Spiral type hollow coil current-sensing device

A current sensor, air-core coil technology, applied in the direction of inductors, voltage/current isolation, circuits, etc., can solve the problems of slow response, poor linearity, low anti-electromagnetic interference ability, etc., to achieve low cost, improve saturation characteristics and linearity The effect of improving the measurement accuracy and anti-electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

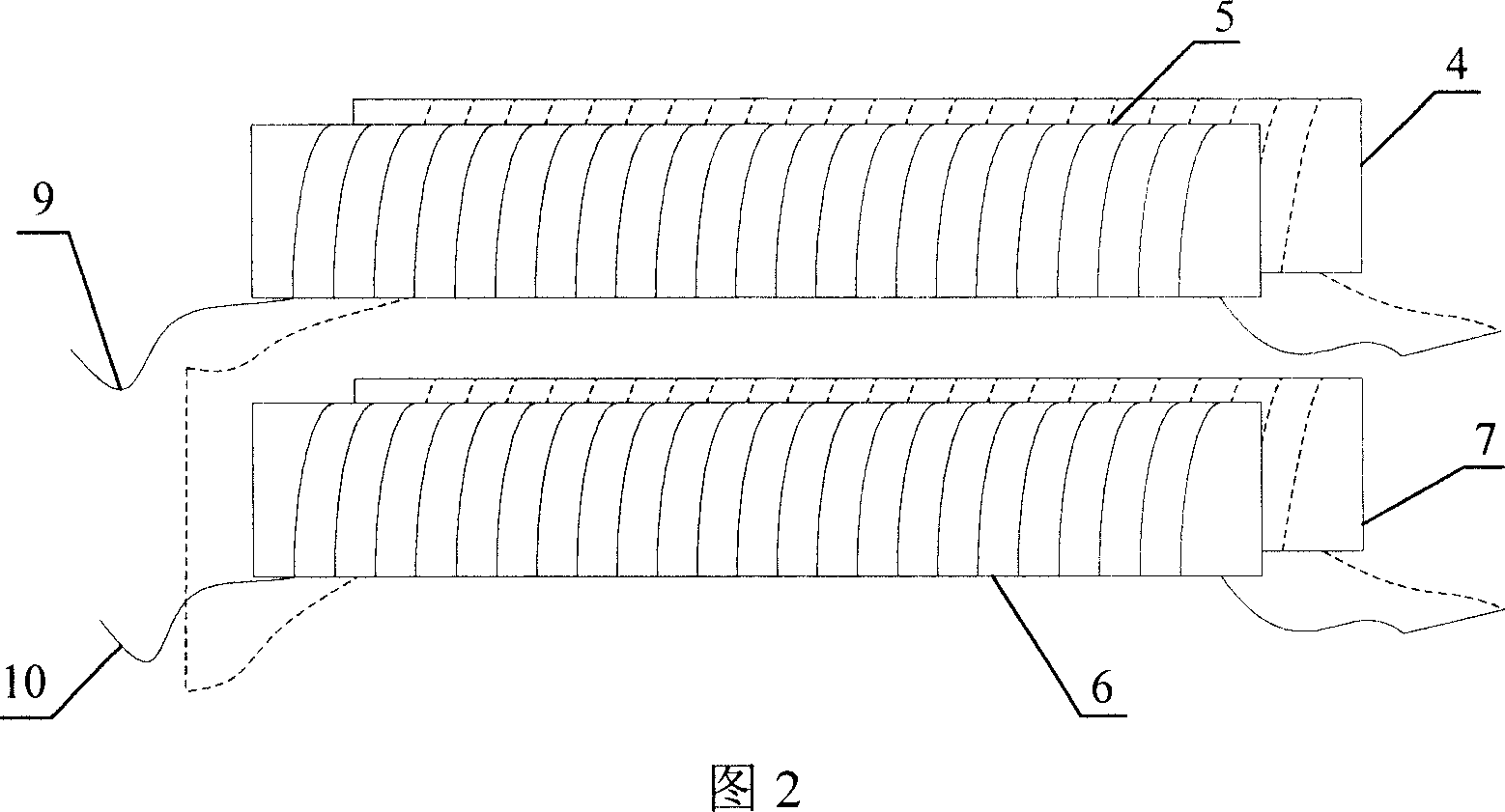

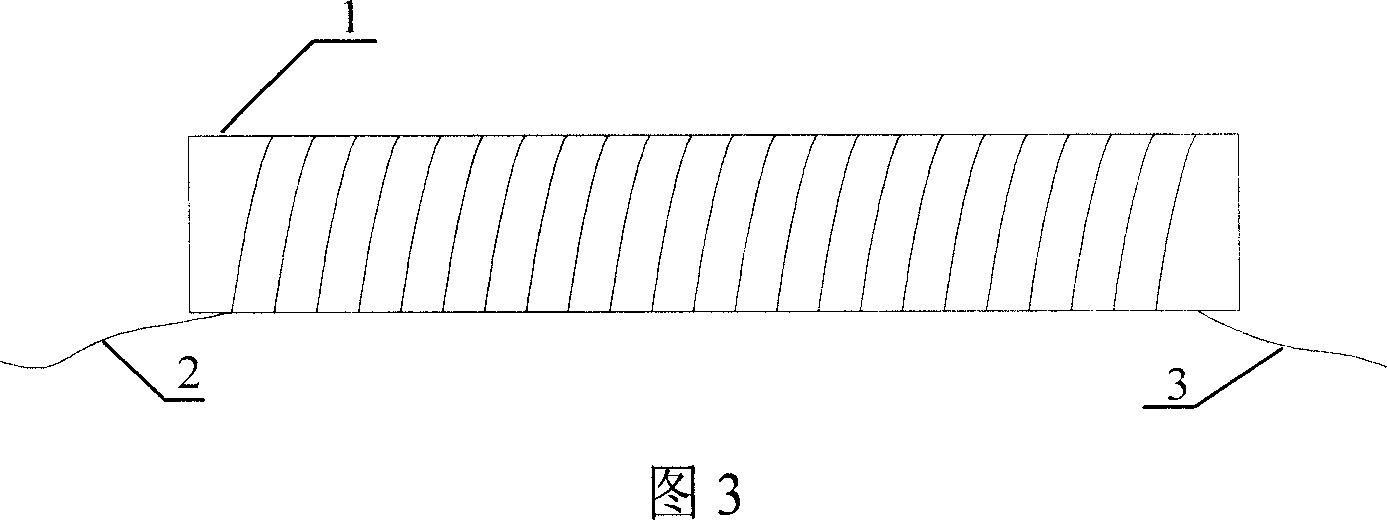

[0022] See Figure 3, 1 in Figure 3 is a non-magnetic straight cylindrical frame, 2 and 3 are the head and tail ends of the secondary coil wound on the frame, and the secondary coil is evenly and densely wound on the frame with thinner enamelled copper wire. Winding