Heat radiator for elevator hoistway

A heat dissipation device and elevator shaft technology, applied in the energy efficiency of elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of large power consumption, large devices, high installation costs and high operating costs, and achieve efficient absorption, Effect of preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

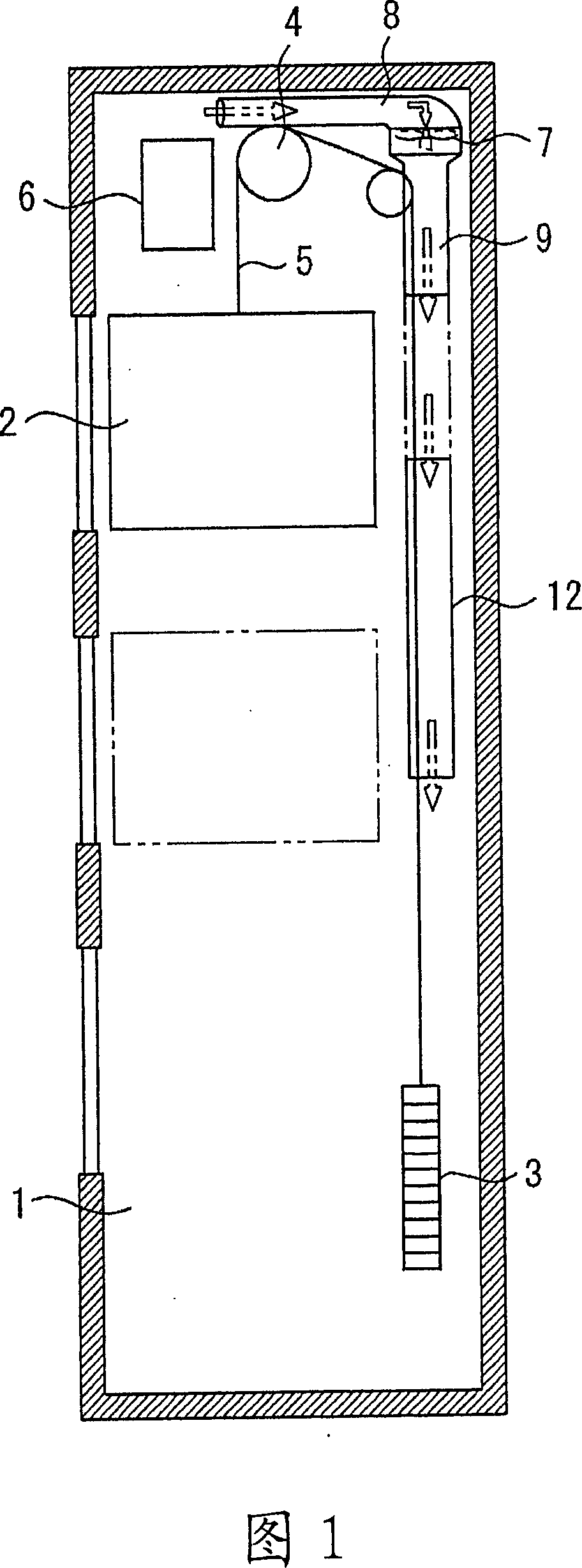

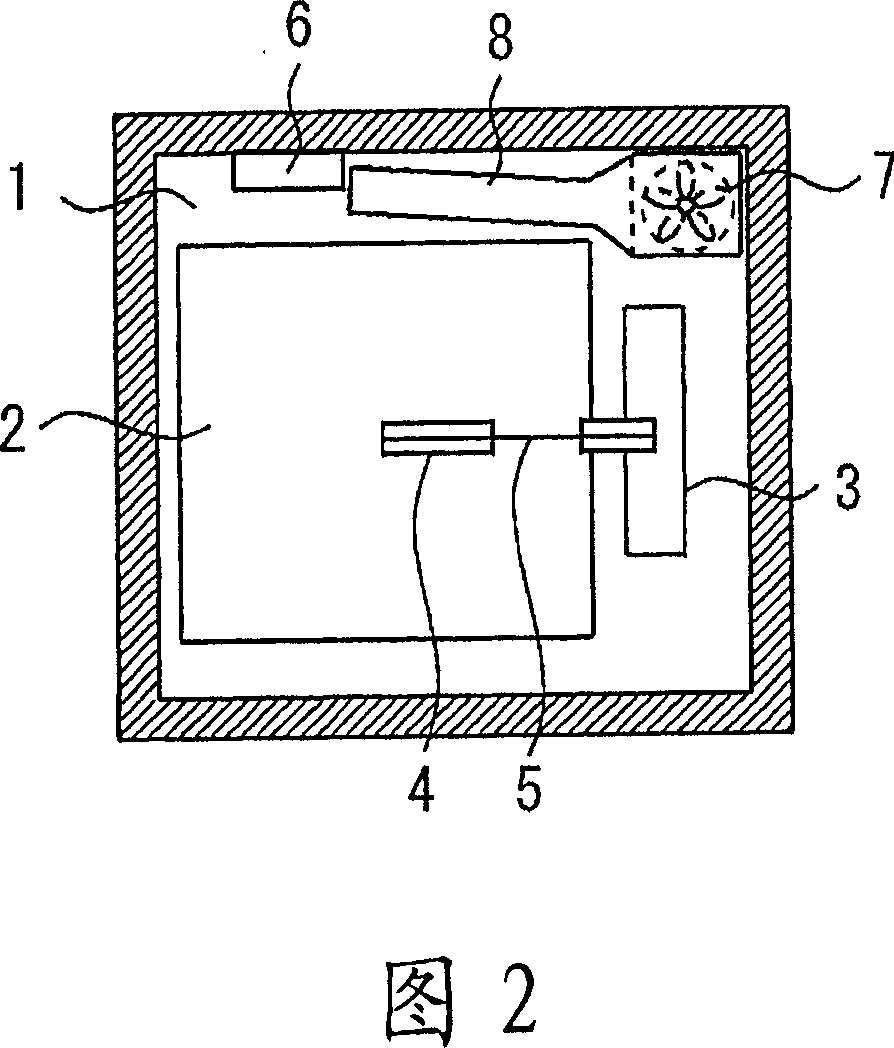

[0026] Fig. 1 and Fig. 2 are longitudinal sectional views and plan views showing a heat radiation device for an elevator shaft according to Embodiment 1 of the present invention. The elevator device of the present invention is a so-called machine-roomless elevator, which includes the following parts: the car 2 of the elevator, which travels along the guide rails in the hoistway 1; 2 running in the opposite direction; the driving device 4, which is arranged in the upper part of the hoistway 1; the rope 5, which connects the car 2 and the counterweight 3 at both ends, and is wound on the driving device 4; and the control device 6, It is arranged on a side wall of the upper part in the hoistway 1 and is used for controlling the driving device 4 . That is, the driving device 4 and the control device 6 , which tend to increase in temperature due to the released heat, are arranged in the upper part of the hoistway 1 .

[0027] In addition, an air blower 7 is provided at an upper co...

