Resin control device of hot runner system for injection molding machine

A fluid cylinder and molding machine technology, applied in the field of resin quantity control, can solve the problems such as the inability to adjust the resin utilization time difference, the inability to perform fine control using the time difference, and the inability to precisely adjust the resin amount, etc., achieving simple structure, saving production costs, Easy work and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

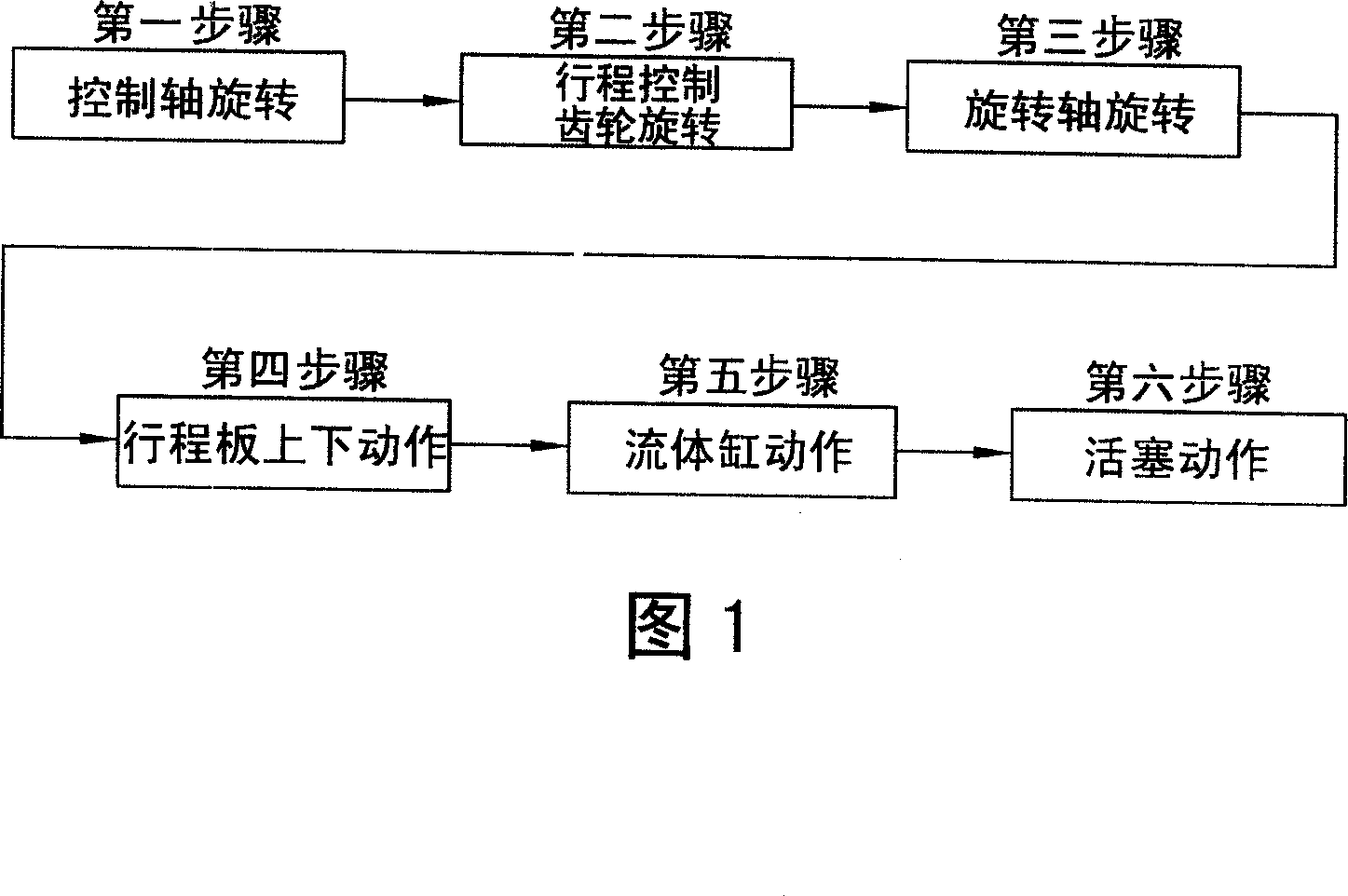

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, the present invention will be described in detail based on the drawings.

