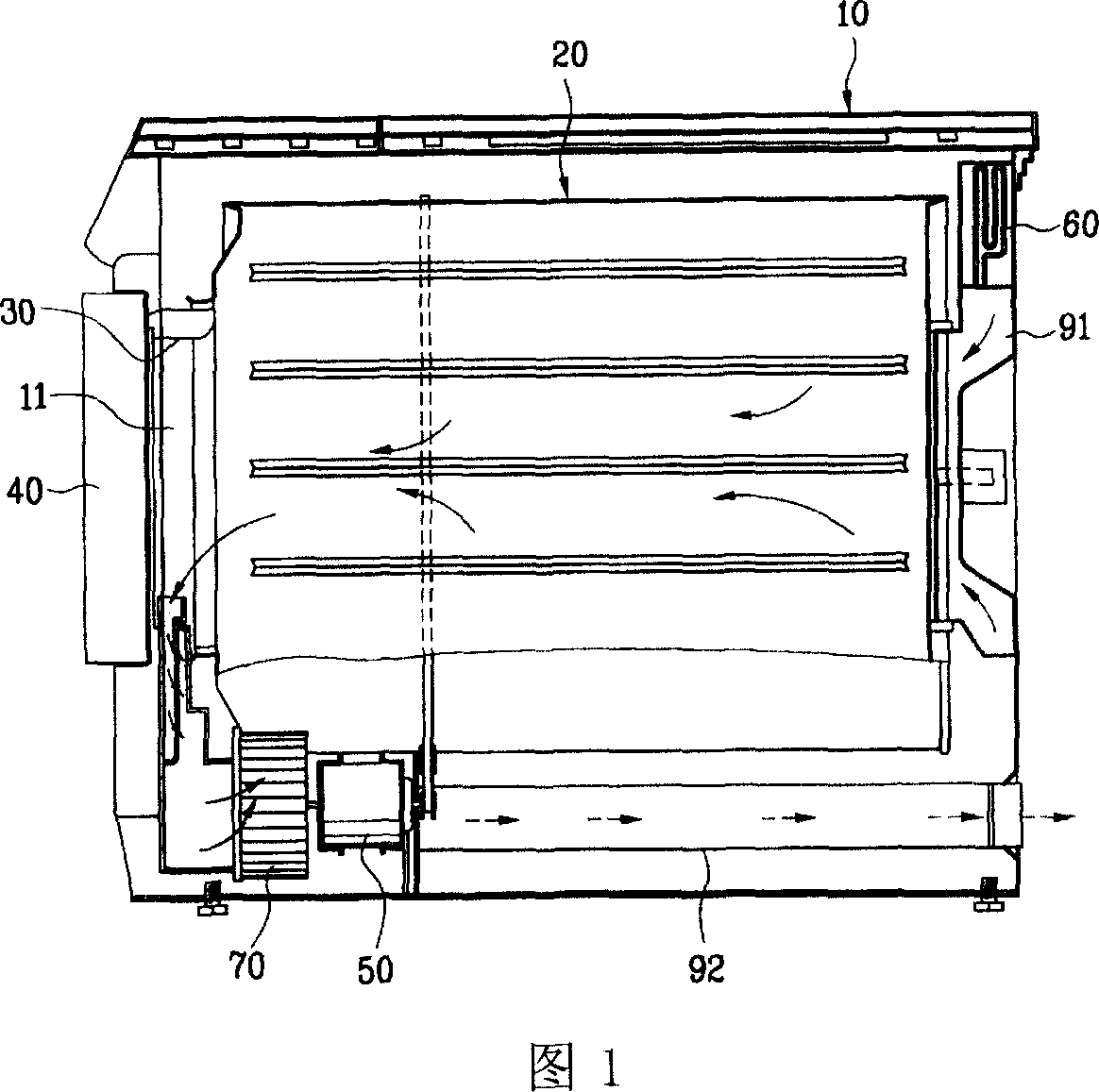

[0058]The tumble dryer 100 includes: a rotatable and agitated drying drum 110, a hot air supply pipe, a hot air supply device 130 and an air condensation device 140; the function of the tumble dryer 100 is to complete drying of clothes,

[0059] The hot air supply pipe is used to guide the flow of high temperature hot air, and the hot air supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com