Collapsible track undercarriage for installation and tensioning

一种履带、履带驱动的技术,应用在环形驱动履带的安装系统领域,达到减小张紧力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

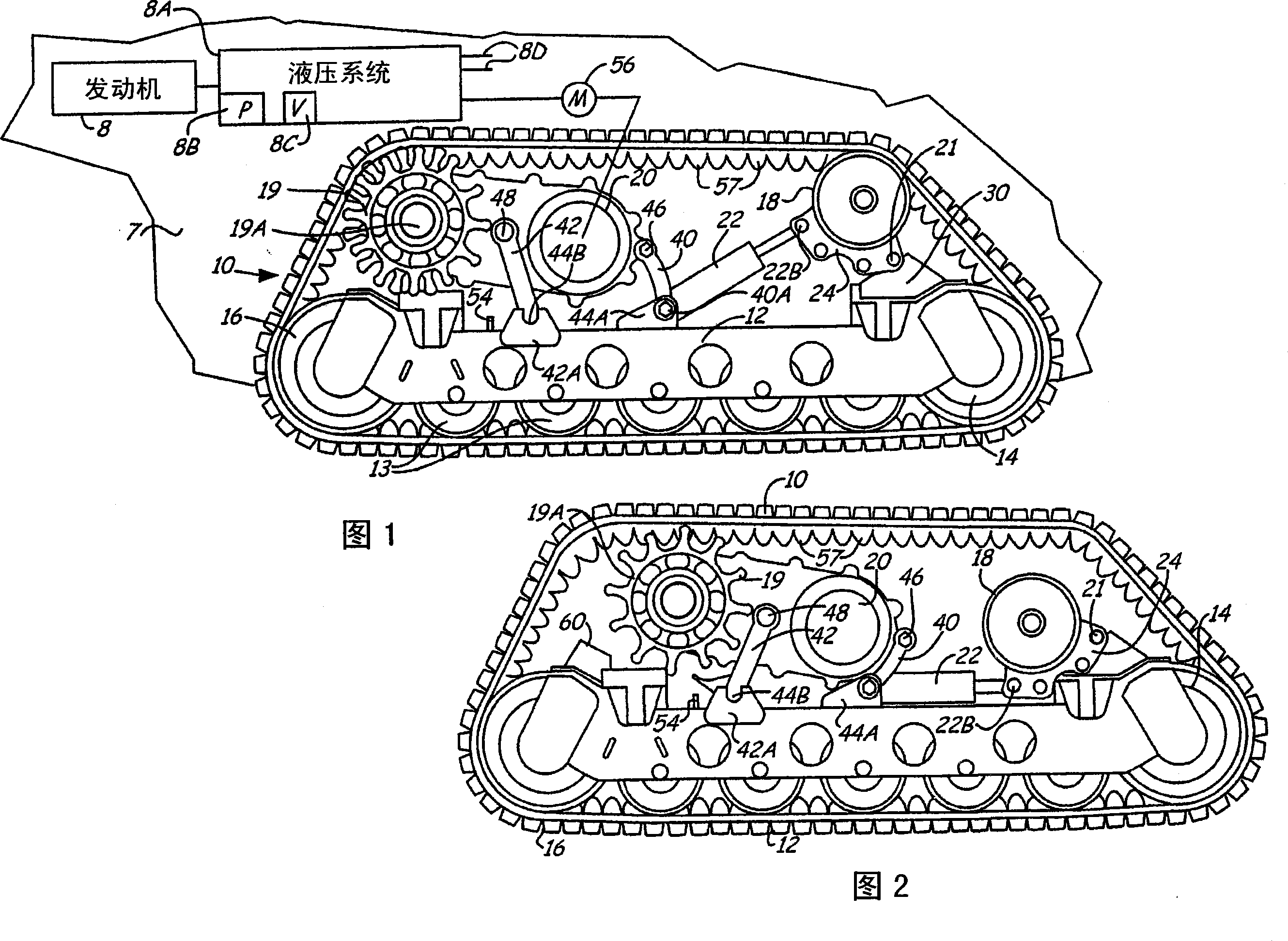

[0026] The compact loader shown at 7 is only schematically illustrated in FIG. 1 and is of conventional design. The loader is powered by an engine 8 to provide power to a hydraulic system 8A comprising a pump 8B, appropriate valves 8C, and various hydraulic controls to be connected along line 8D. Valve 8C controls an electric motor 56 for driving the input shaft of a suitable drive chain box or gear drive mechanism for driving tracks 10 (rubber tracks on each side of frame 7 as shown).

