Centrifugal pump with eccentric structure

An eccentric structure and centrifugal pump technology, which is applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as high production costs and poor manufacturing precision, and achieve reduced manufacturing costs and improved processing Manufacturing accuracy and the effect of improving the roughness of the inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

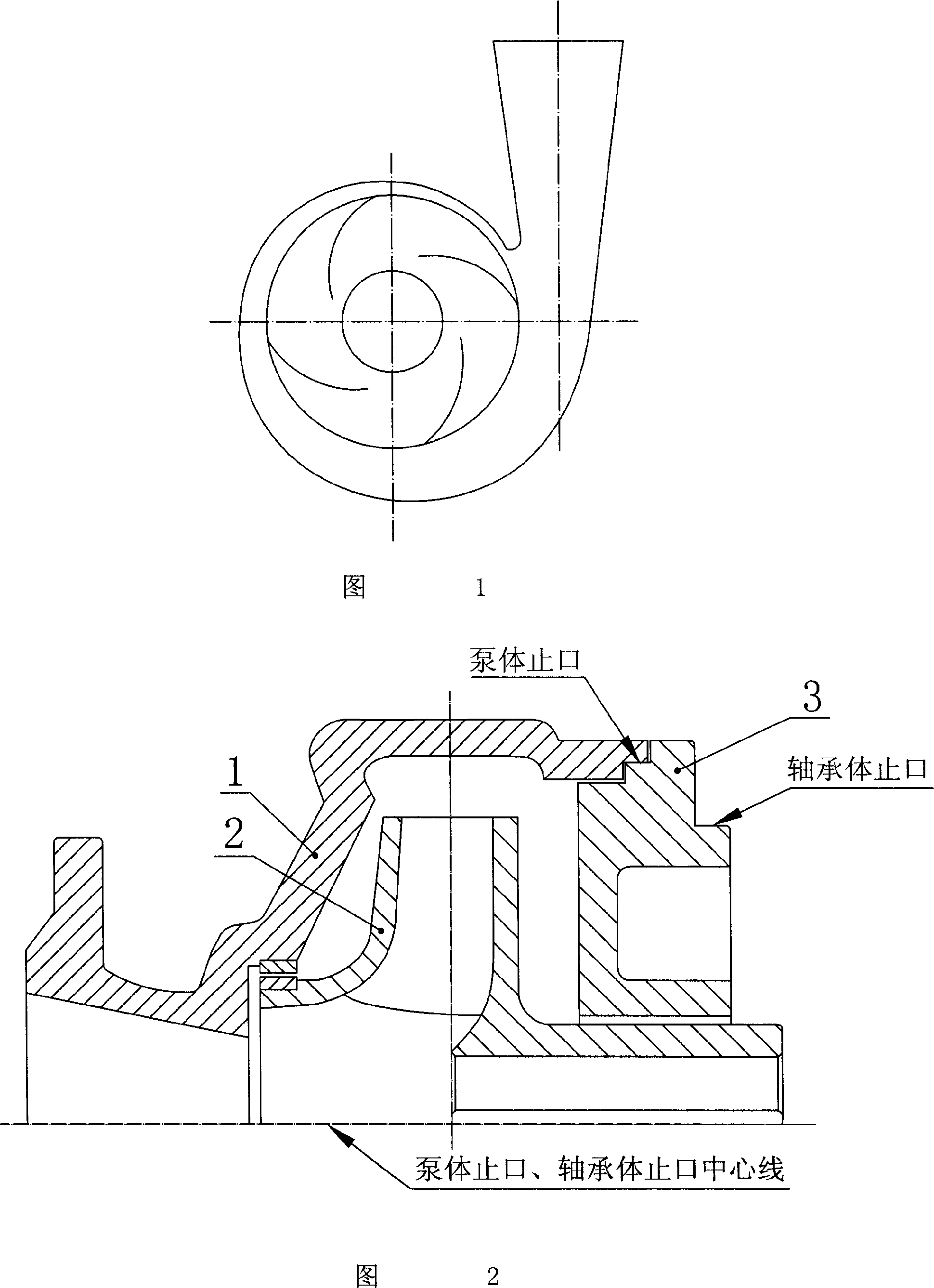

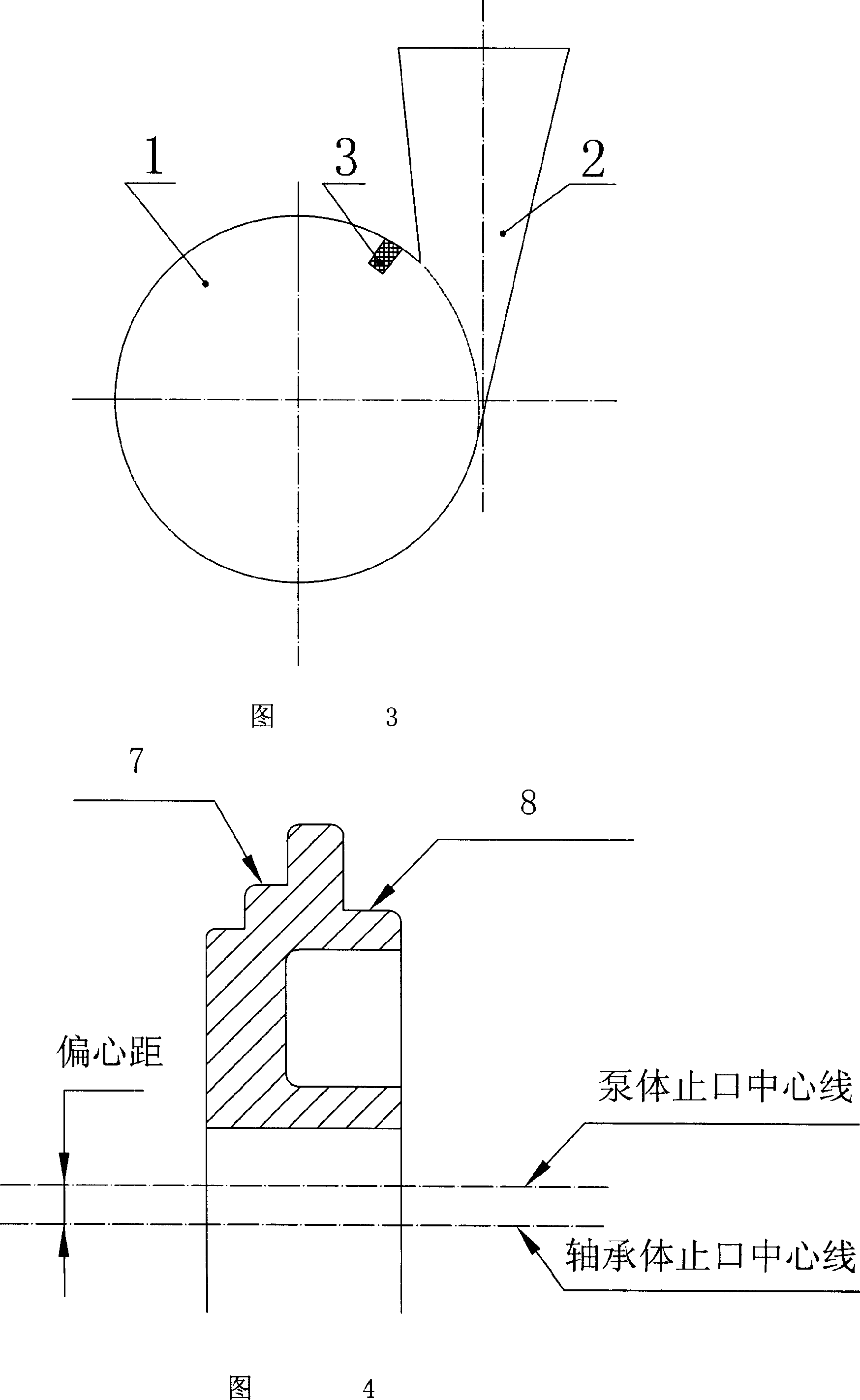

