Crankshaft

A crankshaft and main journal technology, applied in the field of short-stroke engines, can solve problems such as unfavorable maximum torque, achieve high torque and prevent gap formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The main application field of the present invention is a large engine, especially a two-stroke large diesel engine with a large cylinder bore diameter and a small stroke, which is used as a marine propulsion device and the like. As an example of a large unit, mention may be made of a twelve-cylinder large diesel engine with a cylinder bore diameter of 980 mm, in which the stroke has been reduced from 2400 mm to 1200 mm in order to achieve higher rotational speeds. Such an illustration naturally does not constitute any limitation.

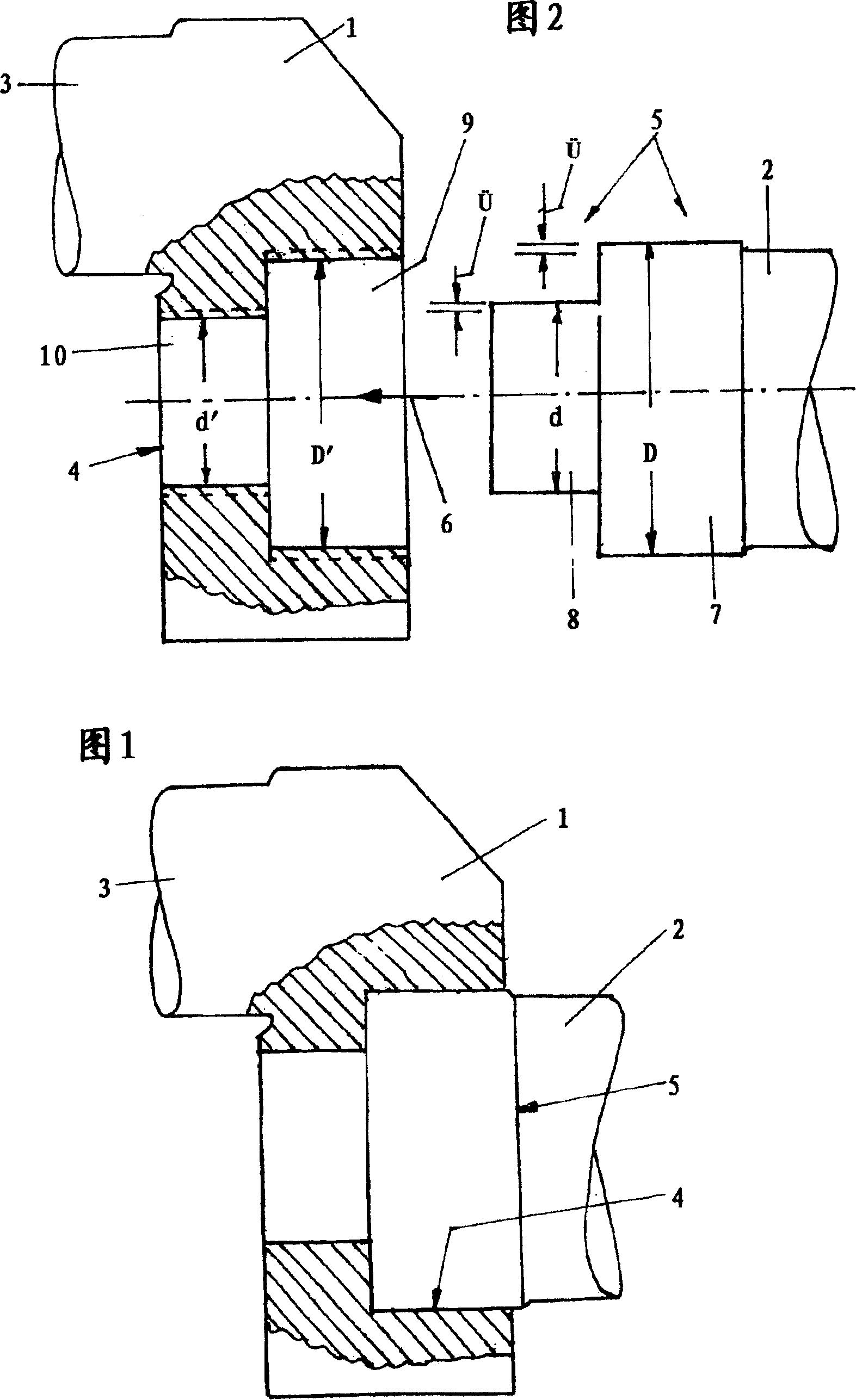

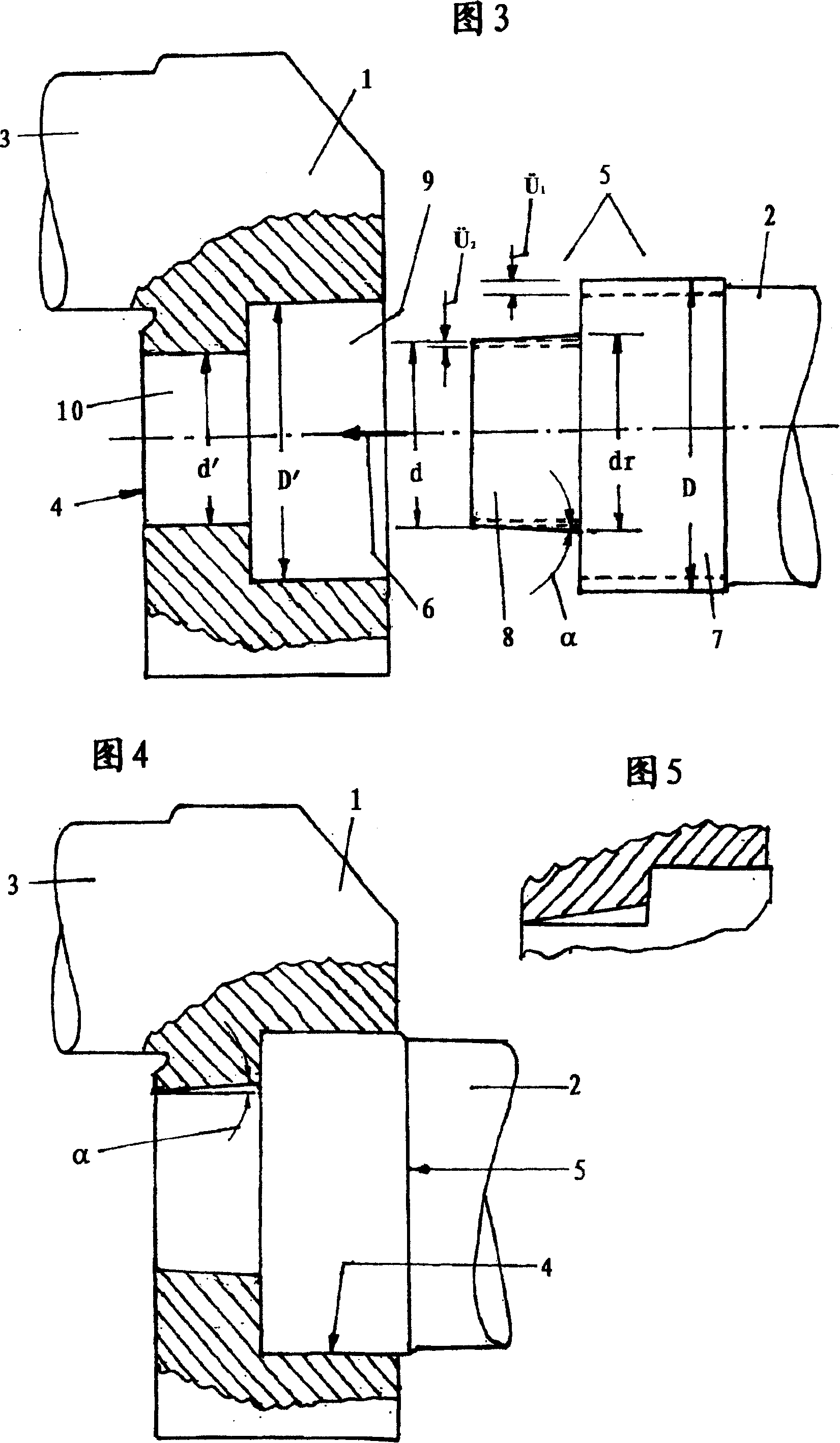

[0020] The crank according to FIG. 1 comprises a crank arm 1 , from which project a main journal 2 on the one hand and, on the other hand, a connecting rod journal 3 oppositely offset in the radial direction. The radial distance between the main journal 2 and the connecting rod journal 3 is less than half of the sum of the diameters of the two journals. FIG. 1 shows a main journal 2 and a connecting rod journal 3 . In a crankshaft of a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com