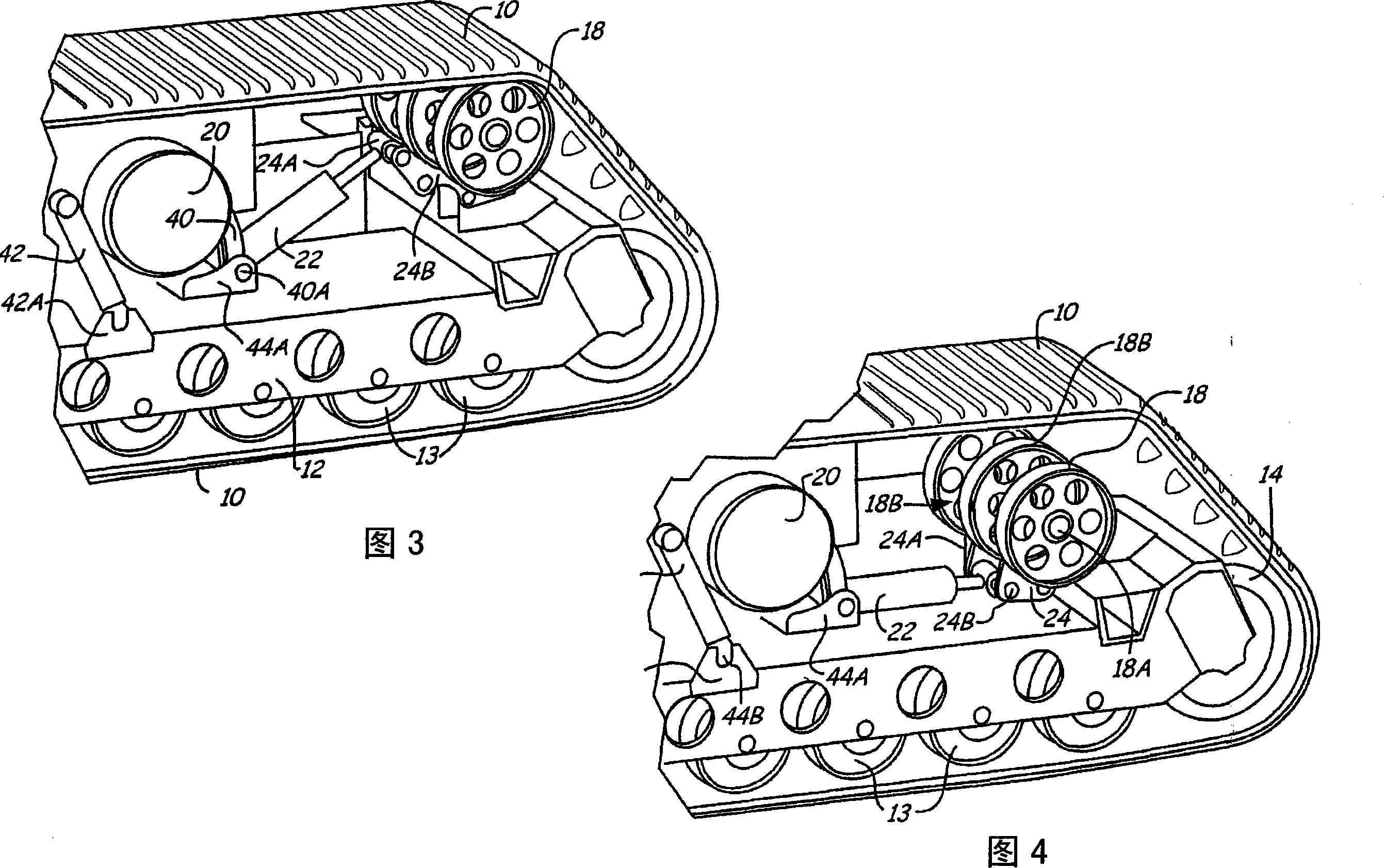

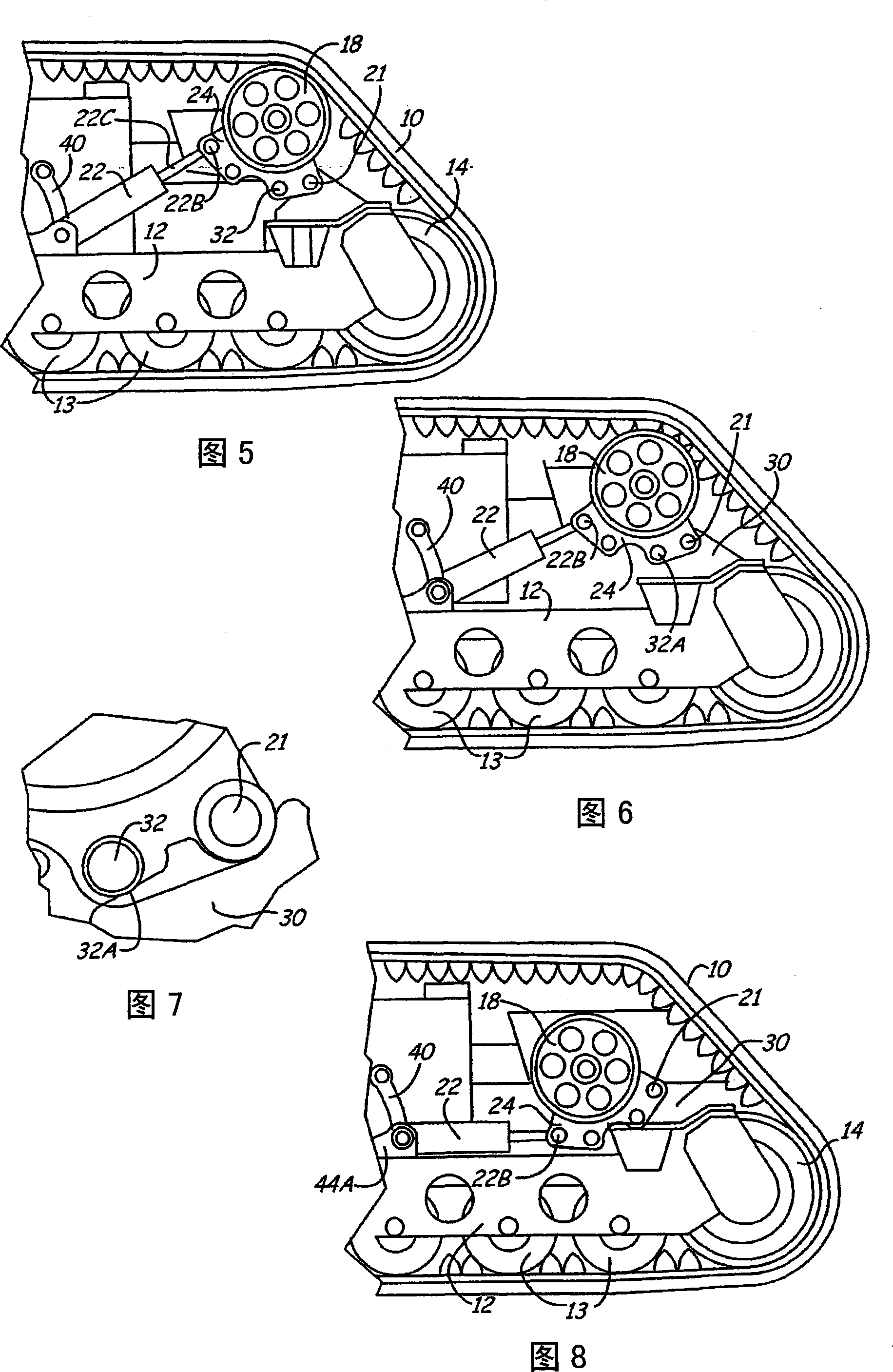

[0027] Figure 1 shows the track on one side of the loader in a working or operating position. A track frame or undercarriage 12 is connected to the loader body or frame 7 in a suitable manner. Track frame 12 supports road wheels 13 mounted on frame 12 to support a lower length of track 10 . Track frame 12 also supports rotatable but fixed front idler rollers 14 and rear idler rollers 16 . The upper front portion of the track 10 is held in the operative position by retractable, tensioned mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com