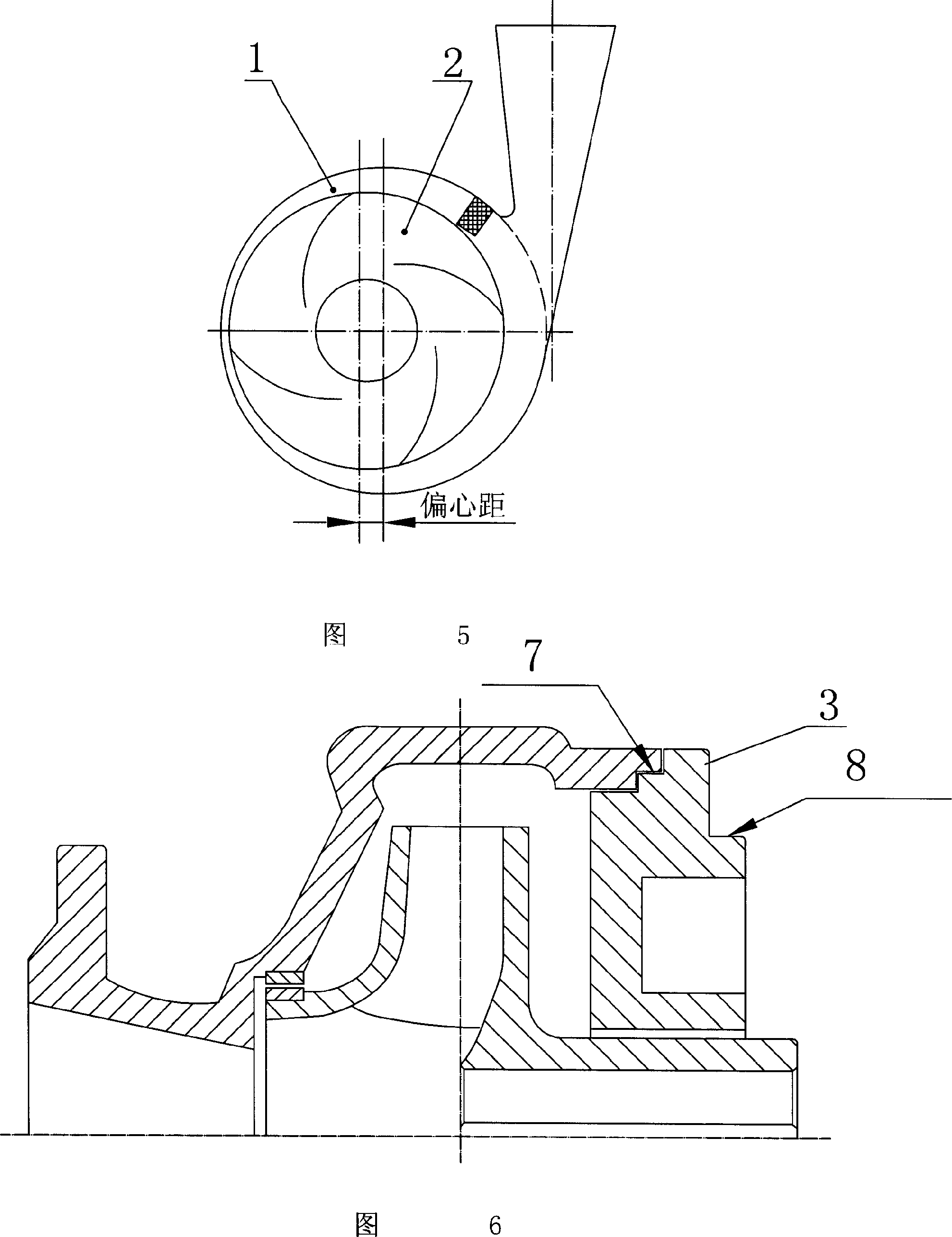

[0017] Referring to Fig. 3, Fig. 4, Fig. 5 and Fig. 6, a centrifugal pump with an eccentric structure includes a pump body 1, a pump cover 3 and an impeller 2, the impeller 2 is located in the pump body 1, and the pump body 1 includes an inner cavity 4, an outlet flange section 5, and a tongue 6, the outlet flange section 5 is fixedly connected to the inner cavity 4, and the inner cavity 4 is a regular cavity with an equal radius circle, so The center of the pump body 1 and the center of the impeller 2 have an eccentricity.

[0018] The pump cover 3 includes a pump body notch 7 and a bearing body notch 8, and the center of the pump body notch 7 and the center of the bearing body notch 8 on the pump cover are eccentric. A partition tongue 6 is installed on the inner cavity 4 near the inlet of the outlet flange section 5 .

[0019] The structure of the pump body is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com