from the head end to the tail end of the skeleton, and then winding back to the head end, repeated winding in this way can finally form a multi-layer multi-turn helical tube sensing coil, preferably in an odd number of turns, so that it is easy to distinguish the head and tail ends of the coil, so that it is convenient for adjacent coils The secondary coils on the skeleton are connected at the head end or at the end in turn, as can be seen from Figure 2.

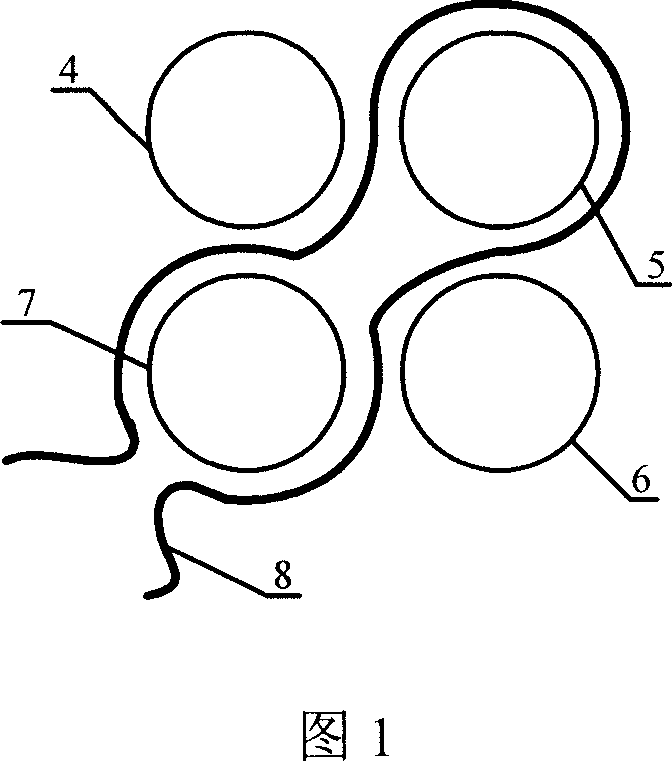

[0023] In Fig. 1, 4, 5, 6, 7 are all the same helical tube sensing coils wound with secondary coils, and are closely and evenly distributed on a circle around a center, leaving gaps for primary conductors to pass through. The primary conductor 8 surrounds half of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com