Embodiment 2

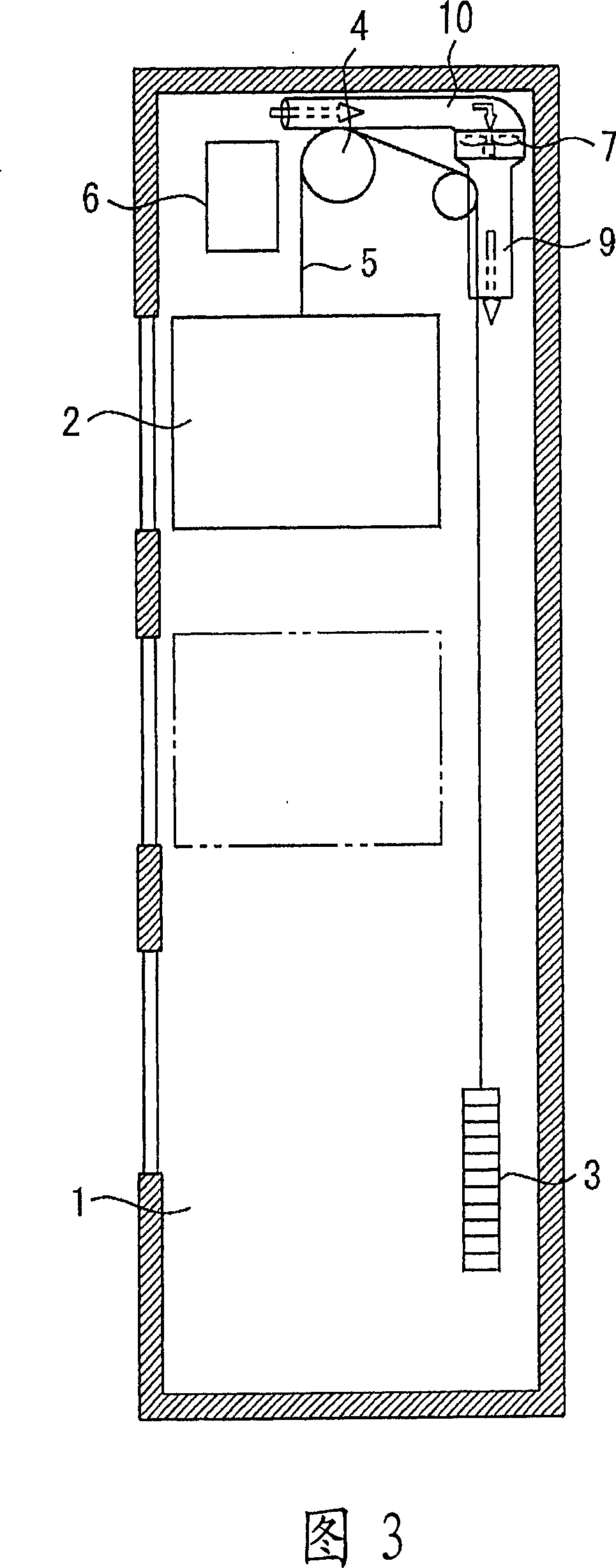

[0033] Fig. 3 and Fig. 4 are longitudinal sectional views and plan views showing a heat radiation device for an elevator shaft according to Embodiment 2 of the present invention.

[0034] In the above-mentioned Embodiment 1, the air inlet of one end of the air intake pipe 8 installed on the air intake side of the blower 7 is configured to come near the top of the control device 6, but in this Embodiment 2, the air inlet installed on the air intake of the blower 7 One end air intake of the air intake pipe 10 on the side is disposed near the driving device 4 . Other configurations are the same as those in Example 1.

[0035] In the heat dissipation device of the elevator hoistway constituted in this way, the heat released from the driving device 4 is sucked from one end of the air inlet pipe 10 due to the blowing effect of the blower 7, and is transported to the exhaust pipe 9, and then to the hoistway. The uppermost car 2 of the hoistway 1 is released below the stop position, ...

Embodiment 3

[0037] Fig. 5 and Fig. 6 are longitudinal sectional views and plan views showing an elevator hoistway heat radiation device according to Embodiment 3 of the present invention.

[0038] In the above-mentioned first embodiment, the blower 7 with the rotation axis in the vertical direction is provided at the corner of the upper part of the hoistway 1, but in this embodiment 3, the blower 13 with the rotation axis in the horizontal direction is arranged in a plan view. The air blower 13 is arranged above the car 2 at a position overlapping with the car 2 . Other than that, the structure is almost the same as that of the first embodiment.

[0039] In the heat radiation device of the elevator hoistway configured in this way, since the blower 13 can be approached from above the car 2, maintenance workers can easily perform maintenance and inspection work on the blower from above the car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com