Gas-water turbulent flow re-mixing tube

A technology of turbulent mixing and mixing tubes, applied in fluid mixers, mixers, mixing methods, etc., can solve problems such as high operating costs, failure to meet mixing requirements, and limited mixing effects, and achieve improved air-water mixing The effect of high efficiency, low manufacturing cost and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structure and advantages of the present invention will be further described below in conjunction with the drawings and embodiments.

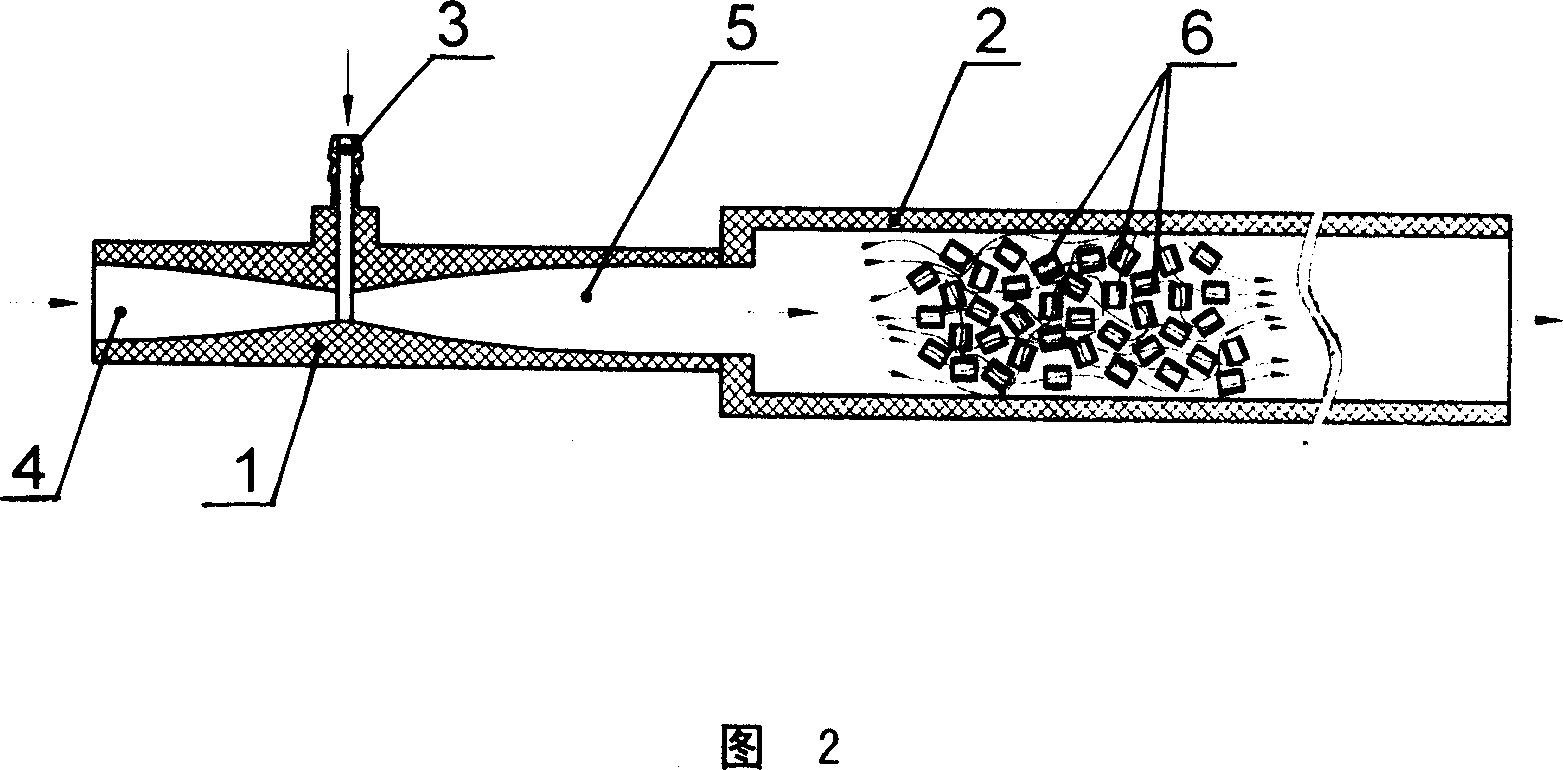

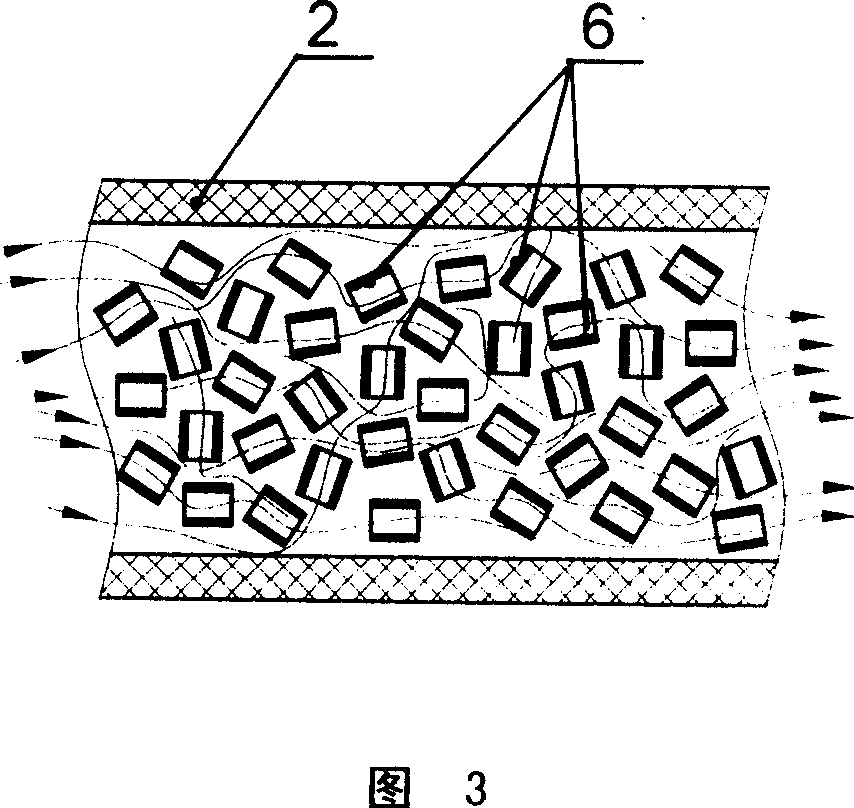

[0011] As shown in Figure 1-3, a gas-water turbulent flow remixing tube, it includes a Venturi jet tube 1, the Venturi jet tube 1 has a booster chamber 4, a negative pressure chamber 5 and an air inlet 3, the Venturi jet tube The pipe 1 is connected to the turbulent flow mixing pipe 2, and the turbulent flow mixing pipe 2 is filled with small and short pipe heads 6 in disorder.

[0012] As shown in Figure 2, when the water with a certain pressure and flow rate flows into the pressurized chamber 4 of the Venturi jet tube 1, a vortex effect is generated in the negative pressure chamber 5, and the air inlet on the Venturi jet tube 1 will be connected The gas in 3 is sucked into the negative pressure chamber 5 to form a gas-water vortex mixing phenomenon. Although it can play the role of air-water mixing, it has been proved that the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com