High-temperature high-pressure kettle test device for optical fiber sensor

An optical fiber sensor, high temperature and high pressure technology, applied in measuring devices, pressure vessels used in chemical processes, elastic deformation gauge type fluid pressure measurement, etc. Can not simulate and other problems, to achieve the effect of design safety, easy disassembly, and water immersion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

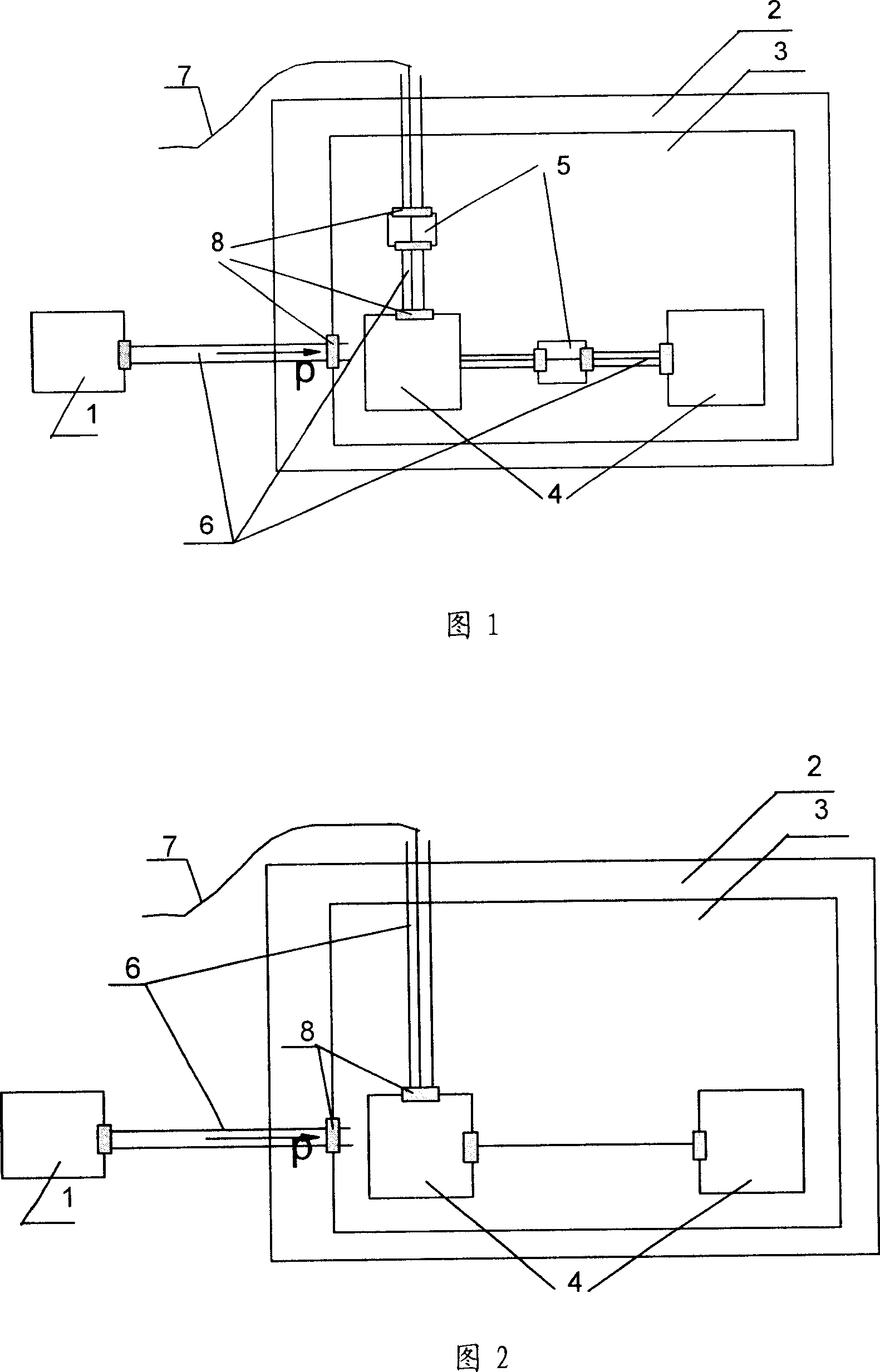

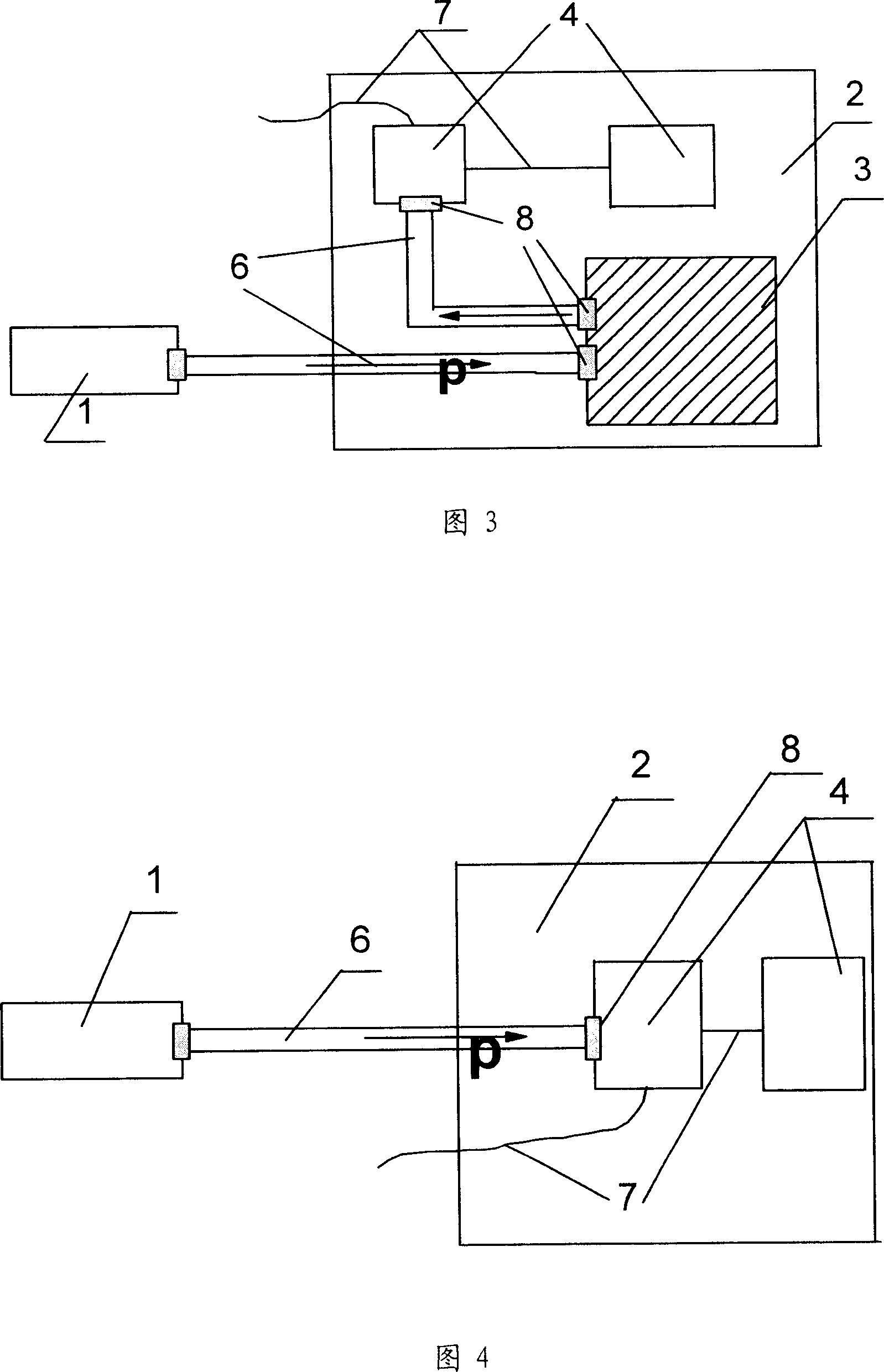

[0027] Referring to the accompanying drawings, the number of serially connected optical fiber sensors 4 marked in each embodiment is two, and the number of serially connected optical fiber sensors 4 can be determined as required during actual application. In Embodiment 1 of FIG. 1 , the optical fiber 7 of the transmission section used to connect two optical fiber sensors 4 is protected by a stainless steel hollow tube 6 . In the second embodiment in FIG. 2 , the optical fiber 7 of the transmission section used to connect two optical fiber sensors does not need to be protected by the stainless steel hollow tube 6 .

[0028] Referring to Fig. 1, it is the embodiment 1 of high-temperature autoclave experimental device in the present invention, high-temperature autoclave experimental device is made of thermostat 2, autoclave 3, high-pressure metering pump (manual or automatic) 1, hollow pipe 6, optical fiber sensor 4 , optical fiber flange plate high pressure protection chamber 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com