High-pressure hydraulic diaphragm metering pump

A diaphragm type, metering pump technology, applied in the field of metering pumps, can solve the problems of shortening the life of three valves and diaphragms, wear, diaphragm damage, etc., to achieve convenient emptying and oil replenishment, simple operation procedures, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

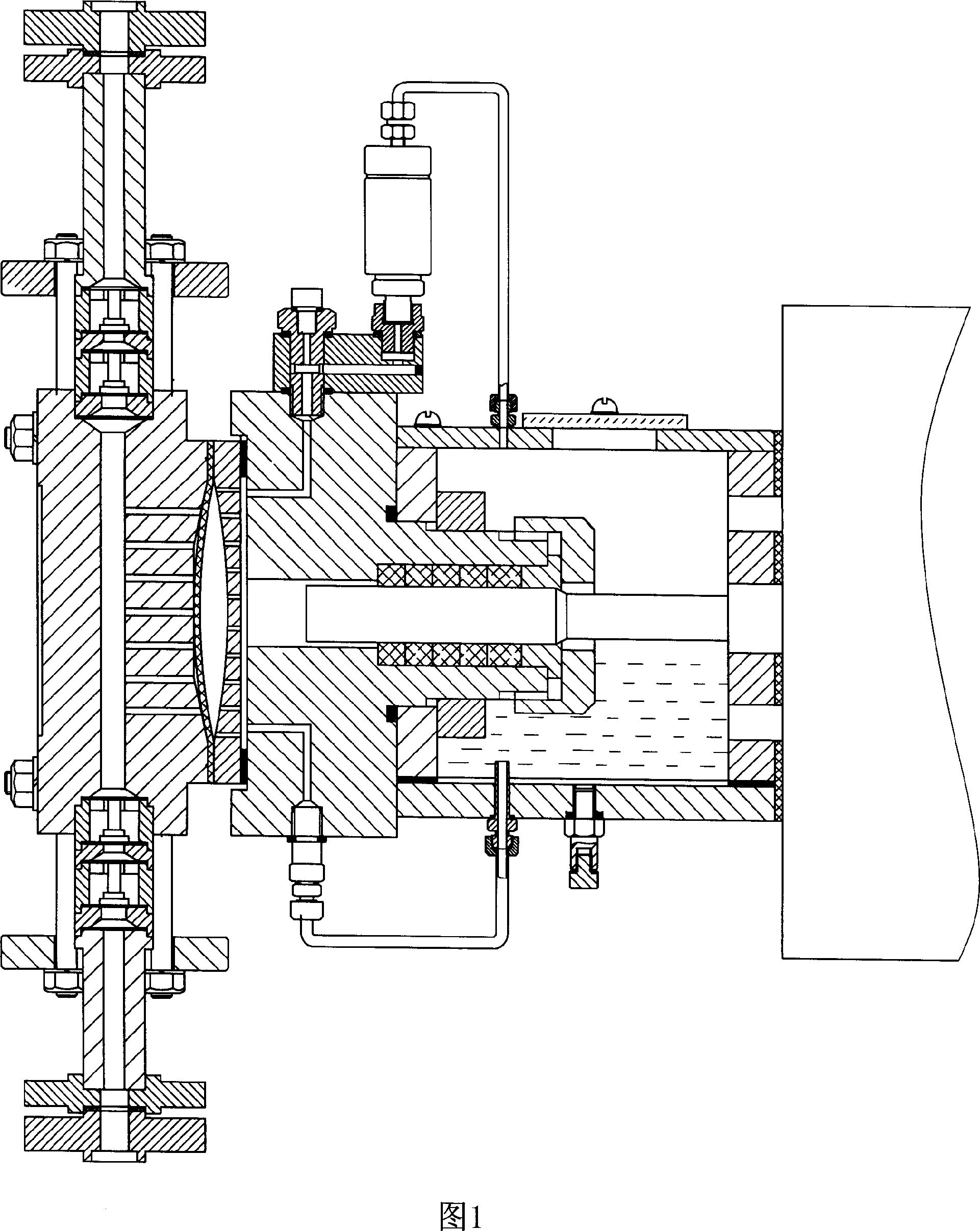

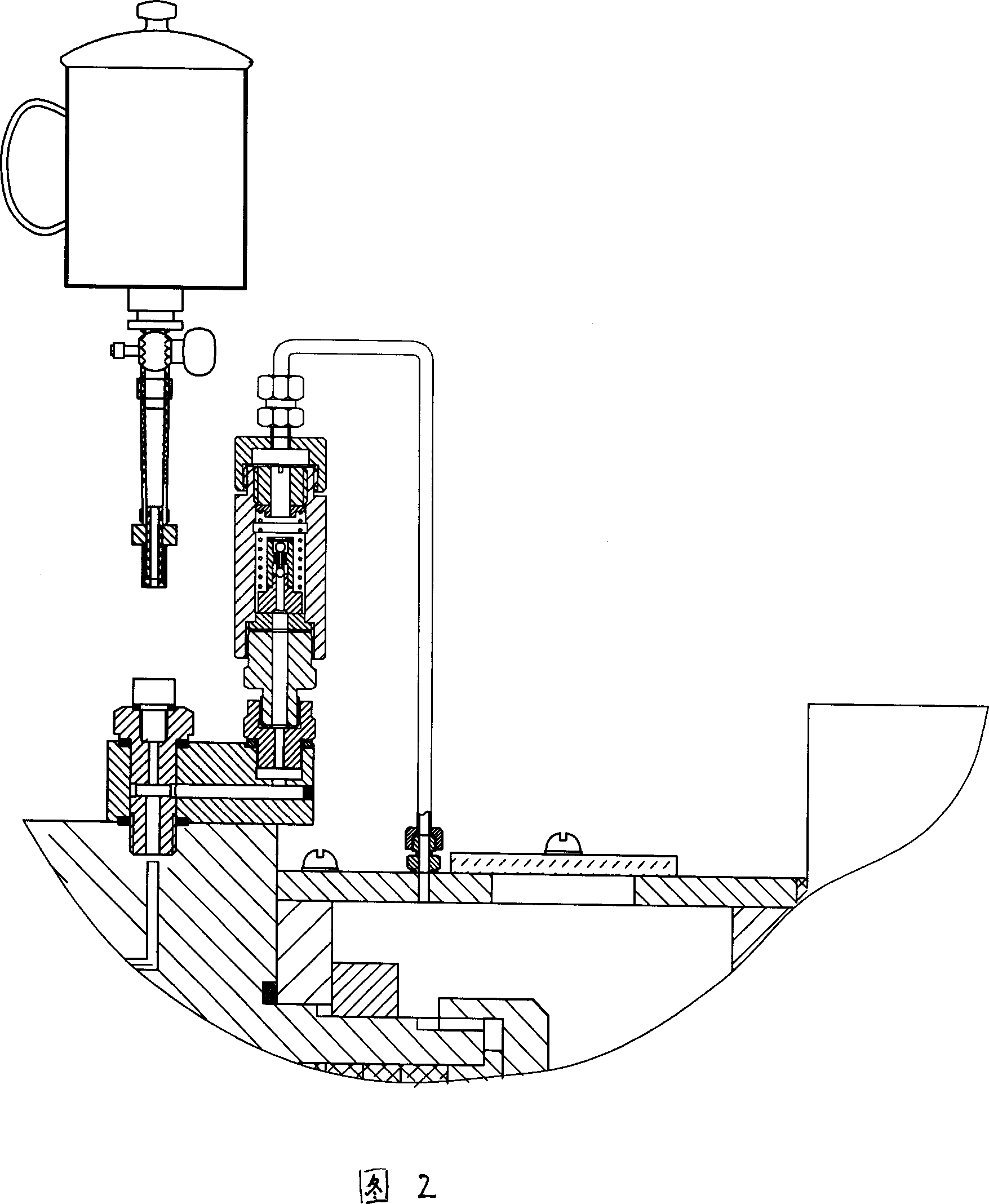

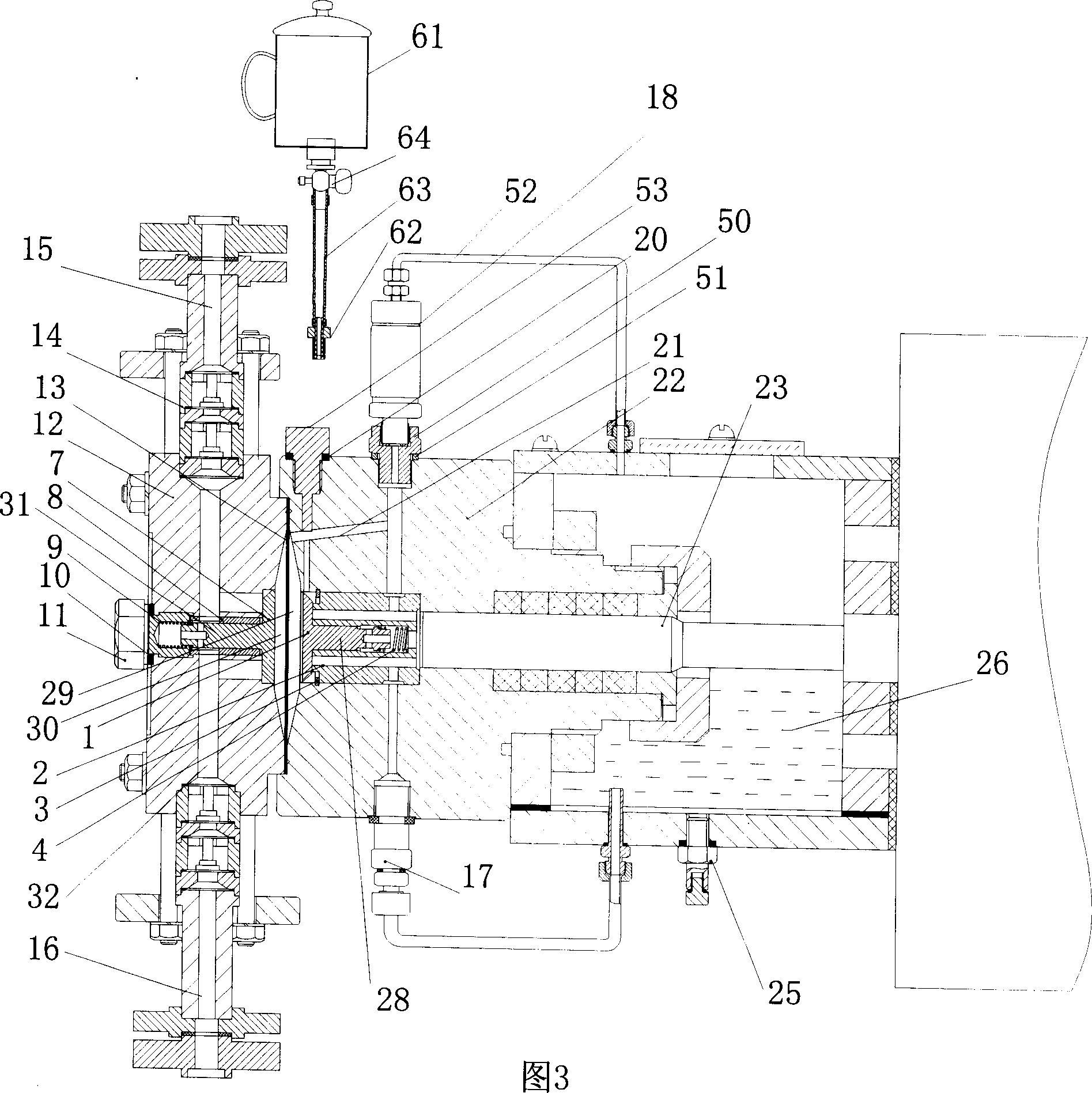

[0029] Referring to the accompanying drawings, the present invention will be described in detail below.

[0030] A high-pressure hydraulic diaphragm metering pump in the present invention includes an oil pool 26, a pump head 12, a diaphragm 13, a cylinder body 22, a plunger 23, and a one-way valve group 14, and also includes a rear-mounted diaphragm plate structure, The rear-mounted diaphragm structure is composed of a rear diaphragm 1, a spring 4 and a cylinder body 22. A hydraulic chamber 29 is formed between the cylinder body 22 and the diaphragm 13. Between the hydraulic chamber 29 and the plunger 23, there is a A guide rod through hole, the inner wall of the guide rod through hole is embedded with a bushing 2, the bushing 2 is fixed in the guide rod through hole of the cylinder body with a collar 3, a through hole is drilled in the center of the bush 2, and the guide rod 28 is movable In the through hole, the bushing 2 is also provided with four through holes connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com