Hydraulic generator mirror plate grinding apparatus and process

A technology for hydroelectric generators and grinding devices, which is applied to machine tools for surface polishing, grinding/polishing equipment, metal processing equipment, etc., and can solve problems such as shortening the operating cycle of the unit, failure to repair, and economic loss of the power plant, so as not to affect the The effect of putting into operation cycle, ensuring processing quality and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

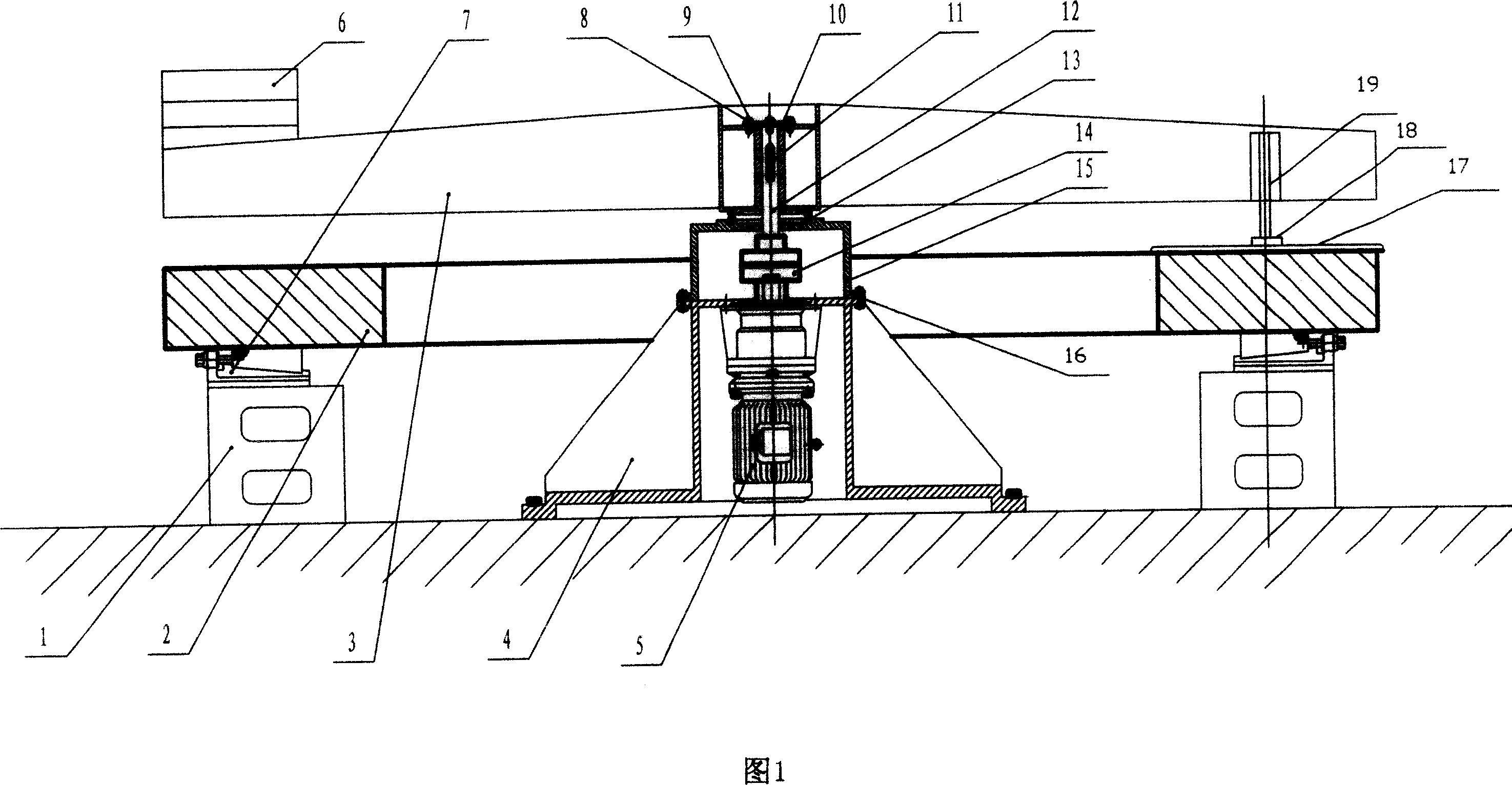

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Referring to FIG. 1 : the grinding device for the mirror plate of the hydroelectric generator includes a base 4 , an upper support 15 , a cantilever 3 , a grinding mechanism, and a driving device 5 .

[0025] The base 4 is a hollow structure welded by steel plates, has a horizontal top plate, and has a hole in the center of the top plate.

[0026] The upper support 15 is also a hollow structure welded with steel plates, and a thrust bearing 13 is arranged on its top plate;

[0027] The swing arm 3 is supported on the thrust bearing 13, wherein the upper end of the shaft 12 is fixedly connected with the swing arm 3 through the key 11, and the lower end thereof extends into the upper support 15. The working end of the swing arm 3 is provided with a grinding mechanism, which is composed of a grinding head 17, a universal joint 18, and a grinding head rod 19 conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com