A method and device for forming a light alloy reducing pipe

A technology of reducing tubes and light alloys, which is applied in the forming of light alloy reducing tubes and thin-walled magnesium alloy reducing tubes. It can solve the problems of complex hydraulic equipment and large springback, and overcome internal stress, strength and hardness. The effect of reducing and disappearing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

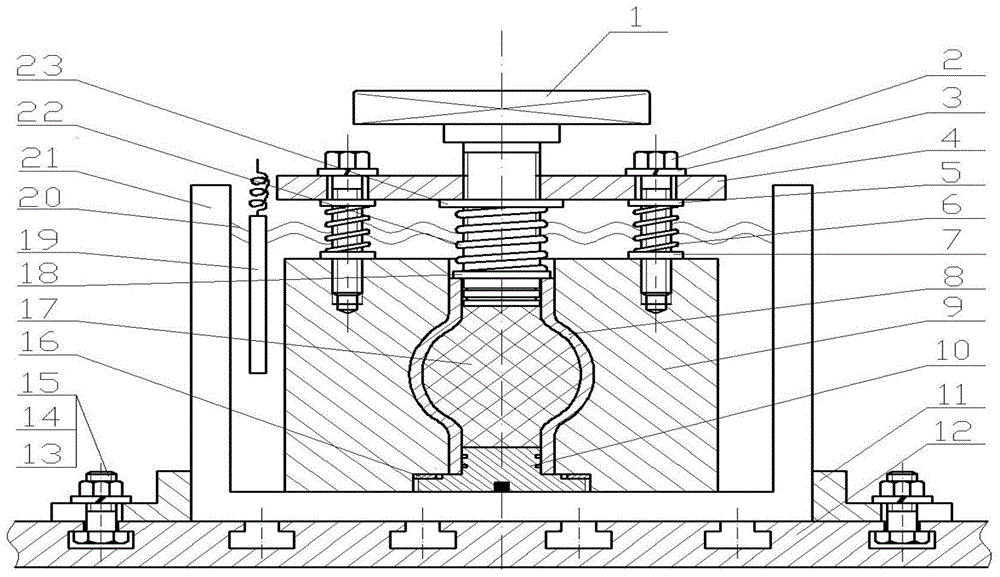

[0024] The specific device and forming method for forming a magnesium alloy tube with a diameter of Φ16 mm and a wall thickness of 0.6 mm using the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The device includes mold workpiece system, heating system and vibration system. The mold workpiece system includes pressure screw 1, compression bolt 2, spring washer 3, pressure plate 4, upper gasket 5, soft spring 6, lower gasket 7, metal tube blank 8, split mold 9, plug 10, anti Loose washer 16, liquid plastic 17, adjustment block 18, strong spring 22 and spring retaining ring 23. The heating system includes a heater 19 , mineral oil 20 and a container 21 . The vibration system includes a clamping plate 11 , a vibrator table 12 , fastening bolts 13 , spring washers 14 and nuts 15 .

[0026] The specific steps of the forming method are as follows:

[0027] (1) First, heat the mineral oil 20 in the container 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com