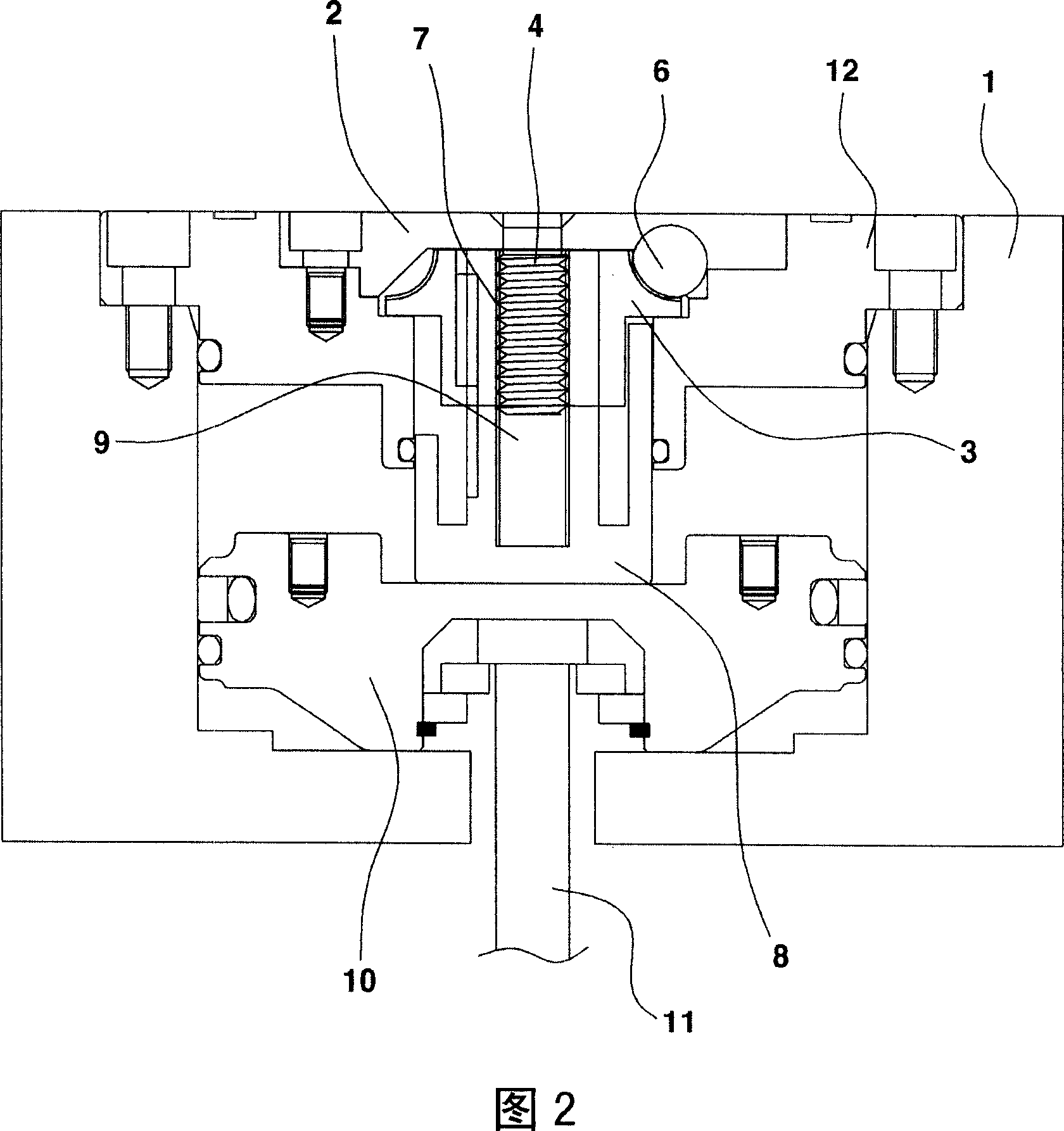

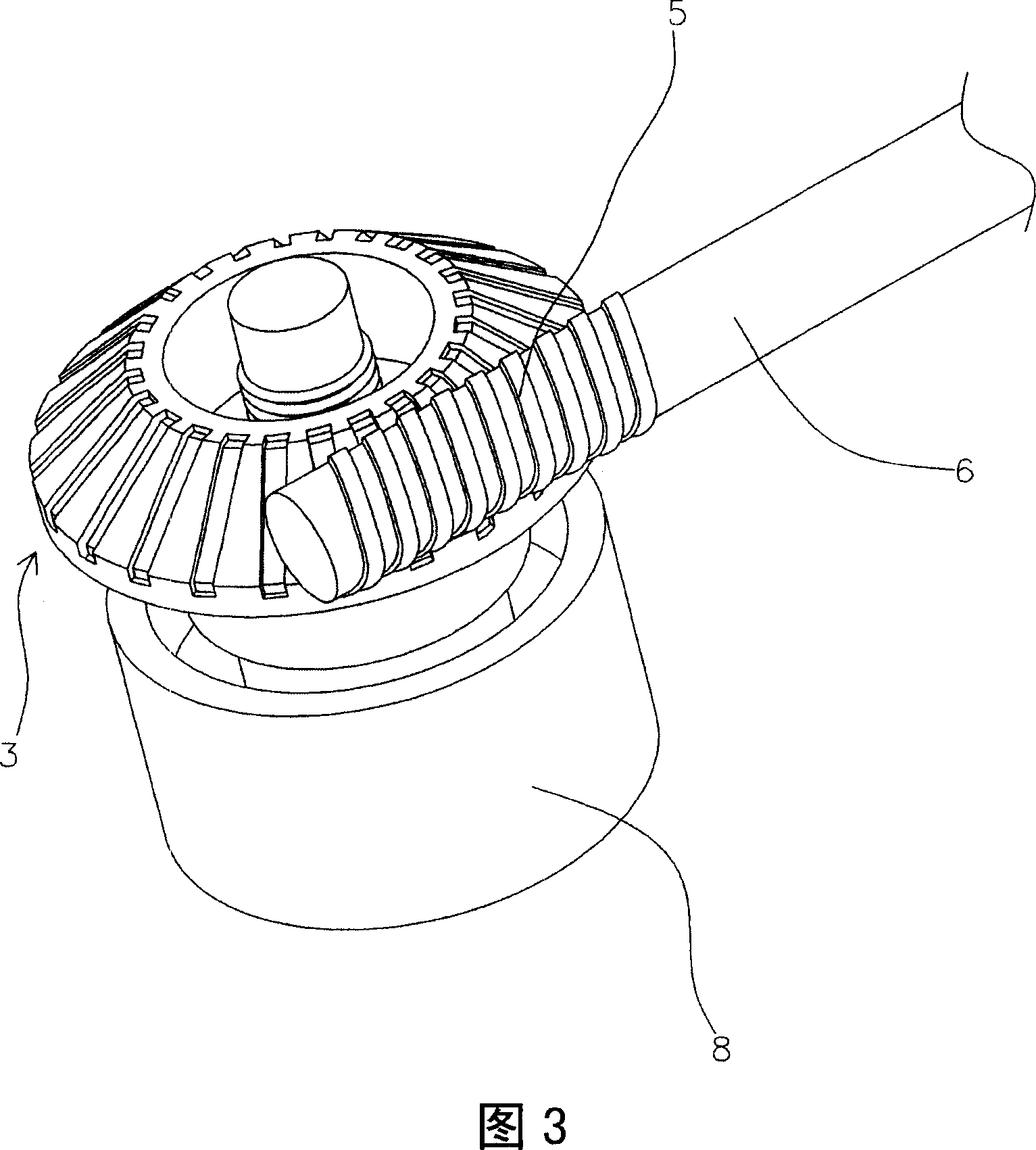

[0015] The present invention is a device in which, in a fluid cylinder for an injection molding machine that operates the fluid cylinder to adjust the amount of resin, the cylinder head 12 is fastened and fixed to the fixed plate 1, and the central part of the cylinder head 12 is fastened and connected to form a fluid cylinder. Cylinder cap 2 is fixed, and in the central part of cylinder cap 2, is provided with the rotating shaft 4 that fastens and connects stroke control gear 3, is formed with threaded part 9 at the lower end portion of rotating shaft 4, on one side of stroke control gear 3 , a control shaft 6 formed with a worm gear 5 is provided, the control shaft can be rotated by a motor or manually, and a stroke plate 8 formed with a threaded part 7 on the inside is provided at the lower end of the stroke control gear 3, so as to be connected with the rotation shaft 4 The threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com